Fabrication of Surface Relief Optical Elements in Ternary

Chalcogenide Thin Films by Direct Laser Writing

I. Voynarovych

1

, R. Poehlmann

2

, S. Schroeter

2

and M. Vlcek

1

1

Department of General and Inorganic Chemistry, Faculty of Chemical Technology, University of Pardubice,

Studentska 573, Pardubice, Czech Republic

2

Leibniz Institute of Photonic Technology, Albert-Einstein-Str. 9, Jena, Germany

Keywords: Direct Laser Writing, Chalcogenide Glasses, Patterned Structures.

Abstract: Direct laser writing with a continuous-wave high intensity and over-band gap laser is applied to realize

surface relief optical elements in ternary As-S-Se and Ge-As-S thin chalcogenide films. The topology of

created structures in dependence on the experimental conditions is investigated. Analyses indicate that the

formation mechanisms of the surface patterns are thermally induced processes generated by the local

heating and involve thermoplastic deformation, mass flow induced by the surface tension gradient and

evaporation. Diffractive gratings with a period of 2.56 m, depths of up to 100 nm, and different periodic

surface structures were patterned at the surface of 1 m thick films. The spectral dependencies of diffraction

efficiency were measured and discussed.

1 INTRODUCTION

The chalcogenide glass (ChG) family exhibits

several interesting properties that can be exploited

e.g. in optical communication, optical sensing, high

density optical recording, and optical lithography. In

particular, their excellent infrared transparency up to

12–20 m, large third order susceptibility, high

refractive index (usually 2–3.2), and ability to

undergo significant irradiation induced structural

modifications make chalcogenide glass films good

candidates for the fabrication of all-optical switches

(Harbold, 2002) and integrated optical elements

(Meneghini, 1998; Viens, 1999). Optical integrated

as well as diffractive elements in chalcogenide

glasses have been fabricated by several techniques

including interference photolithography (Utsugi,

1975; Chomat, 1976; Palyok, 1999), ion

implantation and direct ion/laser beam writing

(Schroeter, 2007; Nordman, 1996). The direct laser

writing (DLW) by a tightly focused laser beam has

been intensively developed during the last decades

as an efficient way to produce 2D and 3D

microstructures. It attracts high interest due to its

inherent advantages like high precision, moderate

cost, high speed, and high flexibility (Thiel, 2010;

Van, 2009).

Among all the variety of chalcogenide glasses

(ChGs), i.e. glasses containing chalcogen elements

(e.g. S, Se, Te), arsenic trisulfide As

2

S

3

(As

40

S

60

) is

one of the most studied and well-known. A

particular interest attract ternary compositions based

on As

2

S

3

for which the substitution of S by Se gives

the possibility to monotonically change optical

properties such as the band gap energy, from 2.4 eV

down to 1.8 eV, and the refraction coefficient from

2.3 up to 2.7 (Gonzalez-Leal, 2003), whereas the

substitution of tri-coordinated As by four-

coordinated Ge causes the glass network to change

from a two-dimensional layered structure to a three-

dimensional structure with a more rigid network

resulting in a significant change of the

thermodynamic properties such as softening

temperatures, viscosity etc. (Feltz, 1993;

Tatsumisago, 1990).

In this paper we compare the behavior of

different ternary As-S-Se as well as Ge-As-S thin

films under cw laser exposure in dependence on the

writing conditions and demonstrate the possibility to

fabricate surface relief diffractive optical elements

by DLW.

2 EXPERIMENTAL

Bulk samples of As and Ge based glasses from

134

Voynarovych I., Poehlmann R., Schroeter S. and Vlcek M..

Fabrication of Surface Relief Optical Elements in Ternary Chalcogenide Thin Films by Direct Laser Writing.

DOI: 10.5220/0005404001340139

In Proceedings of the 3rd International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2015), pages 134-139

ISBN: 978-989-758-093-2

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

ternary systems As-S-Se and Ge–As–S were prepared

by conventional melt-quenching method from high

purity (5 N) elements in evacuated quartz ampoules

for 8 h at 650

o

C (As based samples) or 1000

o

C (Ge

based samples) in a rocking furnace. Thin-film

samples were prepared by vacuum evaporation of

the bulk glassy materials onto clean glass substrates.

The thermal evaporation process was performed

within a coating system (Tesla Corporation, model

UP-858) at a pressure of about 10

-3

Pa. During the

deposition process the substrates were conveniently

rotated by means of a planetary rotation system to

ensure high homogeneity of the film thickness. The

deposition rate was in the range 1–2 nm/s, measured

continuously using the quartz microbalance technique.

The thickness of the thin films was about 1 m

The laser lithography system DWL 66,

Heidelberg Instruments Mikrotechnik GmbH,

equipped with a vertically polarized continuous-

wave He-Cd laser (=442 nm) was used for the

exposures. The maximal laser power available after

the writing objective to expose the samples was

P

max

=1.8 mW. The laser beam was focused to a spot

diameter of about 640 nm by an objective with a

focal length of 4 mm and a numerical aperture of

0.85. The focus distance of the objective is

controlled by an air gauge based autofocus system.

The applied exposure laser power P was tuned by a

rotable polarizer in steps of 10% from P

max

down to

0.4P

max

, resulting in spot intensities between

5.610

5

W/cm

2

and 2.210

5

W/cm

2

. Structures were

patterned at writing speeds of 25-75 mm/s. An

atomic force microscope (Ultraobjective SIS

attached to an optical microscope) was used to

investigate the morphology of the corrugated surface

of the thin films. The transmission spectra and

diffraction efficiencies were measured with the fiber

coupled spectrometer EPP2000 (StellarNet Inc.)

3 RESULTS AND DISCUSSION

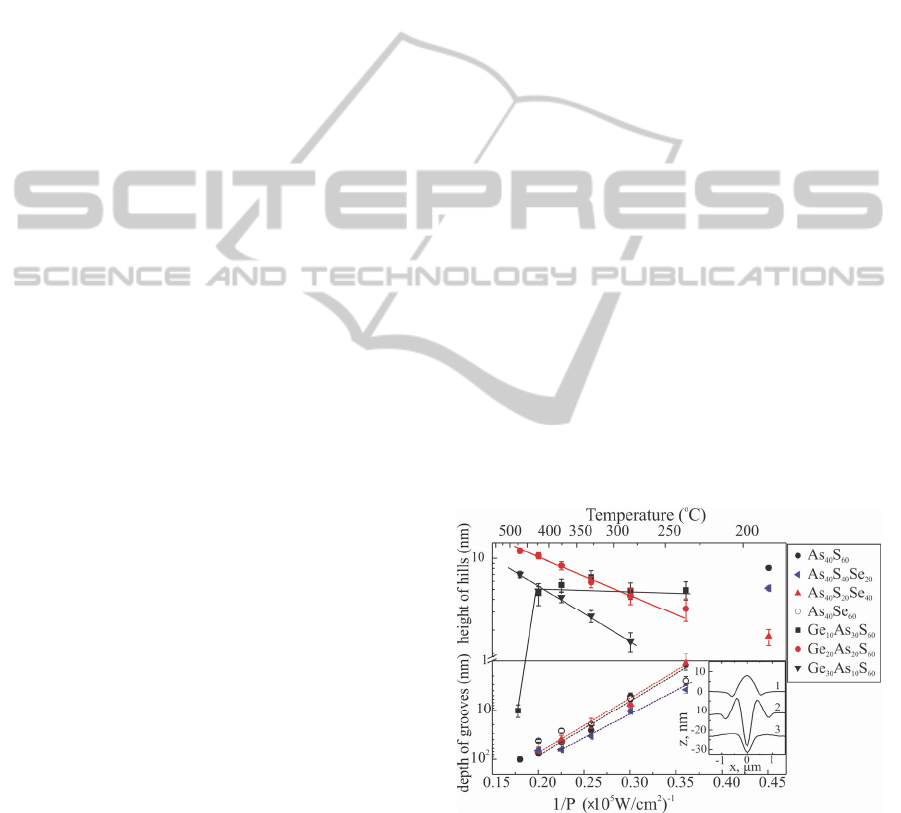

To compare the behavior of thin chalcogenide films

with different optical and thermodynamic properties

under the irradiation with an over band-gap cw laser

a series of single lines was written with different

laser intensities ranging from 2.210

5

to

5.610

5

W/cm

2

on each of the samples of the

different investigated compositions. Created surface

structures were investigated by atomic force

microscopy, and the geometrical profiles of each

line were taken by scanning in the direction

perpendicular to the laser beam movement. The

analysis of such profiles shows that they can be

divided into three main groups (see inset of Fig.1)

indicating various possible formation mechanisms

depending on the laser intensity as well as on the

properties of the distinct thin film.

The curve 1 in the inset of Fig.1 represents a

typical profile for photo-induced expansion that

appears at all used intensities for Ge-As-S thin films

and at low intensity of the writing laser beam for As-

S-Se compositions. In this case the shape of the

corrugated structure follows the Gaussian intensity

profile of the laser beam. The dependences of the

height of the emergent elevations (‘hills’) on the

laser intensity are shown in the upper part of Fig. 1

for different compositions.

The curve 2 in the inset of Fig.1 represents

emerging profiles for the case that a groove with a

simultaneously appearing rim surrounding the center

of the laser spot is created. Formation of such a

profile is typical only for As-S-Se thin films above

an experimentally determined threshold value of

2.810

5

W/cm

2

, whereas for Ge-based ternary

compositions only the creation of grooves without

any rim (see curve 3) was observed. The magnitude

of the groove depth obtained from the AFM images,

is represented in the lower part of Fig. 1 as a

function of exposure intensity for the different

compositions.

As we used an over-bandgap writing laser the

beam energy was totally absorbed within a small

volume of the thin film. The penetration depth d

pd

of

the He-Cd laser beam was evaluated according to

the Beer-Lambert law as d

pd

=1/

(

absorption

coefficient). For As

40

S

60-x

Se

x

compositions d

pd

varies

from 240 nm (x=0) down to 80 nm (x=60) and for

the Ge-based compositions d

pd

is 240 nm almost

independent on the composition. Because of the

extremely high intensity and the total absorption of

the light within a very small volume, the thin

chalcogenide film can be locally and rapidly heated

up to temperatures above T

g

, or even to temperatures

where material decomposition and evaporation take

place. The temperatures on the surface at the center

of a stationary Gaussian heat source for a semi-

infinite solid can be calculated as (Carslaw, 1959):

/

2

√

∗

,

(1)

where, t – duration of laser interaction with the thin

film, w – waist of the laser beam (0.64 m), K and D

are the thermal conductivity and diffusivity of the

glass substrate (110

-2

W/K*cm and 5.3310

-3

cm

2

/s

respectively), P

a

=P(1-R), where P is the power of

the incident beam and R the reflectivity at the air-

film interface. The potential of this model to

FabricationofSurfaceReliefOpticalElementsinTernaryChalcogenideThinFilmsbyDirectLaserWriting

135

describe the thermal evolution in chalcogenide thin

films during over-band gap cw laser irradiation was

demonstrated (Nordman, 1999). The temperatures

calculated for our experimental conditions are

shown as the top axis on Fig.1.

The most common and simple, but remarkably

accurate, relation between the changing rate of any

kinetic parameter and the temperature change is

given by the Arrhenius equation: F=A·exp(-E

a

/k

B

T),

where F is a rate constant, A the pre-exponential

factor, E

a

the activation energy for the change to

take place, T the temperature, and k

B

the Boltzmann

constant.

As can be seen from Eq. (1), the temperature on

the thin film surface is proportional to the laser beam

intensity. The straight line dependences for the depth

of grooves for As-based thin films as well as of the

height of hills for Ge-based compositions (see Fig.1)

on the inverse of the beam intensity (and thus on the

inverse temperature) clearly show that both

parameters obey Arrhenius' equation and we can

thus conclude that the formation mechanisms of the

patterned structures are thermally-induced processes.

The temperature of the thin film’s surface for

exposure power levels at which solely expansion

was observed is close to the glass softening

temperature (180-210

o

C range for As-S-Se and 230-

440

o

C for Ge-As-S ternary compositions (Feltz,

1993). The most realistic mechanism is in this case

the thermoplastic deformation proposed in Refs.

(Zhao, 2013; Shiu, 1999). According to this

mechanism, a locally heated volume expands

preferably in the direction to the film’s interface

with air because of the suppresion of expansion in

other directions by the unheated glass and the plastic

deformation due to the yield stress of heated and

thus softened material.

When, however, the surface temperature of the

chalcogenide film at still higher laser intensities

exceeds the softening temperature of a given glass

composition the viscosity of the exposed material

begins to decrease (Feltz, 1993) and thus melts in

the irradiated spot area resulting in a different

surface corrugation mechanism. The processes of

surface corrugation for the case of a locally molten

material area were theoretically and experimentally

investigated by several authors (Blom, 1983; Cline,

1981; Anthony, 1977). According to the proposed

model, the molten material is pulled from the center

of the molten spot by a shear stress and forms the

rim surrounding the central hole (curve 2 in the inset

of Fig.1), which is the result of a surface tension and

a viscosity gradient, in turn resulting from a

temperature gradient induced by the focused laser

beam with a Gaussian intensity profile. In the case

of Ge-based ternary compositions, the more rigid

glass structure and thus the smaller temperature

dependence of the viscosity (Tatsumisago, 1990) in

combination with a counterflow induced by capillary

pressure can prevent the viscous flow in the given

temperature region.

At the highest intensities available for exposures

only for As-based compositions the process of

decomposition/evaporation−back-condensation takes

place when the temperature exceeds the

experimentally determined threshold temperature of

about 370

o

C.

Having in detail investigated the power

dependence of the resulting structural parameters we

have chosen the maximal available intensity of

5.6x10

5

W/cm

2

and a scan speed of 75 mm/s to

pattern surface relief gratings with a period of

=2.54 m and an area of 5x5 mm

2

into ternary As-

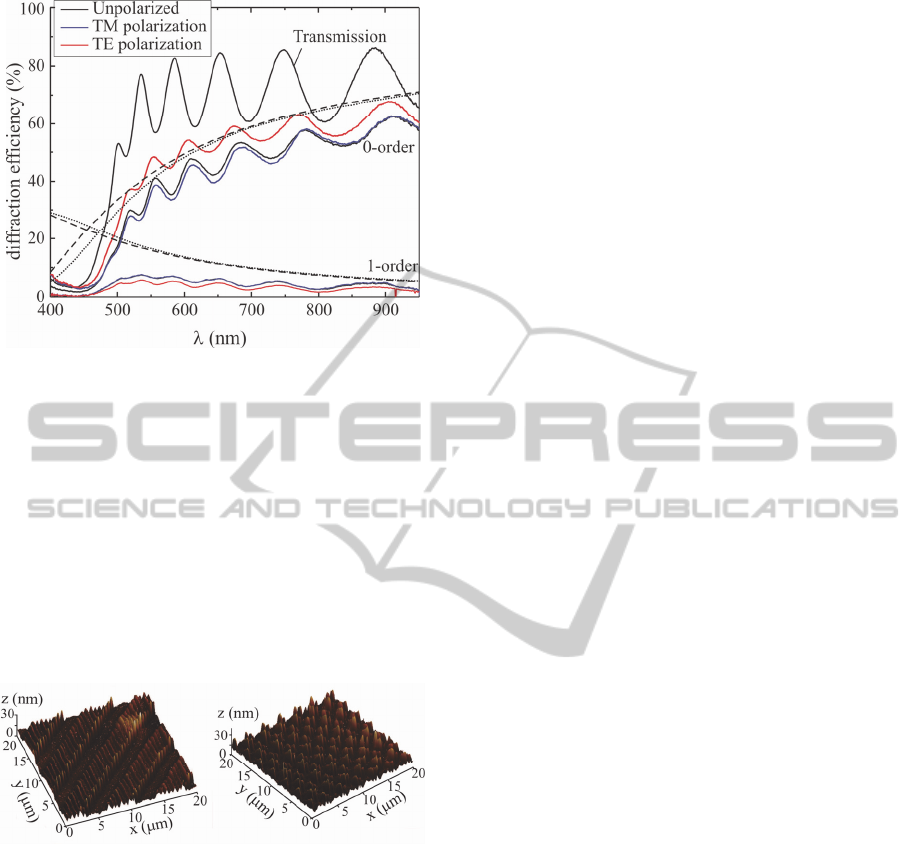

S-Se and Ge-As-S thin films. In Fig.2 are shown the

AFM images of diffraction gratings with a period

=2.54 m patterned by DLW with the chosen

writing parameters on the surface of As

2

S

3

(a) and

Ge

25

As

15

S

60

(b) thin films. The groove depth for the

Ge-containing thin films was only up to 12 nm and

the gratings exhibit thus only very low diffraction

efficiency. But these gratings can be further

developed by wet or dry etching. However, the

depth of grooves for a diffraction grating on As-S-Se

thin films can vary from a few nanometers up to

about 100 nm by choosing appropriate writing

parameters.

Figure 1: Dependences of depth of grooves and height of

hills of corrugated structures on the exposed intensity

(bottom axis) and calculated surface temperature (top axis)

for different ternary Ge-based and As-based thin films.

For the used writing parameters given above the

quality of the grating surface for the As

2

S

3

film is

very good, whereas for lower writing speeds

evaporation and back-condensation processes start to

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

136

Figure 2: AFM scan and averaged profile of the surface

relief grating formed by DLW on the surface of As

2

S

3

(a)

and Ge

25

As

15

S

60

(b) thin films written with an intensity of

5.610

5

W/cm

2

and a scan speed 75 mm/sec.

take place and randomly spread small material

particles emerge at the surface. This causes an

increased level of stray light deteriorating the

diffraction properties.

Binary surface relief diffractive elements can

exhibit very high diffraction efficiency. Let us

consider the case of a surface relief phase grating on

a thin film evaporated on a usual glass substrate as

shown in Fig. 3.

To define whether a grating is thin or thick the

parameter Q can be used (Collier, 1971):

2

Λ

cos

(2)

where

is the free space wavelength, D the grating

thickness, n the average refractive index. For our

structural parameters Q is less than 1 defining the

grating as thin. Applying the scalar diffraction

theory and neglecting the reflection at the air-film

interface for a thin binary surface relief grating with

a fill

factor f, the zero-order transmittance efficiency

into the grating material can be derived as (Jing,

2011)

12

1

∙1Δ,

(3)

whereas for the other diffraction orders m the

efficiency

is given by:

,

(4)

Figure 3: Binary diffraction grating.

with

Δ

2

1

(5)

As can be seen from Eq. 4, the maximal diffraction

efficiency into the first order is

4/

0.405

for the case f=0.5 and

=.

Approximating the grating profile shown in Fig.

2(a) by a binary structure with D=90 nm, and using

the index of refraction for As

2

S

3

(Laniel, 2003)

decreases from 0.96 at

=400 nm to 0.295 at

=1000 nm.

Taking also into account the Fresnel reflection R

at the interface of the chalcogenide film with the air

for the case of normal incidence (

0

=0) the

efficiencies calculated from Eqs. (3) and (4) are

reduced by the factor 1-R, with

1

1

(6)

The diffraction efficiencies into the chalcogenide

film according to the scalar diffraction theory as

calculated using Eq. (3) to Eq. (6) are represented in

Fig. 4.

For comparison are also shown the results of a

rigorous calculation applying the Rigorous Coupled

Wave Analysis (RCWA) (Moharam, 1982).

The main reason for the differences between the

simulations and the measured diffraction efficiencies

is that the calculations are made for the diffraction

into the chalcogenide film and do not take into

account that the diffracted powers in the experiment

are measured after propagation through the

unstructured part of the layer and the glass substrate

into air. For the short wavelength range the

absorption of As

2

S

3

(Laniel, 2003) reduces the

transmitted power significantly. With increasing

wavelength the absorption of As

2

S

3

is rapidly

decreasing, however the reflections at the interfaces

chalcogenide glass / glass substrate and substrate/air

can lower the transmission. Accordingly the

experimental results are spectrally modulated in

similarity with the transmission of the unstructured

thin film also shown in Fig. 4.

In the focus of interest are currently also

photonic crystals composed of periodic

microstructures that affect the propagation of

electromagnetic and/or plasmonic waves in a

specific manner and offer unique properties for the

realization of different photonic devices. Examples

of such periodic surface microstructures that were

FabricationofSurfaceReliefOpticalElementsinTernaryChalcogenideThinFilmsbyDirectLaserWriting

137

Figure 4: Spectral dependence of thin film transmission, 0-

order and 1-order diffraction efficiencies (solid lines)

measured for normal incidence at a grating prepared by

DLW on the surface of an As

2

S

3

thin film with an intensity

of 5.610

5

W/cm

2

and a scan speed of 75 mm/sec and

diffraction efficiencies calculated with scalar and rigorous

diffraction theories (dashed and dotted line respectively).

fabricated by DLW with a resolution down to about

1 m in a Ge

20

As

20

S

60

chalcogenide thin film are

shown in Fig. 5. However, for practical applications

a post-exposure etching process would be required

in order to significantly increase the depth of the

structures.

Figure 5: AFM images of periodic arrays with different

pattern shapes created by DLW in a Ge

20

As

20

S

60

thin film.

4 CONCLUSIONS

The surface corrugation processes induced by the

irradiation of ternary As

40

S

60-x

Se

x

and Ge

x

As

40-x

S

60

thin films with a continuous wave tightly focused

overband-gap laser emitting at 442 nm were

investigated.

Analyses of the topology of the created

structures indicate that the formation mechanisms of

the surface patterns are thermally induced processes

generated by the local heating and involve

thermoplastic deformation, mass flow induced by

surface tension gradient and decomposition/

evaporation mechanism.

By tuning the laser power diffractive optical

elements like diffraction gratings with a period of

2.56 m and various depths or periodic surface

microstructures with feature sizes down to less than

1 micrometer and different shapes were patterned.

The zero- and first-order diffraction efficiencies

were measured for a diffractive grating in a As

2

S

3

thin film within the visible and near infrared spectral

range. A maximal value of 8% for the first

diffraction order was measured.

ACKNOWLEDGEMENTS

This work was supported by the grant

CZ.1.07/2.3.00/30.0058 from the Czech Ministry of

Education, Youth and Sports

REFERENCES

Anthony T. R. and Cline H. E., 1977 ‘Surface rippling

induced by surface tension gradients during laser

surface melting and alloying’, J. Appl. Phys., vol. 48,

pp.3888-3894.

Blom G. M., 1983 ‘Hole formation in tellurium alloy films

during optical recording’, J. Appl. Phys., vol.54,

pp.6175-6182.

Carslaw H. S. and Jaeger J. C., 1959. Conduction of Heat

in Solids, Oxford University, Oxford, 2

nd

ed.

Chomat H., Lezal D., Gregora I., and Srb I., 1976 ‘Relief

holograms in thin films of amorphous As

2

Se

3

under

high laser exposures’, J. Non-Cryst. Solids, vol.20,

pp.427-437.

Cline E., 1981 ‘Surface rippling induced in thin films by a

scanning laser’, J. Appl. Phys., vol.52, pp.443-448.

Collier R. J., Burckhardt C. B., Lin L. H. 1971. Optical

holography, Academic Press, - Technology &

Engineering, 605 p.

Feltz A. 1993 ‘Amorphous Inorganic Materials and

Glasses’, VCH Weinheim/VCH Publishers, New

York,. 446 p.

Gonzalez-Leal J.M., Prieto-Alcon R., Angel J.A., Marquez

E., 2003 ‘Optical properties of thermally evaporated

amorphous As

40

S

60-x

Se

x

films’, Journal of Non-

Crystalline Solids, vol. 315 pp.134–143.

Harbold J. M., Ilday F. O., Wise F. W., Sanghera J. S.,

Nguyen V. Q., Shaw L. B., Aggarwal I. D., 2002

‘Highly nonlinear As-S-Se glasses for all-optical

switching’, Opt. Lett.,vol. 27, pp.119-121.

Jing X., Jin Y., 2011 ‘Transmittance analysis of diffraction

phase grating’, Applied Optics, vol.50. pp. c11-c18.

Laniel J. M., Menard J., Turcotte K., Villeneuve A.,

Vallee R., Lopez C., Richardson K. A., 2003

‘Refractive index measurements of planar

chalcogenide thin film’, J. Non-Cryst. Solids, vol. 328,

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

138

pp. 183–191.

Meneghini C., Villeneuve A., 1998 ‘As

2

S

3

photosensitivity

by two-photon absorption: holographic gratings and

self-written channel waveguides’, J. Opt. Soc. Am. B

vol. 15, pp. 2946-2950.

Moharam M. G., and Gaylord T. K., 1982 ‘Diffraction

analysis of dielectric surface-relief gratings’, J. Opt.

Soc. Am. vol.72, pp.1385-1392.

Nordman N., Salminen O., Kuittinen M., and Turunen

J.,1996 ‘Diffractive phase elements by electron-beam

exposure of thin As

2

S

3

Films’, J. Appl. Phys., vol. 80,

pp.1079-1080.

Nordman O. and Nordman N., 1999 ‘Hole formation

induced by 488.0-nm light in 10-mm-thick amorphous

as-evaporated As

2

S

3

films’, Phys. Rev. B: Condens.

Matter., vol. 60, pp.2833-2838.

Palyok V., Mishak A., Szabo I., Beke D. L., Kikineshi A.,

1999 ‘Photoinduced transformations and holographic

recording in nanolayered a-Se/As

2

S

3

and AsSe/As

2

S

3

films’, Appl. Phys. A, vol. 68, pp. 489-492.

Schroeter S., Vlcek M., Poehlmann R., Fiserova A., 2007

‘Efficient diffractive optical elements in chalcogenide

glass layers fabricated by direct DUV laser writing’, J.

Phys. Chem. Solids, vol. 68, pp.916–919.

Shiu T., Grigoropoulos C. P., Cahill D. G., and Greif R.,

1999 ‘Mechanism of bump formation on glass

substrates during laser texturing’, J. Appl. Phys., vol.

86, pp.1311-1316.

Tatsumisago M., Halfpap B. L., Green J. L., Lindsay S.

M., and Angell C. A., 1990 ‘Fragility of Ge-As-Se

glass-forming liquids in relation to rigidity

percolation, and the Kauzmann paradox’, Phys. Rev.

letters, vol. 64, pp.1549-1552.

Thiel M., Fischer J., von Freymann G., Wegener M., 2010,

‘Direct laser writing of three-dimensional submicron

structures using a continous-wave laser at 532nm’,

Appl. Phys. Lett. vol. 97, p.221102.

Utsugi Y. & Zembutsu S., 1975 ‘Relief type diffraction

grating by amorphous chalcogenide films’, Appl. Phys.

Lett. vol. 27, pp.508-510.

Van Gough D., Juhl A. T. and Braun P. V. 2009,

‘Programming structure into 3D nanomaterials’,

Materials today, vol. 12, p.28.

Viens J-F., Meneghini C., Villeneuve A., Galstian T. V.,

Knystaunas E. J., Duguay M. A., Richardson K. A.,

Cardinal T., 1999 ‘Fabrication and characterization of

integrated optical waveguides in sulfide chalcogenide

glasses’, J. Lightwave Technology vol. 17, pp.1184-

1191.

Zhao D., Jain H., Malacarne L. C., and Pedreira P. R. B.,

2013 ‘Role of photothermal effect in photoexpansion

of chalcogenide glasses’, Phys. Status Solidi B, vol.

250, pp.983–987.

FabricationofSurfaceReliefOpticalElementsinTernaryChalcogenideThinFilmsbyDirectLaserWriting

139