Significance of the Predictive Maintenance Strategies for SMEs

Mincho B. Hadjiski, Lyubka A. Doukovska, Stefan L. Kojnov,

Vladimir V. Monov and Vassil G. Nikov

Institute of Information and Communication Technologies - Bulgarian Academy of Sciences,

Acad. G. Bonchev str., bl. 2, 1113 Sofia, Bulgaria

hadjiski@uctm.edu, {doukovska, vmonov}@iit.bas.bg, slk@iinf.bas.bg, vasilnikov@abv.bg

Keywords: Predictive Maintenance, Advanced Integrated Maintenance Management System (AIMMS), Total

Productive Maintenance (TPM), Reliability Centred Maintenance (RCM).

Abstract: The predictive maintenance is key to long-term profitability of a company in the manufacturing sector

it can have a big impact on the supply, quality and price. The main methods are Total Productive

Maintenance (TPM) and Reliability Centered Maintenance (RCM) and they must satisfy the requirements of

the various small and medium-sized enterprises (SMEs). The paper identifies the barriers to the

implementation of TPM within SMEs. Based upon our analysis a methodology for an integrated

management system for predictive maintenance or the Advanced Integrated Maintenance Management

System (AIMMS) is presented. The results presented in this paper show that AIMMS supports strategic

decisions for predictive maintenance and it helps increase the equipment effectiveness by prioritizing the

criticality of the equipment focusing on specific resources, increasing profits based on the Return On

Investment (ROI).

1 INTRODUCTION

The predictive maintenance includes four stages:

predictive diagnosis, estimation of potential looses,

decision making for device maintenance and

maintenance schedule arrangement. Technological

diagnosis as the basis for predictive maintenance is

established field of scientific and applied invest-

igations. Predictive maintenance based on diagnosis,

prolongs the life of machines and aggregates,

reducing downtime, maintain optimal level of prod-

uction, ensure compliance with the precise timing of

delivery of production (raw materials, energy),

allows for effective management of maintenance of

facilities.

According to the International Standardization

Organization (ISO) “Prognostics is time for est-

imation of damage and risk for one or several future

damages”, (ISO, 13381-I, 2004). Thus technological

diagnosis can be understood as a process of

estimation of Remaining Useful Life (RUL) before

damage occurs, which is estimated based on the

current status of the facility and last operating mode.

In world practice is increasingly accepted that

predictive maintenance can play a key role in the

long-term profitability of a company in the

manufacturing sector with a major impact on timely

delivery, product quality and its ultimate cost. The

importance of maintenance increases in terms of

increasing both the productivity and also the quality

requirements which can only be achieved with a

well-developed and organized maintenance strategy.

In this sense, according to recent advances

in technology there have been developed and tested

many methodologies, tools, techniques and

strategies. The main methods are Total Productive

Maintenance (TPM) and Reliability Centred Main-

tenance (RCM); the developed options are designed

to meet the specific requirements of individual users,

which are usually small and medium-sized

enterprises (SMEs) operating in a very dynamic

business environment. This paper focuses on

identifying difficulties for the implementation of

TPM within SMEs.

In recent years there has been increasing interest

in the operation and management of industrial main-

tenance in a number of organizations. This is due to

the increasing pressure on manufacturing organ-

izations to meet customer and corporate require-

ments; the available equipment and productivity are

central to achieving this goal. According to the

authors’ quote from a paper (Chan, 2005), “Recent

trends show that on the whole many production

276

Hadjiski M., Doukovska L., Kojnov S., V. Monov V. and G. Nikov V.

Significance of the Predictive Maintenance Strategies for SMEs.

DOI: 10.5220/0005427102760281

In Proceedings of the Fourth International Symposium on Business Modeling and Software Design (BMSD 2014), pages 276-281

ISBN: 978-989-758-032-1

Copyright

c

2014 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

systems do not function as expected when it comes

to cost effectiveness in terms of their operation and

maintenance. Lots of companies often operate with

reduced capacities and reduced productivity, while

the prices of their products are high.” A number of

modern maintenance practices for technical support

are designed to allow organizations to target

strategic resources to achieve the maintenance tasks

that are considered crucial for the effective and

efficient operation of the equipment such as the

Total Productive Maintenance (TPM). A number of

organizations announce improvements in existing

equipment, reliability and reduction in the

maintenance costs after the implementation of TPM;

the presented results are published in (Blanchard,

1997; Cooke, 2000). The benefits of TPM are often

defined as an increase in the quality of products,

availability of equipment and reduction of operative

costs, according to the authors of (Cholasuke, 2004;

Bohoris, 1995; Al-Najjar, 1996). In (Nakajima,

1988) it is assumed that TPM is used primarily

because it integrates the functions of production and

maintenance, but more importantly is that it redef-

ines the role of operators and support engineers.

The author of (Nakajima, 1988) Nakajima is

often accepted as the founder of the Total Productive

Maintenance, (TPM); he assumes that the goal of

TPM is to increase the efficiency of the equipment

as well as to maximize the volume of production

from this equipment. This is the result of an effort to

achieve and maintain optimal conditions for the

equipment in order to prevent unexpected failures,

the speed decrease and the qualitative defects during

the manufacturing process according to (Bamber,

1999). Via the application of TPM it is also expected

to be possible to raise the moral of employees and

their satisfaction from the job, suggesting the

integration of workers into every aspect of the

applied TPM. The majority of generally accepted

definitions in TPM, used in (Barnes, 2002; Baglee,

2003; Baglee, 2010), are based on five main pillars

outlined by Nakajima.

2 INTEGRATED MANAGEMENT

SYSTEMS

Since 1996, the management of industrial sites is

aware of the need of implementing systems to

support all business processes (Dochain, 2008; The

ANSVISA 95 Enterprise, 2005). These systems are

known as Enterprise Resource Planning (ERP).

Systems of this type are rapidly moving in large

industrial complexes, but they remain almost

completely cut off from existing DSC or SCADA.

“Islands of automation” appear that are not at all

related informationally and functionally to the

general business management. Since the beginning

of the 21st century this fragmentation begins to be

overcome with the introduction of an intermediate

layer of management – the Manufacturing Execution

Systems (MES) (ISA the Instrumentation, Systems

and Automation Society, 2005). These systems are a

bridge between the technology management and the

business management, so they perform a variety of

roles for the operational management.

The purpose in (Staykov, 2013) is to make an

analysis and assessment of the increasing need of

using sophisticated software systems for managing

business processes. The most important thing is the

information and the success of every business

depends on how fast and effective managers deal

with information.

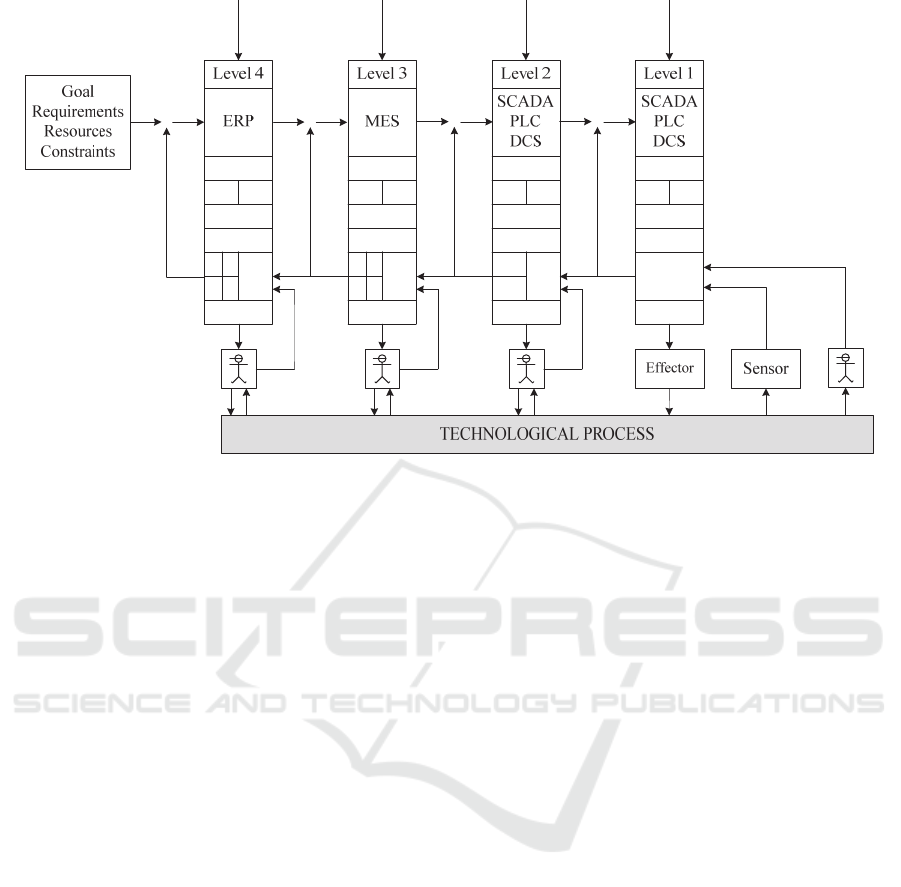

The structure of the integrated management

systems primarily reflects the functions that must be

implemented in a modern integrated management

system of an industrial enterprise. It does not contain

in itself a generalization of the methods and the tools

for integration. This is essential, especially in the

wide variety of engineering solutions that the world's

leading providers offer. Therefore the accepted in

2005 standard ISA-95 is of great help to overcome

internal fragmentation between control functions,

built most often with different strategies, a specific

vision and with a different magnitude. This is an

international standard for the integration of business

systems and control systems for the production

processes shown in Figure 1.

This structure is operative and it includes next

four hierarchical levels.

Level 1 and Level 2 are functionally grouped and

comprise the management of individual devices and

parameters. The generic name Process Control

Systems (PCS) is accepted for them. The so formed

block for Technological Management is treated as a

generalized function in the specific problems

(design, operation, adjustment) and it can be seen as

composed of two levels. The timeline of the PCS-

level are hours, minutes and seconds.

Level 3 comprises all tasks of operative manage-

ment and it is accepted to be marked as MES. The

main functions of this level are:

Complete description of the production schedule;

Management of production resources (people,

equipment, materials);

Specific dispatching of production with an

Significance of the Predictive Maintenance Strategies for SMEs

277

already formulated production schedule;

Optimization of the production process;

Monitoring of the overall production process;

Analysis of the production process (quantity,

quality, time schedule);

Reliability and security of production;

Reliable communication, acquisition and

archiving the operational information;

Implementation of the necessary operative

instructions, as well as forming the tasks for 1-2

level (PCS).

The timeline of Level 3 are days, hours and minutes.

Figure 1: Production processes.

Level 4 is the level of business planning and

logistics – ERP. The main functions of this level can

be divided into two groups.

Functions directly related to the formation of the

tasks for Level 3 (MES). These include:

Production planning;

Long-term production schedule;

Define the requirements for manufactured

products;

Determine resource constraints, level of

inventories, material consumption;

Implement the supply chain of raw materials,

production expedition, the overall logistics of the

enterprise.

Functions relating to the overall business

management, to cover:

Financial accounting – books, fixed assets,

payables, receivables, cash management;

Management accounting – define cost and cost

of production, cost control;

Management of the supply chain – planning and

schedule of supply, processing requests,

purchases;

Management of human resources – recruitment,

training, remuneration, dismissal of staff;

Project management – project-and-resources

planning for their implementation, distribution of

work, pricing and payment, timetables,

implementation units, management activities;

Management of customer relationships – sales

and marketing, customer contact, market

analysis;

Comprehensive business analysis.

The timeline of the ERP-level are months, weeks or

days. For purposes of this paper we are interested in

the functionality of the MES-system.

The main merit of the standard ISA-95 is that it

summarizes the experience of the leading academic

institutions and companies worldwide in the way of

overcoming the isolation between the technological

management (PCS) and the business level (ERP) by

creating a level of operative management MES. The

ISA-95 standard defines the conditions for the

integration of ERP and MES, on the one hand, and

MES and PCS, on the other.

Standard ISA-95 decides primarily structural and

information problems of integration. It to some

extent does not repeal or does not replace the

considerable experience in the application of various

features in the specific automation on the four levels,

accumulated for decades.

3 ANALYSIS OF THE BEST

PRACTICES

1. In every industrial enterprise there are potential

opportunities for improvement, which are in the

range 1–10% by economy of energy resources and

raw materials of 3–5%, 2–7% for increased product-

ion (http://www.automation.siemens.com, http://

www.honeywellprocess.com/en-us).

2. Doing good business and in particular industrial

management becomes more and more expensive.

3. Existing SCADA and DCS can not be changed

Fourth International Symposium on Business Modeling and Software Design

278

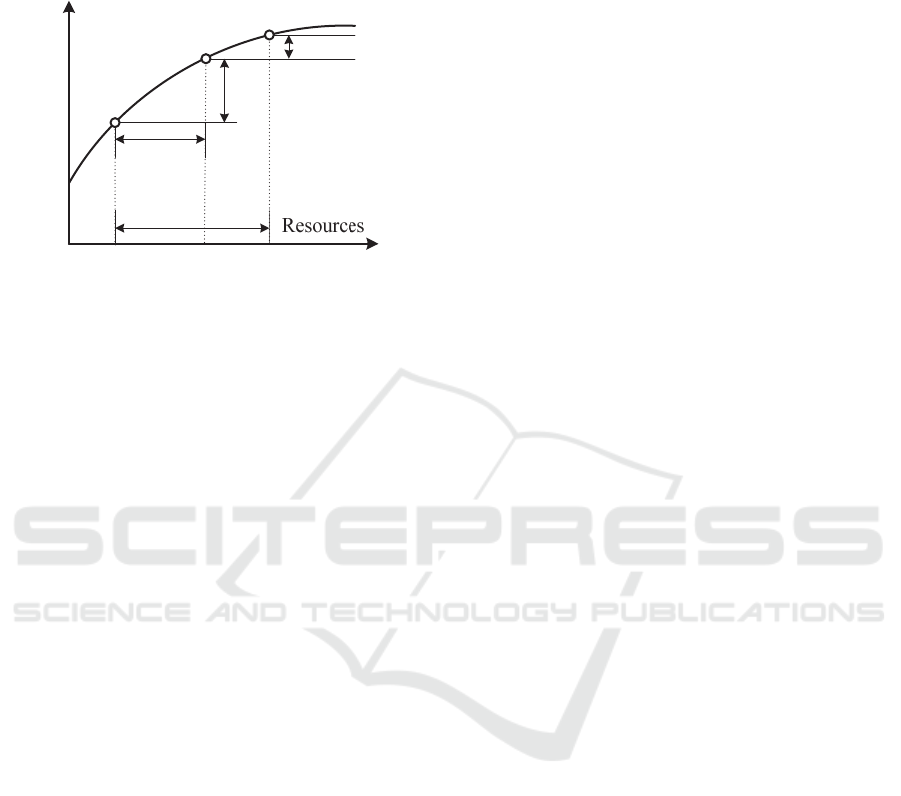

frequently. The best approach is the old control

systems to continue to work, by adding new

technologies of control (Figure 2).

A

B

C

Effect

J

0

J

1

J

2

J

1

R

A

R

B

R

C

R

R

0

J

12

J

2

R

Figure 2: Process control effectiveness.

4. In deciding to develop the management system

one must take into account the influence of many

factors.

The estimated economic impact of flexibility,

quality improvement, increased productivity and

reduced production costs;

Spent money, effort and time;

Reaction of the operating personnel;

Security of humans and also of the facilities;

Satisfy environmental and governmental

regulations.

Unlike the position shown in Figure 2, we have a

multicriteria problem.

5. Reengineering the system must take into account

the specific circumstances:

The degree of automation and information links;

Different final goal to develop the system;

The hardware and software from different

vendors;

Lack of prospects henceforth uses only one

supplier.

6. Only a holistic approach can be effective.

Information integration basically influences its

realization.

7. The human factor is critical to the success of the

integrated system. To do this:

People need to understand the functions of the

system;

They must feel that they are part of the system

with their expertise;

They should not be overloaded by an extra

loading;

They must be sure that the system is safe and

comfortable for them.

8. Outlines of some important drawbacks of private

character:

Monitoring of key industrial indicators –

economic efficiency, safety and reliability is

incomplete and it affects negatively the quality

of decisions;

Underestimated is the use of knowledge,

especially on condition of the unanimous

assessment that skilled and experienced-know-

ledge workers continuously retire without an

equivalent replacement with new footage;

Archival records are used less or not at all

(Castiliio, 2013);

The management of second and third level is

more intuitive than based on online recom-

mendations from DSS;

Security systems (SSMs) are underestimated

from terrorism and from unauthorized access,

especially in terms of increasing wireless

communications.

Figure 3 generalizes the management scheme,

interpreting standard ISA-95 on functional level as

multidimensional multistage system.

Provided, but not addressed in the standard

division of the general part of technology manage-

ment (PCS) at two levels (1 and 2) is considered an

important structural feature. Each level is described

as being of universal attributes, each of which is

multi-dimensional and functionally different for

each of the four levels. The following below

attributes are considered.

Hierarchical level;

Tools for program-technical realization

(SCADA, RLS, DCS, MES, ERP) R;

Used mathematical models М;

Criteria J and restrictions L in the optimization

problem;

Functions performed F;

Control algorithms or decision making А;

Information functions I;

Operative and control actions О, U;

Information disturbances d.

Each level receives its task from the preceding

hierarchical level, including certain requirements in

the form of specifications S

i

, volumes V

i

, criteria J

i

,

limitations L

i

:

iiiii

LJVSr , , ,

(1)

The task is a vector comprising N

i

components to

each i-th level:

iNiijiii

rrrrr , ... , , ... , ,

21

(2)

Significance of the Predictive Maintenance Strategies for SMEs

279

3

M

3

J

3

L

3

F

3

r

3

l

4

M

3

I

1

I

4

I

2

I

4

I

4

F

4

O

4

J

4

L

3

A

4

A

3

O

3

I

1

I

2

I

3

I

2

M

2

J

2

L

2

F

2

A

2

O

1

I

2

I

2

I

2

r

2

l

1

I

2

r

2

l

1

M

1

J

1

L

1

F

1

A

1

O

1

d

2

d

3

d

4

d

4

r

4

l

4

Y

3

Y

2

Y

1

Y

4

u

3

u

2

u

1

u

Figure 3: Generalized scheme.

The feedback y

ij

is an assessment of the operat-

ion of each j-th element of i-th level E

ij

and it has the

same structure as the task r

i

.

The aim of each level is to minimize the error e

i

in terms of the specified criterion J

i

with constraints

S

i

, V

i

, L

i

through controls u

i

:

iii

LVS

i

ueJu

iii

, min arg

,,

(3)

Criteria J

i

and specifications S

i

, volumes V

i

and

limitations L

i

are vector and are different for each

j-th E

ij

element at level i:

iNiijiii

iNiijiii

iNiijiii

iNiijiii

LLLLL

VVVVV

SSSSS

JJJJJ

, ... , , ... , ,

, ... , , ... , ,

, ... , , ... , ,

, ... , , ... , ,

21

21

21

21

(4)

The controls u

i

similarly are vectors, like the

expressions (4), but each element E

ij

may have

several effects due to multidimensionality of the

control:

ijkijijij

uuuu , ... , ,

21

(5)

Operational impacts u

i

can be both automatic

controllers and also the actions of the operating

personnel. A multistage system reflects both the

hierarchical subordination of the lower level with

respect to the upper one and also the inverse

information influence of the lower level at the upper

one. Each level has full access to the information at

a lower level, but it adds also new information in the

information flow upward as a result of the specific

management and information processes at its own

level.

4 CONCLUSIONS

Management of industrial complexes is gaining

acceptance as a functional problem with multiple

criteria the decision of which is possible only via a

holistic approach.

Rapid development and application in DCS and

SCADA receive a number of information techno-

logies. Information integration is a key in building

ERP, MES and PCS joint systems.

The methods of artificial intelligence (neural

networks, fuzzy logic, genetic algorithms) and those

based on knowledge (expert systems, autonomous

agents, CBR) and especially the hybrid systems are

still used only occasionally, but they possess a

significant potential.

Generally ERP-MES-PCS systems are developed

successfully to increase the competitiveness of

industrial complexes in the globalized world.

The successful implementation of an approach to

predictive maintenance taking into account the

nature of activities in SMEs, it must be based on

three main objectives. First, to allow the user to

formulate a strategy of maintenance. Second, to

convert the limited available data into knowledge to

develop a strategy for maintenance. Third, to allow

Fourth International Symposium on Business Modeling and Software Design

280

the user to record and measure the effect of the new

strategy for support, to ensure that future decisions

are based on facts and accurate data. The successful

implementation of the formed in this way model

would lead to the possibility the structure and the

elements of the model to create efficient and

effective strategy to support SMEs.

The main problem in developing a maintenance

strategy is bounded by the lack of appropriate

documentation and the ineffective analysis of

available data. The reasons for this may be the lack

of time for an understanding of the existing

technology, and human relations in general. In

particular, the staff must record their deeds and

actions that relate to the problem; besides there must

be measured the quantifiable, measurable benefits,

which in the short term is difficult to achieve.

Progress is possible if you use a simple system for

recording and analysis that can be easily accessed

and updated. The present research shows that

technology is able to solve emerging needs but it

requires innovative adaptations to solve the existing

problems.

ACKNOWLEDGEMENTS

The research work reported in the paper is partly

supported by the project AComIn “Advanced

Computing for Innovation”, grant 316087, funded

by the FP7 Capacity Programme (Research Potential

of Convergence Regions), partially supported by the

European Social Fund and Republic of Bulgaria,

Operational Programme “Development of Human

Resources” 2007-2013, Grant № BG051PO001-

3.3.06-0048 and partially supported under the

Project № DVU-10-0267/10.

REFERENCES

http://www.automation.siemens.com

http://www.honeywellprocess.com/en-us

Al-Najjar B., 1996. Total Quality Maintenance. In Journal

of Quality in Maintenance Engineering 2 (3), 4–20.

Baglee D., M. Knowles, 2010. Maintenance strategy

development within SMEs: the development of an

integrated approach, In Journal Control and

Cybernetics, 39 (1), 275–303.

Baglee D., R. Trimble, J. MacIntyre, 2003. An invest-

igation into the perceived barriers to total Productive

Maintenance in small and medium enterprises. In

International Conference on Manufacturing Research,

University of Strathclyde, Professional Engineering

Publishing.

Bamber C. J., J. M. Sharp., M. T. Hides, 1999. Factors

affecting successful implementation of TPM: A case

study perspective. In Journal of Quality in

Maintenance Engineering 5 (3), 162–181.

Barnes D., 2002. The complexities of the manufacturing

strategy formation process in practice. In International

Journal of Operations and Production Management

22 (10), 1090–1111.

Blanchard B., 1997. An enhanced approach for

implementing TPM in the manufacturing environment,

In Journal of Quality in Maintenance Engineering 3

(2), 69-80.

Bohoris G. A., C. Vamvalis, W. Trace, K. Ignatiadou,

1995. TPM implementation in Land-Rover with the

assistance of a CMMS. In Journal of Quality in

Maintenance Engineering, 1 (4), 3–16.

Castillio О., P. Melinand, J. Kasprzyk, (Eds), 2013. Recent

Advantages on Hybrid Intelligent Systems, Springer.

Chan F., F. Lau, S. Chan, S. Kong, 2005. Implementation

of Total Productive Maintenance: A case study. In

International Journal of Production Economics 95(1),

71–94.

Cholasuke C. R., R. Bhardwa, A. Jiju, 2004. The status of

maintenance management in UK manufacturing

organisations: results from a pilot survey. In Journal

of Quality in Maintenance Engineering 10 (1), 5–15.

Cooke F. L., 2000. Implementing TPM in plant

maintenance: Some organizational barriers. In

International Journal of Quality & Reliability

Management 17 (9), 1003–1016.

Dochain D., W. Marquardt, S. Won, О. Malik, М.

Kinnaert, J. Lunze, 2008. Monitoring and Control of

Process and Power Systems: Adapting to

Environmental Challenges, Increasing Competitivity

and Changing Customer and Consumer Demands, In

IFAC World Congress, Seoul, Korea, 7160–7171.

ISA the Instrumentation, Systems and Automation

Society, 2005. The ANSVISA 95 Enterprise — Control

System Integration, Research Triangle Park, NC,

USA.

ISO 13381-I, 2004. Condition monitoring and diagnostics

of machines-prognostics – Part: General guidelines.

Int. Standard, ISO.

Nakajima S., 1988. Introduction to TPM: Total Productive

Maintenance

. London, Productivity Press.

Staykov B., T. Atanasova, V. Monov, L. Doukovska,

2013. The ERP Systems in Modern Business and

Corporate Management, In Proceedings of the

International Symposium on Business Modeling and

Software Design – BMSD’13, Noordwijkerhout, The

Netherlands, 281–285.

Significance of the Predictive Maintenance Strategies for SMEs

281