Research on Movement Rules of Soil Particles during EPB Machine

Tunneling with Spoke Cutterhead

Wu Li

1

, Chen Long

1

and Ju Ernan

2

1

Institute of Mechanical Engineering, Dalian Jiaotong University, Huanghe Road 794#, Shahekou Distict, Dalian, China

2

Department of Electronic Engineering, Dalian Neusoft Information Institute, Soft park Road, Dalian, China

Keywords: Spoke Cutterhead, Discrete Element, Soil Particles, Movement Rules, Epb Tunnelling.

Abstract: To discover the movement rules of soil particles around cutterhead during shield machine tunnelling, the

discrete element model of shield machine tunnelling is established. The model is able to simulate the

structure of shield machine, the pressure of ground, the excavation operation process and the flow process

of soils. The cutterhead torque is obtained by running the model, which is accord with the theoretical

calculation results. The displacements of soil particles in the cutterhead system of shield machine at the

different tunnelling time are displayed. The movement of soil particle is periodic, and the period is related to

the cutterhead rotation speed.

1 INTRODUCTION

The tunnel boring machine (TBM), including the

hard rock TBM and the soft ground TBM, is the

advanced large special equipment for tunnel

excavation. A lot of scholars have conducted

extensive research on the hard rock TBM

construction and design (Rostami and

Ozdemir,1993; Burger,2006; Karlheinz,2009;

Abdolreza and Siamak,2012; Peter,2009). For the

soft ground TBM, such as earth pressure balance

(EPB) machine, there are many research on the

relation between the tunneling operation parameters

(Hehua, 2007; Hongxin and Deming, 2006).

Although the EPB machine is already used to

excavate tunnels, and there are some research on the

construction technology, the dynamic interaction

rules between the shield machine and the soils,

which has an important role in improving and

optimizing the system structure, is not clear.

The paper simulates the tunneling process of the

EPB machine with spoke cutterhead by the discrete

element software PFC3D. The displacement

distributions of soil particles in the cutterhead and in

the chamber at different tunnelling time are

obtained. The movement rules of soil particles

during the machine tunnelling are revealed.

2 SIMULATION

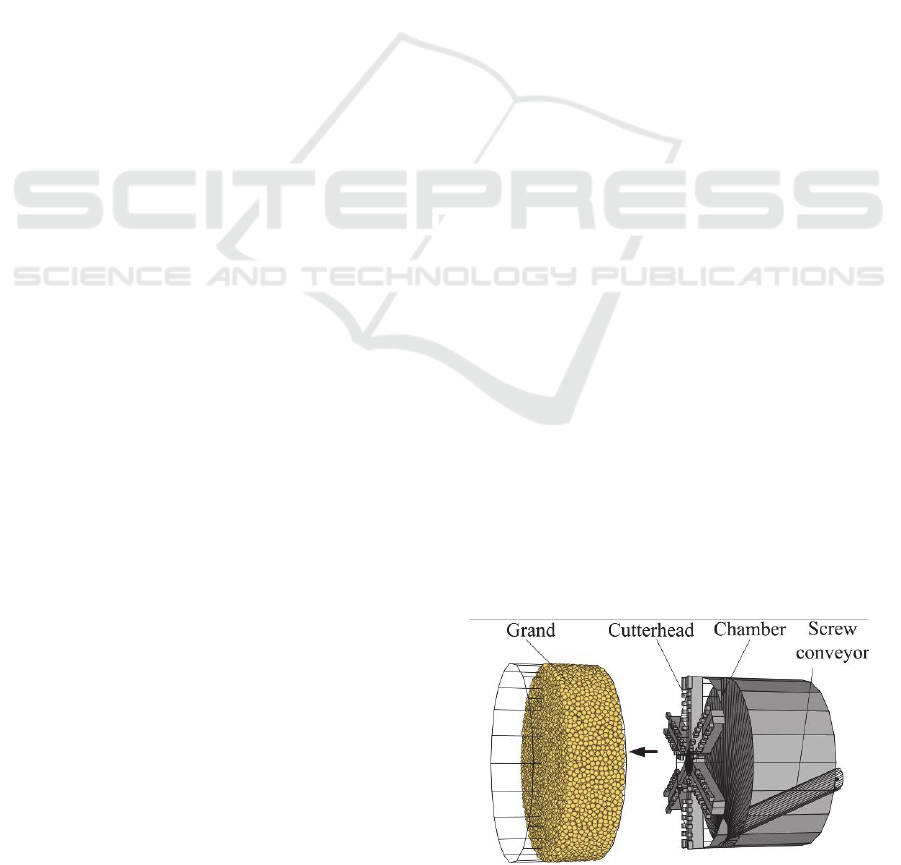

The Discrete Element Method (DEM) model of EPB

shield machine tunnelling, which is shown in

Figure1, consists of two parts. One is the simulated

ground; the other is the tunnelling shield machine.

The model of the shield machine is made up with the

cutterhead, the chamber and the screw conveyor.

The cutterhead is composed of six spokes. The 84

cutters are located on both edges of the spokes. The

opening ratio of the cutterhead is 70%. The structure

parameters of the model are listed in Table.1.

Figure 1: DEM model of shield machine tunnelling.

The DEM model of the shield machine is set up by

wall elements in PFC3D. The cutterhead and the

chamber board are made up with plane walls. The

vertex coordination of the plane walls are obtained

243

Li W., Long C. and Ernan J..

Research on Movement Rules of Soil Particles during EPB Machine Tunneling with Spoke Cutterhead.

DOI: 10.5220/0005103002430248

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 243-248

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

by CAD model of cutterhead. The shield shell and

the outer barrel of screw conveyor are built by

cylinder wall, and the screw is built by spiral wall.

A homogeneous packing of 20,715 particles in a

cylinder container of 6.28 m in diameter and 2 m in

length has been chosen to simulate the soil where the

excavation takes place. The compressive strength of

the soils is 50kPa. The contact models between

particles is selected the standard linear model in

PFC3D. The contact model parameters between

particles are shown in Table 2. The simulated

excavation depth of the ground is 20 m. The ground

pressure is controlled by the servo-mechanism,

which is realized by adjusting the displacement of

the wall constantly to keep the pressure stable (Li,

2013). The rotation speed of the cutterhead is set 2

rpm, the thrust speed is set 60 mm/min, and the

rotation speed of screw conveyor is set 5 rpm. In

PFC3D, the wall has 6 velocity components, so the

machine speed can be realized easily by setting the

velocity components of walls.

Table 1: Structure parameters of DEM model.

Shield

diameter

(m)

Shield

length

(m)

Conveyor

diameter

(m)

Conveyor

length

(m)

Screw

pitch

(m)

Conveyor

angle

(º)

6.28 2 0.84 5 0.56 22

Table 2: Particle parameters.

Normal

stiffness

(N/m)

Shear

stiffness

(N/m)

Friction

coefficient

Particle

density

(kg/m

3

)

Particle

radius

(m)

540000 540000 0.5 2637 0.0625

1) 5s 2) 20s

3) 60s 4) 120s

Figure 2: Shield machine tunnelling process.

The DEM model can reproduce the dynamic

tunnelling process of the shield machine, which is

shown in figure 2.

The DEM model of the EPB shield machine

tunnelling is run for 120 s. When the run time is 120

s, the chamber and screw conveyor are filled with

particles. This means that the cutterhead system

comes into the stable state.

3 MODEL VERIFICATION

3.1 Simulated Torque

The cutterhead torque is measured in the process of

the tunnelling simulation. The simulation torque is

compared to the theoretical calculation to verify the

DEM model. The cutterhead torque is extracted

every 5 s from 0 s to 120 s (Figure 3). The average

simulated cutterhead torque is 1435kNm.

1000

1200

1400

1600

1800

0 102030405060708090100110120

Cutterhead torque / kNm

Time/ s

Simulation torque

Theory torque

Figure 3: Simulated cutterhead torque.

3.2 Calculation Torque

In the DEM model, the simulated cutterhead torque

is composed of cutting torque, the friction torque of

the front side and the back side of the cutterhead.

The theoretical calculation equation of the above

mentioned torque is concluded (Kui, 2011).

The cutterhead cutting torque T

1

is shown in

Equation (1).

22

1maxu

TnqhDn

(1)

Where q

u

is the compressive strength of soils, kPa;

h

max

is the penetration of cutterhead, m, h

max

=v/n, v

is the thrust speed, m/h, n is the cutterhead rotation

speed, rpm; D is the diameter of the cutterhead, m.

The friction torque of the front side of cutterhead

is illustrated in Equation (2).

22

1maxu

TnqhDn

(2)

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

244

Where

is the non opening ratio;

1

is the friction

coefficient between soils and the cutterhead; R

c

is

the radius of the cutterhead, m; R

d

is the active

pressure of soils, kPa.

The friction torque of the back side of the

cutterhead is regard as the same as that of the front

side.

Through calculation, the cutting torque is 473

kNm, the friction torque for each side of cutterhead

is 512 kNm. So the total torque is 1497 kNm. The

average error between the simulated torque and the

calculation torque is 4%, which illustrates the DEM

model is correct.

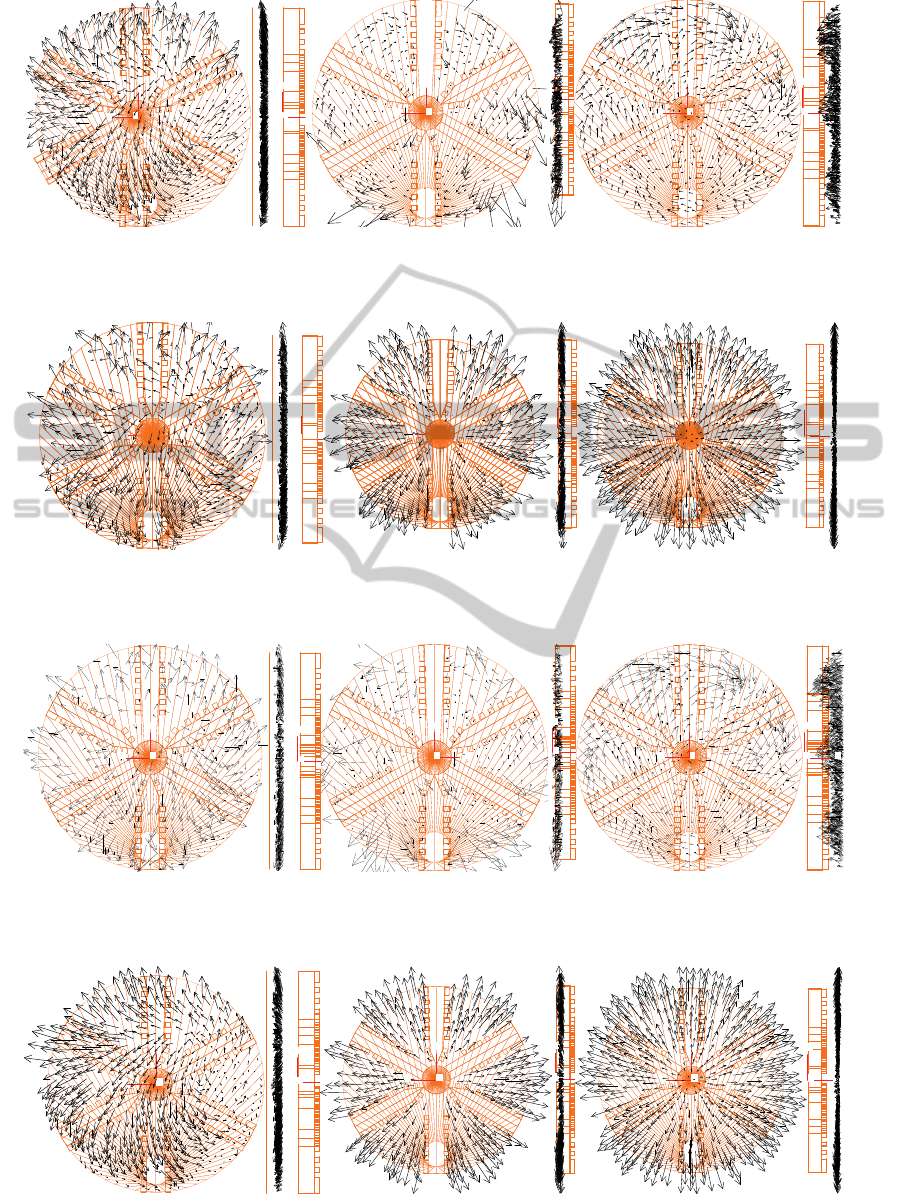

4 PARTICLE MOVEMENT

RULES

During the DEM simulation, the displacement

distributions of soil particles in the chamber and in

the cutterhead are displayed at tunnelling time 0s,

10s, 15s, 20s, 30s, 45s and 60s.

As shown in Figure 4, at time 0 s, the cutterhead,

the shield and the screw conveyor haven’t started to

work, the particles in the cutterhead and in the

chamber both move downward to the chamber board

under the gravity and the ground pressure. The soil

displacement in the cutterhead is higher than that in

the chamber.

At time 10 s (Figure 5), the particles in the

cutterhead rotate along the axis of y anticlockwise. It

is because that the friction torque caused by the

cutterhead conquers the interaction force between

particles, and the cutterhead leads the particle to

move. The bottom particles in the chamber march

toward the screw entrance for the screw rotation.

The above particles in the chamber rotate

anticlockwise.

At time 15 s (Figure 6), in the cutterhead, the

particles displacement in XZ plane is radiate. This is

because that in the circumferential direction, the

distance between particles increases with the

cutterhead rotation further, leading to the interaction

force between particles increases; When the

interaction force is larger than the friction caused by

the cutterhead rotation, the particles slow down the

movement anticlockwise until the velocity of the

particles in circumferential direction reach 0. At this

time, the displacement of particles is subjected to the

radial ground pressure, so the displacement of

particles is radial in XZ plane. The displacement of

particles in the chamber is similar to that at time 10.

At time 20 s (Figure 7), the particles rotate

clockwise in the cutterhead. This is because that the

interaction force between particles is much larger

than the force caused by the cutterhead rotation. At

time 15 s, the force between particles reaches

maximum. By the particles rotate clockwise, the

distance between particles reduces, and the

interaction force between particles reduces too.

When the interaction force reaches 0 N, the particles

begin rotate anticlockwise again. In the chamber, the

bottom particles move toward the inlet of the

conveyor for the screw rotation, and the movement

direction of the above particles is caused by the

ground pressure mainly.

At time 30 s and 60 s (Figure 8 and Figure 10),

the displacement distribution of particles is similar

to that at time 0 s. As shown in Figure 9, the

displacement is similar to Figure 6. It implies that

the motion period of the soil particles is 30 s.

In order to study the relation between the rotation

speed of the cutterhead and the soil particles

movement rules, the DEM model is run again setting

the cutterhead rotation speed 1 rpm. The

displacement distribution of soil particle at run time

30 s is shown in Figure 11. It is shown that the

displacement at time 30 s when cutterhead rotation

speed is 1 rpm is similar to the displacement at time

15s when cutterhead rotation speed is 2 rpm. So the

particle movement period T can be deduced as

equation (3)

60

T

n

(3)

5 CONCLUSIONS

The DEM model of the EPB shield machine

tunnelling was established, and the simulated

cutterhead torque was consistent with the theoretical

calculation results, which illustrated the model was

correct.

The displacement distribution of soils in the

chamber and in the cutterhead during the shield

machine tunnelling was obtained. The distribution

presented periodic variation, and the movement

period of soil particles is related to the cutterhead

rotation speed.

Seen from the figures of displacement

distribution, the soil displacement in the cutterhead

is determined by the cutterhead rotation, the

ResearchonMovementRulesofSoilParticlesduringEPBMachineTunnelingwithSpokeCutterhead

245

X Y

Z

X Y

Z

X Y

Z

X Y

Z

XY

Z

X Y

Z

1) in chamber 2) in cutterhead 3) in front of cutterhead

Figure 4: Displacement distribution of soil particles at 0 s.

X Y

Z

X

Z

X Y

Z

X

Z

X Y

Z

X

Y

Z

1) in chamber 2) in cutterhead 3) in front of cutterhead

Figure 5: Displacement distribution of soil particles at 10 s.

X Y

Z

X

Z

X Y

Z

X

Z

X Y

Z

X

Y

Z

1) in chamber 2) in cutterhead 3) in front of cutterhead

Figure 6: Displacement distribution of soil particles at 15 s.

X Y

Z

X

Z

X Y

Z

X

Z

X Y

Z

X

Y

Z

1) in chamber 2) in cutterhead 3) in front of cutterhead

Figure 7: Displacement distribution of soil particles at 20 s.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

246

X Y

Z

X

Z

X Y

Z

X

Z

X Y

Z

X Y

Z

1) in chamber 2) in cutterhead 3) in front of cutterhead

Figure 8: Displacement distribution of soil particles at 30 s.

X Y

Z

X

Z

X Y

Z

X

Z

X Y

Z

X

Y

Z

1) in chamber 2) in cutterhead 3) in front of cutterhead

Figure 9: Displacement distribution of soil particles at 45 s.

X Y

Z

X

Z

XY

Z

X

Z

X Y

Z

X Y

Z

1) in chamber 2) in cutterhead 3) in front of cutterhead

Figure 10: Displacement distribution of soil particles at 60 s.

X Y

Z

X

Z

X Y

Z

X

Z

X Y

Z

X

Y

Z

1) in chamber 2) in cutterhead 3) in front of cutterhead

Figure 11: Displacement distribution of soil particles at 30 s with cutterhead rotation speed 1rpm.

ResearchonMovementRulesofSoilParticlesduringEPBMachineTunnelingwithSpokeCutterhead

247

interaction forces between particles and the ground

pressure; in the chamber, the displacement of above

soils were subjected to the ground pressure mainly,

and the displacement of the bottom particles were

caused by the rotation of the screw conveyor.

ACKNOWLEDGEMENTS

The authors are grateful to the support of the

National Natural Science Foundation of China

(Study on Dynamic Interaction between Cutterhead

of Shield Tunneling Machine and Soils and Design

Theory of Cutterhead System, Award No.

51105048).

REFERENCES

Rostami,J.,Ozdemir,L.,1993. New model for performance

prediction of hard rock TBMs. In: Proceedings, Rapid

Excavation and Tunneling Conference, 793–809.

Burger,W., 2006. Hard rock cutterhead design. In:

Proceedings of the North American Tunneling 2006

Conference,pp.257–263.

Karlheinz,G., 2009. The influence of TBM design and

machine features on performance and tool wear in

rock. Geomech.Tunnelbau, 2,140–155.

Abdolreza,Y.C., Siamak,H.Y., 2012. Tunnel Boring

Machine (TBM) selection using fuzzy multicriteria

decision making methods. Tunn.Undergr.Space

Technol.30,194–204.

Peter,J.T.,2009.Simple and practical TBM performance

prediction. Geomech. Tunnelbau., 2,128–139.

Hehua Z., Qianwei X., Qizhen Z., Shaoming L.,2007,

Experimental study on the working parameters of EPB

shield tunneling in soft ground. China Civil

Engineering Journal, 40(9):87-94.

Hongxin,W., Deming, Fu., 2006. Mathematical model and

the related parameters for EPB shield tunneling. Tumu

Gongcheng Xuebao, 39, 86–90.

Li W., Tianmin G., Lei L., 2013. Discrete element model

for performance analysis of cutterhead excavation

system of EPB machine. Tunnelling and Underground

Space Technology, 37, 37–44.

Kui C., Kairong H., Xuesong W., 2011. Shield

Construction Technique. China Communications

Press, Beijing.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

248