Modeling and Verification of B-based Distributed Reconfigurable

Control Systems

Raja Oueslati

1

, Olfa Mosbahi

2

Mohamed Khalgui

2

and Samir Ben Ahmed

1

1

Faculty of Sciences of Tunis, University of Tunis El Manar, Tunis, Tunisia

2

LISI, INSAT, University of Carthage, Carthage, Tunisia

Keywords:

Distributed Reconfigurable Control Systems, B Method, Modeling, Formal Verification, Multi-agent Archi-

tecture, Coordination.

Abstract:

The paper deals with the modeling and verification of B based Distributed Reconfigurable Control Systems

(DRCS). A distributed multi-agent architecture is developed, where for each system is affected a Reconfigu-

ration Agent to apply a local automatic reconfiguration, and a Coordination Agent is proposed to harmonize

between systems when any local reconfiguration is applied in a system. We apply the Distributed Reconfig-

urable B “DR-B” formalism to define all possible behaviors, to determine reconfiguration functions for each

system and to execute the appropriate ones to respond to reconfiguration requests and to switch between the

specific distributed configuration at run-time to cope with the coherence of running systems. We verify a

DRCS by using the B method. The goal is to guarantee the consistency and the correctness of the abstract

specification level. Further more, to avoid combinatorial explosion problem in DRCS, we apply the “Check R-

B” tool, to reduce redundant checking of different behaviors sharing similar operations. All the contributions

of this work are applied to two benchmark production systems FESTO and EnAS.

1 INTRODUCTION

Nowadays in industry, the development of safe dis-

tributed control systems is not a trivial activity be-

cause a failure can be critical for the safety of hu-

man being e.g. air and railway traffic control (khalgui

et al., 2012). In this context, one of the mostimportant

challenges is the trade-off between performance and

rapid response to market changes and customer needs.

One of the most promising directions, where consid-

erable progress has been made, to address these issues

is the reconfiguration of Distributed Control Systems

(DCS). We distinguish two types of reconfigurations:

static (offline) and dynamic (online) (Angelov et al.,

2005). The former is applied offline before system

cold starts, whereas the latter is applied automatically

at run-time. In the latter case, two types exist : man-

ual reconfigurations to be executed by users and au-

tomatic (intelligent) reconfigurations to be performed

by intelligent agents that can be a physical resource

(robot, machine ...) or a logical resource (scheduler),

and hybrid reconfigurations which are the combina-

tion of manual and automatic reconfigurations.

To deal with the automatic reconfiguration of dis-

tributed industrial control systems following the B

method, we propose, in this work a new distributed

multi-agent architecture. We define two kinds of

agents: Reconfiguration Agent (RA) which is as-

signed to each system to apply a local automatic re-

configuration and a Coordination Agent (CA) which

handles the coherence of distributed concurrent re-

configurations of different systems. A “DR-B” for-

malism is applied to model distributed reconfigurable

control systems. It consists of three modules: Behav-

ior, Control and Coordinator. The first defines all pos-

sible behaviors of the system, whereas the second is

a set of reconfiguration functions applied to change

each system from one configuration to another one at

run-time by adding or removing some operations in B

machines and the third module coordinates between

the different systems when applying a reconfiguration

scenario by executing the appropriate reconfiguration

functions. This reconfiguration scenario is applied as

a response to improve the system

′

s performance, or

also to recover and prevent hardware/software errors,

or also to adapt its behavior to new requirements ac-

cording to the environment evolution. After the mod-

eling of the DRCS, the next step is to check the cor-

rectness of the DRCS using B method. In order to

avoid combinatorial explosion problem, we apply the

“Check R-B” tool that was implemented, in (Oues-

lati et al., 2014), to reduce redundant checking of dif-

ferent behaviors sharing similar operations. To our

knowledge, this is the first contribution dealing with

124

Oueslati R., Mosbahi O., Khalgui M. and Ben Ahmed S..

Modeling and Verification of B-based Distributed Reconfigurable Control Systems.

DOI: 10.5220/0005244601240131

In Proceedings of the 5th International Conference on Pervasive and Embedded Computing and Communication Systems (PECCS-2015), pages

124-131

ISBN: 978-989-758-084-0

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

the B method to dynamically and automatically re-

configure distributed industrial control systems.

The rest of the paper is organized as follows: in

the second Section, we present the background in

which we introduce B method. In the third Section,

we describe the two benchmark production systems

FESTO and EnAS to be followed in the paper as run-

ning examples to explain our contribution. We define,

in the next Section, the Distributed Reconfigurable

B “DR-B” formalism that we apply to our system.

The distributed multi-agent architecture is proposed,

in the fifth Section. In the sixth Section, we present

the “Check R-B” tool for DRCS. We finish by a con-

clusion and the exposition of our future works.

2 BACKGROUND KNOWLEDGE

We present in this section, the well-known B method.

2.1 Presentation of B

B is a formal method developed by Abrial to support

the software development life cycle from specifica-

tion to implementation (Abrial, 1996). It is based on

Zermelo-Fraenkel set theory and on generalized sub-

stitution. Sets are used for data modeling, General-

ized Substitutions are used to describe state modifi-

cation, and the refinement calculus is used to relate

models at varying abstraction levels. A machine B is

composed of header part allowing the identification

of the abstract machine, static part defining observa-

tions (sets, variables, constants, etc) of the system and

their invariant properties and dynamic part describing

operations changing the state of the system.

2.2 Composition in B

Abstract machines can be combined, through the

clauses INCLUDES, SEES, IMPORTS and USES to

build new specifications (Abrial, 1996). We are inter-

ested to the clause INCLUDES which allows a ma-

chine to be included in another one with read/write

access to the variables of the included machine. A

machine M includes a machine M1 means that M has

a full access to the constants, sets, variables and oper-

ations of M1 and operations of M can be defined by

using any M1 operations. It is worth mentioning that

at most one operation of the included machine can be

called from within an operation of the including ma-

chine. In order to avoid an obvious clash, we have

the possibility to rename a machine while including

it. This is done simply by prefixing, in the clause IN-

CLUDES, the name of the machine we want to re-

name with a certain identifier by a dot (x.M1, y.M1)

as explained in Figure 1.

Machine M(x,n)

............................

INCLUDES

x.M1, y.M1

OPERATIONS

C= PRE condition THEN x.A|| y.B END

END

Machine M1

............................

............................

............................

OPERATIONS

A= PRE ................THEN .........END

B= PRE ................THEN .........END

END

Figure 1: Clause INCLUDES.

3 CASES STUDIES: FESTO AND

EnAS

Two benchmark production systems FESTO and

EnAS (ref, ) are used as intact running examples in

this paper, in order to highlight the contributions of

our work. They are well documented laboratory sys-

tems used by many universities for research and edu-

cation purposes.

3.1 FESTO System

It consists of three units: Distribution Unit, Test Unit,

Processing Unit. The Distribution Unit is formed

of a pneumatic feeder and a converter which trans-

mits cylindrical workpieces from a stock to the Test

Unit. The Test Unit is composed of a detector, a tester

and an elevator. It performs tests on workpieces for

height, type of material and color. Workpieces that

satisfy these tests are transmitted to the Processing

Unit which is composed of a rotating disk, a drill

machine and a control machine. The rotating disk is

composed of locations to contain and transport work-

pieces from the input position, to the drilling position,

to the control position and finally to the output posi-

tion. Four production modes are assumed in this pa-

per to be applied in FESTO, depending on the number

of workpieces NP, as follows:

• Light1: If NP < C1, Then only Drill1 is used for

drilling workpieces.

• Light2: If NP < C1, Then only Drill2 is used for

drilling workpieces.

• Medium: If C1 ≤ NP < C2, Then Drill1 or Drill2

are used for drilling workpieces.

• High: If NP ≥ C2, Then the two drilling machines

are used simultaneously to drill two pieces at the

same time.

If both Drill1 and Drill2 are broken, the system is

completely stopped. We should make FESTO able

to switch production modes automatically at run-time

ModelingandVerificationofB-basedDistributedReconfigurableControlSystems

125

Light1

Light2

Medium

High

Drill1 error

or

user

Drill2 error

or

user

user

Drill1 error

Drill2 error

or

user

Drill1 error

or

user

user

user

user

Figure 2: Allowed reconfigurations of FESTO.

according to any changes in the working environment

caused by errors or user requirements without a halt.

It is assumed that the production modes are inter-

changeable as shown in Figure 2.

3.2 EnAS System

EnAS transports workpieces from FESTO into stor-

ing stations. The workpieces shall be placed inside

tins to close with caps afterwards. The EnAS sys-

tem is mainly composed of a belt, two Jack stations

(J1 and J2) and two Gripper stations (G1 and G2).

The Jack stations place new drilled workpieces from

FESTO and close tins with caps, whereas the Gripper

stations remove charged tins from the belt into storing

stations (ST1 and ST2). Initially, the belt moves a par-

ticular pallet containing a tin and a cap into the first

Jack station J1. Four production modes are assumed

in this paper to be applied in EnAS, depending on the

number of drilled workpieces nbpieces, tins and caps

nb(tins+caps), as follows:

• Policy1: If nbpieces/nb(tins+caps)<C1, Then J1

places and closes, G1 removes into St1.

• Policy2: If nbpieces/nb(tins+caps)<C1, Then J1

places, J2 closes, G2 removes into St2.

• Policy3: If C1≤nbpieces/nb(tins+caps)<C2,

Then J1 places and closes, G2 removes into St2

or J1 places, J2 closes, G1 removes into St1.

• Policy4: If nbpieces/nb(tins+caps)≥C2, Then J1

places, J2 places and closes, G2 removes the tin

(with two pieces) into St2.

The system is completely stopped if both J1 and J2

are broken. We should make EnAS able to switch

policies automatically at run-time according to any

changes in working environment caused by errors or

user requirements without a halt. It is assumed that

policies are interchangeable as shown in Figure 3.

The two systems FESTO and EnAS are linked to

coordinate their work. We define in Table 1 the al-

lowed compositions of behavior modes of the two

systems. To guarantee the correctness and safeness

of the whole system when a local reconfiguration

Policy1

Policy2

Policy3

Policy4

G1 Error

or

user

G2 Error

or

user

G1 Error

or

user

J1 Error

or user

J2 error

or

user

J1 Error

or

user

user

G2 Error

or

user

user

G2 Error

Figure 3: Allowed reconfigurations of EnAS.

Table 1: Allowed coordinations of FESTO and EnAS.

(FESTO, EnAS) (FESTO,EnAS)

(Light1,Policy1) (Light2,Policy3)

(Light1,Policy2) (Medium,Policy3)

(Light1,Policy3) (Medium,Policy1)

(Light2,Policy1) (Medium,Policy2)

(Light2,Policy2) (High,Policy4)

is allowed to be applied in one of them, then the

other should have a proper reaction as a response

to the planed reconfiguration. The behavior modes

Light1, Light2 and Medium of FESTO can cohere

with Policy1, Policy2 and Policy3 of EnAS and High

of FESTO requires Policy4 of EnAS and vise versa.

4 PRESENTATION OF DR-B

FORMALISM

In this section, we propose the “DR-B” formal-

ism to model DRCS following the B method. A

“DR-B” consists of a behavior module which is the

union of all system configurations, a control module

formed by a set of reconfiguration functions handling

automatic transformations between specific config-

urations in the behavior module and a coordina-

tor module that manages appropriate reconfiguration

functions to switch between distributed configuration

without any disturbance. For a DRCS, finite behav-

ior modes (configurations) can be performed and the

time cost for the reconfiguration of the control sys-

tems should be as short as possible to guarantee the

instantaneity, the validity, and more importantly the

safety. Each configuration model is called a B ma-

chine in this paper.

Definition1. A DCS is composed of n systems as

follows DCS = {sys

1

, sys

2

, ..., sys

n

} and each one can

perform behavior modes as follows sys

1

= {x, x

′

, ...},

sys

2

= {y, y

′

, ...} ... and sys

n

= {z, z

′

, ...}. The set of

allowed distributed configurations of the n systems is

defined according to the coherence between the n sys-

tems behavior modes as follows:

SET

allowedcoordinations

= {(x, y, ..., z), (x

′

, y

′

, ..., z

′

), ...}

PECCS2015-5thInternationalConferenceonPervasiveandEmbeddedComputingandCommunicationSystems

126

Example1. The set of allowed coordinators

SET

allowedcoordinators

of the two systems FESTO and

EnAS is presented in Table 1.

Definition 2. A “DR-B” formalism of the n systems

of DCS is a structure defined as follows:

DR-B=(∪(β

sys

i

, R

sys

i

),Coordinator)

where:∪(β

sys

i

, R

sys

i

) is the union of the behavior and

control module of each system sys

i

and Coordinator

is a Coordinator module of the DCS.

Definition 3. Behavior Module. The behavior mod-

ule of a system β

sys

i

is the union of m configurations

of sys

i

, represented as follows:

β

sys

i

= {M

0

, M

1

, ..., M

i

, ...M

m

}

Where:(i) M

0

is the initial B machine corresponding

to the first configuration, (ii) M

i

is the machine repre-

sented by the following tuple:

M

i

= (C, S, Const, P, V, I, Init, Op)

Where:(i) C:the system constraints, (ii) S:the sets,

(iii) Const:the constants, (iv) P:the properties con-

stants , (v) V:the variables, (vi) I:the invariants, (vii)

Init:the initialization of variables and (viii) Op:the

operations.

Definition 4. Control Module. The control module

of a system R

sys

i

is a set of reconfiguration functions

R

sys

i

= {r

i

,..., r

m

} allowing automatic transformations

between configurations. A reconfiguration function

of a system r

sys

i

(x,x

′

)

is a structure changing the system

from a configuration x to another one x’ defined as

follows r

sys

i

(x,x

′

)

= (Cond

sys

i

(x,x

′

)

, S

sys

i

(x,x

′

)

), where:(i)

Cond

sys

i

(x,x

′

)

∈{True, False}:the pre-condition of

r

sys

i

(x,x

′

)

, (ii) S

sys

i

(x,x

′

)

:(

•

M) →(M

•

) is the structure

modification instruction where (

•

M) denotes the

machine M

i

before the application of r

sys

i

(x,x

′

)

and

(M

•

) denotes the target machine M

j

after the recon-

figuration function r

sys

i

(x,x

′

)

is applied. The structure

S

sys

i

(x,x

′

)

models the transformation from a M

i

to

another M

j

machine, when we apply a reconfigu-

ration scenario. If Cond

sys

i

(x,x

′

)

= True, r

sys

i

(x,x

′

)

is

executable, otherwise it cannot be executed. The

structure modification instruction S

sys

i

(x,x

′

)

guides the

system transformation from (

•

M) to (M

•

), including

the addition /removal of operations from a source M

i

,

to obtain a target M

j

machine. The pre-condition of

a reconfiguration function means specific external

instructions and gusty functioning failures.

Definition 5. Coordinator Module. The coordi-

nator module is a set of distributed reconfiguration

functions RD

sys

i

= {rd

i

,..., rd

m

}. A distributed

reconfiguration function rd which allows the system

to apply dynamic reconfigurations at run-time from

the current distributed configuration (x, y, ..., z) to

the target distributed configuration (x

′

, y

′

, ..., z

′

), is a

structure described as follows:

rd

(x,y,...,z),(x

′

,y

′

,...,z

′

)

=

(Cond

(x,y,...,z),(x

′

,y

′

,...,z

′

)

, (r

sys

1

(x,x

′

)

∧ r

sys

2

(y,y

′

)

... ∧

r

sys

n

(z,z

′

)

)),

where: (i) Cond

(x,y,...,z),(x

′

,y

′

,...,z

′

)

∈{True, False}:

the pre-condition of rd

(x,y,...,z),(x

′

,y

′

,...,z

′

)

, (ii)

(r

sys

1

(x,x

′

)

∧ r

sys

2

(y,y

′

)

... ∧ r

sys

n

(z,z

′

)

): the reconfigu-

ration functions of the systems sys

1

, sys

2

... and sys

n

,

respectively.

Cond

(x,y,...,z),(x

′

,y

′

,...,z

′

)

is True if the system can switch

from the current distributed configuration (x, y, ..., z)

to the target distributed configuration (x

′

, y

′

, ..., z

′

)

then r

sys

1

(x,x

′

)

, r

sys

2

(y,y

′

)

, ... and r

sys

n

(z,z

′

)

are exe-

cutable, otherwise they cannot be executed.

Definition6. A DRCS=(∪sys

i

, Coordinator) where

∪sys

i

represents the n systems composing DCS and

Coordinator denotes the coordinator of the appropri-

ate reconfiguration functions of the n systems. When

a reconfiguration scenario of a running system is

allowed, the coordinator should make a decision and

provide an optimal solution for all the other running

systems in the environment.

5 DISTRIBUTED

RECONFIGURABLE B

CONTROL SYSTEMS

In this section, we propose a multi-Agent distributed

architecture for DRCS following B method. We de-

fine two kinds of agents: Coordination Agent (CA)

and Reconfiguration Agent (RA). The RA of each

system is represented by the control module R

sys

i

of

the “DR-B” formalism. The role of any RA is to ap-

ply dynamic reconfigurations on the system. The exe-

cution of a reconfiguration changes the system behav-

ior at run-time from a valid configuration to another

one according to well-defined conditions to adapt it

to its environment. Any uncontrolled automatic re-

configuration applied in a system can lead to criti-

cal problems, serious disturbances in others. There-

fore, CA is defined to cope with the coordination of

the running systems that handle the coherence of dis-

tributed reconfigurations between the different RAs.

When a reconfiguration scenario is allowed, the coor-

dinator should provide an optimal solution for all the

other running systems in the environment such that

the safety and the correctness of the whole system are

guaranteed all along. In order to manage the coordi-

nation between RAs, we define the CA represented by

an abstract B machine which maintains safe reconfig-

uration scenarios that can be applied by the different

RAs.

ModelingandVerificationofB-basedDistributedReconfigurableControlSystems

127

6 APPLICATION TO FESTO AND

EnAS

In this section, we apply the proposed formalism to

the DCS composed of the two systems FESTO and

EnAS in order to explain our contribution. Firstly,

we present all the possible configurations of the two

systems in order to determine their behavior modules.

Secondly, we describe the FESTO and EnAS control

modules. Thirdly, we define the coordinator model of

the two systems.

6.1 FESTO and EnAS Behavior

Modules

According to the fourth production modes, FESTO

behavior module β

FESTO

is composed of eight ma-

chines, presented as follows:

MF1

∆

= op1; op2; op3; op4

MF2

∆

=op1; op2; op3; op5; op61; op7; op62; op11;

op63; op12

MF3

∆

=op1; op2 ; op3; op5; op61; op7

MF4

∆

=op1; op2; op3; op5; op61; op8; op62; op11;

op63; op12

MF5

∆

=op1; op2; op3; op5; op61; op9; op62; op11;

op63; op12

MF6

∆

=op1; op2; op3; op5; op61; op9

MF7

∆

=op1; op2; op3; op5; op61; op10; op62; op11;

op63; op12

MF8

∆

=op1; op2; op3; op5; op61; op10

Piece

ejection

op1

Convert

op2

Test

op3

Elevate

op5

Rotate1

op61

Drill2

op8

Drill1 or

Drill2

op9

Drill1

and

Drill2

op10

Drill1

op7

Tester

failed

op4

Rotate2 Checker

op11op62

Rotate3

op63

Evacuate

op12

Figure 4: Working process of FESTO.

The default initial production mode Light1 can be de-

scribed by the combination of MF1, MF2 and MF3.

In fact, after the execution of op3, a workpiece is re-

moved to op4 or op5 according to the result of the test

unit. Similarly, Light2 is specified by the combina-

tion of MF1 and MF4. The combinations of MF1,

MF5, MF6, and MF1, MF7, MF8 represent respec-

tively the medium and high production modes of the

FESTO system. EnAS can perform four types of be-

havior modes according to the production rate. It’s

behavior module β

EnAS

is composed of twelve ma-

chines, presented as follows:

J1 places

workpiece

op'1

J1 closes tin/

cap

op'2

Belet moves

tin from J1 to

G1

op'3

G1 removes

tin to ST1

op'4

Belet moves

workpiece to

J2

op'6

J2 closes tin/

cap

op'8

Belet moves

tin from J2 to

G2

op'10

G2 removes

tin to ST2

op'11

J2 places

workpiece

op'7

Belet moves

tin from J2 to

G1

op'6

Belet moves

tin from J1 to

G2

op'5

Figure 5: Working process of EnAS.

ME1

∆

= op

′

1 ; op

′

2 ; op

′

3 ; op

′

4

ME2

∆

= op

′

1 ; op

′

2

ME3

∆

= op

′

1 ; op

′

2 ; op

′

3

ME4

∆

= op

′

1 ; op

′

6 ; op

′

8 ; op

′

10 ; op

′

11

ME5

∆

= op

′

1 ; op

′

6 ; op

′

8 ; op

′

10

ME6

∆

= op

′

1 ; op

′

2 ; op

′

5 ; op

′

11

ME7

∆

= op

′

1 ; op

′

2 ; op

′

5

ME8

∆

= op

′

1 ; op

′

6 ; op

′

8 ; op

′

9; op

′

4

ME9

∆

= op

′

1 ; op

′

6 ; op

′

8; op

′

9

ME10

∆

= op

′

1 ; op

′

6 ; op

′

7; op

′

8 ; op

′

10; op

′

11

ME11

∆

= op

′

1 ; op

′

6 ; op

′

7; op

′

8

ME12

∆

= op

′

1 ; op

′

6 ; op

′

7; op

′

8 ; op

′

10

The default initial production mode Policy1 can be

described by the combination of ME1, ME2 and

ME3. Policy2 is specified by ME4 and ME5. The

combinations of ME6, ME7, ME8 with ME9, and

ME10, ME11 with ME12 represent the Policy3 and

Policy4 of the EnAS system, respectively.

6.2 FESTO and EnAS Control Modules

In this section, we describe the RAs of the two sys-

tems FESTO and EnAS allowing automatic changes

between all the system configurations. In the follow-

ing, the four behavior modes of FESTO are denoted

by 1, 2, 3, and 4 corresponding to Light1, Light2,

Medium and High, respectively. The four behavior

modes of EnAS are denoted by 1, 2, 3 and 4 cor-

responding to Policy1, Policy2, Policy3 and Policy4,

respectively. As shown in Figure 2, the RA of FESTO

is represented as follows:

R

FESTO

={ r

FESTO(1,2)

, r

FESTO(1,3)

, r

FESTO(1,4)

,

r

FESTO(3,1)

, r

FESTO(3,2)

, r

FESTO(3,4)

, r

FESTO(4,1)

,

r

FESTO(4,2)

, r

FESTO(4,3)

}

Let us assume that FESTO is in Light1 production

mode when the user requests to change the produc-

tion to Medium. If Cond

FESTO(1,3)

=true, then the

PECCS2015-5thInternationalConferenceonPervasiveandEmbeddedComputingandCommunicationSystems

128

reconfiguration function r

FESTO(1,3)

is executed auto-

matically to respond to this request. To implement

r

FESTO(1,3)

, we execute the structure modification in-

struction S

FESTO(1,3)

including the removal of the op-

eration op7 and the addition of the operation op9. The

S

FESTO(1,3)

is presented as follows:

S

FESTO(1,3)

: MF2 → MF5

After, S

FESTO(1,3)

is executed, Drill2 or Drill1 is used

to drill workpieces. FESTO continues to work in

the Medium mode. We define in the following, the

FESTO controller B machine using the clause IN-

CLUDES for calling the needed FESTO machines, as

follows:

MACHINE FESTO_Controller_machine(........)

CONSTRAINTS ...............................

INCLUDES

a1.MF2(.........),a2.MF2(.........), ....

d1.MF5(.........),d2.MF5(.........),.....

SETS

REQ_FESTO_USER= {No_Req_FESTO, L1, L2, M, H};

VARIABLES req_festo_user

INVARIANT REQ_FESTO_USER: req_festo_user

INITIALISATION req_festo_user:= No_Req_FESTO

OPERATIONS

MF2_to_MF5= SELECT ....................

THEN ANY ...WHERE .................

THEN a1.eject_piece (.........)||

a2.convert(.........)||

a3.test_unit (.........) ||

a4.To_processing_unit (....) ||

a5.rotate1(.........) ||

d1.Drill(.........) ||

a7.rotate2(.........) ||

a8.Check (.........) ||

a9.rotate3(.........) ||

a10.Remove(.........)

END END; ..........................

Where: a1.MF2 (resp. d1.MF5) represents the in-

stance of the MF2 machine (resp. the instance of MF5

machine). For example, a2.convert (resp. d1.Drill)

means the call of the operation convert (resp. Drill)

from the instance of MF2 (resp. MF5).

There are ten different reconfiguration scenarios that

can be applied to EnAS as shown in Figure 3. The

control module of EnAS is represented as follows:

R

EnAS

={ r

EnAS(1,2)

, r

EnAS(1,3)

, r

EnAS(1,4)

, r

EnAS(2,3)

,

r

EnAS(3,1)

, r

EnAS(3,2)

, r

EnAS(3,4)

, r

EnAS(4,1)

, r

EnAS(4,2)

,

r

EnAS(4,3)

}

Let us assume that EnAS is in Policy1 production

mode when the user requests to change the produc-

tion to Policy3. If Cond

EnAS(1,3)

=true, then the

reconfiguration function r

EnAS(1,3)

is executed au-

tomatically to respond to this request. To imple-

ment r

EnAS(1,3)

, we execute the structure modification

instruction S

EnAS(1,3)

including removing operations

op

′

3; op

′

4 and adding operations op

′

5; op

′

11. The

S

EnAS(1,3)

is presented as follows:

S

EnAS(1,3)

: ME1 → ME6

After, S

EnAS(1,3)

is executed, J1 and G2 are used to

store drilled workpieces. EnAS continues to work in

Policy3 mode. We define in the following, the EnAS

controller B machine using the clause INCLUDES for

calling the needed EnAS machines, as follows:

MACHINE EnAS_Controller_Machine(.........)

CONSTRAINTS ..............................

INCLUDES

h1.ME1(...........),h2.ME1(...........),...

n3.ME6(...........),n4.ME6(...........),...

SETS

REQ_USER_ENAS={No_Req_EnAS, P1, P2, P3, P4}

VARIABLES req_enas_user

INVARIANT req_enas_user : REQ_USER_ENAS

INITIALISATION req_enas_user:= No_Req_EnAS

OPERATIONS

ME1_to_ME6= SELECT ................

THEN ANY ......WHERE.............. THEN

h1.place1(...) ||

h2.close1(.....)||

n3.move4(......) ||

n4.remove2(.......)

END END; .........................

Where: h1.ME1 (resp. n1.ME6) represents the in-

stance of the ME1 machine (resp. the instance of ME6

machine). For example, h1.place1 means the call of

the operation place1 from the instance of ME1 and

n3.move4 means the call of the operation move4 from

the instance of ME6.

6.3 Coordinator Module

In this section, we define the CA of the two systems

FESTO and EnAS that executes appropriate recon-

figuration functions of RAs to switch between dis-

tributed configuration without any disturbance to re-

spond to reconfiguration requests. According to Fig-

ure 2 and Figure 3, a state machine is defined as

shown in Figure 6, where each state corresponds to a

specific distributed configuration and each transition

means the system reconfiguration from a distributed

configuration to another. In the following, the vec-

tor (4,3) means that FESTO is in the High production

mode while EnAS is in Policy3 production mode.

There are 58 different reconfiguration scenarios that

can be applied to FESTO and EnAS to respond to user

requests or occurred fault. The Coordinator Module

is represented as follows:

RD

Coordinator

={ rd

(1,1),(1,2)

, rd

(1,1),(1,3)

, ...,

rd

(3,3),(1,1)

, rd

(3,3),(1,2)

, rd

(3,3),(1,3)

,..., rd

(4,3),(3,1)

,

rd

(4,3),(3,2)

, rd

(4,3),(3,3)

}

ModelingandVerificationofB-basedDistributedReconfigurableControlSystems

129

(1.1)

(1.2)

(2.2)

(2.1) (1.3)

(3.3)(2.3)

(3.1) (3.2)(4.4)

1

2

3

4

5

6

7

8

9

10

11

12 13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54 55

56

57

58

33

34

35

Figure 6: Specification of the Coordinator of FESTO and

EnAS.

Let us assume that FESTO is in Light1 when the

user requests to change to Medium and EnAS is

in Policy1 when the user requests to change Pol-

icy3. If Cond

(1,1),(3,3)

= True then the reconfigu-

ration functions r

FESTO(1,3)

and r

EnAS(1,3)

are exe-

cuted automatically to respond to the two requests.

We define in the following the CA represented by

a B machine including FESTO and EnAS controller

machines and taking into account the allowed co-

ordinations of the two systems. Therefore, we

use the clause INCLUDES calling the two RAs

of DCS defined by FESTO

Controller Machine and

EnAS

Controller Machine. The Coordinator machine

is as follows:

MACHINE Coordinator_Machine

INCLUDES FESTO_Controller_Machine(........)

EnAS_Controller_Machine(.........)

OPERATIONS

L1toM_P1toP3= SELECT

req_festo_user=M &req_enas_user=P3

THEN MF2_to_MF5 || ME1_to_ME6

END END; .......................

Where MF2 to MF5 (resp. ME1 to E6) rep-

resents the call of the operation of the in-

cluded machine FESTO

Controller Machine (resp.

EnAS

Controller Machine) that switches the system

from Light2 to Medium (resp. from Policy1 to Pol-

icy3).

The proof obligations of B machines were proved by

the B4free prover and all invariants were preserved by

operations.

7 VERIFICATION OF DRCS

Once a DRCS model is well established, the next step

is the optimal verification to avoid redundant calcula-

tion. In (Oueslati et al., 2014), an optimal verification

algorithm was developed and a prototyped tool called

“Check R-B” is implemented to solve the redundancy

problem of the operations and to validate B machines,

we can consider it as a module that can be added to

B4free. The main idea is to identify for a given dis-

tributed configuration, the operations that should be

checked. An operation should be checked only once

by the B4free prover. So, from one distributed config-

uration to another, only the new operations should be

verified and also old ones that did not respect prece-

dence relationship between them. In this section, we

use the same tool to simulate the verification process

of DRCS.

Example2. Verification of DRCS

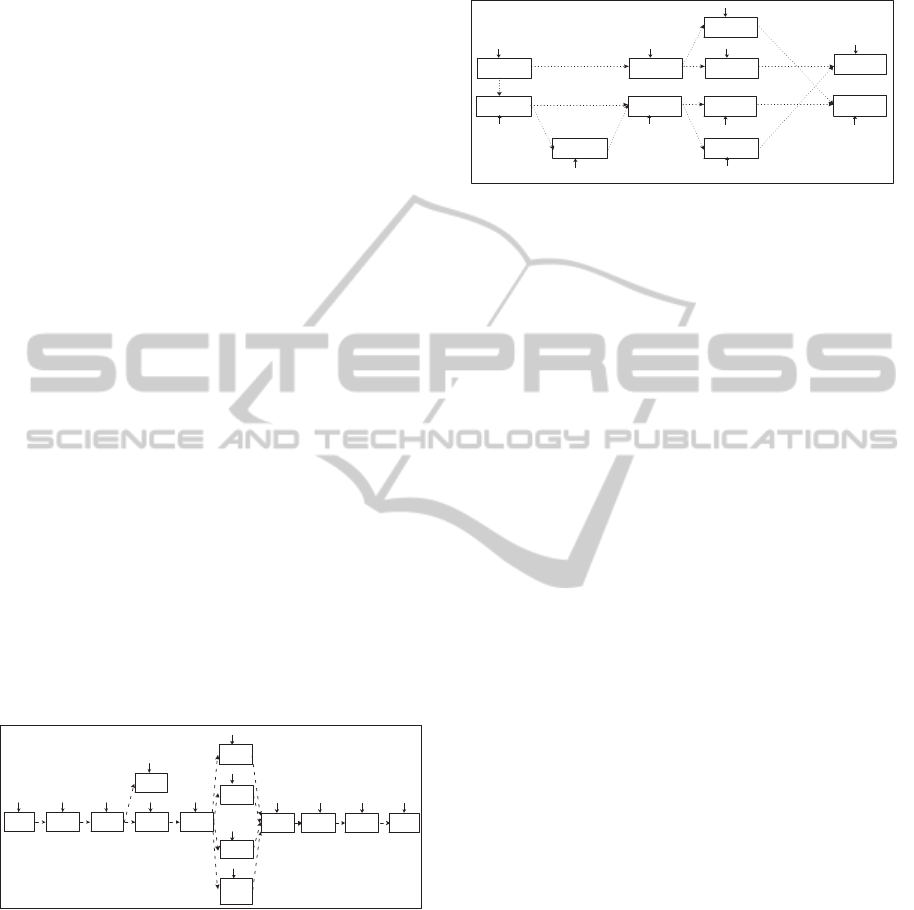

As shown in Figure 7, from the distributed config-

uration (1,1) to (2,3) (resp. (3,3)), only op8 and

op’5;op’11 (resp. op9 and op’5; op’11) need to be

verified, the same operations have not to be checked

again. Further more, from the distributed configura-

tion (1,1) to (2,2) (resp. (3,2)), only operations op8

and op

′

6 ; op

′

8 ; op

′

10 ; op

′

11 (resp. op9 and op

′

6

; op

′

8 ; op

′

10 ; op

′

11 ) need to be verified, since the

others are similar.

(2,2)

op'10

op'11

op'8

op'6

op'1

op8

op61

op5

op3

op2

op1

(1,1)

op'4

op'3

op'2

op'1

op7

op61

op5

op3

op2

op1

(2,3)

op'11

op'5

op'2

op'1

op8

op61

op5

op3

op2

op1

(3,2)

op'10

op'11

op'8

op'6

op'1

op9

op61

op5

op3

op2

op1

(3,3)

op'11

op'5

op'2

op'1

op9

op61

op5

op3

op2

op1

op11

op62

op12

op63

op11

op62

op12

op63

op11

op62

op12

op63

op11

op62

op12

op63

op11

op62

op12

op63

Figure 7: Verification of DRCS:FESTO and EnAS.

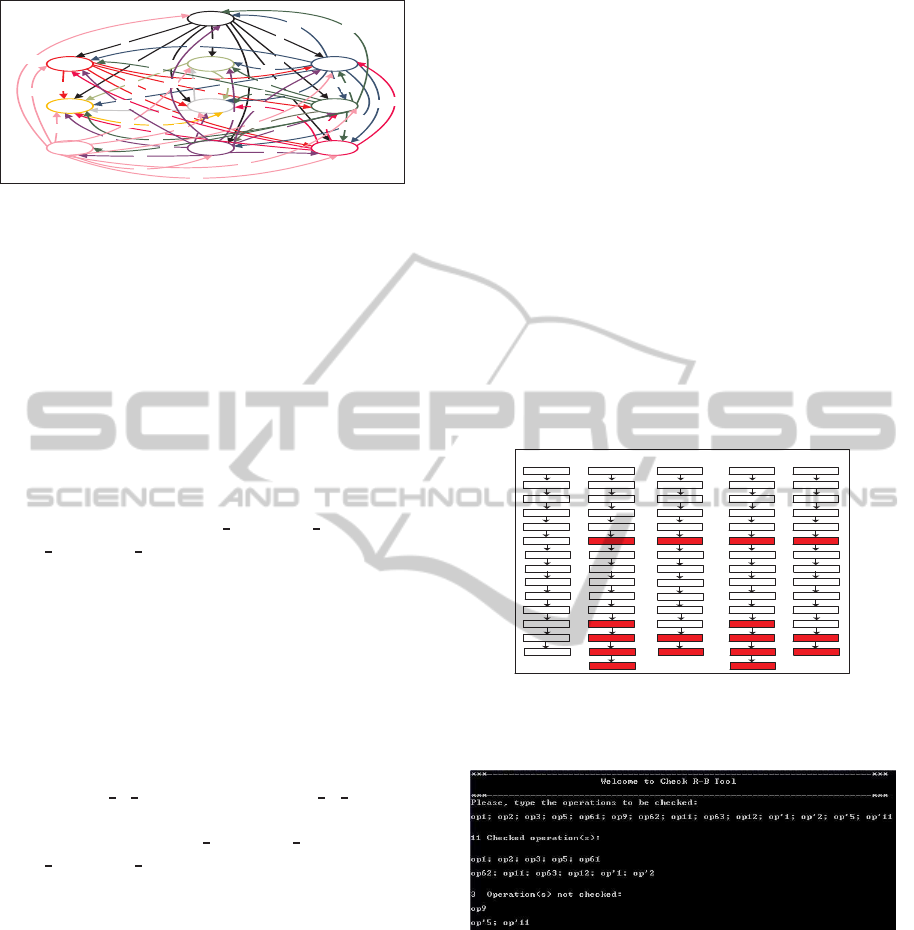

Example3. Simulation of the configuration (3,3)

Figure 8: Simulation of the configuration (3,3).

Let us assume that the user introduces operations cor-

responding to the execution of the distributed config-

uration (3,3). Let us assume that the tool has verified

firstly the distributed configuration (1,1), so a search

in a file containing checked machines will be done. If

a sequence of operations with precedence relationship

already exists, it is not necessary to check it again.

Otherwise, it will be forwarded to the prover. As

shown in Figure 8, the sequence of operations (op1;

op2; op3; op5; op61) and (op62; op11; op63; op12;

op’1; op’2) have already been checked and the oper-

ations (op9) and (op

′

5 ; op

′

11) have to be verified.

PECCS2015-5thInternationalConferenceonPervasiveandEmbeddedComputingandCommunicationSystems

130

Figure 9 shows two curves corresponding to the

comparison between verification process with and

without using “Check R-B”. The values of the ab-

scises axis correspond to the distributed configura-

tions when the system runs two times ((1,1), (2,2),

(2,3), (3,2), (1,2), (3,3), (4,4), (3,1), (1,3), (2,1)) in

order. The ordinate axis correspond to the number of

checked operations. The curve in blue corresponds

to the verification without “Check R-B”. The curve

in pink corresponds to the optimal verification using

“Check R-B”. It is important to note that the num-

ber of checked operations decreases gradually until

the value zero when we use the Check R-B tool as

compared to a direct verification without Check R-B.

0

2

4

6

8

10

12

14

16

18

(1,1)

(2,2)

(2,3)

(3,2)

(1,2)

(3,3)

(4,4)

(3,1)

(1,3)

(2,1)

(1,1)

(2,2)

(2,3)

(3,2)

(1,2)

(3,3)

(4,4)

(3,1)

(1,3)

(2,1)

Distributed Configurations

Number of Checked Operations

Figure 9: Comparison between verification process with

and without using “Check R-B”.

8 CONCLUSION

This paper deals with the modeling and verification

of distributed multi-agent reconfigurable control sys-

tems following the B method. We affect to each sub-

system a CA to apply local automatic reconfigura-

tions, and a CA for any coordination between systems

in order to guarantee safe and adequate distributed

reconfigurations. We propose a “DR-B” formalism

to model DRCS. Further more, to reduce redundant

checking of different behaviors sharing similar oper-

ations, we applied the “Check R-B” tool.

Different directions can be mentioned as further

work. First of all, we plan to generate the C code for

each developed B machine. We plan also to develop

a graphical tool that allows the efficient modeling and

verification of reconfigurable systems with “DR-B”.

REFERENCES

http://aut.informatik.unihalle.de/forschung/testbed/.

Abrial, J.-R. (1996). The B-Book. Cambridge University

Press.

Angelov, C., Sierszecki, K., and Marian, N. (2005). De-

sign models for reusable and reconfigurable state ma-

chines. volume 3824, pages 152–163. 3th Interna-

tional Conference on Embedded and Ubiquitous Com-

puting.

khalgui, M., Mosbahi, O., Hanisch, H., and Li, Z. (2012).

A multi-agent architectural solution for coherent dis-

tributed reconfigurations of function blocks. Journal

of Intelligent Manufacturing, 23:2531–2549.

Oueslati, R., Mosbahi, O., Khalgui, M., and Ben Ahmed, S.

(2014). New solutions for modeling and verification

of b-based reconfigurable control systems. pages 749–

757. 11th International Conference on Informatics in

Control, Automation and Robotics.

ModelingandVerificationofB-basedDistributedReconfigurableControlSystems

131