Multiobjective Optimisation by PSO for Switched Reluctance Motor

(SRM) Drive

Jayanta Mukherjee

1

and Sumana Chowdhuri

2

1

Kalynai Polytechnique College, Westbengal, India

2

Department of Applied Physics, University of Calcutta, Kolkata, India

Keywords: Torque Ripple, PI Control, PWM Control, Hysteresis Control, ZN Method, Total Torque Distortion.

Abstract: Switched Reluctance Motor (SRM), which has many advantages like Induction machine exhibits very

nonlinear characteristics and high torque ripple, the only disadvantages of this machine. Its torque ripple is

dependent on the current profile and also on the turn on and turns off angle of phase excitation and the

speed is dependent on the current command. This work presents one of the Heuristic approaches like

Particle Swarm optimization (PSO) to determine the optimum proportional-integral (PI) controller

parameters and turn on and turn off angles, for minimum torque ripple with optimum torque profile SRM

drive. These offline tuning methods are implemented for the model of a SRM in MATLAB. It has been

observed that by optimizing the controller parameters of a SRM drive with PSO the performance of the

controller is improved.

1 INTRODUCTION

Switched Reluctance Motors (SRM) are fast

becoming a popular alternative to Induction Motors

(IM) in the variable speed drive market. Though the

first SRM was built in 1838, it did not find

widespread use until the late 1970’s. This was due to

the difficulty in controlling the machine. Since the

1960’s, with the advent of power electronics and

high power semiconductor switches, control of the

SRM has become much easier and there has been a

renewed interest in SRM drives. In different

industries, wide range of speed control with fast

torque response regardless of load variation is

required. This can be achieved very efficiently for

SRM (

Miller, 2004). SRM exhibits certain advantages

like simple structure, high speed operation, wide

range of speed control, robustness, high torque per

volume, low rotor inertia, highly fault tolerant

structure etc. but despite of all these advantages one

incipient disadvantage makes this motor inefficient

for industrial application. This is due to the high

torque ripple that exists in the SRM characteristics.

In case of other industrial motors the torque ripple

can be minimised by profiling the motor driving

current. This profiling is done by proper design of

the PI (proportional-Integral) controller. The driving

current is forced to follow the reference current

either by Pulse Width Modulation (PWM) controller

or Hysteresis Controller. In case of SRM current

profiling is not the only solution.

The problem with SRM is due to its higher

degree of nonlinearity in the characteristics

compared to conventional industrial induction motor

or DC motor. It exhibits high torque as well as speed

ripple due to the typical torque characteristics. This

characteristics is due to nonlinear inductance profile

with respect to position and torque is dependent not

only on current but also on inductance profile.

Hence proper design of the controller for SRM

drives is itself an optimisation task.

In this present work a novel optimal design of the

controller for SRM drives has been proposed. Here

the tuning of the controller parameters and also the

position of current firing for every particular phase

are required. Hence the optimisation problem lies for

current shaping so that torque ripple is minimised.

This problem of nonlinearity in its characteristics

and torque ripple increases in case of variable speed

applications. To find out the optimum parameters of

the controller to obtain a good closed loop response

at different operating conditions is a hard task. The

PI controller parameters can be optimized by

conventional tuning methods, such as Ziegler-

Nicholson (ZN) method. Other tuning methods like

pole placement optimization technique are also done

391

Mukherjee J. and Chowdhuri S..

Multiobjective Optimisation by PSO for Switched Reluctance Motor (SRM) Drive.

DOI: 10.5220/0005101403910396

In Proceedings of the 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2014), pages 391-396

ISBN: 978-989-758-039-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

(George, 1994). Now-a-days Evolutionary methods

like Genetic Algorithm (GA), biologically inspired

methods like Particle Swarm Optimization (PSO),

Ant Colony optimisation (ACO) etc. are used for

tuning the parameters of the controllers. These new

tuning techniques can efficiently solve complex

problems like nonlinearity in the plant, variable

speed problems, where the conventional methods

may not optimize the controller parameter so

accurately. PSO is another Heuristic approach

which is inspired by the ability of flock of birds or

herd of animals to adapt to their environment. It was

developed in 1995 by James Kennedy and Russ

Eberhart while attempting to simulate the

choreographed, graceful motion of the swarm of

birds as a part of socio-cognitive study investigating

the motion of collective intelligence in biological

population. In PSO, a set of randomly generated

solutions propagates in the designed space towards

the optimal solution over a number of iteration based

on large amount of information about the designed

space (Kennedy, 1995). Both GA and PSO are

similar in the sense that these two techniques are

population based heuristic search methods and they

approach for the optimal solution by updating

generations. Since these approaches are supposed to

find a solution to a given objective function but

employ different strategies and computation effort, it

is appropriate to compare their performance.

In citation (Hameyer, 2008) the authors perform

a multiobjective optimization in a SRM aiming both

to maximize the mitigation of the torque ripple and

to minimize the degradations of the starting and

mean torques. The technique was applied on the

optimization of some rotor geometrical parameters

with the aid of finite element simulations to evaluate

the approximation points for the Kriging model. In

(Owatchaiphong, 2009), a design methodology is

presented for sizing a SRM. The proposed method

combines the use of genetic and fuzzy algorithms

together to simplify the design method. In (Balaji,

2011) Particle Swarm Optimization (PSO) based

design optimization of SRM has been presented.

Here The SRM design is formulated as multi

objective constrained optimization problem. The

objective functions for obtaining desired design are

maximization of average torque and minimization of

torque ripple with stator and rotor pole arc as design

variables. But all these optimisation are aimed to

optimise motors’ structural design.

Many researchers have applied both GA and PSO in

different fields of engineering e.g. In (Panda, 2007),

the authors have compared GA with PSO for

designing a TCSC based controller for power system

stability improvement.

In this present work we have applied PSO to search

for the optimal PI controller parameters as well as

firing angle and commutation angle of SRM drive

The performance of this optimization techniques in

terms of convergence rate, error minimization and

time complexity is good.

2 MATERIALS AND METHODS

2.1 Switched Reluctance Motor

The Reluctance Motor is an electric motor in which

torque is produced by the tendency of its moveable

part to move to a position where the inductance of

the excited winding is maximized or reluctance of

the winding is minimum. This motor has field coils

as of a DC Motor field winding for its Stator and no

coils or magnets in the Rotor. The rotor is aligned

whenever the diametrically opposite stator poles are

excited. In a magnetic circuit the rotating parts

prefer to come in minimum reluctance (maximum

inductance) position at the instance of excitation.

When two rotor poles are aligned with two stator

poles, another set of rotor poles will be out of

alignment with respect to another set of stator poles.

Hence by switching stator currents in a sequence, the

rotor is rotated.

(,)

(,) (,)

di dL i

VRiLi it

dt dt

(1)

2

1(,)

.

2

e

N

dL i

Ti

dt

(2)

eL

d

TT J B

dt

(3)

The SRM can be modeled using the following

system equations [(1)-(3)], where V, T

e

, T

L

are

applied voltage, electromagnetic torque and load

torque respectively. R and L are the resistance and

inductance of the stator per phase winding. J and B

are inertia constant and damping constants of the

machine. i is the current through the winding and

is the speed of the machine.

(,)

L

i

is the Stator

Inductance, which depends upon the rotor position

(fig 1) and also current in stator winding is a

function of both position and time, it is non-linear

and thus a simple equivalent circuit of SRM is not

possible. The inductance profile is curved at the top;

which causes high Torque ripples, speed

oscillations, increased audible noise and fatigue of

the shaft.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

392

The currents are forced to each phase at an advance

angle

on

and commutated

at commutation angle

off

(Fig1)

.

Again depending upon the magnetic

saturation inductance varies for different current

level or it may be said that non linearity is

introduced both in current and inductance profile.

The magnitude of the current is dependent on load.

But the nonlinearity in inductance profile gives rise

to the torque ripple (Fig .2), as torque is a function

of both the current and the angular position. Hence

smooth control of speed and torque is problem area

for SRM drive. Controller can be designed to

mitigate these problems. In addition to this inherent

motor problem if the input voltage and frequency

fluctuates then this torque ripple problem is

aggregated.

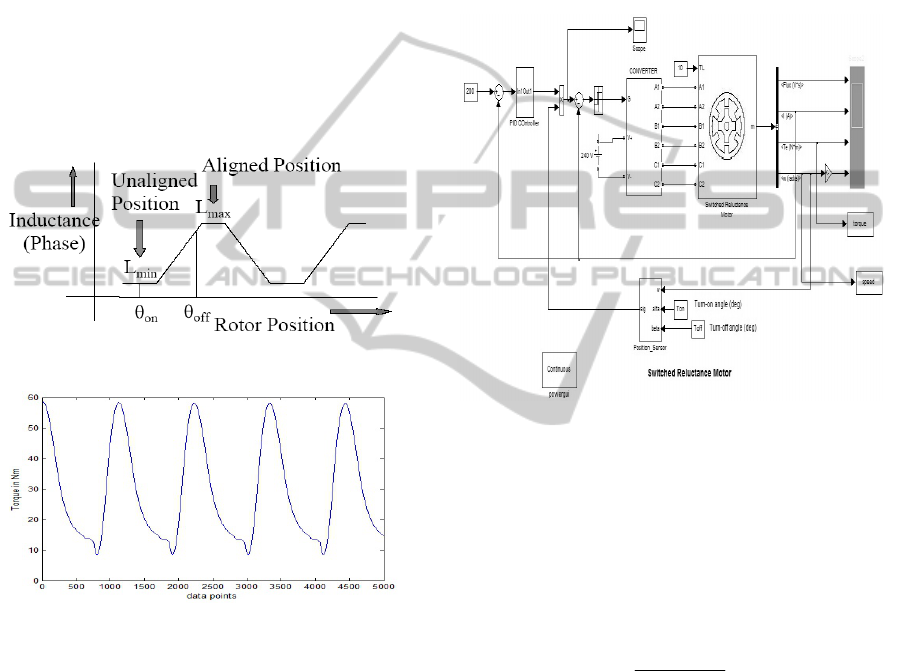

Figure 1: Inductance profile vs. Rotor position.

Figure 2: Torque profile vs. Rotor position (as data

points).

2.2 Basic Plan of the Work

In this work, optimization of the parameters of PI

controller for current control and turn on and turn off

angle control of the controller of a SRM has been

done using PSO. The design has been considered for

a SRM (6/4 pole, 1 HP, 110V) in MATLAB

SIMULINK environment. This tuning has been done

to the model of SRM in offline. The gain parameters

for the current controller for a step input are initially

calculated by Ziegler-Nicholson’s optimization

technique which serves as the parent parameters for

current controller. From the design specification an

initial set for turn-on angle and turn off angle have

been randomly chosen within the permissible range.

For optimization, two different criteria for

smoothening of torque profile have been chosen

which serve as the fitness function of the algorithms.

The current applied to the machine has is

feedback control, which provides current reference

according to the error in torque.

The model of the test SRM is considered as the

Plant model (Fig 3). This model is nonlinear in

nature as the equation (1-3) and as described earlier.

Figure 3: Block diagram of the overall system.

In this wok the objective functions are

represented by eqn 4 and eqn 5. First objective is to

minimise the speed error by PI controller. Second

objective is to minimise of Total Torque Distortion

(TTD) by controlling the gain of the controller and

as well the turn on and turn off angle.

()

ref act

ei i i

(4)

max min

avg

TT

TTD

T

(5)

Where e(i) represents the error in current from

reference current to actual current.

TTD is the total n

phase torque distortion which is considered as the

fitness function.

TTD is calculated as the ratio

between the maximum and minimum torque

difference to average torque for a particular phase.

The output of the PI controller is described by

the following eqn 6 , where M

n

is the output of the

controller at n

th

instant which is derived from the (n-

1)

th

error and k

th

sum of previous errors. k

p

is the

proportional constant and k

i

is the integral constant.

The constrains of these multi objective problem are

eqn 7 and eqn 8.

MultiobjectiveOptimisationbyPSOforSwitchedReluctanceMotor(SRM)Drive

393

(1) ( )

np i

k

M

ken k en k

(6)

min max

min max

ppp

iii

kkk

kkk

(7)

max

ax

onmim on on

offmim off offm

TTT

TTT

(8)

The controller gains like proportional constants

(k

p

) and integral constant (k

i

) are limited by their

minimum and maximum limit beyond which the

controller will lose its stability.

For turn on (T

on

) angle and turn off (T

off

) angle

there are also minimum and maximum limit beyond

which per phase current control will not be

applicable.

2.3 Particle Swarm Optimisation

Particle Swarm Optimization (PSO) is a population

based stochastic optimization technique. It shares

many similarities with evolutionary computation

techniques such as genetic algorithm but the features

of PSO, like easy way of implementation, stable

convergence characteristics and computational

efficiency has made it much superior than others

(Mehdi, 2007 ), (Gaing, 2004) (Banerjee 2010). PSO

is initialized with a group of random particles

(solutions) and then searches for optima by updating

generations. In every iteration, each particle is

updated by following two “best” values. The first

one is the best solution (fitness) it has achieved so

far. (The fitness value is also stored.) This value is

called p

best

. Another “best” value that is tracked by

the particle swarm optimizer is the best value,

obtained so far by any particle in the population.

This best value is a global best and called

best

g

.

When a particle takes part of the population as its

topological neighbours, the best value is a local best

and is called

best

p

. After finding the two best

values, the particle update sits velocity and

positions.

1

2

1

*()*( )

*()*( )

11

id id

id id

id id

id id id

Vn Vn

c rand pbest n present n

c rand gbest n present n

present n present n V n

(9)

Where V

id

[n] is the particle velocity of the

current particle (n). p

best

[n] and g

best

[n] are defined

as state before. rand(n) is a random number between

(0,1). c1 and c2 are learning factors. The values of

c1 and c2 can be calculated as in eqn 10.

111 1

222 2

()*()

()*()

ter

fi i

axiter

ter

fi i

axiter

i

ccc c

m

i

ccc c

m

(10)

Where c

1i

, c

1f

, c

2i

and c

2f

are constants, iter is the

current iteration number and m

axiter

is the number of

maximum allowable iteration. The objective of such

modification is to boost up the global search over the

entire search space.

3 IMPLEMENTATION

In this section how the program has been

implemented in MATLAB is described.

3.1 Optimization of PI Controller using

Ziegler-Nichol’s Method

From all the methods designed to optimize PID

controller, Ziegler and Nichols’ method is mostly

used (Ogata, 2010). The methods are based on

characterization of process dynamics by a few

parameters and simple equations for the controller

parameters. The first method is applied to plants

with step responses. This type of response is typical

of a first order system with transportation delays.

The second method targets plants that can be

rendered unstable under proportional control. The

technique is designed to result in a closed loop

system with 25% overshoot. This is rarely achieved

as Ziegler and Nichols determined the adjustments

based on a specific plant model. Here the second

methods have been used, Kcr is the gain at critical

oscillation and Pcr is the time period. The controller

gains are specified in according to a rule (Table 1).

Table 1: PID Controller parameters.

PID Type Kp Ki Kd

P 0.5 Kcr Infinite 0

PI

0.45

Kcr

Pcr/1.2

PID 0.6 Kcr Pcr/2 Pcr/8

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

394

3.2 Optimisation of the Plant by PSO

Algorithm for PSO:

Initialise k

p

, k

i

values using

Z-N method

Initialisation of T

on

and T

off

for a particular range for

which the reluctance is

minimum and reluctance is

approaching maximum

Generate the initial k

p

,k

i

,T

on

and T

off

for a number of

population size in the

vicinity of the initial

values as real number.

Set generation =1

Simulate the SRM model by

setting the parameters of k

p

,

k

i

, T

on

and T

off

of the PI

controller for this set of

population size.

Calculate the error in torque

ripple for a particular

period of time for which the

current of that phase reaches

speed for each set of

population size for a

particular speed demand

While(!maximum iteration

number is achieved)

calculate fitness functions

Select the fittest individual

according to the fitness

function

Calculate p

best

of each

individual and g

best

of the

population

Update the velocity and

position of the best fitted

individual with pbest and

gbest

Increase the generation by

number 1

Compute k

p

, k

i

, T

on

and T

off

for the i

th

string

Simulate the plant with this

set of values

Evaluate fitness (i

th

) of the

simulation output

Perform selection mechanism to

generate sub-generation

Check the convergence

criteria.

4 RESUTS

Here a current demand is given. The problem is

started with a particular T

on

and T

off

angle and PI

controller parameters. The current profile and torque

profile is shown in fig4 with this initial sets of

parameters.

Here TTD= 1.75

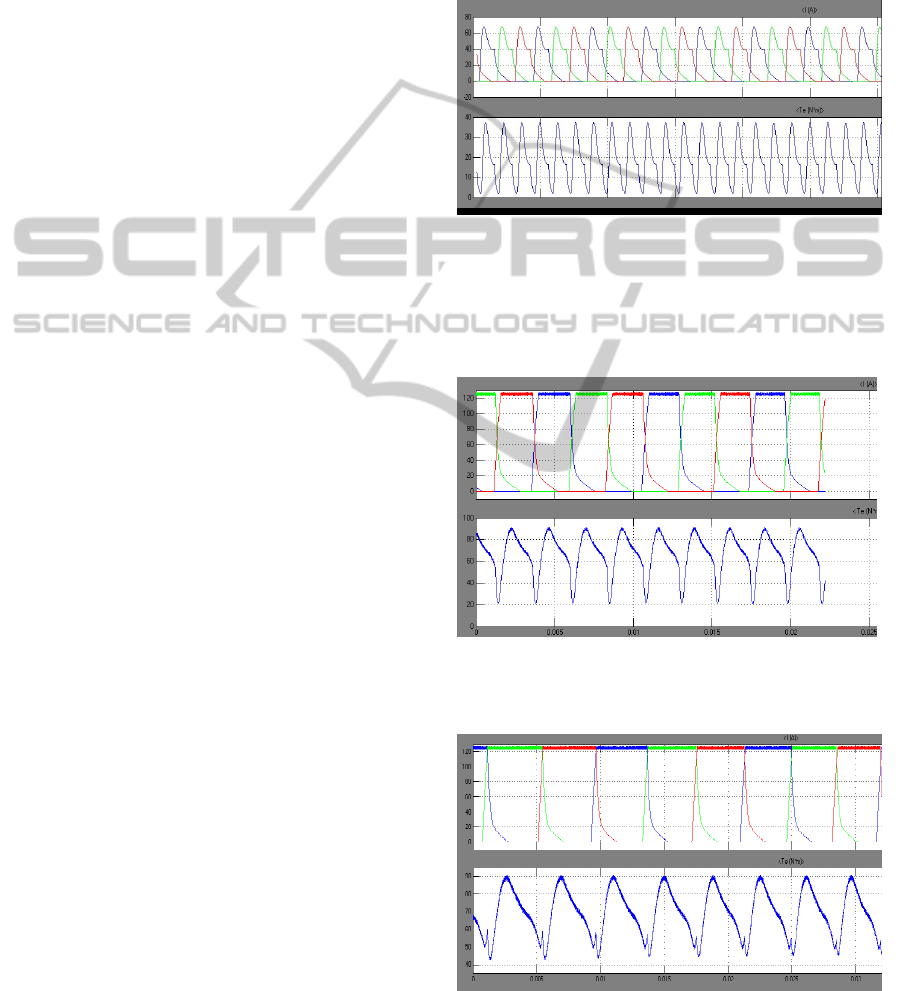

Figure 4: The current profile (upper) and the torque

developed (lower) before tuning the parameters.

After 20 iteration it has been found that the current

profile as well as the torque profile has been

improved (Fig 5).

Figure 5: The current profile (upper) and the torque

developed (lower) during tuning (after 20 iteration),

TTD=1.3.

Figure 6: The current profile (upper) and the torque

developed (lower) during tuning (after 50 iteration) with

TTD=0.78.

MultiobjectiveOptimisationbyPSOforSwitchedReluctanceMotor(SRM)Drive

395

After 50 iteration the torque profile has further been

improved. So far optimized value of the controller

coefficients are K

p

= 2.97, K

i

=1.23, T

on

=44.5

o

and

T

off

=77.6

o

obtained after 50 generations.

The present work provides immense research

possibilities for the future. This optimisation

problem is very much suitable since the SRM

exhibits very non linear characteristics. GA based

optimization will also be carried out and relative

comparison will be made between PSO and GA.

The stability considerations for controller design can

be augmented with the present scheme, which would

be regarded as a further constraint while computing

the fitness function. This work can be utilized to

solve optimization problems involving design of

controllers for more complex and non-linear

electromagnetic machines. This method as described

can be extended for SRM in online and time

complexity will be studied.

REFERENCES

T J E Miller, Electronic Control of Switched Reluctance

Machines, Newnes, Newnes ower Engineering

Series, 2004, ISBN 0 7506 50737.

Hameyer, Mitigation of the Torque Ripple of a Switched

Reluctance MotorThrough a Multiobjective

Optimization, IEEE Transactions on Magnetics, Vol.

44, No. 6, June 2008, pp 1018-1024.

Satit Owatchaiphong, Nisai H. Fuengwarodsakul, Multi-

Objective Based Optimization for Switched

Reluctance Machines Using Fuzzy and Genetic

Algorithms, IEEE conference Proceedings PEDS2009,

pp 1530-1532.

M. Balaji and Dr.V.Kamaraj, Design Optimization of

Switched Reluctance Machine using Particle Swarm

Optimization, International Conference on Electrical

Energy Systems (ICEES), 2011, pp164-169.

Kapsiotis,George., Tzafestas, Spyros., “PID self –tuning

control combining pole placement and parameter

optimization features (original research article)

Mathematics and Computers in Simulation”, Volume

37, Issues2-3,30 November1994, Pages133-142.

Eberhart,R., Kennedy,J., “Particle swarm optimization,” in

Proc. IEEE Int. Conf. Neural Networks, vol. IV, Perth,

Australia, 1995, pp. 1942–1948.

Panda, Sidhartha., Padhy, “Comparison of particle swarm

optimization and genetic algorithm for TCSC-based

controller design”, Department of Electrical

Engineering, Indian Institute of Technology, Roorkee,

Uttaranchal 247667, India, International journal of

Electrical and Electronics Engineering 1:5 2007.

Mehdi, Nasri., Hossein Nezamabadi-pour, and Malihe

Maghfoori, “A PSO Based Optimum Design of PID

Controller for a Linear Brushless DC Motor”, in

World Academy of Science, Engineering and

Technology 26 2007.

Gaing, Z.-L., “A particle swarm optimization approach for

optimum design of PID controller in AVR system,”

IEEE Trans. Energy Conversion, vol.19, pp. 384-391,

June 2004.

Banerjee, T., Choudhuri, S., Bera, J.N, Maity,A., “Off-line

optimization of PI and PID controller for a vector

controlled induction motor drive using PSO”,

(ICECE), 2010 International Conference on Electrical

and Computer Engineering, 18-20 Dec. 2010, On

Page(s): 74 – 77, ISBN: 978- 1-4244-6277-3.

Ogata, Katshuhiko, “Modern Control Engineering” (PHI

Learing Private Limited, Fifth edition,2010).

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

396