Data Mining Analysis of Turn around Time Variation

in a Semiconductor Manufacturing Line

Il-Gyo Chong

1

, Chenbo Zhu

2

and Yanfeng Wu

3

1

Semiconductor R&D Center, Samsung Electronics, 1 Samsungjeonja-ro, Hwaseong-si 445-330, Republic of Korea

2

College of Economics and Management, Zhejiang University of Technology, 288 Liuhe Road, Hangzhou, China

3

School of management, Fudan University, 670 Guoshun Road, Shanghai, China

Keywords: Semiconductor Manufacturing Line, Turn around Time (TAT), Data Mining, Variable Selection, Variable

Importance in the Projection (VIP) Scores, Partial Least Squares Regression.

Abstract: Variation reduction of Turn Around Time (TAT) in a manufacturing line is one of the important issues for

line optimization. In a manufacturing line with many sequential process steps such as semiconductor

fabrication, it is not easy to find the root causes of the TAT variation because (1) there might be a big time

gap (more than 30 days) between cause and effect, and (2) there are so many machines (or tools) related

with a process. The purpose of this paper is to propose a data mining based method to identify the root cause

of TAT variation. We also aim to validate the performance of the proposed method through a simulation

study.

1 INTRODUCTION

We consider a Turn Around Time (TAT) reduction

problem of a manufacturing line that consists of

many sequential process steps such as

semiconductor fabrication. Due to long time gap

(more than 30 days) between cause and effect, it is

difficult to make a timely solution. When engineers

make a solution of the cause, the cause is not a

current problem. Thus, in the field, a mostly used

strategy for reducing TAT focuses on solving

current problems of each machine under one’s own

supervision. However this strategy requires many

human resources and does not provide priority of the

causes because engineers do not know how much

the cause will make an effect on the TAT.

Furthermore, if there are many machines (or tools)

in a manufacturing line, the problem becomes more

difficult to assign the resource to solve the problem.

Specially, when investing for buying new machines,

identifying the true causes is very important because

the cost of a machine is recently very expensive in a

high technology industry.

The objective of this paper is to propose a data

mining based method which identifies the root cause

of TAT variation. Firstly, we build a relation model

between time variables of each process step (e.g.,

tool processing, waiting time, etc.) and the TAT by

using Partial Least Squares Regression (PLSR).

Secondly, we calculate the VIP scores of importance

of the time variables by applying the Variable

Importance in the Projection (VIP) method to the

PLSR model. We apply the proposed method to two

simulation experiments which mimic the real

situation. The result shows good performance. More

exhaustive simulation study is underway.

The rest of the paper is organized as follows. A

brief description of PLSR, the VIP method for

selecting important variables, and the concept of the

proposed method is given in Section 2. Section 3

describes the simulation design and experiment

factors. Simulation results of two different cases are

given in Section 4. Finally, Section 5 concludes the

current work with a summary.

2 PROPOSED METHOD

2.1 VIP Method based on PLSR

2.1.1 Partial Least Squares Regression

In case of single response y and p variables, PLS

regression model with h (hp) latent variables can

185

Chong I., Zhu C. and Wu Y..

Data Mining Analysis of Turn around Time Variation in a Semiconductor Manufacturing Line.

DOI: 10.5220/0005253301850189

In Proceedings of the International Conference on Operations Research and Enterprise Systems (ICORES-2015), pages 185-189

ISBN: 978-989-758-075-8

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

be expressed as follows (Geladi, 1986; Eriksson,

2001).

X = TP

t

+ E (1)

y = Tb + f (2)

In Eq. (1,2), X (n×p), T (n×h), P (p×h), y (n×1), and

b (h×1) are respectively used for variables, X scores,

X loadings, a response, and regression coefficients

of T. The k-th element of column vector b explains

the relation between y and t

k

, the k-th column vector

of T. Meanwhile, E (n×p) and f (n×1) stand for

random errors of X and y, respectively. Generally,

by using the Nonlinear Iterative Partial Least

Squares (NIPALS) algorithm, a weight matrix W

(p×h) is obtained to make || f || (Euclidian norm) as

small as possible and, at the same time, to derive a

useful relation between X and y.

NIPALS algorithm: in case of single y

Assume that the n×p matrix X and the column vector

y have been standardized to have mean 0 and unit

variance. In the following, t

k

, p

k

, and w

k

respectively

stand for the k-th column vector of T, P, and W. The

k-th latent variable is obtained iteratively as follows

(k = 1,2, …,h). Thus, model parameters in Eq. (1,2)

are determined accordingly.

Step 1 y

(k)

←y

(k-1)

- b

k-1

t

k-1

; y

(1)

←y

and X

(k)

←X

(k-1)

- t

k-1

p

k-1

t

; X

(1)

←X

Step 2 w

k

t

= y

(k)

t

X

(k)

/ y

(k)

t

y

(k)

Step 3 w

k

←w

k

/ ||w

k

||

Step 4 t

k

= X

(k)

w

k

/ w

k

t

w

k

Step 5 p

k

t

= t

k

t

X

(k)

/ t

k

t

t

k

Step 6 t

k

←t

k

||p

k

||

Step 7 w

k

←w

k

||p

k

||

Step 8 p

k

←p

k

/ ||p

k

||

Step 9 b

k

= y

(k)

t

t

k

/ t

k

t

t

k

Here, a variable selection method using PLS

regression will be considered.

2.1.2 VIP Method

The VIP score of a variable is a summary of the

importance for the projections to find h latent

variables (Wold, 1993). The VIP method shows

excellent simulation results in identifying important

variables when multicollinearity is present (Chong,

2005).

The VIP score for the j-th variable can be

calculated by Eq. (3). On the other hand, since the

average of squared VIP scores equals 1, ‘greater

than one rule’ is generally used as a criterion for

variable selection.

∑

/

|

|

∑

where SS

(3)

2.2 Cause Analysis of TAT Variation

In this section, we describe the proposed method to

find causes for TAT variation using the VIP method.

We consider a manufacturing process line which

consists of S sequential process steps. There are

historical data having N production observations. Let

t

is

and w

is

be tool and waiting time in s-th step for the

ith production (i=1,2,…,N). Now, we prepare

historical data

{(y

i

, x

i

), i = 1,2,…,N}

where {xi = (ti1, ti2,…,tiS, wi1,wi2,…,wiS)} (4)

In (4), y

i

and x

i

are the TAT variable and S tool

and waiting time variables for the ith production.

The VIP scores for S tool and waiting time variables

are obtained by firstly building the PLSR model

from the dataset (4) and secondly applying the VIP

method. We select tool and waiting time variables

with VIP score greater than 1 as the major causes

highly related to the TAT variable.

3 SIMULATIONS

3.1 Design of Simulation

We generate datasets in Eq. (4) by running a

simulation manufacturing model defined as Eq. in

(5). We assume that a simulation manufacturing

model consists of 8 sequential process steps (i.e.,

S

1

→S

2

→…→S

8

) and TAT, y

i

follows a linear model

having S tool and waiting time variables as Eq. in (5).

∑

where

~

N1,

, (i=1,2,…,N) (5)

In Eq. (5), tool time variables follow the normal

distribution and waiting time variables are

determined by simulation runs as Eq. (6).

w

is

= process_start_time

is

- process_end_time

i(s-1)

(6)

3.1.1 Production Order

At each simulation time, production order occurs

with probability p and the volume of each order is

ICORES2015-InternationalConferenceonOperationsResearchandEnterpriseSystems

186

the ceiling value of a uniform random variable from

the uniform distribution (0, b) as in Eq. (7, 8).

eventthatanorderoccurs~Bernoulli (7)

~

0,

(8)

So, the expected order volume at each simulation

time is as in Eq.(9).

E(daily order volume) = E(order occurs) × E(volume)

(9)

3.1.2 Tool Time in Abnormal Status

There are two kinds of abnormal status in a tool: (i)

mean shift and (ii) variation increase. In s-th process

step, we generate the abnormal tool time from Eq.

(10).

~

N1

,

,

(i=t

abnormal start

,…, t

abnormal end

) (10)

3.2 Experimental Factors

There are eight simulation experiment factors as in

Table 1 to mimic a manufacturing line which

consists of many sequential process steps.

4 RESULTS

In this paper, we consider a sequential line which

consists of eight processes. We fixed the number of

product mix and variation of tool time under normal

status of Table 1 to 1 and (1/12)

2

respectively.

4.1 Case 1: Mean Shift of Tool Time

Table 1: This summarizes simulation experiment factors.

Factors Levels or description

No. of process steps 8, 80, 800

Production order rate Bernoulli(p)

Volume of order

Ceiling value of Unif(0, b);

b is an integer.

No. of product Mix 1, 2, 3

Variance of tool time

under normal status

2

in Eq. (5)

Variation ratio of tool

time under abnormal

status

k in Eq. (10)

Mean shift of tool time

under abnormal status

t

abnormal

in Eq. (10)

Time period of

abnormal status

[t

abnormal start

, t

abnormal end

] in

Eq. (10)

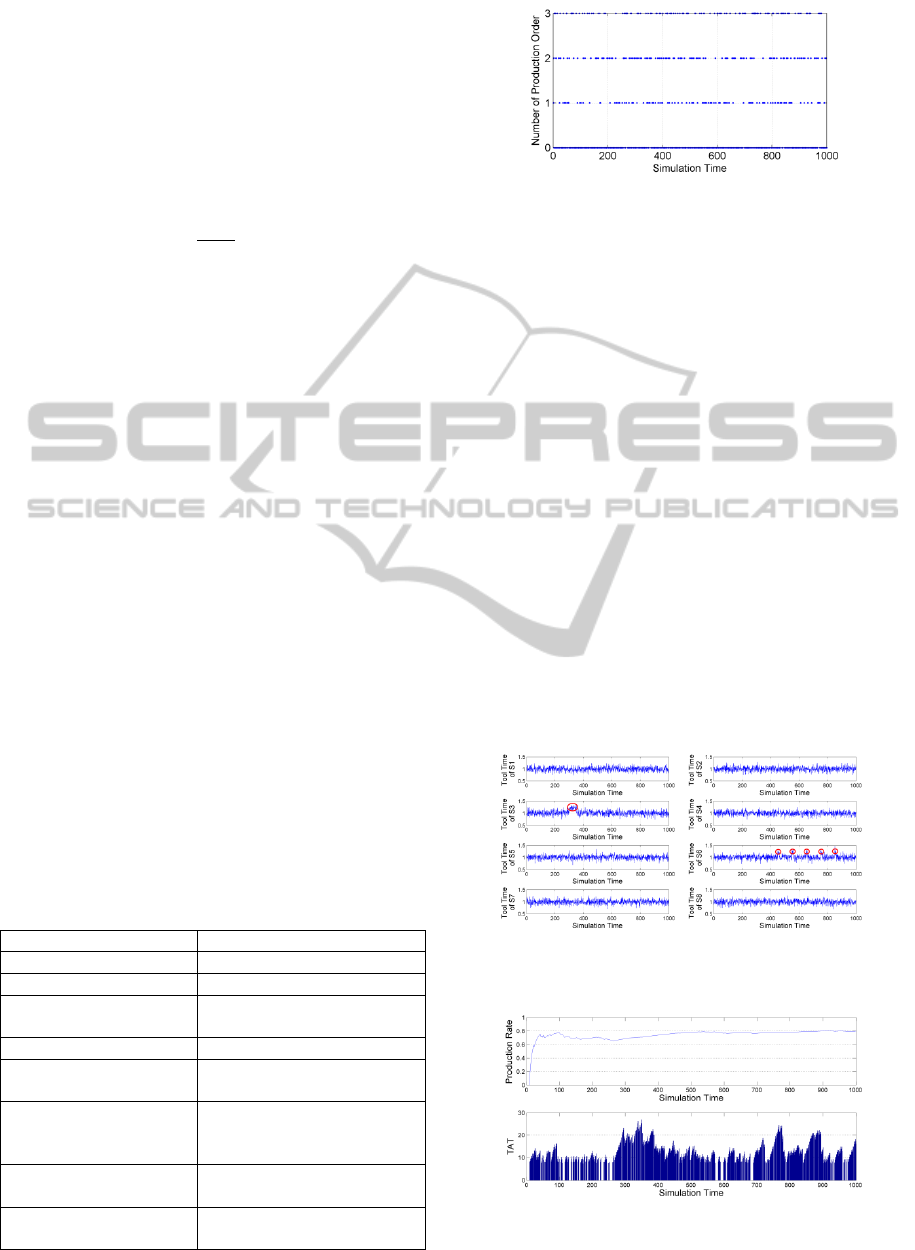

Figure 1: This shows an example of production order

(experiment parameter p = 0.4 and b = 3).

We assumed that production order is the Bernoulli

random variable with probability p = 0.4 and the

volume of order is the ceiling value of random value

generated from the Uniform distribution with

parameters 0 and 3. Thus, the expected production

order per simulation unit time is 0.8 by Eq. (9).

Figure 1 shows an example of production order

along the simulation time from 1 to 1,000.

We assumed two abnormal steps having mean

shift of tool time as in Eq. (11) and Eq. (12).

~

N

10.3,

1/12

, ∈300,350 (11)

~

N

10.3,

1/12

i [450,460] or [550,560] or [650,660]

or [750,760] or [850,860] (12)

Figure 2 shows the trend of tool time of all

process steps. Tool time varies around 1 except Step

3 and Step 6.

Figure 2: Mean shift of tool time is assumed in Step S3

and S6. Red circles denote mean shift of tool time.

Figure 3: The range of TAT is about 20 unit time in the

case1 (experiment parameter p = 0.4 & b = 3).

DataMiningAnalysisofTurnaroundTimeVariationinaSemiconductorManufacturingLine

187

Figure 3 shows simulation results of production rate

(= number of all processes completed products per

unit simulation time) and TAT over the simulation

time. TAT ranges from 7.5 to 26.9.

Table 2: Variables with VIP scores greater than 1 are

important ones which affect the variation of TAT.

Ran

k

Variable Name VIP Score

1 Waiting Time in Step 1 2.44*

2 Waiting Time in Step 2 1.79*

3 Waiting Time in Step 3 1.55*

4 Waiting Time in Step 6 1.29*

5 Waiting Time in Step 5 0.83

6 Waiting Time in Step 7 0.74

7 Tool Time in Step 3 0.71

8 Waiting Time in Step 4 0.71

9 Waiting Time in Step 8 0.50

10 Tool Time in Step 5 0.30

11 Tool Time in Step 1 0.27

12 Tool Time in Step 4 0.21

13 Tool Time in Step 6 0.19

14 Tool Time in Step 7 0.09

15 Tool Time in Step 8 0.08

16 Tool Time in Step 2 0.08

To discover the cause of TAT variation, the

proposed method was applied. Table 2 shows the

results of the VIP scores. We selected four variables

with VIP scores greater than 1 as important variable

highly related with TAT variation (waiting time in

S1, S2, S3, and S6). The method found all of two

intended abnormal variables (waiting time in S3 and

S6). Furthermore, the method indicated that random

batch order most affects the TAT variation (waiting

time in S1 and S2).

4.2 Case 2: Variation Increase of Tool

Time

In this case, we assumed abnormal status in S3 and

S6 step where the variance of tool time increases as

in Eq. (13) and Eq. (14). Figure 4 shows the trend of

tool time of S3 and S6 step over the simulation time.

~

N

1,

1/4

, ∈300,350 (13)

~

N

1,

1/4

i [450,470] or [550,570] or [650,670]

or [750,770] or [850,870] (14)

To create production order, we set experiment

parameters as p = 0.5 and b = 3. The range of TAT

is 37 unit simulation time as shown in Figure 5

(from 40.3 to 77.4 unit simulation time after 200 unit

simulation time).

Figure 4: Variance increase of tool time is assumed in Step

S3 and S6. Red circles denote variance increase of tool

time.

Figure 5: The range of TAT is about 37 unit time in the

case2 (experiment parameter p = 0.5 & b = 3).

To identify causes of the variance, we applied

the proposed method and obtained the VIP scores as

in Table 3. The method selected four variables as

important ones: waiting time in S1, S3, S7, and S6.

All of two intended abnormal variables (S3 and S6)

were found.

Table 3: Variables with VIP scores greater than 1 are

important ones which affect the variation of TAT.

Rank Variable Name VIP Score

1 Waiting Time in Step 1 2.90*

2 Waiting Time in Step 3 1.62*

3 Waiting Time in Step 7 1.61*

4 Waiting Time in Step 6 1.01*

5 Waiting Time in Step 4 0.69

6 Waiting Time in Step 5 0.61

7

Waiting Time in Step 2

0.45

8

Waiting Time in Step 8

0.33

9

Tool Time in Step 2

0.30

10

Tool Time in Step 5 0.17

11

Tool Time in Step 4 0.15

12

Tool Time in Step 3

0.15

13

Tool Time in Step 7 0.10

14

Tool Time in Step 6 0.09

15

Tool Time in Step 8

0.07

16

Tool Time in Step 1

0.07

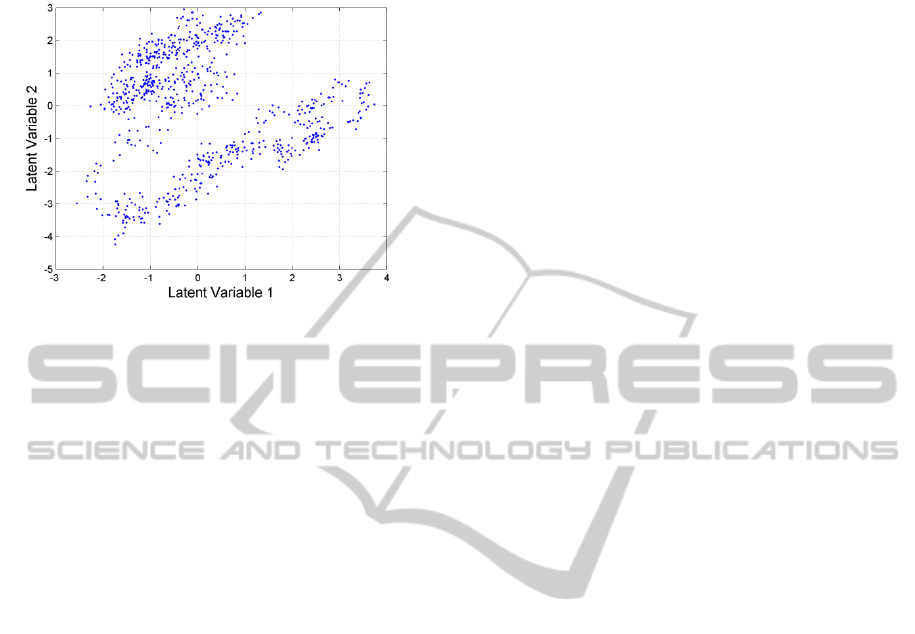

4.3 Latent Variable Analysis

We can visualize all observations of data used in

Case 2 with only two latent variables obtained from

PLSR model as shown in Figure 6. It seems like

there are several clusters along the simulation time.

There would be different important variable sets

ICORES2015-InternationalConferenceonOperationsResearchandEnterpriseSystems

188

according to the cluster. Research regarding this

issue is underway.

Figure 6: Several clusters are found by dotting with first

and second latent variables of PLS regression. The same

data in Case 2 were used.

5 CONCLUSIONS

In this paper, we propose a data mining based

method to find the causes of the variation of TAT in

a manufacturing line with many sequential process

steps. In our simulation case studies, the method

performed well. Exhaustive simulation study and

research about the relationship between variables

and TAT are currently underway.

ACKNOWLEDGEMENTS

The work described in this paper is supported by a

research program from Samsung electronics.

REFERENCES

Chong, I.G., Jun, C.H., 2005. Performance of some

variable selection methods when multicollinearity is

present. In Chem. And Intelligent Laboratory Systems

78(103-112).

Eriksson, L., Johansson, E., Kettaneh-Wold, N., Wold, S.,

2001. Multi-and Megavariate Data Analysis, Umetrics

Acedemy. Sweden.

Geladi, P., Kowalski, B., 1986. Partial least-squares

regression: a tutorial. In Anal. Chim. Acta 185(1-17).

Wold, S., Johansson, E., Cocchi, M., 1993. 3D QSAR in

Drug Design; Theory, Methods, and Applications

(523-550), ESCOM, Holland.

DataMiningAnalysisofTurnaroundTimeVariationinaSemiconductorManufacturingLine

189