Data Acquisition in Cast Iron Foundries by Image Analysis

Bernd Dreier, Florian Blas and Alexander Kostgeld

Research projekt - IDA, University of Applied Sciences Kempten, Bahnhofstr. 64, 87439 Kempten, Germany

Keywords:

Image Processing, Data Acquisition, Process Monitoring, Object Detection, Industrial Applications.

Abstract:

The project IDA - Intelligent Data Acquisition is an interdisciplinary project in the fields of applied informat-

ics and mechanical engineering. Its purpose is to collect process relevant information in industrial foundry

processes like iron casting with handmade and mechanically made molds. Currently a lot of data sets are col-

lected by hand. But these contain inaccuracies and errors and are not available digitally for further analysis.

As a result it is not possible to evaluate them automatically. In particular it is not possible to conclude from a

defect cast part to the whole set of its production parameters. We develop several procedures to collect these

data sets and prepare them for computation in data analysis algorithms. The acquisition of digitally available

data in IDA is done mostly by optical sensors. In this paper we describe our approach especially regarding

marking and recognition of relevant objects. Furthermore we show first results in environments close to reality.

1 INTRODUCTION

In foundries the main problems in data acquisition

are missing continuity in the manufacturing processes

and difficult environmental conditions, for example

high temperatures above 1300 degree Celsius. As

an obvious result it is for example not possible to

work with transmitters like RFID tags. The operating

range for common RFID tags is up to 200 degree Cel-

sius, (Nicholson and Monahan, 1999). Other prob-

lems like difficult lighting conditions, air contamina-

tion and colorless elements complicate the data acqui-

sition by optical sensors, some of them are shown in

Figure 1.

Figure 1: Air contamination and difficult light conditions

during furnace tapping.

During the first project phase we analyzed the ex-

isting processes and identified the main reasons of

faulty parts. From common knowledge about foundry

processes we then gathered the different pieces of

data, which are necessary to identify the circum-

stances leading to the errors. Different procedures

must be implemented to collect the necessary data

mostly with digital image processing operations. At

this stage one main subject has been identified: Map-

ping of cast parts and sand cores to their date of cast-

ing respectively their use in a mold. This mapping is

essential for an assignment of faulty parts to the pa-

rameters of the casting process.

In the following section we want to motivate re-

search investigation in foundries. After that we de-

scribe the approach of our project and the current state

of two main subjects in our project, especially object

identification (tracking). The comparison with related

work in industrial research will be done in the subsec-

tions because the relevant research activities are quite

distinct for our different subjects. Finally, we will

give an overview of our achievements and an outlook

to further work.

1.1 Economic Dependency

Resources needed for production of cast parts are

mostly imported, like pig iron or coal. Other impor-

tant components are the seldom earth elements (SEE)

like Cerium or Bismuth. These elements are neces-

sary to influence the metallurgical structure of the cast

iron. For the extraction of these SEE strong econom-

ically hazardous procedures are exercised.

63

Dreier B., Blas F. and Kostgeld A..

Data Acquisition in Cast Iron Foundries by Image Analysis.

DOI: 10.5220/0005281600630070

In Proceedings of the 10th International Conference on Computer Vision Theory and Applications (VISAPP-2015), pages 63-70

ISBN: 978-989-758-091-8

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

Main exporter of SEE is China, according to a re-

cent study the annual demand of SEE remains con-

stant, but the export rate of China decreased in the

last years. This is shown in Figure 2, an evaluation of

”Statista”, about the consumption of SEE.

Figure 2: Evaluation about the SEE consumption toward the

export value of China - the main exporter of SEE.

The low export rate since 2011 led to increasing

prices for the raw materials as described in Figure 3.

This trend was very difficult for the German foundry

branch. Since the last years the price fluctuation is

also occurred from the stock exchange.

Figure 3: Cost trend of SEE in the last years.

2 PROJECT DESCRIPTION

The research project IDA develops new ways to com-

bine existing iron casting processes with modern im-

age processing operations to collect process specific

information. There are no existing procedures to col-

lect such information yet, at least in medium sized

foundries. The main target is to record data sets which

are currently not collectable. With these data sets

it will be possible in the future to make predictions

of the cast part during the running production pro-

cess. An early intervention is possible and can reduce

scrap. However, the creation of the described predic-

tions is not subject of IDA. These were developed in

an earlier research project, (D. Hartmann, 2014).

2.1 Process Analysis

As described in Section 1 it is possible to make qual-

itative forecasts about a cast part, if data sets of the

casting process are available. However, different cast-

ing processes must be analyzed separately. Most of

the problems can be found in middle class foundries.

In IDA we work with three foundries and we eval-

uated the individual data situation of each project

partner. Each foundry has been analyzed concerning

their current data acquisition. It could be found that

the data situation strongly depends on the different

production processes. Foundries that produce high-

volume use molding machines that provide a good

data situation, but it is difficult to assign the given

data to an individual cast part or to a casting defect

as mentioned before.

However, in low-volume foundries which produce

with handmade molds the identification of cast parts

is not problematic, but the processes depend on the

situation and can change during the production and

data acquisition is mostly not realized at the moment.

To improve the general data situation it is necessary

to collect additional data sets and improve the data

assignment. These data sets can be categorized by the

following keywords:

• Cast part marker

• Sand core identification

• The way of melt

• Optical character recognition

• Cast spurt monitoring

• Flask layout

The main area of research in cast iron foundries

was the metallurgical properties. Whereby most of

the usable data sets come from the spectral analysis

of the melt, and the mechanical properties like im-

pact strength or tensile strength. Data correlations be-

tween the sand core and the mold and their influences

for an individual cast part cannot be rated at the mo-

ment. Professional literature describes the high influ-

ence rate of the molding sand to the cast part errors.

Values more than 70% are described in (Gagne, 2004)

at page 87.

2.2 Acquisition Methods

Error causes have been identified for the development

of the acquisition methods. For the data acquisition

new procedures were established who are capable to

VISAPP2015-InternationalConferenceonComputerVisionTheoryandApplications

64

integrate into the foundry process. To collect the im-

age data different camera types are necessary to col-

lect the image data:

• Industrial Cameras are used for:

– Cast part identification

– Object detection and tracking

– Optical character recognition

• Thermal image cameras are used for:

– Temperature detection

– Slag detection

– Fill level detection

The data transfer can be realized by a local area

network. For smaller data sets it is also possible to

use a wireless network. The data transfer in wireless

networks is not affected by the electromagnetic emis-

sion. Nowadays temperature measuring lances work

with wireless LAN in front of the furnace.

3 CURRENT STATE

Based on decisions about platform independency,

availability and real time usage, the test application

is developed in Qt using C++. For common image

processing operations OpenCV is used. The graphi-

cal user interface is developed as a debug and moni-

toring tool. The implementation of data interfaces is

not planed by IDA but can be done in the future.

To simplify the implementation we decided to de-

fine different modules. Every module works as an

own workflow and can be started and managed from

the graphical user interface. The user can decide

which module should be observed and can interact

with it.

The combination of these modules can change by

the field of application. A foundry with mold ma-

chines can define other module constellations than a

foundry with hand made molds.

3.1 Individual Marker Detection

The implementation of individual marker detection

was developed to solve the individualization of the

production of cast parts in molding machines. This

is also demanded by the automotive industry, leading

to cast parts with a complete traceability, (Clemens,

2008). During the implementation and further analy-

sis of the marker elements another field of application

could be found with the labelling of ladles and molds.

3.1.1 Recent Work

Several different ways are available for the marking of

castings. Most of them are very expensive or not pre-

cise enough. The availability of procedures depends

also on the cast way. Handmade forms can be labeled

with pre-made numbers that are inserted into the neg-

ative form. However, machine made molds can just be

marked during the short production process. The list

of available marker elements is as short as the corre-

sponding academic literature described in (Wadhwa,

2013).

Cast clocks are not precise enough, because they

use one number for a specified time span. In the

professional journal ”Giesserei”, the University Harz

presents an innovative cast clock (Meissner, 2011)

but the device cannot be integrated into a molding

machine because of the relatively big control unit.

Whereby the procedure with laser marker can be done

precise enough, but the devices are too expensive

(Meissner, 2011).

The United States Patent (Hovorka, 1996) de-

scribes a procedure using an expandable plastic tag

and a slot in the cast part. The main problem of

this process is the size requirement, also described in

3.1.3. Another problem is that cast parts produced in

molding machines cannot be marked in the order they

are produced. The plastic tag must be inserted to the

cast part by hand but they travel a long distance in

the automatical molding machine and overtake each

other. At least in the shaker or the sandblaster, which

are necessary to release them from the molds. We

found that cast parts got a delay of nearly 10 - 15 min-

utes. By a clock cycle up to 7 seconds the procedure

is not exact enough for the data mapping.

The test of the availability of other code elements

for example the gray code described in (E.N.Gilbert,

1957) showed that the redundance is absolutely suf-

ficient but the size requirements based on the neces-

sary individual marker elements and the forgeability

in cast parts are not suitable. Figure 4 shows a gray

code element with 8 different positions. The individ-

ual positions are not enough as it has been described

in 3.1.2. In our experience it was also not possible to

scale them down to our size requirements from 3.1.3.

Figure 4: Gray code with 8 positions from (Gray, 1947).

DataAcquisitioninCastIronFoundriesbyImageAnalysis

65

3.1.2 Marker Specific Requirements

The requirements to the representable area are also

different. The area for the marker detection depends

on the mold machine. At the moment every cast part

gets the cast day and the nest number. The cast part

can just be identified to the production day and to the

nest number. With the current available data sets it is

not possible to define exactly which melt was used for

the production of a specific part.

Based on these findings, we developed a new code

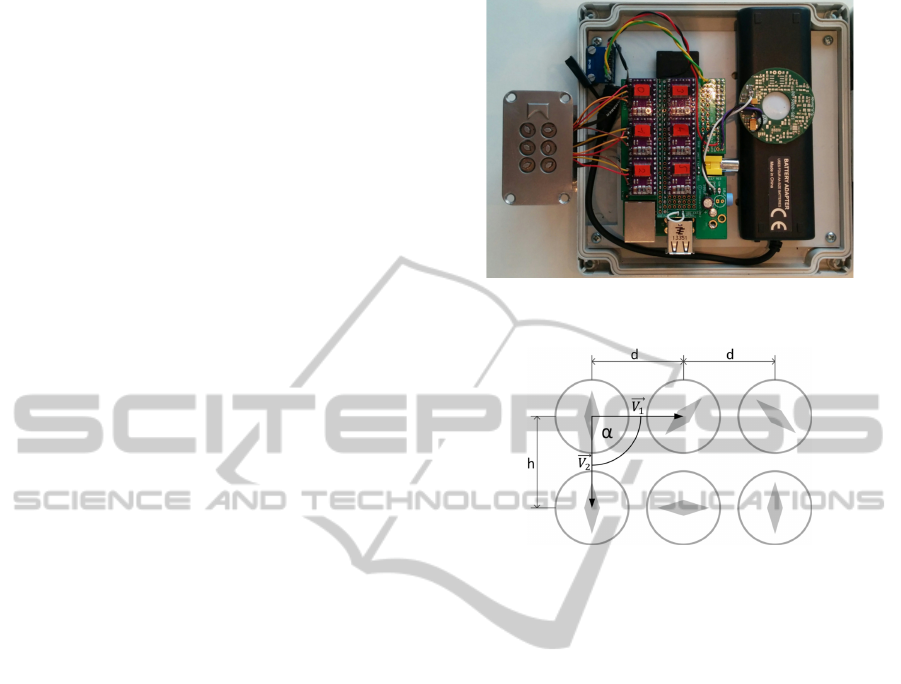

and a corresponding marking element. It is based on

currently 6 needles, which can have different orienta-

tions. A picture of the marking element in a test sce-

nario is shown in Figure 5. With the new procedure

the mold number can be added to the cast part. Every

cast part gets an additional identification element and

is individual determinable. To test the usage of the

marker elements in foundries different test cases were

defined. To ensure the usability, six needles are suffi-

cient to mark every cast part in a production charge.

With the six needles a maximum count of 4096 in-

dividual positions are available. Assumed by a cycle

time of 7 seconds nearly 1000 molds can be molded in

a charge of 2 hours, without idle time. If more mark-

ers are necessary more needles can be added to the

marker device. On the current used prototype every

needle has 4 positions. The results of an test proto-

type showed that more positions are not detectable, as

described in Section 3.1.8.

3.1.3 Size Requirements

To secure a minimal modification on the cast part and

on the molding machine a few specific values must

be added. The actual available size on the cast parts

is 30mm x 16mm. The available size for the marker

control device depends on the negative mold actually

a mold thickness of 40mm is necessary.

The device is designed to work completely auto-

nomic. No additional connections like external en-

ergy supply or a connection to a control device are

necessary. Figure 5 shows the test arrangement to

controll the marker device.

3.1.4 Detection Procedure

For detection of a cast part the location and interpre-

tation of the needle positions is needed. The detec-

tion procedure is separated into different steps, all of

them are necessary for a complete rating. Through the

following steps the surrounding circles of the needles

can be detected with processes like hough transforma-

tions. The circles must be rated based on their posi-

tions. This process is similar to the described process

Figure 5: Test arrangement of the marker device. As a mo-

tor controller a raspberry Pi was used with a breakout kit.

Figure 6: Schematically dimensioning of the marker detec-

tion element.

of the traffic sign detection from (Lorsakul, 2007).

Difficult light conditions and air contaminations like

fog are also comparable problems.

The whole image processing pipeline for this task

can be seen in Figure 7.

In the following subsections we will outline our

solutions for the different stages above.

3.1.5 Orientation Detection

A position helper element was defined and integrated

to the marker device, to detect the position and ori-

entation. But the dimensions of the orientation ele-

ment was to small, especially with draughts. Figure 8

shows the result of the line detection. It was planned

to use the Hough line detection, as described in (Duda

and Hart, 1972), and evaluate the detected lines in ref-

erence to their orientation and length. But the results

are not applicable.

The detection and interpretation of the needles are

not affected. The problem is the orientation and clas-

sification of the needles, and must be noted in the code

interpretation 3.1.9. At the moment two different ori-

entations are possible.

VISAPP2015-InternationalConferenceonComputerVisionTheoryandApplications

66

Figure 7: The image processing pipeline of the marker de-

tection procedure.

Figure 8: The line detection generates quite good results by

the circles, but the orientation helper on the left side can not

be detected.

3.1.6 Circle Detection

With the OpenCV method houghCircles it is possi-

ble to detect the needle positions. The method offers

some parameters like a threshold for the canny edge

detector or some circle features as described in (La-

ganiere, 2011) at page 176. Another influence to the

Hough transformation can effect with a Gaussian blur.

It is necessary to smooth the structure of the cast part

to reduce the mismatches, and improve the quality of

the circle detection.

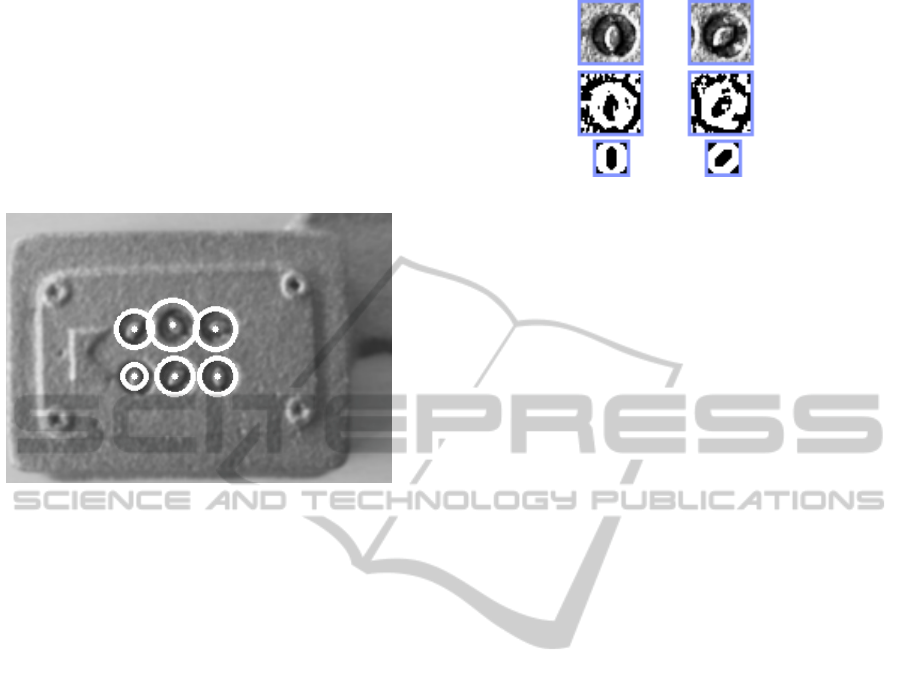

Figure 9 shows the detected circles, in the upper

image a lot of wrong circles are detected, the image

below was done with the described blur. This ef-

fect was described from (Laganiere, 2011) on page

176 and (Lorsakul, 2007). Similar operations are de-

scribed by (Kimme et al., 1975), in this case the circle

detection was improved with thresholding operations.

Figure 9: Circle detection: Original grayscaled image - a

lot of circles are detected because of the cast part structure,

the smoothed image shows just a few mismatches.

If the smooth effect is too much the circle detec-

tion does not deliver all needle positions. The marker

element can’t be detected if too many needles are

missing and the circle rating can not be done.

3.1.7 Circle Rating

A cast part can show more circles than given by the

marker element. Beside the cast part structure dif-

ferent influences like borehole markers, cast errors

and other geometric elements can be detected as mis-

matches by the circle detection. To handle this situa-

tion we developed a procedure based on our geomet-

ric properties as described in Figure 6. The first step is

to create cluster with circle accumulations. After this

preselection all single detected circles lying outside

are no longer considered.

In the following procedure we define ”used cir-

cles”. A used circle describes the position of a nee-

dle and will be used to make a segmentation of the

original image data. The definition of a used circle

depends on the dimensioning of the marker detection

DataAcquisitioninCastIronFoundriesbyImageAnalysis

67

element. Each circle needs two or three neighbours

in a specified distance according to the position. Fig-

ure 10 shows the needle position after the building of

clusters.

Caused by irregularities of different influences

like lightning conditions, cast structure or cast errors

the detected center can differ from the real needle po-

sition. Affected by these variations it is necessary to

define thresholds for the rating.

Figure 10: Detected needle positions after the clusterisation

procedure.

To ensure that the circles are part of the marker

element it is necessary to calculate the distance be-

tween them. Another advantage of the arrangement is

that the circles are connected with a square angel. The

scalar product of the vectors between the neighbours

is nearly 0, because of the before described irregular-

ities.

3.1.8 Needle Identification

The needle identification needs the original image

data. The positions of the detected circles from sec-

tion 3.1.7 indicates the needle positions. These posi-

tions are used to create for each needle a segment of

the original image. To detect the needle orientation,

different matching procedures can be used. Because

of irregularities like cast defects and cast structure it

is necessary to work with similar image processing

operations as described in section 3.1.6. Every needle

has 4 predefined positions.

To detect the needle orientation different match-

ing procedures are available, the best results are de-

termined by the template matching with 4 position

templates. With more than 6 positions in the given

size and in average lighting conditions a lot of miss

matches occurred and detecting rate drops below

80%. These errors are attributed to inaccuracies and

cast errors, which we will find in realistic environ-

ments.

For the template matching it was necessary to de-

fine an extraction process to ensure that the influences

Figure 11: Template for the template matching procedure -

the Figure shows the possible orientations {0, 1, 2, 3}.

caused by cast structure, color differences and differ-

ent light conditions can be minimized. This effect is

also described by (Parker, 2011) on page 333.

The best results of the matching procedure could

be determined by the usage of the needle shape. To

extract the needle contour of the segmented image

we are using different algorithms. The first step is

a downscale of the segmented image. This reduces

the influences of the cast defects and the cast struc-

ture. The normalization increases the contrast of the

image and optimizes the differences between the nee-

dle and the circle. By a Gaussian blur influences of

cast defects and structure can also be minimized.

For shape extraction we are using an adaptive

threshold. Threshold methods with an constant value

were not sufficient. Furthermore an adaptive thresh-

old is more robust respectively to non uniform illumi-

nations and the background, as described in (Leong

and Yue, 2009).

The resulting binarized image contains the shape

of the needle and can be used as input for the template

matching procedure of OpenCV. Figure 11 shows the

different stages for the recognition of needle posi-

tions.

With the used test images all needles could be de-

tected. To use the application in real foundry condi-

tions the process we expect that the detection has to

be even more robust. The planed improvements are

described in section 3.1.11.

3.1.9 Code Interpretation

The marker detection is based on a four number sys-

tem, as described in section 3.1.2 and 3.1.8. Several

standard algorithms are available for the interpreta-

tion and can be used for the implementation.

3.1.10 Result

With the implementation of the marker detection were

proved that a identification of the marker elements is

possible. To ensure the practicability in real world

environments additional works must be done. In Sec-

tion 3.1.11 the next steps for the implementation are

VISAPP2015-InternationalConferenceonComputerVisionTheoryandApplications

68

described.

The marker device must be improved with an ori-

entation element. The currently used element can not

be detected at the moment as described in Section

3.1.5.

3.1.11 Next steps

It is planed to improve the result of the marker de-

tection and minimize error rates. To improve the

matching additional procedures like support vector

machines can be implemented and tested (Baggio,

2012), another approach would be the identification

by keypoints like ORB, as described in (Ethan, 2011).

To improve the detectability of the marker the device

will receive an new orientation helper. The current

problems are described in Section 3.1.5.

3.2 Sand Core Identification

The high influence rate of the molding sand was de-

scribed in Section 2.1. A lot of cast errors are caused

by mold and not by melt. Core breaks, breakouts or

gas blows are some of them. But the most cast errors

have different influences, (Hasse, 2003) page 4. In

many cases it is difficult to determine the real reasons.

To simplify the finding of cause-impact coherences it

is necessary to merge mold specific information to the

cast part. For sand cores this is not possible at the mo-

ment. On the other side, sand cores are necessary to

shape complex geometric molds.

We investigated in the idea of the identification of

a sand core by sand structure like an individual ”fin-

gerprint”. To test the practicability of image detection

processes to identify a simple sand core shape it was

necessary to make some different images from differ-

ent sand cores, this is described in 3.2.2. Figure 12

shows the structure and the shape of a sand core.

Figure 12: Sand core with simple shape and sand structure.

3.2.1 Recent Work

To the best of our knowledge, no one has investigated

in the identification of sand cores as we could not find

similar research work.

However, general matching procedures like key-

point detection and matching or template matching

procedures are available and approved. For exam-

ple the ORB keypoint detection, described in (Ethan,

2011), can be used for the detection tests. The detec-

tion process with ORB keypoints is quite faster, and

free to use instead of SIFT and SURF (Ethan, 2011).

3.2.2 Test Setup

With the first test it was planned to show that ev-

ery core is individual and distinguishable, and can

be detected from other sand cores. The test area was

about 50 different sand cores, with a pre-defined dis-

tance from the camera. This reduces influences to the

matching result, for example scale variances.

Every circle element with the sand core structure

was segmented from the image. The segmented im-

age is used to test different image processing proce-

dures with the original images. Every segmented cir-

cle is matched with all sand cores. That means we

could match 50 segmented images with 50 original

images. And got an matching pool of 2500 posibili-

ties for our evaluation.

For the matching procedure we defined different

algorithms. First of all we tested an template match-

ing. But the problem was the rotation as described in

Section 3.2.3.

All segmented images could be detected, but the

main problem of the template matching procedure is

that the results are highly influenced of the orientation

of the original sand core.

The second tested procedure was a key point de-

tection using ORB keypoints, described in (Ethan,

2011). Figure 13 shows the result of the matching

procedure.

Figure 13: Keypoint detection procedure with correct

match.

The results to distinguish sand cores by their in-

dividual structure are quite good, all cores could be

identified. But the evaluation of the keypoint detec-

tion shows similar problems as the template matching.

Rotation and scale variances have a highly influence

rate to the matching process.

DataAcquisitioninCastIronFoundriesbyImageAnalysis

69

3.2.3 Result

In the foundry the matching procedures can not be

used at the moment. The sand cores pass through a

long way between the production and the assembly to

the mold. On the whole way the orientation of the

sand core can not be defined and the distance of the

camera can change.

However we could show that the sand cores are

distinguishable. In Section 3.2.4 we suggest some ad-

ditional procedures for continue works on the sand

core identification.

3.2.4 Next Steps

To improve the identification rate of the sand cores

additional physical notches can be added to the sand

cores to simplify the orientation detection of the sand

cores. Another approach can be done by object de-

tection. The shape of the sand core can be detected

and delivers additional information about the position

orientation and distance.

4 CONCLUSION

In this research paper we have shown that optical

sensors may well be used for data acquisition in the

rough environments of foundries. Especially for mid-

dle sized foundries with automation levels from low

to medium this approach is very promising. We have

developed a complete object marking and recogni-

tion system for cast parts, including a self developed

code, an autonomous mechanical marking element

for molds and a procedure to recognize the marked

cast parts by image analysis. With the planned im-

provements described above we expect to achieve ac-

ceptable failure rates. Furthermore we have investi-

gated in sand core identification by image analysis.

In that process we are not as close to an industrial

application like in the case of cast parts. The main

problem in this case is, that the recognition methods

which work well are not rotation invariant. We plan to

improve this method by adding notches to the cores,

which allows the recognition procedure to identify the

orientation in a first step.

Our next steps are further improvements for the

processes described in this paper, especially regarding

the robustness of our algorithms. Furthermore, there

are more process parameters to be acquired, e.g. anal-

ysis of cast spurts and flask layout or damage recog-

nition for sandcores. The initial analysis of our col-

leagues of mechanical engineering has shown, that the

first two important acquired data sets described in this

paper will already help to reduce failure rate in the ex-

amined foundries extremely. It is important to men-

tion, that only a few defect cast parts may cause very

high impact to total cost and, of course, to nature, be-

cause especially in medium sized foundries cast parts

tend to be quite large, up to ten or twelve tons.

REFERENCES

Baggio, D. (2012). Mastering OpenCV with Practical Com-

puter Vision Projects. PACKT Publishing, Birming-

ham, 1st edition.

Clemens, H. (2008). BuhlMark praegt die Produktdaten

auf das Gussteil und macht damit jedes Teil eindeutig

rueckverfolgbar.

D. Hartmann, J. Gottschling, S. M. M. S. (2014). Intelli-

gente Prozesssteuerung in Giessereien.

Duda, R. O. and Hart, P. E. (1972). Use of the Hough Trans-

formation To Detect Lines and Curves in Pictures.

E.N.Gilbert (1957). Gray Codes and Paths on the n-Cube.

Ethan, R. (2011). Orb: an efficient alternative to sift or surf.

In Computer Vision (ICCV), 2011 IEEE International

Conference on, pages 2564–2571. IEEE.

Gagne, M. (2004). Sorelmetal Gusseisen mit Kugelgraphit.

Rio Tinto Iron and Titanium, Montreal (Quebec), 1st

edition.

Gray, F. (1947). Gray Code.

Hasse, S. (2003). Guss und Gefuegefehler. Schiele und

Schoen, Berlin, second edition edition.

Hovorka, F. (1996). Method for identifying cast parts. US

Patent 5,584,113.

Kimme, C., Ballard, D., and Sklasnky, J. (1975). Finding

Circles by an Array of Accumulators.

Laganiere, J. (2011). OpenCV 2 Computer Vision Appli-

cation Programming Cookbook. PACKT Publishing,

Birmingham, 1st edition.

Leong, L. K. and Yue, W. (2009). Extraction of 2D Barcode

Using Keypoint Selection and Line Detection. In Ad-

vances in multimedia information processing - PCM.

Springer-Verlag.

Lorsakul, A. (2007). Traffic Sign Recognition for Intelli-

gent Vehicle/Driver Assistance System Using Neural

Network on OpenCV.

Meissner, K. (2011). Die neue Giessuhr vollflexibles

Markiersystem fr Gussteile.

Nicholson, M. and Monahan, B. (1999). Having the capa-

bility of operating over a broad range of temperatures;

capable of operation in harsh, high temperature fac-

tory environments. US Patent 5,973,599.

Parker, J. R. (2011). Algorithms for Image Processing and

Computer Vision. Wiley Publishing, Inc., Indeanapo-

lis, second edition edition.

Wadhwa, R. S. (2013). Traceability and Data Support in

SME Manufacturing.

VISAPP2015-InternationalConferenceonComputerVisionTheoryandApplications

70