Building Multi-Robot System based on Five Capabilities Model

Atef Gharbi

1

, Dhouha Ben Noureddine

2

and Nadhir Ben Halima

3

1

National Institute of Applied Sciences and Technology, Tunis, Tunisia

2

Faculty of Science of Tunis, Tunis, Tunisia

3

College of Computer Science and Engineering, Taibah University - Yanbu Branch, Yanbu Al-Bahr, Saudi Arabia

Keywords:

Multi-Robot Systems, Five Capabilities Model, Distributed Planning, Benchmark Production System.

Abstract:

Multi-Robot System (MRS) is considered as a particular form of Multi Agent System (MAS) by specifically

addressing planning and social abilities. The design of autonomous robots includes the design of team be-

haviors constituted by several intelligent agents each one has to interact with the other autonomous robots.

The problem faced is how to ensure a distributed planning through the cooperation of the distributed robotic

agents. To do so, we propose to use the conept of five capabilities model which is based on Environment, Self,

Planner, Competence and Communication. We illustrate our line of thought with a Benchmark Production

System used as a running example to explain our contribution.

1 INTRODUCTION

With Multi-Robot System (MRS), we face two im-

portant matters: (i) the detection of a need for action:

the need for action must be discovered by supervis-

ing the application and its environment and analyz-

ing data obtained. (ii) the planning of the action: it

consists to envisage the action (by proposing which

modifications need to be made) and by programming

it.

Using a multi-agent approach, the robot archi-

tecture can be decomposed into flexible autonomous

subsystems (agents). The architecture can then be de-

scribed at a higher level, defining the agents that have

to be in the system, the role of each of them, the in-

teractions among them, the actions each of them per-

forms, and the resources they need. Since the multi-

agent system is inherently multi-threaded, each agent

has its own thread of control; each agent decides

whether or not to perform an action at the request

of another agent (autonomy); agents establish agree-

ments among themselves, while keeping their auton-

omy sharing their knowledge and acting together to

accomplish specific common goals. Agents need to

interact to coordinate their activities so that control

of the robot is achieved. All of those processes, the

agent’s own decision making, interaction and coordi-

nation need to be highlighted. To do so, we propose

the design of a Robotic Agent according to the 5 Ca-

pabilities model (5C) proposed by (van Aart, 2004),

(C. J. van Aart and Schreiber, 2004). The 5 Capabil-

ities model is separated into five dimensions: Envi-

ronment, Self, Planning, Competence and Communi-

cation. These dimensions are said models where each

model represents one specific capability of the robotic

agent. First of all, a robotic agent needs to interact

with the environment in which it operates thanks to

sensors (providing data) and actuators (executing ac-

tions) therefore we define the Environment Model. To

know what tasks to be executed, we define the Self

Model. The self model is used to know the robotic

agent’s perception of its own being and state. In other

terms, it consists of ongoing tasks. The planning of

ongoing tasks is the concern of the Planner Model.

A planner model is ensuring some kind of reasoning

about task selection, execution control, time monitor-

ing and emergency handling.

The Competence Model ensures the methods the

abilities and the knowledge that enables the robotic

agent to execute the task that is designed for it. The

multi-robot system has the appropriate Communica-

tion Model in order to avoid non-feasible, unsecured

and fortuitousactions that can provokeundesirable re-

sults by a single robot for the whole system, the differ-

ent robotic agents have to interact together following

a specific communication protocol.

This paper introduces a simple Benchmark Pro-

duction System that will be used throughout this ar-

ticle to illustrate our contribution which is devel-

opped as Robot-based application. We implement

270

Gharbi A., Ben Noureddine D. and Ben Halima N..

Building Multi-Robot System based on Five Capabilities Model.

DOI: 10.5220/0005465002700275

In Proceedings of the 10th International Conference on Evaluation of Novel Approaches to Software Engineering (ENASE-2015), pages 270-275

ISBN: 978-989-758-100-7

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

the Benchmark Production System in a free plat-

form which is JADE (JavaTM Agent DEvelopment)

Framework. JADE is a platform to develop multi-

agent systems in compliance with the FIPA speci-

fications (Salvatore Vitabile, 2009), (Chuan-Jun Su,

2011), (Bordini and all., 2006).

In the next section, we present the Benchmark

Production System. The third section introduces the

Environment Model by specifying the sensors, the ac-

tuators and the safety requirements. The fourth sec-

tion presents the Self Model which describes the dif-

ferent tasks to be executed by the robotic agent with

a formal specification. We introduce in the fifth sec-

tion the Planner Model. The sixth section presents

the Competence Model based on Fuzzy Logic Sys-

tem. Finally, we study the Communication Model in

particular the message exchanged through a commu-

nication protocol. We conclude in the last section.

2 BENCHMARK PRODUCTION

SYSTEM

As much as possible, we will illustrate our contri-

bution with a simple current example called RARM

(Branislav Hrz, 2007). We begin with the description

of it informally, but it will serve as an example for var-

ious formalism presented in this article. The bench-

mark production system RARM represented in the fig-

ure 1 is composed of two input and one output con-

veyors, a servicing robot and a processing-assembling

center. Workpieces to be treated come irregularly one

by one. The workpieces of type A are delivered via

conveyor C1 and workpieces of the type B via the

conveyorC2. Only one workpiece can be on the input

conveyor. A robot R transfers workpieces one after

another to the processing center. The next workpiece

can be put on the input conveyor when it has been

emptied by the robot. The technology of production

requires that first one A-workpiece is inserted into the

center M and treated, then a B-workpiece is added

in the center, and last the two workpieces are assem-

bled. Afterwards, the assembled product is taken by

the robot and put above the C3 conveyer of output.

the assembled product can be transferred on C3 only

when the output conveyor is empty and ready to re-

ceive the next one produced.

We model the individual robot systems as distributed

agents that deal autonomously with both local task

planning and with conflicts that occur due to the pres-

ence of other robotic agents. The overall behavior

of the RARM as a whole is then an emerging func-

tionality of the individual skills of and the interaction

among the forklifts.

A

Conveyor C1

A

B

C

o

n

v

e

y

o

r

C

3

B

Conveyor C2

Position p1

Position p2

Position p3 Position p4

P

osit

io

n

p

5

P

o

sitio

n

p6

Robot r

Processing unit

M

Figure 1: The benchmark production system RARM.

3 ENVIRONMENT MODEL

Perception is responsible for collecting runtime infor-

mation from the virtual environment. The perception

component supports selective perception, enabling a

robotic agent to direct its perception to its current

tasks. The perception component interprets the rep-

resentation resulting in a percept. A percept consists

of data elements that can be used to update the robotic

agent’s current knowledge.

3.1 Actuators

The system can be controlled using the following ac-

tuators: (i) movethe conveyorC1 (act1); (ii) move the

conveyorC2 (act2); (iii) move the conveyorC3 (act3);

(iv) rotate robotic agent (act4); (v) move elevating the

robotic agent arm vertically (act5); (vi) pick up and

drop a piece with the robotic agent arm (act6); (vii)

treat the workpiece (act7); (viii) assembly two pieces

(act8).

3.2 Sensors

The control program receives information from the

sensors as follows: (i) Is there a workpiece of type A

at the extreme end of the position p1? (sens1) (ii) Is

the conveyor C1 in its extreme left position? (sens2)

(iii) Is the conveyor C1 in its extreme right position?

(sens3) (iv) Is there a workpiece of type A at the pro-

cessing unit M? (sens4) (vi) Is the conveyorC2 in its

extreme left position? (sens5) (vii) Is the conveyorC2

in its extreme right position? (sens6) (viii) Is there a

workpiece of type B at the extreme end of the posi-

tion p3? (sens7) (ix) Is there a workpiece of type B at

BuildingMulti-RobotSystembasedonFiveCapabilitiesModel

271

the processing unit M? (sens8) (x) Is the conveyorC3

in its extreme left position? (sens9) (xi) Is the con-

veyor C3 in its extreme right position? (sens10) (xii)

Is there a workpiece of type AB at the processing unit

M? (sens11) (xiii) Is the robotic agent arm in its lower

position? (sens12) (xiv) Is the robotic agent arm in its

upper position? (sens13)

4 SELF MODEL

We represent the Self Model of a robotic agent with a

formal specification which is Petri Net.

To simlify the representation, we take in considera-

tion only the treatment of a workpiece A (i.e. the

transfer of a piece A by the robotic agent, the pro-

cessing with the unit M and finally the transfer to

the output). Let the circles in Figure 2 denoted by

p

1

, p

2

, p

5

and p

7

correspond to four subsystems as

follows: input conveyor (p

1

), robot (p

2

) , processing

unit (p

5

) and output conveyor (p

7

). Let the other cir-

cles correspond to the following operations: transfer

of a workpiece into the processing unit by means of

the robotic agent (p

3

), treating operation (p

4

), transfer

of the treated workpiece on the output conveyor (p

6

).

The circles are called places of Petri nets. The pres-

ence or availability of a workpiece at the cell input is

modeled by a dot in place p

1

. We say that a token

is in p

1

. Analogously, a token in p

2

means that the

robotic agent is free or available to transfer a work-

piece. A vertical bar denoted as t

1

is called a tran-

sition. It symbolizes an event. In this case, it is the

start of the transfer operation. Transition t

2

represents

the end of the transfer and start of the treating opera-

tion. Clearly, realization of this event requires that the

transfer has been performed and the processing unit is

available. t

3

denotes the end of the treating and start

of the workpiece transfer on the output conveyor; t

4

is the end of the output transfer and arrival of a work-

piece on the output conveyor. The token distribution

describes an actual state of the system. It changes

through a so-called transition firing. A transition fir-

ing is possible if all places before this transition have

enough tokens the transition is said to be enabled. Fir-

ing has the following effect: one token is taken from

all places before the transition and one token is placed

into each place located after the transition. The effect

complies with the so-called firing rules just described.

According to Figure 2 both conditions are met for a

workpiece transfer. The next system state: the robotic

agent moves the workpiece from the input conveyor

into the processing unit.

P1

P3 P4 P6

t1 t2

t3 t4

P2

P7

P5

Figure 2: Petri Net of processing workpiece A.

5 PLANNER MODEL

Distributed planning is considered as a very complex

task (David Jung, 1999), (Oscar Sapena, 2008). In

fact, distributed planning ensures how the multi-robot

system should plan to work together, to decompose

the problems into subproblems, to assign these sub-

problems, to exchange the solutions of subproblem,

and to synthesize the whole solution which itself is

a problem that the robotic agents must solve (Sergio

Pajares Ferrando, 2013), (Pascal Forget, 2008), (Ma-

lik Ghallab, 2014).

The conceptual model of a robotic agent is constituted

by three components including (i) the planner, (ii) the

plan-execution agent, and (iii) the world in which the

plans are to be executed (the formal representation is

based on the work (Malik Ghallab, 2004)).

The planner’s input includes descriptions of the state

transition system denoted by Σ, the initial state(s) that

Σ might be in before the plan-execution robotic agent

performs any actions, and the desired objectives (e.g.,

to reach a set of states that satisfies a given goal con-

dition, or to perform a specified task, or a set of states

that the world should be kept in or kept out of, or a

partially ordered set of states that we might want the

world to go through). If the planning is being done

online (i.e., if planning and plan execution are going

on at the same time), the planner’s input will also in-

clude feedback about the current execution status of

the plan or policy. The planner’s output consists of ei-

ther a plan (a linear sequence of actions for the robotic

agent to perform) or a policy (a set of state-action

pairs with at most one action for each state).

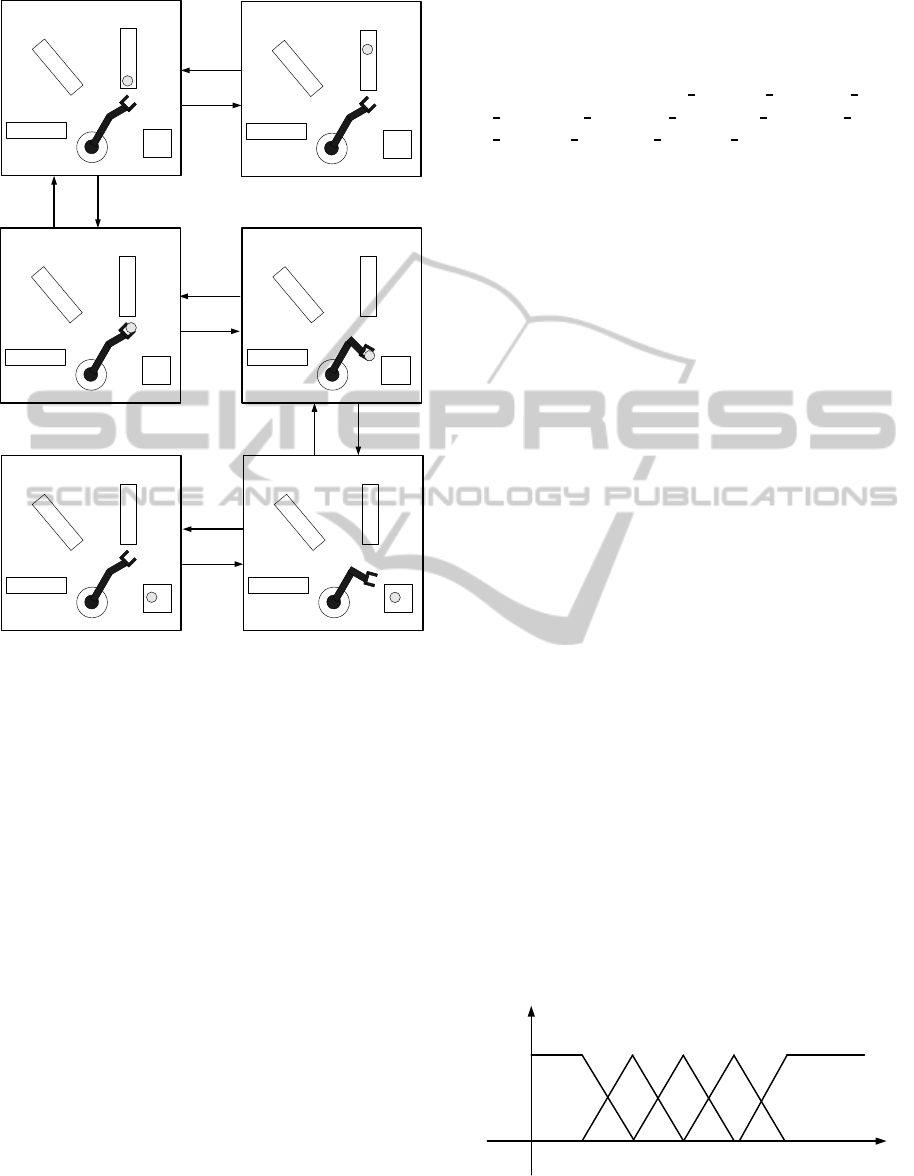

Running Example

According to figure 3:

• A set of positions {p

1

, p

2

,...} : A position is used

to localise the workpiece A, B or AB;

• A set of robotic agents {r

1

, r

2

, ...} : Each robotic

agent transfers a workpiece one after one to be

processed;

• A set of workpieces of type A {a

1

,a

2

, ...};

• A set of workpieces of type B {b

1

,b

2

, ...};

• A set of workpieces of type AB {ab

1

,ab

2

, ...};

ENASE2015-10thInternationalConferenceonEvaluationofNovelSoftwareApproachestoSoftwareEngineering

272

A Position

p1

Position

p2

Robot r

Processing

unit M

S

0

C1_right

C1_left

take1 put1

A

Conveyor

C1

C

o

n

v

e

y

o

r

C

3

Conveyor

C2

Position

p1

Position

p2

Robot r

Processing

unit M

S

1

A

Position

p1

Position

p2

Robot r

Processing

unit M

S

3

Position

p1

Position

p2

Robot r

Processing

unit M

A

S

4

Conveyor

C1

C

o

n

v

e

y

o

r

C

3

Conveyor

C2

Conveyor

C2

Conveyor

C2

Conveyor

C1

Conveyor

C1

C

o

n

v

e

y

o

r

C

3

C

o

n

v

e

y

o

r

C

3

A

Conveyor

C1

C

o

n

v

e

y

o

r

C

3

Conveyor

C2

Position

p1

Position

p2

Robot r

Processing

unit M

S

2

R1_left

R1_right

take1put1

Conveyor

C1

C

o

n

v

e

y

o

r

C

3

Conveyor

C2

Position

p1

Position

p2

Robot r

Processing

unit M

A

S

5

R1_right

R1_left

Figure 3: The first state-transition for RARM.

• A set of conveyors {C

1i

, C

2i

, C

3i

} : A conveyor C

1i

(resp. C

2i

, C

3i

) is responsible for transfering set of

workpieces of type A (resp B, AB);

• A set of processing Centers M {M

1

, M

2

,...} : first

one A-workpiece is inserted into M and processed,

then one B-workpiece is added into the center M,

and last both workpieces are assembled.

The set of states is {s

0

, s

1

, s

2

, s

3

, s

4

, s

5

, s

6

, s

7

, s

8

, s

9

,

s

10

, s

11

, s

12

, s

13

, s

14

, s

15

, s

16

}

There are nine possible actions in the domain.

• a workpiece of type A is trasnported to the left

from position p1 to position p2;

• the robotic agent transports a workpiece of type

A;

• the piece is put in the processing unit M;

• a workpiece of type B is trasnported to the left

from position p3 to position p4;

• the robotic agent transports a workpiece of type

B;

• the piece is put in the processing unit M;

• the robotic agent picks up the assembled piece;

• the assembled piece is put on the conveyor C3;

• a workpiece of type AB is trasnported to the right

from position p5 to position p6.

The set of actions is {C1

le ft, C1 right, R1 left,

R1

right, C2 left, C2 right, R2 le ft, R2 right,

C3 left, C3 right, R3 left, R3 right, take

1

, take

2

,

take

3

, load

1

, load

2

, load

3

, put

1

, put

2

, put

3

, process

1

,

process

2

}

6 COMPETENCE MODEL

The Competence Model of a robotic agent is based on

a Fuzzy Logic Control. This methodology is usually

applied in the only cases when exactitude is not of

the need or high importance (Jianhua Dai, 2013). The

basic form of a fuzzy logic agent consists of (Zadeh,

2008): Input fuzzification, Fuzzy rule base, Inference

engine and Output defuzzification.

Running Example

(i) Fuzzification. The number of defected pieces is

measured through a sensor related to the system. The

range of number of defected pieces varies between 0

to 40, where zero indicates the rate of defected pieces

of A that is null (each piece is well) and 40 indicates

the rate of defected pieces of A is very high.

Now assume that the following domain meta-data val-

ues for these variable, VF = very few, F = few, Md

= medium, Mc = much, VMc = very much. Assume

that the linguistic terms describing the meta-data for

the attributes of entities are: VF = [0,..,10], F =

[5,..,15], Md = [10,..,20], Mc = [15,..,25] and VMc

= [20,..,40].

Based on the metadata value for each attribute the

membership of that attribute to each data classifica-

tion can be calculated. In the Figure 4, triangular and

trapezoidal fuzzy set was used to represent the state

of defected pieces from A classifications (i.e. state of

defected pieces from A classification levels: VF , F,

Md, Mc, VMc whereas state of defected pieces from B

classification levels: F, Md, Mc).

Number of

defected pieces A

VF Md VMc

1

0

Degree of

Membership

F Mc

5 10 252015

Figure 4: Fuzzy State of defected pieces from A.

BuildingMulti-RobotSystembasedonFiveCapabilitiesModel

273

(ii) Rule Engine

We take as example, the first column from the Table 1

:

IF number of defected pieces from A is Very Few and

number of defected pieces from B is Few Then Pro-

duction is High.

IF number of defected pieces from A is Few and num-

ber of defected pieces from B is Few Then Production

is High.

...

Table 1: Fuzzy Control rules for the robotic agent.

A B F Md Mc

VF H H M

F H H M

Md H M L

Mc M L N

VMc M L N

(iii) Defuzzification. Defuzzification is the conver-

sion of a fuzzy quantity to a precise quantity. There

are many methods to calculate it such as Max mem-

bership, Centroid method, Weighted average method,

Mean max membership, Center of sums, Center of

largest area and First (or last) of maxima. Obviously,

the best defuzzification method is context-dependant

(Zadeh, 2008).

7 COMMUNICATION MODEL

Communication is responsible for communicative in-

teractions within a multi-robot system. Message ex-

change enables robotic agents to share information

directly and set up collaborations. The communica-

tion module processes incoming messages and pro-

duces outgoing messages according to well-defined

communication protocols. To do that, we implement

the different robotic agents with the platform JADE

(for more details, we refer to (Fabio Bellifemine,

2010b), (Caire, 2009), (Fabio Bellifemine, 2010a),

(Fabio Bellifemine, 2004)).

Running Example

In the Communication Model, we distinguish two

kinds of participating:

• The Initiator robotic agent (RARM

a

): it is the

robotic agent which starts the communication. In

fact, whenever an event occurs in a specific plant,

the associated robotic agent RARM

a

acts to man-

age it. If it decides to apply a new policy, then it

informs the other robotic agents. It searches the

list of robotic agents, sends a request to apply a

new policy and waits the response from them.

• The robotic Agent (RARM

b

): it is the i

th

agent

that receives a request from Initiator robotic agent

(RARM

a

) for a new policy. Firstly, it checks the

possibility to apply this new policy. If it is possi-

ble, it sends a positive answer. If it is not possible,

it sends a negative answer (see Figure 5).

RARM

a

RARM

b

Search the robotic

agents

*[j:=1..nbR, j <> i] Ask for new policy

* [nbResp = nbR- 1]

refuse

accept

apply the new policy

cancel the new policy

treat the

request

Figure 5: The scenario communication.

Algorithm: RARM

Communicate().

begin

if (requesting==true)

switch (step)

case 0:

RARMagent = searchAgent();

NbRobots = RARMagent.length();

// Send the request to all RARM Agents

for (int j = 1; j <= NbRobots; j++)

if (j ! = i)

msg.addReceiver(RARMagent[j]);

msg.setContent(policy);

msg.setPerformative(REQUEST);

msg.setTime(currentTime());

send(msg);

step++;

break;

case 1:

// Receive all accept/refusals from RARM Agents

reply = receive();

if (reply ! = null)

if (reply.getPerformative() == ACCEPT)

ENASE2015-10thInternationalConferenceonEvaluationofNovelSoftwareApproachestoSoftwareEngineering

274

nbResp++;

if (nbResp == NbRobots-1)

step++;

else

block();

break;

case 2:

// apply the new policy

setPolicy(p);

applyPolicy(p);

step = 0;

break;

end

8 CONCLUSION

The main aim of this paper is how to ensure a dis-

tributed planning in Multi-Robot System composed

of several intelligent autonomous robotic agents able

to take the initiative instead of simply reacting in

response to its environment. Our solution to this

problem is the use of the 5 Capabilities Model (as

it was presented, 5 levels: Environment, Self, Plan-

ner, Competence and Communication). The 5 Ca-

pabilities Model can be easily implemented where

each model is represented with a process collaborat-

ing with the other processes. The 5C Model, based

on the principle of separation of concerns, has the

following interests: (i) The design is general enough

to cope with various kinds of embedded-software ap-

plication (therefore, the 5C Model is uncoupled from

the application); (ii) The robotic agent is represented

through five dimensions where each model is inde-

pendent from the other which permits to change one

without having to change the other.

Our future work is the design of an autonomous

robot integrating cognitive abilities with other capa-

bilities such as locomotion, prehension, and manipu-

lation where each of these robot capabilities involves

different aspects of intelligence, and different intelli-

gent tools have to be used consistently to implement

them.

REFERENCES

Bordini, R. and all. (2006). A survey of programming lan-

guages and platforms for multi-agent systems. Infor-

matica, 30(1):33–44.

Branislav Hrz, M. Z. (2007). Modeling and control of

discrete-event dynamic systems with petri nets and

other tools. page 67.

C. J. van Aart, B. J. W. and Schreiber, A. T. (2004). Or-

ganizational building blocks for design of distributed

intelligent system. International Journal of Human-

Computer Studies, 61(5):567599.

Caire, G. (2009). JADE TUTORIAL : JADE PROGRAM-

MING FOR BEGINNERS.

Chuan-Jun Su, C.-Y. W. (2011). Jade implemented mo-

bile multi-agent based, distributed information plat-

form for pervasive health care monitoring. Applied

Soft Computing, 11(1):315–325.

David Jung, A. Z. (1999). An architecture for dis-

tributed cooperative planning in a behaviour-based

multi-robot system. Robotics and Autonomous Sys-

tems, 26(23):149–174.

Fabio Bellifemine, Giovanni Caire, D. G. (2004). Develop-

ing Multi-Agent Systems with JADE.

Fabio Bellifemine, Giovanni Caire, T. T. G. R. (2010a).

JADE PROGRAMMERS GUIDE.

Fabio Bellifemine, Giovanni Caire, T. T. G. R. R. M.

(2010b). JADE ADMINISTRATORS GUIDE. The

publishing company.

Jianhua Dai, H. T. (2013). Fuzzy rough set model for set-

valued data. Fuzzy Sets and Systems, 229(3):54–68.

Malik Ghallab, Dana Nau, P. T. (2004). Automated Plan-

ning.

Malik Ghallab, Dana Nau, P. T. (2014). The actor’s view

of automated planning and acting: A position paper.

Artificial Intelligence, 208(3):1–17.

Oscar Sapena, Eva Onaindia, A. G. M. A. (2008). Engi-

neering applications of artificial intelligence. Some

Fine Journal, 21(5):698–709.

Pascal Forget, Sophie DAmours, J.-M. F. (2008). Multi-

behavior agent model for planning in supply chains:

An application to the lumber industry. Robotics and

Computer-Integrated Manufacturing, 24(5):664–679.

Salvatore Vitabile, Vincenzo Conti, C. M. F. S. (2009). An

extended jade-s based framework for developing se-

cure multi-agent systems. Computer Standards & In-

terfaces, 31(5):913–930.

Sergio Pajares Ferrando, E. O. (2013). Context-aware

multi-agent planning in intelligent environments. In-

formation Sciences, 227:22–42.

van Aart, C. J. (2004). Organization principles for multi-

agent architectures. PhD thesis, University of Amster-

dam, Faculty of Social and Behavioural Sciences.

Zadeh, L. A. (2008). Is there a need for fuzzy logic? Infor-

mation Sciences, 178(13):2751–2779.

BuildingMulti-RobotSystembasedonFiveCapabilitiesModel

275