Biodegradable Passive Resonance Sensor

Fabrication and Initial Testing

Timo Salpavaara

1

, Ville Ellä

2

, Minna Kellomäki

2

and Jukka Lekkala

1

1

Department of Automation Science and Engineering, Tampere University of Technology,

Korkeakoulunkatu 3, Tampere, Finland

2

Department of Electronics and Communications Engineering, Tampere University of Technology, Tampere, Finland

Keywords: Biodegradable, Passive Resonance Sensor.

Abstract: Biodegradable resonance circuits were studied. The circuits have a novel two-layer resonator structure

without galvanic through hole vias. A patterned magnesium layers were evaporated on biodegradable PLA

sheets by using a 3D printed mask. The circuits were assembled by heat sealing two magnesium patterned

sheets together to encapsulate the circuit structure. An inductive link is used to wirelessly detect the

resonance frequency of the circuit. The circuits were tested when immersed in de-ionised water and saline.

According to the tests, the designed resonator structure can be measured in aqueous environment. The

resonance of the tested circuit was observable at least for 51 hours. The concept still needs more

development to extend degradation time and to increase the stability during immersion.

1 INTRODUCTION

Implanting sensors into the body of a patient is for

fair reasons considered an extreme procedure

regardless of the benefits that can be achieved. The

main advance of the method is that the measurement

is not hindered by the sensor-skin interface. The

implanting procedure is more acceptable if it is done

at an unavoidable surgical operation due to injury or

disease. The threshold of using implantable sensors

is even lower if sensors are not permanent and thus

do not need a surgical removal operation. The

biodegradable sensors are developed to utilize this

niche.

One of the key features of an implantable sensor

is to access it by using a wireless link. RF or

inductive links are the most commonly used. The

structure of a passive resonance sensor that utilizes

an inductive link is very simple. Thus this method

has been utilized in many implantable (Collins 1967;

Chen et al. 2010) and biodegradable (Salpavaara et

al. 2012; Luo et al. 2014) sensor studies. A passive

resonance sensor is an LC circuit that is inductively

read by another coil. In this configuration, the

measurand is affecting the sensor coil or capacitor

thus altering the measured impedance of the reader

coil. Another approach is to link the measurand to

the losses in the LC circuit. To create a

biodegradable resonance circuit, coil and capacitor

structures are needed. Thus the methods for making

biodegradable patterned conductive and isolating

layers are needed. In addition, the sensor has to be

assembled and encapsulated without compromising

the made structures.

Conductive parts or layers can be made of

biodegradable metals (zinc, iron and magnesium) or

conductive polymers. The conductive polymers,

however, usually have too high resistivity for

passive resonant sensor applications. One

determining feature of the passive resonance circuit

is the Q-value. In order to achieve high Q-values the

resistance of the coil structure has to be small. For

this reason good conductivity is needed and the

fabrication method has to allow the preparation of

thick conductor layers. Bounty et al. made

conductive structures by using an electric discharge

machining to pattern 3 mm think iron and

magnesium sheets (Boutry et al. 2011). Luo et al.

have used an alternative method which utilizes

electroplating zinc and iron to create over 60 μm

thick coil wires (Luo et al. 2014). The evaporation

processes can be used to form patterned layers,

however, the time needed to deposit thick layers is a

problem. By using magnesium, high evaporation

rates can be achieved. Magnesium has been used to

form conductive areas to make wires, coils and

127

Salpavaara T., Ellä V., Kellomäki M. and Lekkala J..

Biodegradable Passive Resonance Sensor - Fabrication and Initial Testing.

DOI: 10.5220/0005255901270131

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2015), pages 127-131

ISBN: 978-989-758-071-0

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

capacitors (Hwang et al. 2012).

The possible substrate materials for biodegra-

dable sensors can be polymers, silk and

bioresorbable glass. Biodegradable polymers are

divided into two groups: synthetic and those derived

from natural resources. There are also two

dominating degradation mechanisms: surface

erosion or bulk erosion. The surface eroding

polymers would make excellent candidates for

sensor fabrication because their water absorption

may be lower. One of the commonly used and well

tested group of biodegradable polymer polylactides,

(PLAs), unfortunately, degrades with bulk erosion.

Other suitable candidates for biodegradable polymer

substrates are polycaprolactone (PCL),

polyglycolide PGA, poly(3-hydroxybutyrate) (PHB)

and their co-polymers (Luo et al. 2014). Luo et al.

used Poly (L-lactide) PLLA as substrate material for

the passive resonance sensors. Another tested

substrate material for biodegradable sensors is

solution-casted silk (Hwang et al. 2012). They also

proposed the use of MgO

and SiO

2

as isolating

materials which are needed to coat conductors.

Besides individual fabrication processes, an

engineering problem arises with the assembly of the

fabricated structures. In comparison to a typical

silicon sensor fabrication, biodegradable structures

are prone to get compromised when new processing

steps are done over earlier layers. As an example,

magnesium layers break if any following steps

include water and many polymer structures will

deform if they get in contact with solvents. To solve

this problem, evaporation processes using physical

masks can be utilized (Hwang et al. 2012). This

method does not include photoresist masks which

have to be patterned and then removed by solvent.

Another method is to use embossing and lamination

techniques (Luo et al. 2014).

In this paper, ongoing research for methods of

designing and fabricating biodegradable passive

resonance sensors is discussed. The methods of

biodegradable sensor fabrication are developed and

combined in a novel way to create a biodegradable

resonator structure that can be modified to make

implantable sensors. The designed prototype

structure is assembled and tested in vitro.

2 FABRICATION METHODS AND

DESIGN

The principal idea of the presented biodegradable

resonator concept is to evaporate magnesium and

silicon dioxide on PLA sheets through a physical

mask. Then two sheets are stacked and combined to

a resonator structure by heat sealing. This method

encapsulates magnesium layers which are otherwise

prone to water. Another leading design feature is to

avoid galvanic through hole vias between the

conductive layers. Instead, conductive layers on the

separate sheets are connected by capacitors which

are formed when the sheets are heat sealed together.

The simplified cross-section of the design is shown

in Fig 1.

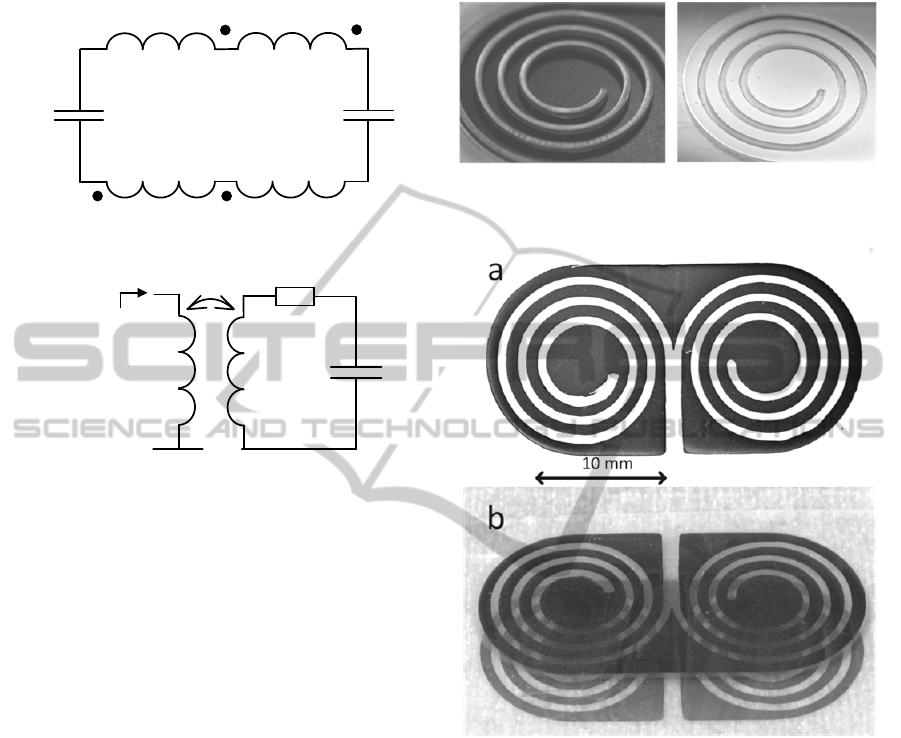

The electrical schematic diagram of the designed

circuit is presented in the Fig. 2a. This structure has

four coil and two capacitor structures. The schematic

does not include parasitic components. The

measured electrical behaviour of the presented

structure is similar to a simple RLC circuit and thus

can be roughly modelled as shown in Fig. 2b. The

resistance (Rs) is representing both the ohmic losses

in the magnesium layers and the dielectric losses

around and in the circuit. The inductor in the model

(Ls) represents the combination of four circular

planar coils (L1 to L4) on two opposing PLA sheets

and the inductance of the other connecting wires in

the circuit. In the final structure, four coils are

placed in a way that a changing uniform magnetic

field will induce currents that charge two main

capacitances in the circuit. The capacitor (Cs) in the

model is representing the capacitance of the two

electrode areas that are located inside the circular

coils and the combination of all parasitic

capacitances in the structure. The Fig. 2b also

illustrates the utilized wireless measurement

principle.

Figure 1: The cross-section of the resonator structure.

The idea behind this design can be derived from

a concept where a planar coil and a parallel-plate

capacitor are combined to an LC circuit by using a

through hole via between the layers. Instead of via,

another similar capacitor can be used to connect

layers. The capacitors are in series which has to be

taken account when the resonance characteristics are

designed. This kind of design, however, would be

unsymmetrical and in practice it would take almost

similar area as two planar coils and two parallel-

PLA

Mg

SiO2

50 nm

7.5 μ m

1 mm

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

128

plate capacitor electrodes per layer. Thus the set of

four coils and two capacitors is adopted in this

design to maximise the inductance in the circuit.

Figure 2: The electrical configuration of the fabricated

resonance circuit (a). The measurement setup and the

simplified model of the resonance circuit (b).

The substrate PLA sheets are made of PLA

(Purac Corbion Purasorb PLD962). First, granules

are melt processed to a 10 mm diameter rod. Then

the rod is cut to smaller pieces which are

compressed to 500 μm thick sheets by using elevated

temperature and simultaneous pressure. One side of

the polymer is compressed against glass sheet to

make the surface of the polymer smooth enough for

the evaporation process. Finally, the sheets are cut to

40 mm by 30 mm pieces.

The magnesium is patterned by using physical

masks during the evaporation process. In this case,

the masks were created by extrusion type 3D

printing. This decision was made to test the

capabilities of 3D printing and to accelerate the

prototyping process. The extrusion path was

manually designed to be as continuous as possible

since the most of the irregularity of the 3D printed

object occurs when the extrusion is started or

stopped. Also one design criterion of the designed

masks is that the objects have to support themselves.

In practice this means that printed mask has to be

continuous and there cannot be parts that sag when it

hung on the roof of the evaporation chamber. The

99.99% pure magnesium was evaporated on the

PLA sheets as a 7.5 μm ± 0.3 μm thick layer. The

mask and the evaporated coil pattern are shown in

Fig. 3. The magnesium layer was coated with 50 nm

SiO

2

-layer which acts as an electrical isolator

between the capacitor plates.

Figure 3: The 3D printed mask and corresponding

magnesium pattern on PLA sheet.

Figure 4: The magnesium patterned PLA sheet (a) and

resonator structure assembly (b).

A resonator structure was assembled by stacking

two patterned PLA sheets (Fig. 4) together with

patterned sides facing each other. In addition, two

patterned layers are placed in a way that coils on the

opposite sheets turn opposite directions. The sheets

were pressed together in a workbench and each edge

was trimmed and heat sealed to waterproof the

structure.

3 RESULTS

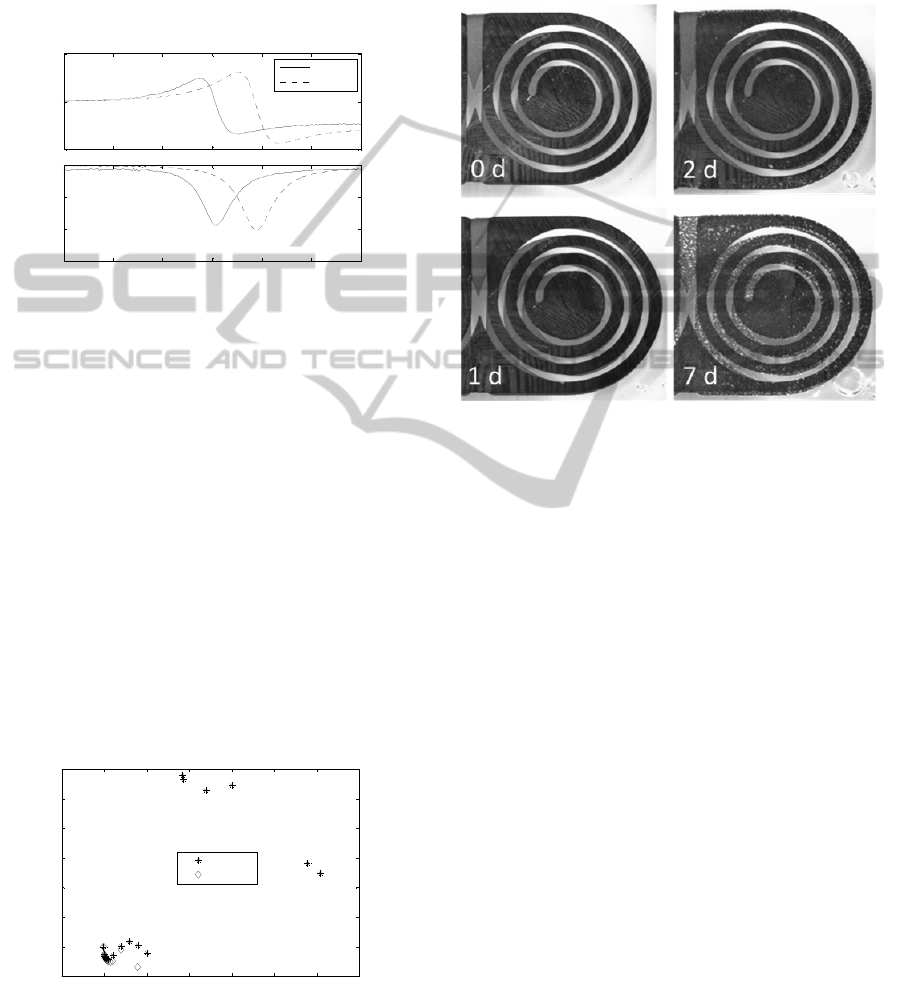

The impedance magnitude and phase of the

resonators were measured in air by using an

impedance analyser (Agilent 4396B with impedance

L1

Mutual

inductance

Lr Ls

Measurement

Cs

Rs

L2

L3 L4

C1 C2

a

b

BiodegradablePassiveResonanceSensor-FabricationandInitialTesting

129

test adapter) and an external coil (diameter 40 mm).

The impedance of the reader coil was also measured

separately and this baseline was removed from the

measurements. The two sample sensors have

similarly shaped responses curves at clearly separate

frequencies (Fig. 5). The frequencies of the phase

dips (f

p

) of these sensors are at 50.8 MHz and 58.9

MHz.

Figure 5: The magnitude and phase responses of the

resonance sensors measured in air.

The sensor 1 was immersed in 30 ml of 9 mg /

ml saline and sensor 2 in 30 ml of de-ionized water.

The sensors were supported from the edges in a way

that there was a 1 mm thick liquid layer under and

over the tested object. The temperature of the test

environment was 22 Cº. The changes of f

p

are shown

in Fig. 6. The initial drop due to the immersion is

fairly similar in both cases. This is followed by the

expected decrease of the f

p

. After two hours of

immersion, the f

p

starts to increase again. This

continues until roughly 6

th

hour in the case of sample

one. After 6 hours, signals start to degrease again

and in the case of sample 2, the decrease of f

p

was

faster. The measurement of the sample 2 was

stopped after 8

th

hour. The f

p

of sensor 1 increased

dramatically between ten and twenty hours. The

resonance was still clearly detectable until 51

st

hour.

Figure 6: The frequencies of the phase dips of the tested

sensors during immersion to de-ionized water and saline.

The degradation was also visually monitored (Fig.

7). There are no visual signs of degradation during

the first 24 hours. The magnesium conductors start

to show degradation after 48 hours of immersion to

saline. After one week immersion in saline, the

corrosion is clearly visible all over the magnesium

patterns.

Figure 7: The degradation of the magnesium conductors

begins to be visually detectable after 2 days immersion to

saline.

4 DISCUSSIONS

The proposed structure for a biodegradable resonator

has been successfully demonstrated. The scheme to

avoid galvanic through hole vias can be realized.

This simplifies the manufacturing process and the

presented fabrication method has only a few process

steps. The optimization of the presented structure

may yield better results; however, modelling all the

parasitic components in the structure is a

complicated task.

The 3D printed physical masks worked well in

this application. The performance of the printers will

improve in coming years which may encourage

using them for mask fabrication. However, it should

be noticed that masks with fine details were only

used to pattern magnesium in this study and their

temperature limitations should be considered if used

in other applications.

The general design is not especially sensitive to

fabrication tolerances since the two made resonators

have similar response curves. The difference in the

resonance frequencies in air is not too significant

considering manual assembly and the 3D printed

masks. The main reason for the difference in the

20 30 40 50 60 70 80

-5

0

5

Frequency (MHz)

Magniture (ohm)

20 30 40 50 60 70 80

-15

-10

-5

0

Frequency (MHz)

Phase (deg)

Sensor 1

Sensor 2

-10 0 10 20 30 40 50 60

-5

0

5

10

15

20

25

30

Time (h)

Frequency (MHz)

Saline

DI-water

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

130

resonance frequencies of this design is estimated to

be the parallel plate capacitors assembly. In addition

to alignment errors, the structure is sensitive to

assembly pressure and the mechanical properties of

the substrate PLA sheets. As process steps are

developed, the resonance frequencies can set more

accurately and variation will be smaller.

The main drawbacks of sample prototypes are

the short durability in aqueous environment and the

instability of the resonance characteristics due to the

water absorption of PLA. The changes in the

resonance characteristics of the tested circuits were

so large that the measurements have to be verified

with more parallel samples before any better

conclusions can be drawn. Also the hydrolysis test

of the device has to be longer and samples have to

be measured with more dense intervals. It can be

estimated that instability is caused by the absorbed

water which changes the electrical fields inside the

sensor structure. Other likely cause for instability is

that unfixed capacitors plates will move as PLA

absorbs water and swells. This may explain the large

increase in the resonance frequency after first 10

hours of immersion.

The current study proved that the PLA sheets

alone do not provide adequate encapsulation for

magnesium. As a quick fix, magnesium oxide can be

evaporated under and top of the magnesium layer

since this material has been used to modify the

degradation (Hwang et al. 2012). The magnesium

can also be replaced with more slowly degrading

metal like zinc, this, however, is unlikely to fix the

instability problem and zinc has smaller conductivity

compared with magnesium. Replacing PLA with a

surface eroding polymer can be a valid option since

the designed structure worked well in test conditions

before water had time to absorb in the structure.

Another option is to modify the water absorption of

the PLA for example with a coating.

The structure is sensitive to pressure variations

due to the mechanical changes in the assembled

capacitors. This can be utilized in order to make

pressure sensors or the sensitivity may be mitigated

by filling the empty space that is left in the structure.

Replacing the air in the structure with biodegradable

hydrophobic material and fixing the capacitors

plates together will make the structure more durable

and may improve stability during immersion. In

present design, only the edges of the PLA sheets

were fixed.

The research will continue by modifying the

designed resonator structure. The short-range goal is

to develop a resonator that is stable for months.

Then the design will be modified to be sensitive to a

specific measurands like pressure or permittivity

outside of circuit.

REFERENCES

Boutry, C.M., Chandrahalim, H. & Hierold, C., 2011.

Characterization of RF Resonators Made of

Biodegradable Materials for Biosensing Applications.

Procedia Engineering, 25, pp.1529–1532.

Chen, P.-J. et al., 2010. Wireless Intraocular Pressure

Sensing Using Microfabricated Minimally Invasive

Flexible-Coiled LC Sensor Implant. Journal of

Microelectromechanical Systems, 19(4), pp.721–734.

Collins, C.C., 1967. Miniature passive pressure transensor

for implanting in the eye. IEEE transactions on bio-

medical engineering, 14(2), pp.74–83.

Hwang, S.-W. et al., 2012. A physically transient form of

silicon electronics. Science (New York, N.Y.),

337(6102), pp.1640–4.

Luo, M. et al., 2014. A Microfabricated Wireless RF

Pressure Sensor Made Completely of Biodegradable

Materials. Journal of Microelectromechanical

Systems, 23(1), pp.4–13.

Salpavaara, T. et al., 2012. Biodegradable encapsulation

for inductively measured resonance circuit. In

Bioinformatics & Bioengineering (BIBE), 2012 IEEE

12th International Conference on. Larnaca: IEEE, pp.

11–13.

BiodegradablePassiveResonanceSensor-FabricationandInitialTesting

131