The Air Distribution Network Design Problem

A Complex Non-linear Combinatorial Optimization Problem

Sandy Jorens

1

, Annelies De Corte

2

, Kenneth S

¨

orensen

2

and Gunther Steenackers

3

1

Faculty of Applied Engineering, University of Antwerp, EMIB, Hoboken, Belgium

2

Faculty of Applied Economics, University of Antwerp,ANT/OR Operations Research Group, Antwerp, Belgium

3

Faculty of Applied Engineering, University of Antwerp, Op3Mech, Hoboken, Belgium

Abstract: The objective of the air distribution network

design optimization problem is to find the material

and dimensions of each duct and fan in an air dis-

tribution network so that the total cost is minimized

without violating aerolic constraints. Since the 1960s

much research has been dedicated to the simulation

and optimization of air distribution networks and nu-

merous methods have been developed to solve this op-

timization problem. This paper aims to outline the

current state-of-the-art in air distribution network de-

sign optimization and highlights the main shortcom-

ings. Additionally, previous research is extended by

presenting a model that integrates the network layout

decisions into the optimization problem. In this prob-

lem, called the air distribution network design opti-

mization problem the location of the fans and ducts

in the network are determined so that the total cost of

the network is minimized. This novel combinatorial

optimization problem is characterized by discrete de-

cision variables, and non-linear constraints. This pa-

per also motivates the need for benchmark instances

to evaluate the performance of existing or new de-

veloped optimization methods and advance future re-

search in the field op air distribution network design

optimization. A software tool is developed in this PhD

research to generate such instances.

1 RESEARCH PROBLEM

1.1 Air Distribution Network Design

(ADND)

One of the most energy-consuming and cost expen-

sive (up to 35% in Belgium) parts of a heating, ven-

tilation and air conditioning (HVAC) system is the

air distribution system. Both the energy and mate-

rial costs can be reduced significantly if air distribu-

tion systems or networks are designed properly. The

quality of their design largely determines the effec-

tiveness, energy-efficiency and comfort of the build-

ing’s HVAC system.

Air distribution systems in non-residential build-

ings can be seen as large tree-networks of supply air

ducts that convey conditioned air from one or more

resource nodes, e.g. air handling units (AHU) or fans,

out through the building to multiple demand nodes

(terminal units). Usually, the air is returned back to

the AHU to be conditioned again or exhausted from

the building by the extraction and exhaust air duct-

work respectively. It is the design engineer’s respon-

sibility to design the air distribution system in such

a way that each demand point is provided with the

required airflow at adequate pressure. The energy

needed to distribute the air and overcome all the pres-

sure losses of the various components in the network

(e.g. fittings, silencers, dampers) is delivered by one

or more fans.

The design process of air distribution systems can

be subdivided in different phases. First, the duct-

work’s layout needs to be determined, i.e., the route

that the branched ductwork follows starting from the

resource node to the demand nodes (terminal units) in

the building. Second, all duct types (i.e., size and ma-

terial) and fan(s) are selected. Last, dampers for the

different branches in the system are calculated to bal-

ance the system and ensure that every demand point

receives the correct airflow.

1.2 State of the Art

Since the 1960s, much research has been dedicated to

the simulation and optimization of air distribution net-

works (ADN) (Bouwman, 1982),(Kim, 2001),(Tsal

and Behls, 1986),(Tsal et al., 1988),(Wang, 1986).

Numerous design methods have been developed to

support the design engineer in the second phase of

the design process, namely the duct sizing and fan se-

lection, starting from a given ductwork layout. Gen-

erally, current duct design methods can be subdivided

in two main categories.

10

Jorens S., De Corte A., Sörensen K. and Steenackers G..

The Air Distribution Network Design Problem - A Complex Non-linear Combinatorial Optimization Problem.

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

The first category consists of non-optimizing

methods that rely on simple heuristics which do

not explicitly take into account prevailing local eco-

nomic conditions. Instead of optimizing an objec-

tive function, these methods only use assumptions for

variables such as the air flow velocity and friction

losses, which are based on rules of thumbs and the

designer’s experiences (Asiedu, 2000),(Mitchel and

Braun, 2012). The obtained designs are workable, but

not necessarily optimal.

The Equal Friction and Static Regain method are

the two most commonly used methods in this category

(ISSO, 1994),(Mitchel and Braun, 2012). In the first

method, the frictional pressure drop per unit length of

the duct (Pa/m), i.e. the friction rate, is maintained

constant throughout the duct system, where the fric-

tional pressure drop is associated with the duct wall

friction. This method is straightforward but involves

judgement in the selection of the friction rate, since

there is a wide range of possible values for the fric-

tion rate. The objective of the static regain method

is to obtain the same static pressure at diverging flow

junctions and before each terminal unit by changing

downstream duct sizes (Figure 1). This method of

duct sizing is based on Bernoulli’s equation, which

states that a reduction of velocities results in a con-

version of dynamic pressure into static pressure. The

velocity for the root section is an arbitrary parameter

and depends on the design engineer’s experience.

Figure 1: Schematic of pressure distribution for static regain

design, where pt = total pressure, p = static pressure and pv

= velocity or dynamic pressure (Mitchel and Braun, 2012).

The second category consists of optimization

methods. Their main goal is to determine duct sizes

according to optimal pressure losses and select a fan

according to the optimal fan pressure that minimizes

life cycle costs (LCC) (Asiedu, 2000),(Taecheol et al.,

2002),(Tsal et al., 1988). The Reduced Gradient

(Arkin and Shitzer, 1979), Quadratic Search and the

Modified Lagrange Multipliers methods (Tsal and

Adler, 1987) are some of the many computer-aided

numerical optimization methods used for network op-

timization. These methods are all continuous meth-

ods and thus, they are not adequate to deal with dis-

crete parameters such as nominal duct sizes. In 1968

Tsal and Chechic developed a method based on Bell-

man’s dynamic programming method (1957). Unfor-

tunately, when exact methods such as dynamic pro-

gramming are used for large combinatorial optimiza-

tion problems (i.e. NP hard problems) like ADN,

combinatorial explosions occur, resulting in exces-

sively long computation times (S

¨

orensen and Glover,

2013).

The most widely known optimization method is

the T-method (Tsal et al., 1988), which is also based

on dynamic programming (Tsal and Behls, 1986).

The method’s objective is to find duct sizes and se-

lect a fan so that the system’s life-cycle cost is min-

imized. The calculation procedure of the T-method

consists of three main steps. First the entire duct sys-

tem is condensed into a single duct section for find-

ing the ratios of optimal pressure losses using sec-

tional aerolic characteristics (= system condensing).

After calculating the optimal system pressure loss in

the second step, a fan is selected. Last, the sys-

tem pressure is distributed throughout the system sec-

tions (= system expansion). Although this method

is recommended by ASHRAE (American Society of

Heating, Refrigeration and Air Conditioning Engi-

neers) (ASHRAE, 2009), it is hardly used in prac-

tice. Yaw Asiedu (Asiedu, 2000) and Huan-Ruei

Shiu (Shiu et al., 2003) list the main shortcomings of

the T-method for large complex ADN. Yaw Asiedu,

for example, states that metaheuristic techniques such

as evolutionary metaheuristics are needed to tackle

large complex network designs and proposes a Seg-

regated Genetic Algorithm (Asiedu, 2000). Contrary

to exact optimization algorithms, metaheuristics do

not guarantee the absolute optimality of the obtained

solutions. However, they provide solutions that are

“good enough” in an “acceptable” computing time.

Other (meta)heuristics that were used to deal partly

or completely with the duct optimization problems

are for example Simulated Annealing (Wang, 1986)

and the Nelder and Mead downhill simplex method

(Kim, 2001). Although recent papers have been

published (Fong et al., 2010),(Kashyap, 2013),(Vi-

tooraporn and Kritmaitree, 2003), these mainly re-

iterate the same ideas of previous research (Asiedu,

2000),(ISSO, 1994),(Tsal et al., 1988), i.e. they focus

only on the duct sizing and fan selection and, more

important, the objective function of the ADN opti-

mization problem is largely the same as the objective

functions defined in previous research.

Previously developed methods are often tested

solely on two or three test networks, including the

ASHRAE benchmark network (Figure 2). This net-

TheAirDistributionNetworkDesignProblem-AComplexNon-linearCombinatorialOptimizationProblem

11

work, however, does not reflect a realistic ADN in

non-residential buildings. On the supply side, the

ASHRAE network contains only one fan (resource

node) which provides six terminal units (demand

nodes) of air. Realistic networks in hospitals or large

office buildings can have hundreds of terminal units

and multiple fans.

Figure 2: ASHRAE duct system example (ASHRAE,

2009).

1.3 Problem Statements

In general, three main shortcomings can be identified

that characterize previous research on air distribution

network optimization:

First, existing optimization methods only focus

on the second phase of the design process, i.e., they

only determine the size of each duct and/or fan in

the network and consider the network layout to be

given. The layout itself is determined using rules of

thumbs, which result in designs that are workable, but

not necessarily optimal. Clearly, the layout of the net-

work and the duct sizes are interrelated decisions that

jointly influence the quality of the air distribution sys-

tem.

Second, due to lack of benchmark instances, cur-

rent optimization methods have not been adequately

tested, and thus no strong conclusions can be drawn

on their performance in realistic circumstances nor

can their performances be compared to other exist-

ing methods. As a result, air distribution systems

are generally largely designed manually, and rely for

their performance on the knowledge and experience

of the engineer in charge of the design (Mitchel and

Braun, 2012). Clearly, the field of air distribution de-

sign would benefit greatly from models and methods

that allow more advanced automation.

Last, no modern metaheuristic techniques have

been used to solve the air distribution network design

(ADND) optimization problem. Since the last innova-

tive research conducted in the field of ADN optimiza-

tion, many new metaheuristic techniques have been

developed to handle the optimization of large combi-

natorial problems.

2 OUTLINE OF OBJECTIVES

The overarching aim of this PhD project is to tackle

aforementioned shortcomings in five steps. The first

two steps have already been performed and their out-

come is described in this document.

1. Formulating the air distribution network design

problem (ADND) as a single-objective, non-linear

combinatorial optimization problem, in which

both the layout decisions and the duct and fan

type decisions are taken simultaneously (see Sec-

tion 3.1);

2. Developing a software tool that generates a large

database of realistic artificial ADN that can be

used for testing purposes. These instances can be

used to compare the performance of existing and

future optimizations methods and evaluate their

robustness (see Section 3.2);

3. Developing a simulation model that can simulate

large air distribution networks of arbitrary com-

plexity. The simulation method will be used dur-

ing the optimization phase to calculate the objec-

tive functions and constraints of a given network

configuration. Moreover, the model will be ad-

dressed during the validation phase of the opti-

mization algorithm to determine the added value

compared to the traditional methods;

4. Developing an efficient metaheuristic that is able

to calculate the optimal air distribution network

configuration. The simulation model will be re-

sponsible for the major part of the computation

time, making it essential that the metaheuristic has

to be able to generate candidate solutions intelli-

gently, i.e. generate only high-quality solutions.

Moreover, the metaheuristic needs to be flexible

so that it can be extended to realistic networks;

5. Representing the ADND optimization problem as

a multi-objective optimization problem with the

minimization of the life cycle cost, energy con-

sumption and initial material cost as conflicting

objective functions (see Section 4.2).

ICORES2015-DoctoralConsortium

12

3 METHODOLOGY

3.1 Formulation of the Air Distribution

Network Design Optimization

Problem

In this research an ADN is represented as a graph

G(N,E) with E being the set of edges that represent

(potential) ducts and N the set of nodes representing

junctions, points of demand (terminal units), and (po-

tential) points of supply (fans). The possible locations

of the fan(s), as well as the possible fan types, and

all possible types of ducts between any pair of nodes

are assumed to be known and given as input to the

optimization algorithm. The required airflow at each

terminal unit and thus the total airflow for the entire

ADN is also assumed to be predetermined. The out-

put of the optimization algorithm will be either a min-

imum cost spanning tree with one large fan or multi-

ple subtrees where each subtree has its own fan (Fig-

ure 3).

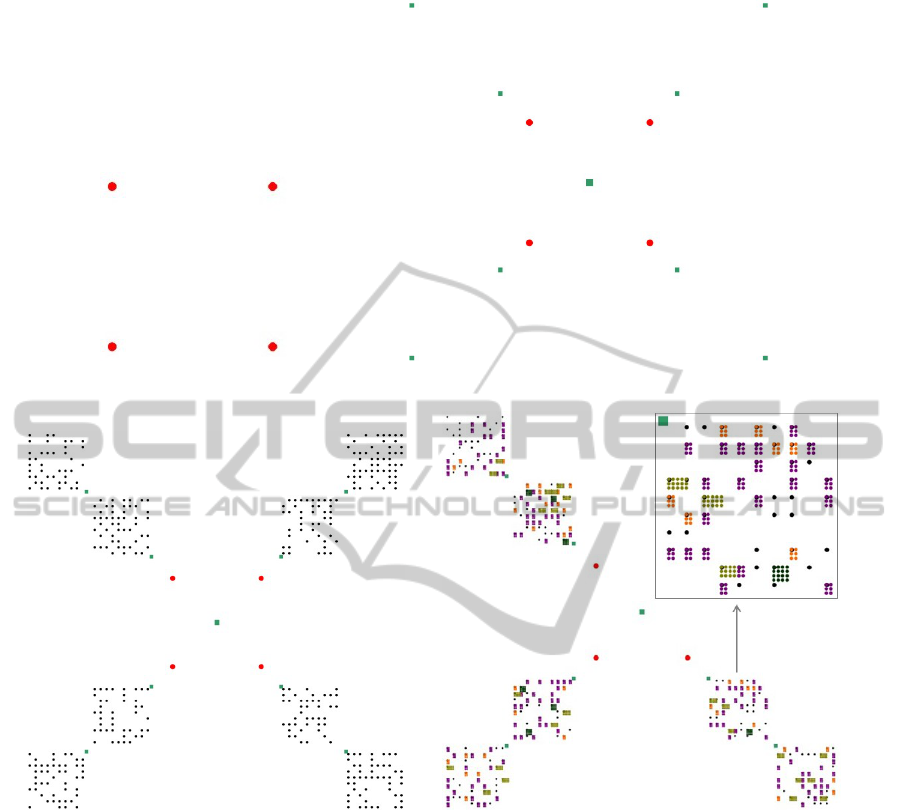

Figure 3: ADN with 1 fan (a) and 5 ADN with 5 fans (b).

Although real-life ADN should be evaluated on

multiple criteria (installation cost, life-cycle cost,

noise levels, . . . ), minimization of the installation

cost is generally seen as the most important objective.

We therefore define the ADND problem as a single-

objective optimization problem. The objective func-

tion is defined as the sum of the duct costs and the fan

costs:

minimize cost =

∑

d∈D

∑

t∈T

x

td

C

td

L

d

+

∑

f ∈F

∑

s∈S

x

s f

C

s f

(1)

In the equation x

td

is a discrete decision variable

that determines whether duct d of type t is selected

(x

td

= 1) or not (x

td

= 0). The same applies to the

fan selection, i.e. when a fan of type s is selected, x

s f

equals 1 and when a fan of type s is not selected, x

s f

equals 0. The first term of equation 1 represents the

cost of the ductwork, which depends on both the total

length L

d

of each duct d, the type t selected for duct

d, and the cost per unit of length for a duct of type

t. Each duct type has a different nominal duct size

(chosen from a list of commercially available types

T ) and specific material characteristics, resulting in a

certain unit cost per meter C

td

. The second term of

the formula represents the material cost of the fans,

where C

s f

is the cost of a fan of type s. The type of a

fan is amongst others determined by its size, fan per-

formance or characteristic curves and its application

field (centrifugal or axial fan).

Significant for the design of air distribution sys-

tems is the large number of constraints to which it is

subjected. Generally these can be divided in two main

categories: physical and external constraints. The

physical constraints such as mass and pressure bal-

ancing are determined by the physical laws that act

upon the ADN and are decisive for the proper func-

tioning of the system. The external constraints are

imposed by the fact that the ADN needs to be built in

an environment that does not allow infinite degrees of

freedom.

The mass balance or mass conservation law states

that the mass of air (expressed in kg) flowing into a

node in the network per unit of time (in s) equals the

mass of air flowing out of this node and must be sat-

isfied for each node n ∈ N:

∑

˙m

in

=

∑

˙m

out

(2)

The total airflow rate in the entire air distribution

system, i.e. the airflow that is delivered every second

by the fans in the system, equals the sum of the de-

sired airflow rates at each terminal unit. These airflow

rates are assumed to be given.

The pressure balancing constraint requires that the

pressure losses are the same for all duct paths in the

network. If this constraint is not fulfilled, balancing

dampers must be installed to balance the air flow in

the system. Since every balancing damper induces ex-

tra pressure losses and thus an extra cost, the designer

should aim to meet this constraint. The pressure drop

(expressed in Pa) due to friction for a constant-area

duct is given by the Darcy-Weisbach equation:

∆p = f

L

D

H

ρv

2

2

(3)

where f is the friction factor (dimensionless), L

the duct length (m), D

H

the hydraulic diameter (m), ρ

the density (kg/m

3

) and v the average velocity (m/s).

The last grouping of terms is also called the veloc-

ity or dynamic pressure. Parameter D

H

is determined

by the type of duct and is assumed to be given for

each available type. The density ρ of the medium is

given and considered to be constant for the whole air

distribution system. Parameter v depends on the duct

type that is selected and the pressure loss in that duct.

TheAirDistributionNetworkDesignProblem-AComplexNon-linearCombinatorialOptimizationProblem

13

Lastly, the friction factor f depends on both the se-

lected duct type and the velocity v.

The second category of constraints, i.e. external

constraints can be further subdivided in mandatory

(hard) and non-mandatory (soft) constraints, where

the latter stands for the preferences from the designer

or building owner that do not predominantly con-

tribute to the proper functioning of the system (e.g.,

a preference for smaller ducts or a specific duct lay-

out from an aesthetic point of view). Mandatory con-

straints, however, ensure that the obtained design is

feasible (limited set of commercially available duct

sizes, limited space, . . . ):

L

i

≤ D

i

≤ U

i

(4)

where:

• D

i

= diameter of duct section i, where i = 1, 2,. . . ,

n and D

i

∈ T ,

• n = the number of duct sections in the air distribu-

tion system (unitless),

• L

i

and U

i

= the lower and upper bounds of duct

section i, due to velocity or geometric constraints,

• D

i

, L

i

and U

i

are expressed in meter.

The evaluation of the physical and external con-

straints requires the simultaneous solution of a set of

non-linear equations. These equations depend on the

values chosen for the decision variables in the way

mentioned before. Solving these equations can be

done using software such as Dymola, i.e. an equation

based software with domain specific knowledge.

The ADND optimization problem is therefore a

complex combinatorial optimization problem. The

evaluation of the constraints requires the simultane-

ous solution of a set of non-linear equations. It can

be posited that such a problem is outside the realm of

exact methods and can be best approached by meta-

heuristic techniques. S

¨

orensen and Glover define

metaheuristics as “high-level, problem-independent

algorithmic frameworks that provide a set of guide-

lines or strategies to develop heuristic optimization al-

gorithms” (S

¨

orensen and Glover, 2013). Metaheuris-

tics are also particularly well-suited in a simulation-

optimization environment where either the objective

function or the constraints (such as in this case) re-

quire a run from a simulation module to be evaluated.

The development of such a simulation module or a

metaheuristic for the ADND optimization problem,

however, is outside the scope of this paper.

3.2 Generation of Artificial Air

Distribution Networks (Benchmark

Instances)

Currently a database of benchmark instances is lack-

ing and thus the performance of existing and new

ADN optimization methods cannot be evaluated and

compared properly. The software tool developed in

this paper attempts to address this shortcoming by

generating realistic artificial ADN, based on insight

into real-life building plans and typical ADN design

procedures. By means of adjustable parameters, in-

stances of arbitrary size and characteristics are gener-

ated. To this end, supply ADN in multi-storey office

buildings and universities or school buildings can be

simulated. Although these types of buildings differ in

their demand pattern, they generally share a similar

layout. Each building can be subdivided in different

zones, depending on their heating, cooling and venti-

lation needs, where each zone contains several rooms,

which are interconnected through hallways. The sup-

ply ductwork runs typically from the centralized AHU

or fan(s), located in a technical room or on the roof,

vertically through the shafts to the several floors of the

building. From there the air ducts run horizontally

above the false ceiling of the corridors to the differ-

ent zones and rooms that need to be ventilated and/or

conditioned. The dimensions of the shafts (height and

width) and the false ceiling (height) influence both the

sizing and the layout of the ductwork significantly.

The network generator developed in this paper and

written in C++ is based on this layout principle.

Basically the generation of the benchmark in-

stances is carried out in two main phases. First, input

is required from the user about the characteristics of

the building, including the building type, number and

dimensions of the shafts and the number and size of

the different zones that need to be ventilated and/or

conditioned. Second, the ADN are generated algo-

rithmically whereby sequentially the nodes and edges

are generated in the graph. The edges represent the

air ducts in the network.

The second step is described in detail in the fol-

lowing subsections and shown graphically. Figures 4

to ?? illustrate step by step the generation of ADN

for a multi-storey office building with four shafts and

consisting of eight zones.

3.2.1 Generation of the Nodes in the Graph

Per fan, a rectangular grid is created, whereby only

a percentage of the grid points will be allocated as

hallway nodes, i.e. junctions. Both the size of the

grid and the percentage are adjustable parameters.

ICORES2015-DoctoralConsortium

14

Figure 4: generation of shafts (left) and supply nodes (right).

Figure 5: generation of hallway nodes (left) and room nodes (right).

Generation of Shafts. Nodes of the type ‘shaft’ are

characterized by a set of coordinates (x, y) and a

demand that equals zero m

3

/h. Additionally, maxi-

mum dimensions (height and width) are assigned to

these types of nodes, which will determine the maxi-

mum permitted diameter of the incoming and outgo-

ing ducts.

As can be seen in figure 4, the shafts are gener-

ated on the perimeter of a rectangle with the origin

(0,0) as centre. Up to eight shafts can be generated

per building.

Generation of All Potential Supply Nodes. In a

second step, the (potential) fan locations are gener-

ated, including a discrete set of potential fan types that

can be installed at the corresponding locations. Each

fan type is represented by its performance curves. The

first supply node, i.e. the primary fan, is generated in

the origin (0,0) of the graph. Additionally, for ev-

ery zone in the building, secondary supply nodes are

generated, where each fan and thus zone is associ-

ated with a shaft. Besides the number of zones, the

distances between the zones and the shafts can be ad-

justed as well by the user.

Generation of Zones. As mentioned in section 3.2,

a zone contains multiple rooms which are intercon-

nected through hallways.

• Hallway Nodes (Junctions). Per fan, a rectangu-

lar grid is created, whereby only a percentage of

the grid points will be allocated as hallway nodes,

i.e. junctions. Both the size of the grid and the

percentage are adjustable parameters.

TheAirDistributionNetworkDesignProblem-AComplexNon-linearCombinatorialOptimizationProblem

15

Figure 6: Generation of main ducts.

Figure 7: Generation of hallway ducts (left) and room ducts (right).

• Room Nodes. All spaces in non-residential build-

ings can be classified into different types. De-

pending on the function of the building, some

types of rooms may be more or less present. The

ratio between the room types is given in table 1,

where only the spaces with an airflow demand are

taken into account. The percentages given in ta-

ble 1 are assumed average values based on multi-

ple real-life building plans. However, since these

percentages can vary considerably from building

to building, they are represented as adjustable pa-

rameters in the software tool.

Every hallway node generated in the previous

step, has a γ% chance to get assigned a room type,

where γ is an adjustable parameter. Which room

type that is assigned depends on the percentages

given in table 1. For instance, in the case of an

Table 1: Occurrence of different room types in a building.

Room types Office building Universities

Small office 65% 20%

Open office 15% /

Meeting room 15% 20%

Restaurant 5% 10%

Class room / 30%

Auditorium / 20%

office building, a small office has a 65% chance

of being generated, an open office and reception

each 15% and a cafeteria or restaurant 5%.

The characteristics of the various room types are

given in table 2. The airflow rates and floor ar-

eas in are calculated based on the occupancy rate

per room type, using to the European standard EN

ICORES2015-DoctoralConsortium

16

Table 2: Characteristics of the different room types.

Room type Max. occupancy Floor area # nodes Airflow rate/node Total airflow rate

(no. of people) (m

2

) (-) (m

3

/h/node) (m

3

/h)

Small office 10 150 6 50 300

Open office 20 300 15 40 600

Meeting room 16 56 6 80 480

Restaurant 165 250 16 300 4800

Class room 40 160 15 80 1200

Auditorium 200 800 29 200 5800

Table 3: Classification of indoor air quality or IAQ (typical

range of outdoor air for a non-smoking area).

Category Description Rate of outdoor air

(m

3

/h/person)

IDA 1 High IAQ > 54

IDA 2 Medium IAQ 36 - 54

IDA 3 Moderate IAQ 22 - 36

IDA 4 Low IAQ < 22

13779, which applies to the design and implemen-

tation of ventilation and room conditioning sys-

tems for non-residential buildings subject to hu-

man occupancy. It focuses on the definitions of

the various parameters that are relevant for such

systems. The air rates used in this paper are those

that are associated with an acceptable air quality

IDA 3 in a non-smoking area (table 3).

3.2.2 Generation of the Edges in the Graph

In a second phase, the software tool generates all po-

tential edges or ducts in the graph. Similar to the

nodes, the ducts are characterized by a set of param-

eters such as a roughness coefficient, a start and end

node, a length (i.e. the Euclidian distance between the

start and end node) and a maximum (hydraulic) diam-

eter. The last parameter implies that all smaller duct

sizes can be installed as well at this location. Since

supply ADN are subjected to a telescopic constraint,

i.e. the diameter of an upstream duct must not been

less than the diameter of a downstream duct, the size

of the set of potential ducts will reduce when going

downstream in the system.

Generation of Main Ducts. First, ducts are created

which connect the shafts with the centralized supply

node and the corresponding secondary supply nodes.

Moreover the shafts and secondary fans are connected

mutually as well. As mentioned in before, the max-

imum diameter of these ducts is determined by the

dimensions of the shafts in the building.

Generation of Ducts in the Zones:

• Hallway Ducts

For every set of hallway nodes generated, a mini-

mum spanning tree, connecting all hallway nodes

associated with one fan, is drawn, using Prim’s

algorithm. The begin-nodes and end-nodes of the

edges or ducts are assigned to these edges while

drawing the spanning tree. The edge weights or

duct lengths equal the Euclidean distances be-

tween the begin-nodes and end-nodes.

• Room Ducts

All demand nodes within a room are connected

by triangulation. The begin-node, end-node and

length of each duct are defined by the triangula-

tion itself. The maximum diameter of the ducts,

however, depends on the room type as every room

type has a different demand (table 2). The char-

acteristics of the artificial ADN that are generated

by the software tool and described in the previ-

ous subsections are available in both Graph ML

and text file format, which can serve as input file

for optimizations methods developed in future re-

search.

4 STAGE OF THE RESEARCH

4.1 Conclusions and Accomplishments

Since the 1960s, much research has been dedicated to

the simulation and optimization of ADN. Numerous

design methods have been developed to support the

design engineer in the second phase of the design pro-

cess, namely the duct sizing and fan selection, start-

ing from a given ductwork layout. This paper pro-

vides a thorough critical review of previously devel-

oped methods for duct size optimization and proposes

some recommendations for future research in the field

of ADN optimization.

Moreover, two of the four objectives outlined in

section 2, have already been accomplished. First, the

TheAirDistributionNetworkDesignProblem-AComplexNon-linearCombinatorialOptimizationProblem

17

air distribution network design (ADND) problem is

represented as a non-linear combinatorial optimiza-

tion problem, which can best be solved with meta-

heuristic optimization techniques. Previous research

is extended by integrating the network layout into

the formulation of the optimization problem. Ad-

ditionally, the need for realistic artificial benchmark

instances is motivated and a software tool to gen-

erate these kinds of instances is proposed. To this

end, instances for multiple-floor office building and

school or university buildings can be generated. In the

very near future, the software tool will be extended to

generate instances for other non-residential buildings

such as sport complexes and industrial buildings. The

tool will become freely available to foster research in

the field ADND optimization and will be useful for

testing purposes.

4.2 Pointers for Future Research

As mentioned in section 2 ‘Outline of Objectives’,

the next step in this research is developing a simu-

lation model in Dymola that can simulate large ADN

of arbitrary complexity. It will be used during the op-

timization phase to calculate the simplified objective

function and the constraints of a given network con-

figuration as formulated in section 3.1. Subsequently

an efficient metaheuristic algorithm will be developed

for this simplified ADND optimization problem.

Since the design of air distribution systems de-

pends strongly on the requirements of the end user,

the long term aim of this research is to represent the

ADND optimization problem as a multi-objective op-

timization problem with the minimization of the life

cycle cost, energy consumption and initial material

cost as conflicting objective functions. Conflicting in

the sense that, for example, a larger cross-section of

the ductwork induces higher material costs, but lower

energy consumption. A Pareto-set of non-dominated

solutions will be generated by the optimization algo-

rithm and it is up to the decision taker to make a trade-

off between the different solutions.

5 EXPECTED OUTCOME

The final outcome of this research is an efficient op-

timization method that supports the decision-making

of the contractor, engineering office or architect dur-

ing the design phase of large, complex air distribution

networks in non-residential buildings.

ACKNOWLEDGEMENTS

This research was partially supported by the Interuni-

versity Attraction Poles (IAP) Programme initiated by

the Belgian Science Policy Office (COMEX project).

REFERENCES

Arkin, H. and Shitzer, A. (1979). Computer aided optimal

life-cycle design of rectangular air supply duct sys-

tems. ASHRAE Transactions, 85.

ASHRAE (2009). ASHRAE Handbook - Fundamen-

tals, chapter 21: Duct design, pages 21.1–21.67.

American Society of Heating, Refrigeration and Air-

Conditioning Engineers.

Asiedu, Y. (2000). Life-cycle cost analysis and probabilis-

tic cost estimating in engineering design using an air

duct design case study. PhD thesis, University of

Saskatchewan.

Bouwman, H. B. (1982). Optimum air duct system design.

PhD thesis, Technische Hogeschool Delft.

Fong, K. F., Yuen, S. Y., Chow, C. K., and W., L. S. (2010).

Energy management and design of centralized air-

conditioning systems through the non-revisiting strat-

egy for heuristic optimization methods. Applied En-

ergy, 87:3494–3506.

ISSO (1994). Luchtkanalen drukverlies-, thermische en

akoestische berekeningen. ISSO.

Kashyap, M. (2013). Carbon fiber composites for duct de-

sign based on vav network in hvacs system. Interna-

tional Journal of Emerging Trends in Engineering and

Development, 2:67–73.

Kim, T. (2001). Optimum duct design for variable air vol-

ume systems. PhD thesis, Oklahoma State University.

Mitchel, J. W. and Braun, J. (2012). Heating, ventilation

and air conditioning in buildings. Wiley.

Shiu, H., Ou, F., and Chen, S. (2003). Optimization de-

sign of exhaust duct system in semiconductor factory

using dynamic programming method. Building and

Environment, 38:533–542.

S

¨

orensen, K. and Glover, F. (2013). Metaheuristics. In

Gass, S. and Fu, M., editors, Encyclopedia of OR/MS,

3rd edition, New York. Springer.

Taecheol, K., Spitler, J. D., and Delahoussaye, R. D. (2002).

Optimum duct design for variable air volume systems

- part 1: problem domain analysis of vav duct sys-

tems and part 2: optimization of vav duct systems.

ASHRAE Tran, 108:96–127.

Tsal, R. J. and Adler, M. S. (1987). Evaluation of numer-

ical methods for ductwork and pipeline optimization.

ASHRAE Transactions, 93.

Tsal, R. J. and Behls, H. F. (1986). Evaluation of duct de-

sign methods. ASHRAE transactions, 92.

Tsal, R. J., Behls, H. F., and Mangel, R. (1988). T-

method duct design - part 1: optimization theory and

part 2: calculation procedure and economic analysis.

ASHRAE transactions, 94:90–151.

ICORES2015-DoctoralConsortium

18

Vitooraporn, C. and Kritmaitree, P. (2003). Modified t-

method duct design for use in thailand. ASHRAE Jour-

nal, pages 10–24.

Wang, F. (1986). Computer aided optimal design of duct

system using simulated annealing. Master’s thesis,

Oklahoma State University.

TheAirDistributionNetworkDesignProblem-AComplexNon-linearCombinatorialOptimizationProblem

19