High Power Laser Diodes with Optical Feedback

Contribution to Doctoral Consortium

Dennis Bonsendorf

LIMO Lissotschenko Mikrooptik GmbH, Bookenburgweg 4-8, Dortmund, Germany

Ruhr-Universität Bochum, Universitätsstraße 150, Bochum, Germany

1 RESEARCH PROBLEM

High power direct diode lasers, as they are used in

material processing or photonic pumping

applications, are sensitive to back reflected light,

which is usually called “optical feedback”. This

feedback is generated unintendedly by optical

surfaces of laser processing tools like cutting heads

or by the processed surface itself. In material cutting

or welding processes copper or aluminum are highly

reflective materials (Steen, 2010) and photonic

crystals can be origin of unwanted radiation even at

changed wavelength (Dowley, 1998). Inside the

laser system the beam transformation or the fiber

coupling unit generates optical feedback. In some

applications optical feedback is actually desired as

part of the design. Volume Bragg gratings (VBG)

reduce the spectral width by utilization of feedback.

However, there is a price to pay, when the reflected

light reaches the emitter of the laser diodes it can

result in spectral modulation, lifetime reduction or

catastrophic optical (mirror) damage (COMD).

2 OUTLINE OF OBJECTIVES

To provide laser systems with reliable and stable

operation in the presence of optical feedback, design

guidelines have to be elaborated and evaluated.

To do this a measurement setup is developed to

apply optical feedback to laser diodes, which is

controlled in intensity and direction. Its influence on

the electrical and optical properties of the laser diode

is observed. Laser diode bars with different types of

semiconductor material, structure and emitter count

are investigated. Then the parameters with influence

the probability of disturbance or device failure are

identified. These parameters can rise or lower the

risk of a COMD.

The influence of emitter position variation in

fast-axis direction (smile) was evaluated. Optical

components used for beam transformation,

combination or fiber coupling have individual

behavior to the generation of optical feedback.

The study is mostly application related as the

used laser diodes and optical elements are

commonly used components and optical layouts.

This ensures that the gathered information lead to

developments of protection strategies and devices

for industrial laser diode systems against the threat

of optical feedback.

3 STATE OF THE ART

Laser diodes are typically designed for stand-alone

operation. For example the front facet reflectivity is

optimized to achieve highest efficiency or highest

brightness. However, the presence of optical

elements is not taken into account, although they

influence the internal resonator design. From the

point of view of the laser diode manufacturer this

point is comprehensible as the field of applications

is wide it is difficult to optimize laser diodes to

cover multiple optical scenarios.

For this reason the interaction between optical

system and laser diodes were subject to extensively

investigations (Ohtsubo, 2010). Especially single

mode laser emitters with optical feedback got high

attention. This is an effect of the commonly use of

these types of laser diodes in the communication

technology (Kaminow, 2013). In contrast, the

information on broad area laser emitters and

especially on laser bars are sparse. Also long term

effects of optical feedback to the reliability of laser

diodes are not yet understood.

4 METHODOLOGY

This chapter describes the measurement techniques

and procedures to gather the information about laser

device failure due to optical feedback.

47

Bonsendorf D..

High Power Laser Diodes with Optical Feedback - Contribution to Doctoral Consortium.

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

4.1 Laser Diodes

The used laser diodes are commercially available

components. They are mounted p-side down on a

passively cooled cooper heat sink. All laser diodes

used in experiments are checked in advance. This

includes visual inspection of front facet, recording of

optical power to current and voltage (PIV)

characteristics as well as spectral measurements and

near and far field intensity distributions. The

different types are listed in Table 1.

Table 1: Batches of test laser diodes.

Batch Material Wavelength Emitter No.

A AlGaAs 808 nm 19

B InGaAs 980 nm 10

C InGaAs 1010 nm 10

Laser diodes of batch A based on semiconductor

material containing aluminum and are well known

for susceptible behavior against optical feedback.

Laser diodes with InGaAs semiconductor are more

robust. Two versions with different wavelengths are

tested (batch C and D).

4.2 Detection of Failure Threshold

The threshold of device failure has to be identified to

derive design limits. Optical and electrical behavior

is observed to gather indicators connected to defined

feedback intensities.

4.2.1 Test Setup

The setup has to be suitable to measure and control

the amount of optical feedback reflected towards the

laser diode. The optical system has to be comparable

to commonly used designs for laser systems.

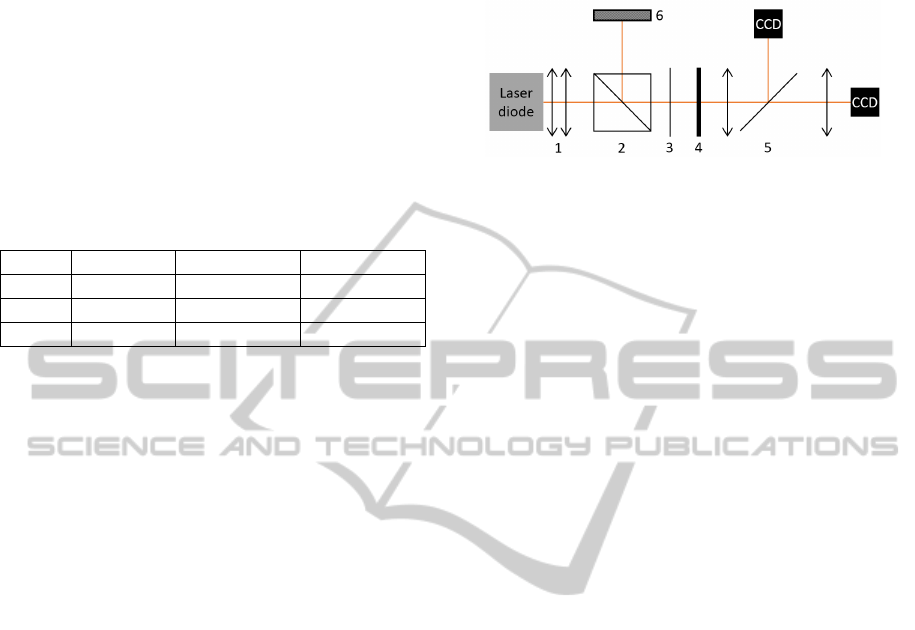

In Figure 1 the basic layout of the test system is

illustrated. The radiation of the laser diode is

collimated by cylindrical lenses in fast- and slow-

axis direction. An array of biconvex lenses rotates

the beam of each emitter geometrically by 90

degrees to achieve a more symmetric beam

parameter product. This component is part of the so

called beam transformation system (BTS). Note, that

the nomenclature of slow- and fast axis direction are

now inverted. The collimated beam is transmitted

through a polarization beam splitter and a quarter

wave plate. After reflection at a mirror the beam

passes the polarization optics again. Depending on

the angle of the wave plate, a part of the beam is

reflected at the beam splitter and hits on a power

measurement head. The remaining radiation is

transmitted towards the laser diode and focused via

the collimation lenses back onto the emitter.

Figure 1: Measurement setup with variable feedback

intensity and beam diagnostics. 1) collimation optics 2)

polarization beam splitter 3) wave plate 4) feedback mirror

5) beam splitter 6) power measurement head.

Closely behind the BTS two slit blades are

mounted to limit the transmitted radiation to a

defined number of emitters. This allows determining

the influence of optical feedback on a single or

multiple emitters.

The electrical properties of the laser diode are

monitored using a calibrated resistor together with a

voltmeter. Photodiodes are used to measure the

optical intensity. They are referenced to a

commercial power measurement head. An optical

imaging system is used to observe both, the near-

field intensity distribution of the emitter facet and

the far-field intensity distribution. A spectrometer

takes the spectrum of the laser beam.

This measurement setup is automated as the

quarter wave plate rotation is motorized and the

measured data are collected by data loggers and

software acquisition.

4.2.2 Procedure

The optical feedback beam is adjusted by

manipulating the angle of the reflection mirror. The

electrical and optical behavior of laser diodes with

optical feedback is used to find the optimal

alignment. Details to this behavior are given in

chapter 5.1. Several steps are necessary to optimize

the feedback injected into the laser emitter. First, the

laser diode is operated without the feedback mirror

and the centroid of the near-field intensity

distribution is marked. After adding the feedback

mirror the laser diode is operated below laser

threshold. The mirror angle is varied along slow axis

direction until the signal on the camera reaches its

maximum. This step uses the threshold reduction

effect due to optical feedback. In fast axis direction

the mirror is tilted until the intensity distribution

reaches the before marked position. Now the

threshold reduction current value can be determined.

Due to temperature expansion a slight

PHOTOPTICS2015-DoctoralConsortium

48

readjustment is necessary at the working point. At

high operation currents a lower feedback level has to

be chosen to avoid damage to the laser diode. The

spectrum is used as an indicator of maximal

feedback injection, as the wavelength rises with

higher feedback.

Depending on the test scenario the load of the

laser diode starts minimal and is than raised until

device failure. The load is controlled either by the

feedback intensity or the operation current.

4.3 Long Term Tests

Industrial field experience has shown that optical

feedback may lead to reduced lifetime of laser

diodes. Devices with an initially stable operation

condition may fail with time delay. This

presumption is analysed by the following long term

test.

4.3.1 Test Setup

Twenty-four devices of batch C are used in this long

term test. Each was collimated in both axis and then

applied to a reflective element. The transmitted

radiation was absorbed by a beam dump. The

devices were split up into four groups equipped with

different feedback levels. The reflective elements

were a 20 % VBG, a 10 % VBG and a plate with

8,2 % broadband feedback, respectively. One group

was used as reference without optical feedback.

Every laser diode is monitored by a photodiode

and the data recorded by a logger.

4.3.2 Procedure

All laser diodes are operated at their working point

(I = 55 A). Optical output power and spectra of each

laser diode are measured frequently and the emitters

are inspected if a COD occurred. The test is

cancelled when several laser diodes have damaged

emitters.

5 RESULTS & ANALYSIS

5.1 General Behavior Due to Optical

Feedback

This chapter shows the influence of optical feedback

to the optical and electrical properties of laser

diodes. These properties indicate how much of the

feedback is coupled back into the emitter. Basing on

this information the alignment of the feedback

mirror is evaluated.

5.1.1 Results

The laser threshold current is reduced due to optical

feedback. 808 nm bars (batch A) have a typical laser

threshold of 7,15 A (standard deviation σ = 0,23 A)

which is reduced to 4,56 A (σ = 0,38 A) with optical

feedback. The laser threshold current of 980 nm bars

of batch B without feedback is 4,38 A (σ = 0,21 A)

and is reduced to 2,98 A (σ = 0,10 A) with feedback.

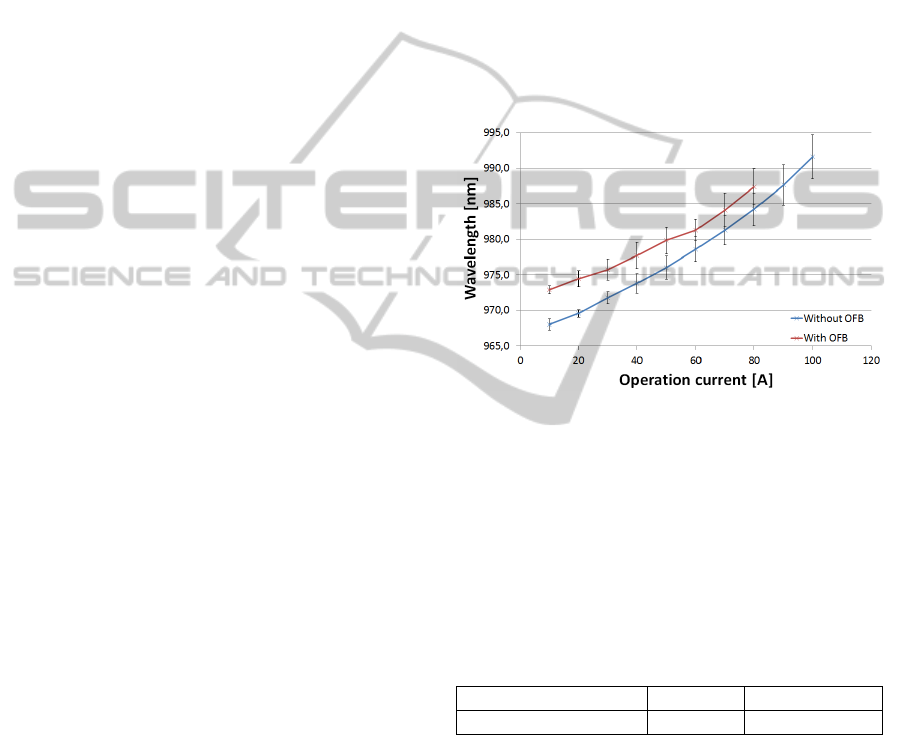

The wavelength of the emitted radiation shifts to

longer wavelengths when the feedback intensity

rises. In Figure 2 the wavelength depended of optical

feedback at different operation currents is compared.

Figure 2: Central wavelength with and without optical

feedback of laser diodes of batch B.

The operation voltage of the laser diode

decreases with optical feedback intensity. As the

emitters of the laser bar are parallel operated this

effect occurs more intensive when all emitters are

exposure to optical feedback. Depending on the

intensity the operation voltage can be lowered to the

values given in Table 2.

Table 2: Voltage reduction by optical feedback.

Batch A B & C

Voltage reduction 14 mV 8 mV

5.1.2 Discussion

The presented values are only given at a qualitative

level of optical intensity. Future presentation will be

able to give them in context of a quantitative

feedback level injected into the laser diode emitters.

This will be possible as a result of the calculations

and beam simulations introduced in chapter 5.4.

The laser threshold current has a strong

dependence to the intensity of optical feedback. It

has a high suitability as a criterion of how well the

HighPowerLaserDiodeswithOpticalFeedback-ContributiontoDoctoralConsortium

49

feedback mirror is aligned. The physical background

of laser threshold reduction can be explained by the

Kobayashi-Lang rate equations, which are not

subject of this survey (Kobayashi and Lang, 1980).

It can be shown that the feedback mirror operates as

an external resonator and has an influence of the

electron-photon transition of the semiconductor.

The wavelength rises with higher amount of

optical feedback. This effect can be caused by a

raising temperature, which would affect a higher

band gap of the electron transition. The

semiconductor temperature rises due to absorption

of the feedback radiation, which doesn´t fulfil the

resonator condition.

Operation voltage reduction is observed with

increased optical feedback. This effect might be also

a result of the temperature change of the

semiconductor bulk. There are several sources

reporting of the temperature dependence of the

semiconductor voltage. There are applications using

this method as a thermal detector (Ryu, 2005).

For this work it is most important that a

significant dependence of the optical feedback

intensity to the laser threshold current, wavelength

and operation voltage could be shown. Therefor

these parameters can be used to evaluate the quality

of the feedback beam alignment.

5.2 Detection of Failure Threshold

5.2.1 Results

Laser diodes of batch A are operated at nominal

current of 50 A. The feedback intensity is raised

until COD occurs. This measurement is performed

for single emitters which are isolated with slit blades

and whole bars. The mean value and standard

deviation of this series are given in Table 3. The

OFB power is calculated from the device optical

output power reduced by the power ejected by the

polarization optics.

Table 3: Optical feedback power at device failure of laser

diodes of batch A.

OFB

power

Standard

deviation

Isolated Emitter 1,3 W 0,15 W

Whole bar 0,8 W 0,09 W

When testing laser diodes of batch B raising the

optical feedback intensity doesn´t compulsory lead

to COD. Instead, the operation current is raised in

10 A steps until device failure. The test has been

performed for isolated emitters, 3-emitter-packs and

whole bars. The current values causing a COD are

given in Table 4.

Table 4: Operation current at device failure of laser diodes

of batch B.

Current at

COD

Standard

deviation

Isolated Emitter 92 A 3 A

Neighbored emitter 70 A 2,8 A

Whole bar 60 A 2,7 A

During determination of device failure threshold

also spectra of the laser beam are taken. Figure 4

Error! Reference source not found. shows the

spectrum of an isolated emitter of batch A. The

optical feedback power is varied. Two points are

noticeable: First, at 0,4 W feedback power there is a

significant change of the spectrum. Second, above

1,1 W the spectrum series ends; this is due to COD.

Simultaneously the near field distribution is

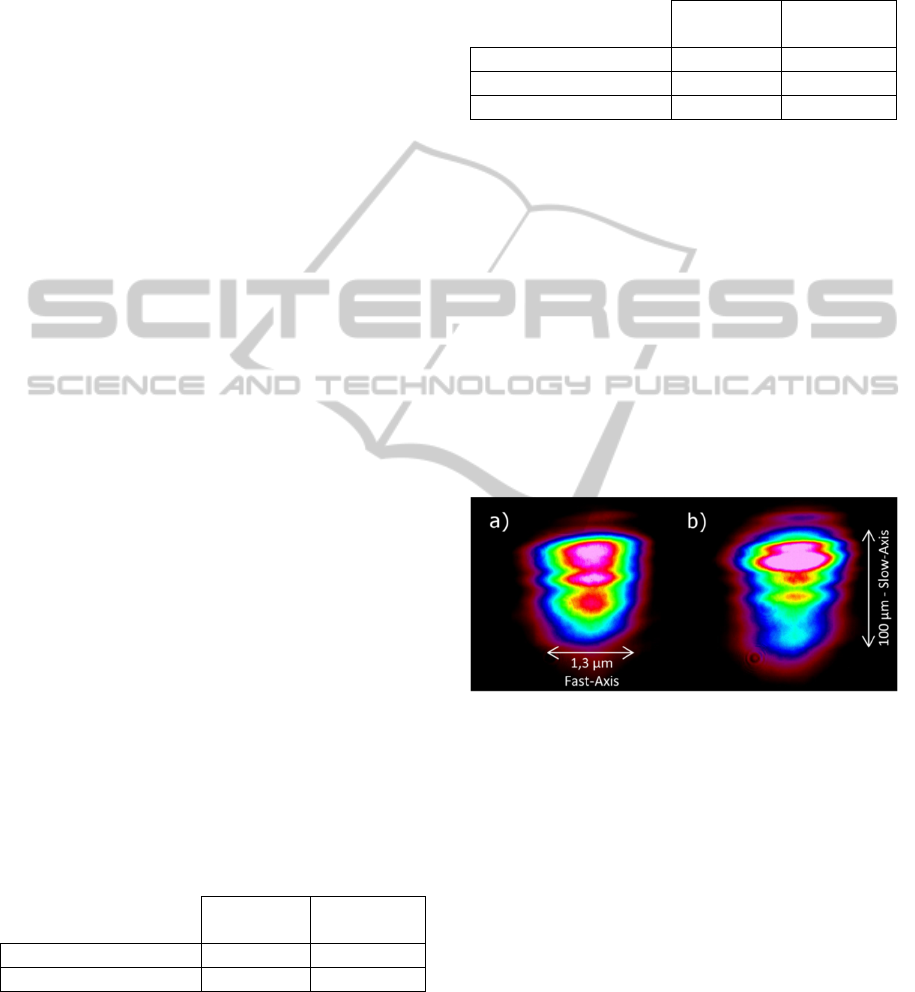

captured. In Figure 3 two shots are compared: one at

a feedback power below 1,1 W leading to the change

in the spectrum and one above. The spots with the

highest intensity moved and the size of the spot is

larger. This shows that the near field distribution

changed at the same moment as the spectrum.

Figure 3: Near field distribution a) before and b) after

change in spectrum.

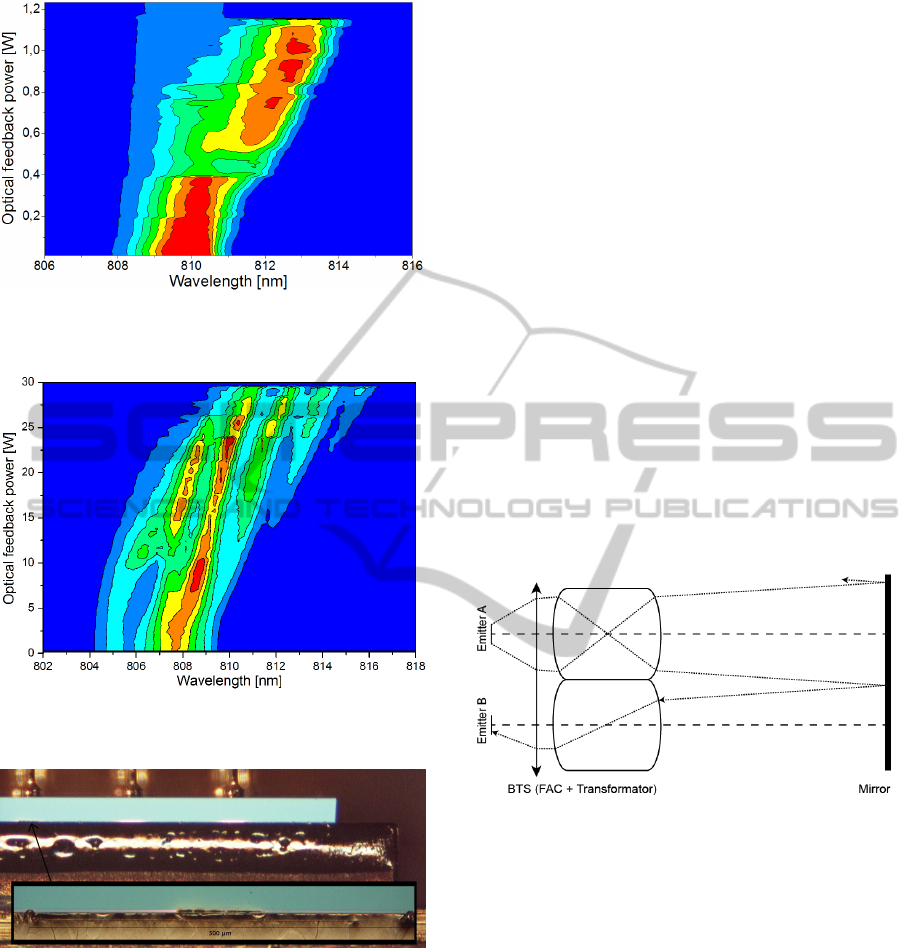

In the next step the spectrum of a whole bar

(batch A) is observed. The feedback is applied to all

emitters at the same time. The contribution of the

different emitters to the spectrum and their variation

due to optical feedback is illustrated in Figure 5.

After finishing the COD threshold measurement

the laser diodes are examined with a light

microscope. Figure 6 shows a typical front facet of a

laser diode with COMD. The blue-green colored

part represents semiconductor. In the bottom part of

the figure the heat sink is visible. As the device was

operated in LED operation mode the violet stripe

represents the remaining radiation generated by the

emitter.

PHOTOPTICS2015-DoctoralConsortium

50

Figure 4: Spectrum shift by feedback intensity variation in

case of an isolated emitter.

Figure 5: Spectrum of whole bar of batch A with varied

optical feedback intensity.

Figure 6: Light-microscope picture of facet with COMD.

The violet area is radiation from LED operation mode of

the laser diode.

5.2.2 Discussion

The measurements prove the expectation that

devices of batch A are less robust against optical

feedback than devices of batch B. The value named

OFB power is the power generally reflected towards

the emitter. It is not equal to the power injected into

the emitter because losses at optical elements have

to be taken in account. This value will be calculated

in future.

The failure threshold is higher in case of an

isolated emitter compared with several emitters with

optical feedback. First, this can be due to a higher

thermal load of the semiconductor when several

emitters are applied of optical feedback. The

radiation is partly absorbed in the bulk material and

heats up. The higher temperature can increase the

risk of COD.

Second, the emitters are subject of direct

radiation from other emitters. All emitters are

collimated by the same FAC lens, but each emitter

has its own lens array element of the beam

transformer (compare Figure 7). The beam has a

remaining divergence after collimation and the beam

expands by propagation. The returning beam can be

larger than the lens array aperture. The part of the

beam which doesn´t fit through its array element is

then coupled to the beam path of the neighbored

emitter. On this way it is finally coupled into that

emitter. That means that an emitter of a laser bar has

a higher optical load due to the optical feedback of

its neighbored emitters.

Figure 7: The beam emitter from Emitter A expands due to

its remaining divergence. After reflection the beam can hit

on the transformator array segment of the emitter B.

The laser diode has several optical properties. It

could be shown that these correspond to each other.

Changes in the spectrum lead to changes in the near

field distribution. Intensity peaks in the near field

distribution are observed to be the origin of COD.

The position of these intensity peaks might be at the

same position of the defects visible on the front facet

investigated by light microscopy after COD.

5.3 Long Term Behaviour

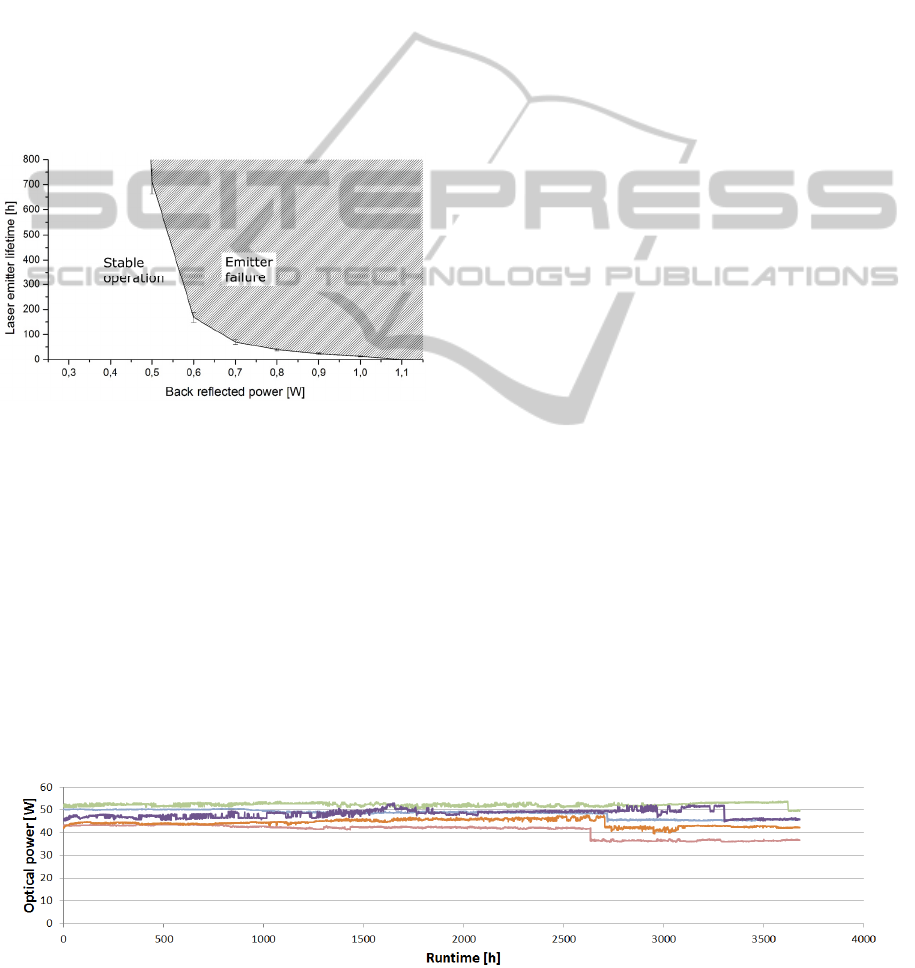

5.3.1 Test Results

Optical feedback has the ability to damage a laser

diode instantly. This damage threshold can be

HighPowerLaserDiodeswithOpticalFeedback-ContributiontoDoctoralConsortium

51

determined as shown before. When a laser diode is

operated below this damage threshold this doesn´t

correspond to a stable operation mode. The COD

can occur time-delayed.

To demonstrate this behaviour each one emitter

per test procedure is isolated. The optical feedback

intensity is variable and set to a value below instant

COD threshold. The time to COD is measured and

the mean values are shown in Figure 8. At feedback

levels close to the instant COD threshold the emitter

lifetime is very short and lasts between several hours

to several days. When the optical feedback intensity

is lowered further the lifetime is significantly higher.

The measurement point with the longest lifetime

before COD was at half the instant COD threshold

and ran for about 700 hours.

Figure 8: Runtime until device failure dependent on

optical feedback intensity. In this chart measurement

series of laser diode batch A are presented.

Another scenario operates with a far lower

feedback, which is instead applied for a longer time

period. This scenario has been examined by a long

term test using laser diodes of batch C. Figure 9

shows the optical power of five of 28 during the

whole test. At these five devices a COD of one

emitter occurred. Three of the failure laser diodes

were equipped with a 20 % VBG, while two had a

8,2 % broad band feedback. The first device failure

happened after 2700 hours of operation, the test has

been cancelled after 3700 hours.

One of the laser diodes has been inspected by

spectroscopic methods in advance. In cooperation

with the team around Dr. Tomm of the Max Born

Institute Berlin the bar was observed by laser beam

induced current (LBIC) procedure. This can show

defects present inside or on the surface of the

semiconductor (Fang, 1992). One emitter of a bar

indicated defects inside the bulk material. During the

test exactly this emitter failure.

5.3.2 Discussion

In further steps an appropriate model is developed to

describe this behaviour. The “Weibull”-distribution

might be suitable to fit the measurement results. It is

commonly used for reliability analysis and

description of failure probability (Ohring, 1998).

Moreover there are studies about lifetime reduction

of laser diode systems, which are subject to other

stress factors, like cooling temperature or operation

current increase. If device failure behaves similar in

both cases, optical feedback and other stress factors,

the same physical reason for COD might be

responsible.

The long term test shows that even feedback

rates of commonly used optical elements can reduce

the lifetime of laser diodes drastically. It is not yet

shown why two laser diodes with lower feedback

had COD. There might be a difference between

narrow and broad band feedback.

An interesting result is that the emitter with

defects showed COD during he test. It can be an

indication that device failure occurs preferable at

emitters with existing defect cells. To provide more

data another test run with laser diodes inspected by

the LBIC procedure is currently in preparation.

5.4 Describing Model

5.4.1 Optical System Modelling

The amount of optical feedback reaching the laser

diodes facet can be calculated. Therefore the

Figure 9: Optical power trends of five laser diodes operated in the long term test. Three with 20 % VBG and two with 8,2 %

broad band feedback. The drop in each trend indicates the moment of emitter failure.

PHOTOPTICS2015-DoctoralConsortium

52

components of a laser diode system have to be

described individually. The optical components

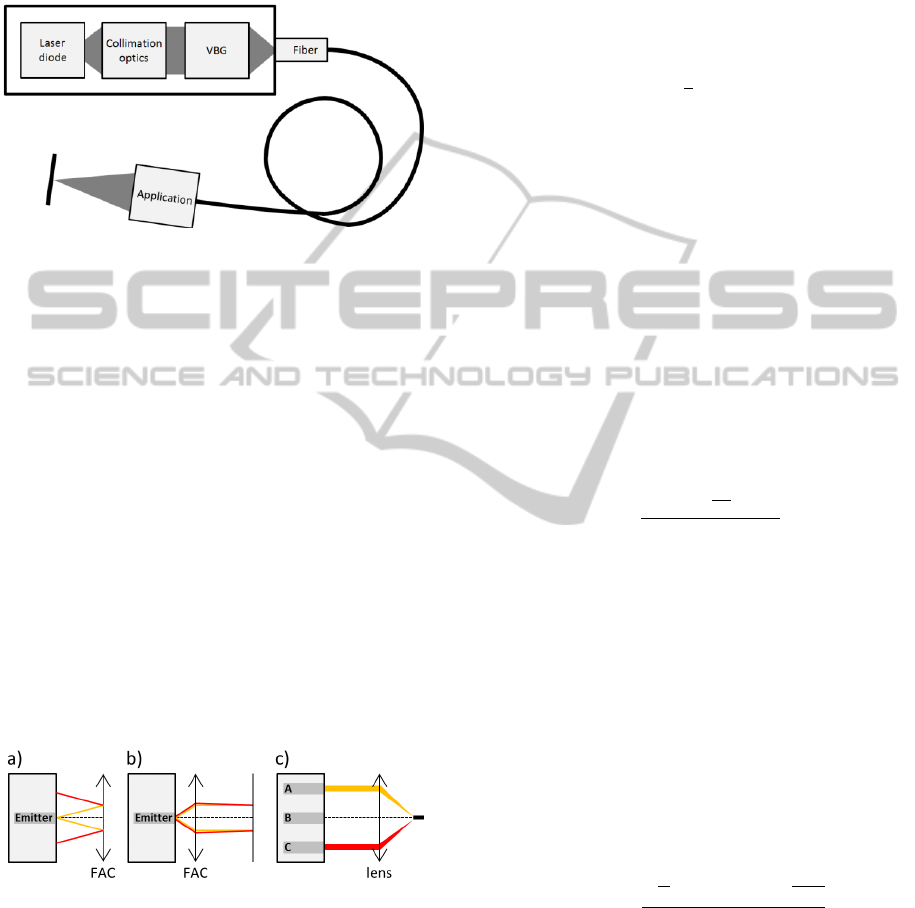

shown in Figure 10 are typical for high power laser

diode systems. However, VBG and fiber coupling

are optional and depend on the application needs.

Figure 10: Typical elements of an optical system relevant

for amount of optical feedback.

The optical elements can be divided into three

main groups and their belonging beam paths are

drafted in Figure 11. a) Collimation optics. The

divergent laser beam and hits on the fast axis

collimation (FAC) lens. Commonly the first flat

surface has a distance of only 70 to 150 µm to the

emitter. The light is reflected divergent and only a

small part is reflected into the emitter. b) Selective

optics. The beam is collimated and hits a plane

surface, where it is partly reflected. As the reflected

beam is collimated it can be transmitted over long

distances inside the optical system. c) Focusing

optics. The beam is focused on the plane surface of

an optical element like a light guiding fiber. This

case is interesting, when observing a multi emitter

bar. Each emitter beam path is mirrored and reversed

and ends finally at an emitter opposite of the original

one. Here a strong coupling between each two

emitters can be observed.

Figure 11: Three groups of optical elements contributing

to the amount of optical feedback: a) collimation optics, b)

selective optics and c) focusing optics. Yellow lines

represent forward beams, red illustrates reflected beams.

The optical power reaching the laser diodes facet

is calculated by the emitter output power

the reflectance R of the reflective element and

the transmission efficiency of the optical system.

P

P

(1)

While

and R can be measured has to be

calculated. describes how much of the angular and

the spatial intensity distribution of a laser diode

emitter is transmitted through the optical system. As

the intensity distribution of an emitter is not

homogenous it is approximated by a super Gaussian

distribution.

(2)

This is valid for spatial and angular distribution

by picking according parameters. σ represents the

half width or angle of radiation at 1/e² intensity,

respectively. The SG value is used to fit the

Gaussian distribution to the measured intensity

distribution.

is used to set the result to 1, when the

integral over the whole range is calculated.

The constraints of the integral depend on the

individual optical component. Depending on the

number of variables equation 2 has to be integrated

in both spatial and both angular directions.

FAC Reflection (Figure 11a): Beams emitted

from the facet from one point are reflected back into

the active region by fulfilling these upper and lower

angular constraints:

,

tan

2

2

(3)

By changing emitter height h

E

to width w

E

and

emitting point position y

E

to x

E

the integration

constraints in slow axis direction are given.

Additionally this has to be integrated spatially in x

and y direction.

FAC aperture (Figure 11b): Due to remaining

divergence the beam size increases after collimation.

When reflected through the optical system it can be

cut of at the aperture of the optical elements.

Especially the FAC lens has typically a small

aperture A. The integration constraints of equation 2

are given by the distance d between FAC lens and

reflective element and focal length f:

,

tan

2

2tan

(4)

In this case only the fast axis direction has

influence to the transmission efficiency and has to

be integrated angular and spatial.

Smile: Induced through mechanical stress by

soldering a laser chip onto a heat sink the center of

an emitter has an offset ∆ to the optical axis. The

angular distribution is not relevant in this case. Here

HighPowerLaserDiodeswithOpticalFeedback-ContributiontoDoctoralConsortium

53

the spatial integration constraints are modified.

,

∆

(5)

On this way the influence of all optical

components to the total amount of optical feedback

reaching the emitter can be described.

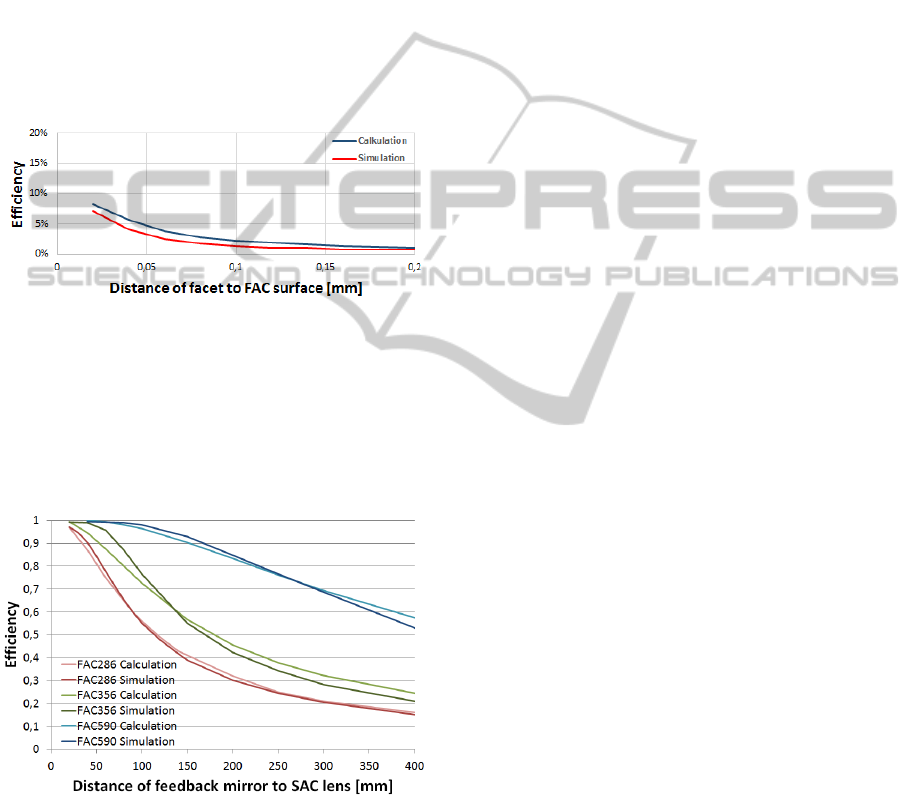

5.4.2 Validation & Discussion

For validation these equations were calculated with

the parameters of typically optical components and

simulated with the optical design software ZEMAX.

Figure 12 shows the results of the equation 2

with the constraints of equation 3 compared with the

simulation of light reflected at the FAC lens surface.

Figure 12: Efficiency of the transmission of the reflected

beam through the FAC lens aperture.

This has also been done for equations 2 and 4

describing the beam cut off due to exceed of lens

aperture. Several FAC lens types are used. The

comparison of calculated and simulated values is

plotted in Figure 13.

Figure 13: Efficiency of the transmission of the reflected

beam through the FAC lens aperture.

Both figures show a good agreement of

calculation and simulation.

In a future step measurement data will be added

to these plots.

6 STAGE OF THE RESEARCH

The experimental work of this research project has

proceeded to final stage. Measurement series with

different devices are completed. Defect threshold of

isolated bars and multiple emitters are determined.

Additionally a long term test in cooperation with the

MBI Berlin is in preparation. In the next stage the

observed effects of optical feedback to the laser

diode properties are compared and described by

physical theory. To calculate the optical power

injected into the laser diode emitters a

comprehensive optical model will be elaborated.

This will finally describe the coupling efficiency of

the reflected light. Within the next months parts of

the presented work will be published in peer-

reviewed journals.

Based on the results of this work LIMO will be

capable to integrate protection devices into laser

diode systems. For this purpose knowledge of the

damage threshold of the used laser diodes, influence

of the optical components and application are

necessary. This information will be derived from the

next stage research and lead to a reliable operation

of high power laser diode systems.

REFERENCES

Dowley, M., 1998. Diode Pumped Solid State (DPSS)

Lasers: Applications and Issues. Optical Society of

America.

Fang, W., Ito K., 1992. Identifiability of Semiconductor

Defects from LBIC Images. SIAM J. Appl. Math.,

52(6), 1611–1626.

Kaminow, I., Li, T., Willner, E., 2013. Optical Fiber

Telecommunications Volume VIA: Components and

Subsystems. Academic Press.

Kobayashi, K., Lang, R., 1980. External optical feedback

effects on semiconductor injection laser properties.

IEEE J. Quantum Electron 16, 347-355.

Steen, W., Mazumder, J., 2010. Laser Material

Processing. Springer.

Ohtsubo, J., 2010. Semiconductor Lasers: Stability,

Instability and Chaos. Springer.

Ohring, M., 1998. Reliability and Failure of Electronic

Materials and Devices. Academic Press.

Ryu, H., et. al., 2005. Measurement of junction

temperature in GaN-based laser diodes using voltage-

temperature characteristics. Applied physics letters

87, 093506.

PHOTOPTICS2015-DoctoralConsortium

54