The Design, Performance and CFD Analyses of Regenerative Blower

used for Fuel Cell System

Chan Lee and Hyun Gwon Kil

Department of Mechanical Engineering, University of Suwon, Hwaseong, Korea

Keywords: Regenerative Blower, Design, Performance, CFD.

Abstract: For efficient design of regenerative blower used for fuel cell system, the design and the performance

analysis methods of regenerative blower are developed, and CFD modelling and simulation are carried out

on the designed blower. The design process of regenerative blower is conducted to determine the geometries

of rotating impellers and stationary side channel with several design variables. The performance analysis on

the designed blower is made by incorporating momentum exchange theory between impellers and side

channel with mean line analysis method, and its pressure loss and leakage flow models are constructed from

related fluid mechanics data and correlations which can be expressed in terms of blower design variables.

The internal flow field of blower is analysed by using the CFX code, a CFD code specialized for fluid

machinery. The present performance analysis method is applied to four existing models for verifying its

prediction accuracy, and the comparison between the prediction and the test results are well-agreed with a

few percentage of relative error. Furthermore, the present design and performance analysis methods are also

applied in developing a new blower used for fuel cell application, and the newly designed blower is

manufactured and tested through chamber-type test facility. The performance prediction by the present

method is well-agreed with the test and the CFD simulation results. Therefore, from the comparison results,

the prediction design and performance analysis methods are shown to be suitable for the actual design

practice of regenerative blower.

1 INTRODUCTION

Regenerative blowers are usually operated with high

pressure rise at low flow capacity, so widely used

for air/ hydrogen supply in fuel cell applications.

However, because regenerative blowers are

operating with low efficiency or a lot of pressure

loss (Badami and Mura, 2012), there are growing

industrial needs for high-efficiency regenerative

blower development. Since the pressure loss is

strongly dependent on the internal flow phenomena

of regenerative blower, for developing high-

efficiency blower, reliable design method with

accurate performance analysis model considering the

flow effects should be developed and applied to

actual design practice of blower industries.

The early theoretical researches on regenerative

blower and pump have been conducted to investigate

the flow pattern and the energy transfer mechanism

of fluid inside the machines, and showed that the

energy transfer to fluid is achieved by the

momentum exchange of the helical-torodal fluid

motion between rotating impeller and fixed side

channel of regenerative machine (Wilson et al.,

1955: Hollenberg and Porter, 1979). Recent

researches by Badami and Mura have been devoted

to improving the performance analysis method of

regenerative blower by using momentum exchange

theory, and the prediction results have been

compared and well-agreed with test and 3-D CFD

results. However, since their analysis model requires

model constants which user should specify, it needs

the generalization of the constants in terms of

blower design and operation parameters (Badami

and Mura, 2011: Badami and Mura, 2012). Lee et al.

proposed an analysis method for regenerative blower

performance by using momentum exchange theory,

and tried to generalize their model constants from

relevant regenerative blower and fluid mechanics

experimental results (Lee et al., 2013).

In the present study, a simple but reliable design-

analysis method of regenerative blower is developed

as in-house program called as the FANDAS-Regen

code. Regenerative blower performance is predicted

751

Lee C. and Gwon Kil H..

The Design, Performance and CFD Analyses of Regenerative Blower used for Fuel Cell System.

DOI: 10.5220/0005104007510755

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 751-755

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

by incorporating mean line analysis method with the

momentum exchange theory between rotating

impeller blades and fixed side channel of blower.

The performance prediction accuracy of the present

method is verified by comparing the prediction with

the measurement results of several actual

regenerative blowers, and the comparison results

show the present method is capable of predicting

blower pressure, efficiency and power very

accurately.

Furthermore, with the use of the present design-

analysis method, a new regenerative blower is

designed, manufactured and tested by using

chamber-type test facility, and its internal flow field

is analyzed by the CFX code, a CFD code

specialized for fluid machinery. The comparison

between the present performance prediction, the

CFD simulation and the test results are well-agreed

within a few percentage of relative error, and they

also show that the present design-analysis method is

very suitable for the actual design practice of

regenerative blower.

2 DESIGN AND ANALYSIS

2.1 Blower Design Method

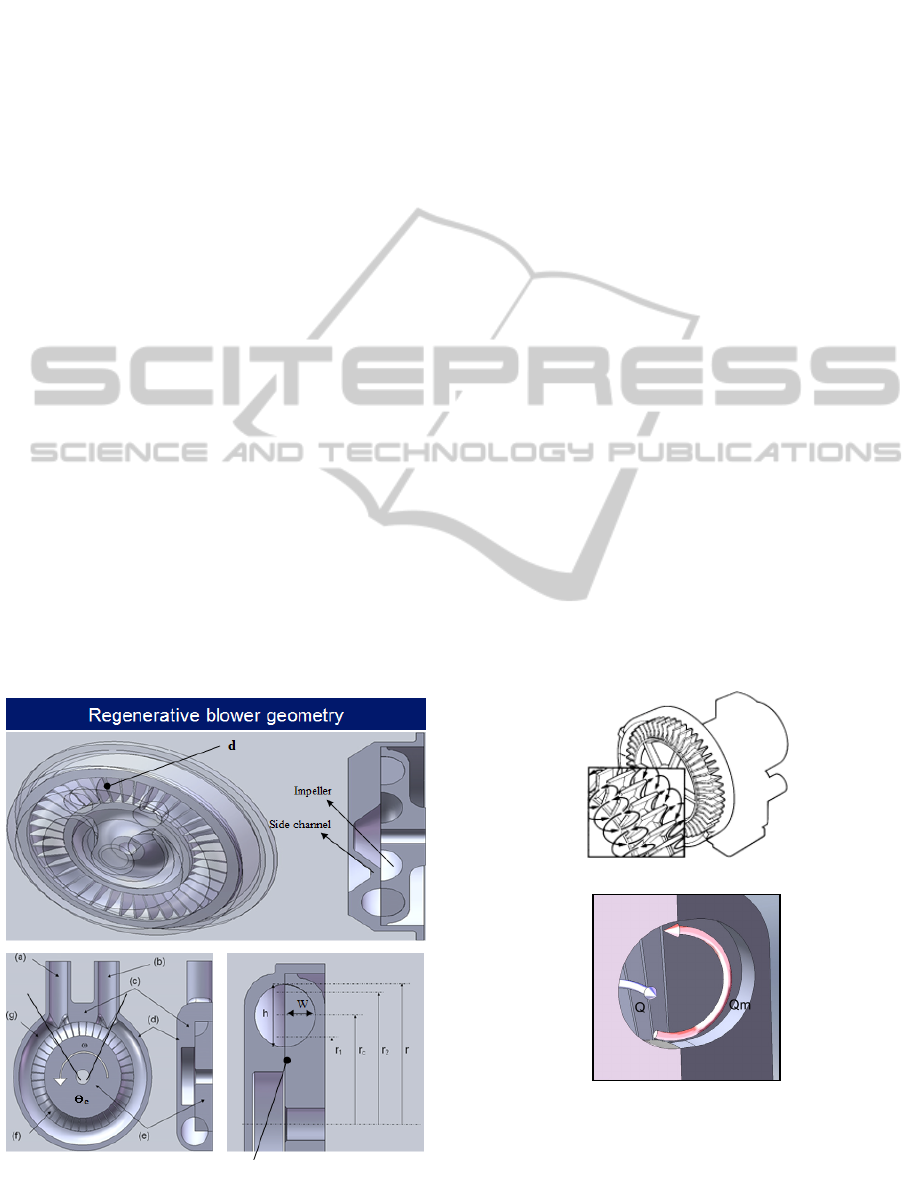

In general, regenerative blower is composed of

rotating impellers and fixed side channel and its

geometry is shown ( Badami and Mura, 2011) in

Fig.1.

Figure 1: Geometry and design variables of regenerative

blower.

The main design variables of rotating impellers and

fixed side channel are defined as follows:

- Rotation speed (N)

- Tip diameter (D

2

=2r)

- Channel height (h)

- Channel width (W)

- Impeller blade inlet angle (β

1

)

- Impeller blade outlet angle (β

2

)

- No. of impeller blades (Z)

- Impeller blade thickness (d)

- Axial clearance(c)

- Extension angle (θ

c

)

Once the blower design variables are defined, 3-

D blower geometry design can be achieved and then

used for the input data of performance analysis and

CFD simulation.

2.2 Blower Performance Analysis

Models

In the present study, the performance of blower is

analysed by combining the mean line analysis

method for fluid flow and the momentum exchange

theory between impellers and side channel. As

shown in Fig. 2, the gas flow inside regenerative

blower shows typically three dimensional and

helical-toroidal motion where fluid rotates in and

passes along the space between rotating impeller

blades and fixed side channel. The present study

assumes mean streamline as the representative one

of the three dimensional fluid flow phenomena.

(a) Flow behavior inside regenerative blower

(b) Cross section view on helical-toroidal flow

Figure 2: Flow pattern of regenerative blower.

Through the momentum exchange between fluid and

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

752

impeller due to this flow motion, gas pressure is

gradually raised along tangential flow path and its

overall pressure rise( ∆p

s

) is calculated by

2

2112

2

1

2(/4)

1

2

sm uu

pf

cc

pQ CC

rr

KK

Aur r u u

u

(1)

where

Here ρ, u, Q

m ,

φ are fluid density, impeller rotation

speed, flow capacity and flow coefficient. More

detailed description and variable definition about

momentum-exchange theory are referred to Badami

and Mura (Badami and Mura, 2012).

Since the fluid flow inside blower results in both

the pressure losses due to fluid friction, turbulence

and mixing and the leakage flow through the axial

clearances between impeller disc and side channel,

the present method needs the pressure loss and the

leakage flow models.

So, in the present study, the pressure loss and the

leakage flow models are constructed by using well-

known fluid mechanics correlations corresponding

to pressure loss and leakage flow sources as shown

in Table 1. It is noted that all the present pressure

losses and the leakage models are expressed as the

functions of blower design variables (Lee et al.,

2013).

Table 1: Model constants for pressure losses and leakage

flows.

Table 2 summarizes the main design variables of

four actual regenerative blowers used to verify the

present performance prediction accuracy, and all the

blowers are applied in fuel cell applications (Hwang

Hae Elelc., 2012: Badami and Mura, 2011: Gardner

Denver, 2006).

Figs. 3-6 show the performance prediction

results of Mini H-200, Mini H-100, Badami and

Gardner Denver models by the present method,

which are well-agreed with the measurement over

entire flow capacity range.

Table 2: Design variables of four regenerative blowers.

Flow capacity[LPM]

0 50 100 150 200 250 300 350

Efficiency[%], Power[kW]

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

Static pressure[mmAq]

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

: Static pressure[ mmAq]-Pred.

: Efficiency [%]-Pred.

: Power[kW]-Pred.

: Static pressure[mmAq]-Exp.

Figure 3: Performance predictions of Mini-H200 model.

Flow capacity[LPM]

0 50 100 150 200 250 300 350

Efficiency[%], Power[kW]

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

Static pressure[mmAq]

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

: Static pressure[ mmAq]-Pred.

: Efficiency [%]-Pred.

: Power[kW]-Pred.

: Static pressure[mmAq]-Exp.

Figure 4: Performance predictions of Mini-H100 model.

2

22

222

cot1

uA

Q

A

A

u

u

r

r

u

C

c

mcu

)/22(1.15.1])/(1[

)/22(1.15.1

2

2

21

2

2

2

rrZ

u

u

r

r

u

C

u

11

c

uA

Q

2

1

1

11

22

2

1

2

2

1

2

2

2

cotcot

sin

1

2

1

uA

Q

A

A

u

u

r

r

uA

Q

A

A

A

A

K

c

mcc

c

mc

m

0

2

1

2

1

2

1

2

2

2

2

2

1

u

u

u

u

r

rr

c

c

TheDesign,PerformanceandCFDAnalysesofRegenerativeBlowerusedforFuelCellSystem

753

Flow capacity[LPM]

0 100 200 300 400 500 600 700 800

Efficiency[%], Power[kW]

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

Static pressure[mmAq]

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

: Static pressure[mmAq]-Pred.

: Efficiency[%]-Pred.

: Power[kW]-Pred.

: Static pressure[mmAq]-Exp.

: Efficiency[%]-Exp.

Figure 5: Performance predictions of Badami model.

Flow capacity[LPM]

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700

Efficiency[%], Power[kW]

0

10

20

30

40

50

60

70

80

90

100

110

120

Static pressure[kPa]

0

5

10

15

20

25

30

35

40

45

50

55

60

: Static pressure[mmAq]-Pred.

: Ef f iciency[%]-Pred.

: Pow er[kW]-Pred.

: Static pressure[mmA q]-Exp.

Figure 6: Performance predictions of Gardner Denver

model.

2.3 Blower CFD Analysis Method

Based on the blower design of section 2.1, CFD

modelling and simulation are conducted to

investigate the internal flow field of blower. The

present study employs the CFX code, a CFD

program specialized for fluid machinery analysis,

where 3-D RANS (Reynolds-stress Averaged Navier

Stokes equations) solver is used with SST (Shear

Stress Transport) turbulence model. The mesh

generation on rotating impellers and stationary side

channel is made, and the interface between rotating

and stationary flow surfaces is treated by using

frozen rotor scheme (CFX, 2013).

3 APPLICATION RESULTS

The present design and analysis methods are applied

to develop a new regenerative blower used for fuel

cell application. The design requirements and

variables of new blower are summarized as follows:

- Rotation speed = 8000 rpm

- Tip diameter( 2r ) = 122 mm

- Side channel height( h ) = 23 mm

- Side channel width( W ) = 9 mm

- No. of impellers( Z ) = 39

Based on the design variables, the new regenerative

blower is manufactured as shown in Fig. 7.

Figure 7: Manufactured model of newly designed blower.

Figure 8: Mesh system of newly designed blower.

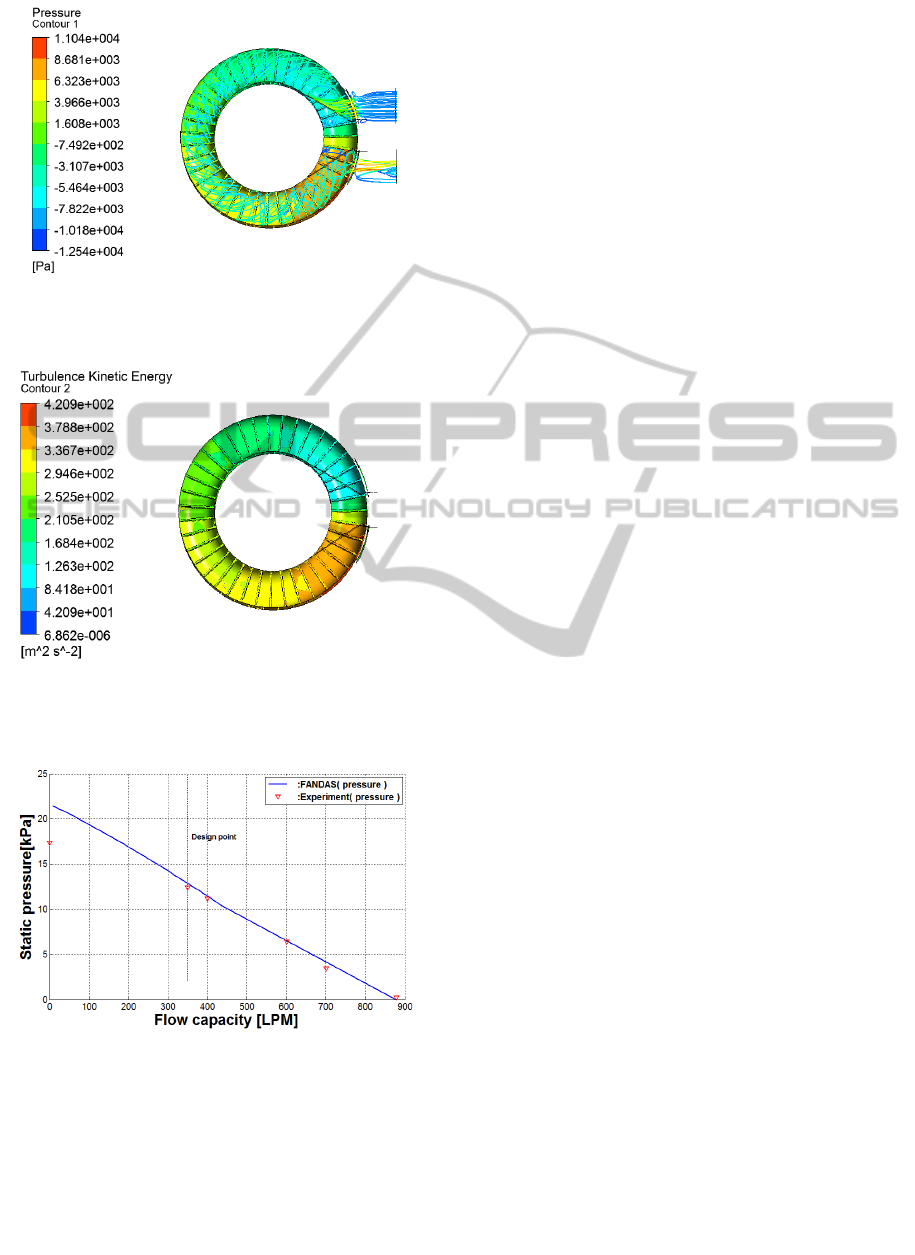

Fig. 8 shows the mesh system for the CFD analysis

on the internal flow between rotating impellers and

fixed side channel of newly designed blower. The

CFD computation results on the fluid flow and the

pressure rise through rotating impellers and side

channel are depicted in Fig. 9. As shown in Fig. 9,

the predicted streamline shows the fluid flow

between impellers and side channel is helical-

toroidal motion, and the pressure rise of fluid

passing through tangential flow path is linearly

increased.

Fig. 10 shows the turbulent kinetic energy inside

blower, which is produced due the helical-toroidal

fluid motion between impellers and side channel and

is also linearly increased along tangential flow path.

The performance of newly designed blower

predicted by the present method is compared with

the test results obtained from chamber-type test

facility. As shown in Fig. 11, the predicted pressure

curve is well-agreed with the test except at very low

flow capacity.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

754

Figure 9: Streamline and static pressure of newly designed

blower.

Figure 10: Turbulent kinetic energy of newly designed

blower.

Figure 11: Pressure curve of newly designed blower.

4 CONCLUSIONS

The present study develops the design-analysis

method which can be applied to the development

process of regenerative blower. The present method

is applied to the performance prediction of four

existing blowers, and is also coupled with CFD

simulation in developing a new regenerative blower

used in fuel cell system. The prediction results by

the present method are well-agreed with the test

results within a few percentage of relative error.

Therefore the present method is expected to be the

reliable design tool suitable in developing

regenerative blower.

ACKNOWLEDGEMENTS

This work was supported by the Development of the

Regenerative Blower for fuel cell application of the

Korea Institute of Energy Technology Evaluation

and Planning (KETEP) grant funded by the Korea

government Ministry of Trade, Industry & Energy,

Republic of Korea.

REFERENCES

W.A. Wilson, M.A. Santalo and J.A. Oelrich, 1955, A

Theory of the Fluid Dynamic Mechanism of

Regenerative Pumps, Trans. ASME, 77, 1303-1316.

J.W. Hollenberg and J.H. Potter, 1979, An Investigation of

Regenerative Blowers and Pumps, Trans. ASME J. of

Eng. For Industry, 110, 147-152.

M. Badami, and M. Mura, 2012, Comparison between 3D

and 1D Simulations of Regenerative Blower for Fuel

Cell Applications, Energy Conversion and

Management, 55, 93-100.

C. Lee, H.G. Kil, G.C. Kim, J.G. Kim, J.H. Ma, and K.H.

Chung, 2013, Aero-acoustic Performance Analysis

Method of Regenerative Blower, J. of Fluid

Machinery( in Korean ), 16(2).

M. Badami and M. Mura, 2011, Setup and Validation of a

Regenerative Compressor Model Applied to Different

Devices, Energy Conversion and Management, 52,

2157-2164.

S.E. Wright, 1976, The Acoustic Spectrum of Axial Flow

Machines, J. of Sound & Vibration 45(2), 165-223.

B.D. Mugridge, 1976, Noise Characteristics of Axial and

Centrifugal Fans as Used in Industry, Shock and

Vibration Digest, 45(3).

M.E. Goldstein, 1976, Aeroacoustics, McGraw-Hill.

Regenerative blower performance and noise test report,

2012, Hwang Hae Electric Co.

Catalogue module1, A Gardner Denver Product, 2006.

ANSYS-CFX user manual, ANSYS Inc., 2013.

TheDesign,PerformanceandCFDAnalysesofRegenerativeBlowerusedforFuelCellSystem

755