3D Positioning Algorithm for Low Cost Mobile Robots

Rafael Socas, Sebasti´an Dormido, Raquel Dormido and Ernesto F´abregas

Department of Computer Science and Automatic Control, UNED, Juan del Rosal 16, 28040, Madrid, Spain

Keywords:

3D Positioning, Mobile Robots, Sensors.

Abstract:

A new 3D positioning algorithm for low cost robots is proposed. The algorithm is based on a Finite State Ma-

chine to estimate the position and orientation of the robot. The system sets dynamically the parameters of the

algorithm and makes it independent of the noise in the sensors. The algorithm has been tested for differential

wheel drive robots, however it can be used with different types of robots in a simple way. To improve the

accuracy of the system, a new reference system based on the accelerometer of the robot is presented which

reduces the accumulative error that the odometry produces.

1 INTRODUCTION

In mobile robots applications a good positioning and

orientation estimation are crucial (Borenstein and

Feng, 1995). Different techniques can be used to

solve this problem. The most common techniques

can be divided in seven categories (Borenstein et al.,

1997; Lee and Park, 2014): 1. Odometry; 2. Inertial

navigation; 3. Magnetic compasses; 4. Active bea-

con; 5. Global Positioning Systems; 6. Landmark

navigation; and 7. Model matching. At the same

time, they can be categorized into two groups based

on the position measurements: relative, (also called

dead-reckoning which includes the categories 1 and

2) and absolute (which includes the rest of the cate-

gories). Many applications usually combine two of

them, one of each group to compensate the lacks of a

single method.

The low cost robots frequently have few sensors.

They typically have wheel encoders, accelerometers

and obstacle detectors (Siegwart et al., 2011; Everett,

1995; Faisal et al., 2014). For this reason, in this kind

of platforms, the techniques that can only be applied

are Odometry and Inertial Navigation. Although both

techniques produce accumulative errors they provide

a good short-term accuracy. The odometry measures

the distance that each wheel of the robot has trav-

elled over the time. With this information, the posi-

tion and the orientation of the robot can be obtained.

On the other hand, inertial navigation uses accelerom-

eters and gyroscopes to measure the acceleration and

the rate of rotation of the robot. These measurements

have to be integrated to obtain the position and the

orientation by inertial navigation techniques. How-

ever, the cost of the gyroscopes constrains on the en-

vironments in which they are practical for use. In low

cost robot the techniques that can be used to estimate

the position are odometry and inertial navigation with

accelerometers. In general way, low cost accelerome-

ters have poor signal to noise ratio when the robot has

small accelerations (common situation in many appli-

cations, for example in robots with constant speed),

for this reason, the positioning and orientation esti-

mation by accelerometers in low cost platforms is a

bad solution (Liu and Pang, 2001). On the other hand,

the accelerometers have a good performance in tilt an-

gles estimation (Trimpe and D’Andrea, 2010; Luczak

et al., 2006).

In this paper a new 3D positioning algorithm for

for low cost robots is proposed, it combines odometry

and tilt estimation to obtain the position and the orien-

tation in 3D. Also, the tilt estimation is used as a ref-

erence system to reduce the orientation error that the

classical odometry produces. The paper is organized

as follows. Section 2 presents the 3D positioning in

mobile robots applications. The proposed algorithm

is presented in section 3. The experimental results are

analysed in section 4. And finally, the conclusions

and future work are presented in section 5.

2 3D POSITIONING AND

ORIENTATION

The estimation of the position and orientation of mo-

bile robots is one of the basic preconditions for their

5

Socas R., Dormido S., Dormido R. and Fabregas E..

3D Positioning Algorithm for Low Cost Mobile Robots.

DOI: 10.5220/0005480900050014

In Proceedings of the 12th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2015), pages 5-14

ISBN: 978-989-758-123-6

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

autonomy. The aim of this work is to estimate the

position and orientation of the robot in 3D. Both es-

timations can be defined as a vector with six com-

ponents po = { ˆx, ˆy, ˆz,

ˆ

ϕ,

ˆ

θ,

ˆ

ψ} (Roberson and Schwer-

tassek, 1988). The position ( ˆx, ˆy, ˆz) and the orientation

(

ˆ

ϕ,

ˆ

θ,

ˆ

ψ) are defined with respect to the world frame

(O) as it is shown in Figure 1. The elevation

ˆ

θ, the

bank

ˆ

ψ and the heading

ˆ

ϕ are the Tait-Bryan angles.

Finally, on the robot, the moving frame (O

m

) is de-

fined.

Moving

Frame

World Frame

Moving

Frame

Figure 1: Position (ˆx, ˆy, ˆz) and orientation (

ˆ

ϕ,

ˆ

θ,

ˆ

ψ) with re-

spect to the world frame (O).

When the robot is travelling on a flat surface S,

a new reference frame can be defined O

s

(surface

frame). Via odometry the position (ˆx

o

, ˆy

o

) and the ori-

entation

ˆ

ϕ

o

with respect to the surface frame can be

calculated. A tilt estimation based on an accelerom-

eter is used to obtain the elevation

ˆ

θ and the bank

ˆ

ψ

angles of the surface S with respect to the world frame

(see Figure 2).

With the parameters ˆx

o

, ˆy

o

,

ˆ

ϕ

o

,

ˆ

θ and

ˆ

ψ the com-

ponents of the vector po can be calculated. The

methodology to estimate it will be explained in the

following sections.

2.1 Position and Orientation Estimation

via Odometry

Two differential wheels robots are the most common

low cost mobile robots. These systems usually have

wheel encoders, an accelerometer and other sensors

to avoid obstacles. When the robot is travelling on

a flat surface its position and orientation can be esti-

mated using odometry (Abbas et al., 2006; Jha and

S

S

S

a)a)

b)

c)

Figure 2: a) Position (ˆx

o

, ˆy

o

) and orientation (

ˆ

ϕ

o

) with re-

spect to the surface frame (O

s

). b) Elevation angle (

ˆ

θ). c)

Bank angle (

ˆ

ψ).

S

Figure 3: Position (ˆx

o

, ˆy

o

) and orientation (

ˆ

ϕ

o

) with respect

to the surface frame (O

s

).

Kumar, 2014). Wheel encoders allow to measure the

distances that each wheel has travelled (D

l

for the left

wheel and D

r

for the right wheel). With D

l

, D

r

and

the distance between the two wheels L (see Figure 3),

the position and the orientation of the robot can be

calculated in discrete-time using equations(1)-(3).

ˆ

ϕ

o

[n] =

ˆ

ϕ

o

[n− 1] +

D

l

[n] − D

r

[n]

L

(1)

ˆx

o

[n] = ˆx

o

[n− 1] + D

c

∗ sin(

ˆ

ϕ

o

[n]) (2)

ˆy

o

[n] = ˆy

o

[n− 1] + D

c

∗ cos(

ˆ

ϕ

o

[n]) (3)

where

D

l

: Distance travelled by left wheel.

D

r

: Distance travelled by right wheel.

D

c

: Mean distance defined by D

c

=

D

l

+D

r

2

.

L: Distance between the two wheels.

2.2 Tilt Estimation

The accelerometer is sensitive to the total accelera-

tion of the mobile robot. It is composed of the inertial

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

6

acceleration, the gravity field g, the centripetal and

the tangential acceleration. This sensor measures the

three components (a

x

,a

y

,a

z

) of the total acceleration

with respect to the moving frame (O

m

). In the two dif-

ferential wheel drive robots considered in this paper,

the gravity field is the most important component of

the acceleration, for this reason, the rest of them are

not considered.

On the other hand, the robot is made to drive three

possible rotations: the elevation

ˆ

θ, the bank

ˆ

ψ and the

heading

ˆ

ϕ angles with respect to the world frame (O).

With this assumption, the sensor in the robot is mea-

suring the gravity field g (because the movements of

the robot do not produce other accelerations or they

are irrelevant) with respect to the moving frame on

the robot (see Figure 4). In the world frame the ac-

celeration is always the same (0,0,−g) where, on the

other hand, the relationship between the accelerations

in the two frames and the rotation angles is defined by

(4).

Moving

Frame

a)

b) c)

Figure 4: a) Gravity field with respect to the moving frame,

the components (a

x

,a

y

,a

z

) are the measurements of the ac-

celerometer. b) Robot with elevation angle

ˆ

θ. c) Robot with

a bank angle

ˆ

ψ.

a

x

a

y

a

z

= R(

ˆ

θ,

ˆ

ψ,

ˆ

ϕ) ∗

0

0

−g

(4)

The rotation matrix R(

ˆ

θ,

ˆ

ψ,

ˆ

ϕ) depends on the or-

der of rotations. Therefore to calculate the angles

ˆ

θ,

ˆ

ψ and

ˆ

ϕ it is necessary to know the order of rotation.

Considering a robot that rotates first an angle

ˆ

θ and

then an angle

ˆ

ψ, the measurements in the accelerom-

eter are described by (5).

a

x

a

y

a

z

=

−g∗ cos(θ) ∗ sin(ψ)

−g∗ sin(θ)

−g∗ cos(θ) ∗ cos(ψ)

(5)

If the robot rotates first an angle

ˆ

ψ and then an angle

ˆ

θ, the accelerometer measurements are given by (6).

a

x

a

y

a

z

=

−g∗ sin(ψ)

−g∗ cos(ψ) ∗ sin(θ)

−g∗ cos(ψ) ∗ cos(θ)

(6)

Comparing (5) and (6) the components a

x

and a

y

are

different in each equation, and therefore, we can con-

clude that the problem is undetermined. If the robot

has gyroscopes, the order of rotations can be esti-

mated and consequently the rotation angles can be

calculated. As we mentioned before, low cost robots

frequently have an accelerometer but they do not have

gyroscopes. For this reason, in a general way in this

kind of robots the elevation

ˆ

θ and the bank

ˆ

ψ angle

can not be estimated.

3 ALGORITHM ARCHITECTURE

The limitations of the low cost robots to estimate the

elevation and the bank angles has been analysed in

Section 2. To avoid these problems in this paper we

assume that:

a) The two-wheel differential robot can travel only

on a flat surface and,

b) this surface might have an elevation angle or a

bank angle, but not both angles at the same time.

With the previous assumptions, to estimate the po-

sitioning in 3D and the orientation of the robot, the

discrete-time architecture depicted in Figure 5 has

been proposed.

Wheel

Encoders

Accelerometer

Low Pass

Filter

Finite State Machine

Threshold

Calculator

Figure 5: Algorithm architecture.

As it is shown in the Figure 5, the algorithm is

composed of the following signals and blocks:

3DPositioningAlgorithmforLowCostMobileRobots

7

a) Input signals, D

l

[n] and D

r

[n] directly reading

from wheel encoders, and a

x

[n], a

y

[n] and a

z

[n] from

the accelerometer.

b) A low pass filter to remove the noise in the sen-

sor’s signal. The outputs of this blocks are a

xf

[n],

a

yf

[n] and a

zf

[n].

c) A threshold calculator which obtains the thresh-

old values (t

hx

[n] and t

hy

[n]), these values will be

used in the Finite State Machine (FSM) to define the

changes between states.

d) The FSM which estimates the position and ori-

entation parameters.

e) And finally, the output signals

(ˆx[n], ˆy[n], ˆz[n],

ˆ

ϕ[n],

ˆ

θ[n],

ˆ

ψ[n]).

3.1 Low Pass Filter

Low pass filtering of the signals from the accelerom-

eter is a good way to remove the noise (both mechan-

ical and electrical) (Seifert and Camacho, 2007). In

this work, an IIR filter has been proposed (7).

a

if

[n] = (1 − α) ∗ a

i

[n] + α∗ a

if

[n− 1] (7)

for i = {x,y,z}

The inputs are the accelerometer’s signal

(a

x

[n],a

y

[n],a

z

[n]) and the outputs are the filtered

signals (a

xf

[n],a

yf

[n],a

zf

[n]). The parameter α sets

the cut off frequency and the group delay of the filter.

In the design process, α has to be selected to obtain

a good balance between the noise reduction and the

delay in the acceleration measurements.

3.2 Threshold Calculator

As we mention before, the positioning algorithm is

based on a Finite State Machine. The states, as they

will be explained in the next section, depend on the

values of the elevation angle

ˆ

θ[n] and the bank angle

ˆ

ψ[n]. When the robot is on a surface with

ˆ

θ[n] ≈ 0 or

ˆ

ψ[n] ≈ 0, the noise in the accelerometer sensor could

produce changes between states and the system could

be unstable. For this reason, the algorithm needs a

threshold system to control the changes between the

states taking in account the noise in the sensors.

As we will explain later, when the elevation and

the bank angle are close to zero (

ˆ

θ ≈ 0,

ˆ

ψ ≈ 0), the

values of the accelerations a

xf

[n] and a

xf

[n] should be

zero except by the noise in the sensor. For this reason,

the noise in these measurements will be considered in

the threshold calculator.

The noise n

x

[n] and n

y

[n] in the acceleration sig-

nals a

x

[n] and a

y

[n] can be estimated by the difference

between the acceleration signals and their filtered sig-

nals as shown in (8) and (9).

n

x

[n] = a

x

[n] − a

xf

[n] (8)

n

y

[n] = a

y

[n] − a

yf

[n] (9)

Then a simple moving averagehas been used to obtain

a stable value of the noise, then the function atan() is

applied to calculate the threshold angles by (10) and

(11).

t

hx

[n] = atan

1

l

l

∑

k=1

abs(n

x

[k])

!

(10)

t

hy

[n] = atan

1

l

l

∑

k=1

abs(n

y

[k])

!

(11)

In this way the proposed system obtains two dynamic

threshold values (t

hx

[n] and t

hy

[n]) one for each accel-

eration signal. Moreover, it has a degree of freedom,

the parameter l, which will be set depending on how

the level of noise changes over the time.

The proposed threshold calculator is depicted in

Figure 6.

…..

…..

…..

…..

Figure 6: Threshold calculator. The threshold values are

obtained as a moving average of the noise in the sensor.

3.3 Finite State Machine

A Finite State Machine (FSM) has been included in

the architecture to estimate the position in 3D of the

robot (see Fig. 5). The inputs are the wheel en-

coders, the filtered accelerations and the threshold

values. The outputs are the estimation of the position

( ˆx[n], ˆy[n], ˆz[n]) and the orientation (

ˆ

ϕ[n],

ˆ

θ[n],

ˆ

ψ[n]) of

the robot. As we mentioned before, the robot only can

travel on a flat surface and this surface could have an

elevation angle or a bank angle with respect to the

world frame, but it can not have two rotations at the

same time. Taking into account these considerations,

in this section the behaviour of the FSM have been

developed.

As it is shown in the Figure 7, the FSM has

five states and five conditions to change between the

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

8

Rotation X+

Rotation X-

Rotation Y+

Rotation Y-

(State 0)

(State 1)

(State 2)

(State 3) (State 4)

Start

Figure 7: The FSM has five states (State 0, 1,2,3,4 and 5)

and five transition conditions (C

0

,C

1

,C

2

,C

3

and C

4

).

states. The meaning of each state is presented in the

following definitions:

a) State 0: The robot is on a surface without ele-

vation angle (

ˆ

θ ≈ 0) and without bank angle (

ˆ

ψ ≈ 0)

with respect to the world frame.

b) State 1: The robot is on a surface with a positive

elevation angle (

ˆ

θ > 0) and without bank angle (

ˆ

ψ ≈

0).

c) State 2: The robot is on a surface with a neg-

ative elevation angle (

ˆ

θ < 0) and without bank angle

(

ˆ

ψ ≈ 0).

d) State 3: The robot is on a surface with a positive

bank angle (

ˆ

ψ > 0) and without elevation angle (

ˆ

θ ≈

0).

e) State 4: The robot is on a surface with a nega-

tive bank angle (

ˆ

ψ < 0) and without elevation angle

(

ˆ

θ ≈ 0).

On the other hand, we assume that the system

works in discrete-time, in each sample time the mea-

surements of the sensor (D

l

[n], D

r

[n], a

xf

[n], a

yf

[n],

a

zf

[n]) are available.

The conditions (C

0

,C

1

,C

2

,C

3

,C

4

) which control

the changes between states are defined as function

of the components of the acceleration (a

xf

[n], a

yf

[n],

a

zf

[n]), the threshold values (t

hx

[n] and t

hy

[n]) and two

positive guard parameters (H and h) as it is presented

in the following equations (12)-(18):

θ

tilt

= atan(a

yf

[n]/a

zf

[n]) (12)

ψ

tilt

= atan(a

xf

[n]/a

zf

[n]) (13)

C

0

: (abs(θ

tilt

) ≤ t

hy

[n] + h)

&(abs(ψ

tilt

) ≤ t

hx

[n] + h)

(14)

C

1

: θ

tilt

> t

hy

[n] + H (15)

C

2

: θ

tilt

< −t

hy

[n] − H (16)

C

3

: ψ

tilt

> t

hx

[n] + H (17)

C

4

: ψ

tilt

< −t

hx

[n] − H (18)

The parameters H and h create two guard bands

around the threshold values. These guards bands

make a new threshold value (t

hy

[n] + H or t

hx

[n] + H)

when the elevation and bank angles increase and an-

other one (t

hy

[n] + h or t

hx

[n] + h) when they decrease.

This method avoids instabilities when θ

tilt

≈ t

hy

or

ψ

tilt

≈ t

hx

. These parameters have to be set taking

in account the level of noise in the sensor.

3.4 Position and Orientation Estimation

In each state of the FSM an estimation of the 3D po-

sitioning has to be calculated. In the state 0 the clas-

sical odometry has been applied. For the rest of the

states a combination of tilt estimation and odometry

have been used. The aim of the 3D positioning esti-

mation is to calculate the position vector of the robot

(po[n] = { ˆx[n], ˆy[n], ˆz[n],

ˆ

ϕ[n],

ˆ

θ[n],

ˆ

ψ[n]}). Depending

on the state where the robot is, different equations

have to be applied. In the following sections, these

equations will be defined.

3.4.1 Estimation in State 0

In state 0, due to the tilt is zero, the classical odometry

has to applied as it is presented in (19)-(24).

ˆ

ϕ[n] =

ˆ

ϕ[n− 1] +

ˆ

ϕ

o

[n] (19)

ˆx[n] = ˆx[n− 1] + D

c

[n] ∗ sin(

ˆ

ϕ[n]) (20)

ˆy[n] = ˆy[n− 1] + D

c

[n] ∗ cos(

ˆ

ϕ[n]) (21)

ˆz[n] = ˆz[n− 1] (22)

ˆ

θ[n] = 0 (23)

ˆ

ψ[n] = 0 (24)

where

ˆ

ϕ

o

[n]: Heading estimation by odometry

D

l

[n]−D

r

[n]

L

D

c

[n]: Mean distance D

c

[n] =

D

l

[n]+D

r

[n]

2

.

L: Distance between the two wheels.

3.4.2 Estimation in State 1 and 2

The elevation angle

ˆ

θ[n] can be calculated in state 1

by (25) and in state 2 by (26).

ˆ

θ[n] = atan

p

a

xf

[n]

2

+ a

yf

[n]

2

−a

zf

[n]

!

(25)

ˆ

θ[n] = atan

p

a

xf

[n]

2

+ a

yf

[n]

2

a

zf

[n]

!

(26)

In both states the components

ˆ

ϕ[n], ˆx[n], ˆy[n] and

ˆ

ψ[n] have the same expressions (27) - (30)

ˆ

ϕ[n] =

ˆ

ϕ[n− 1] +

ˆ

ϕ

o

[n] (27)

3DPositioningAlgorithmforLowCostMobileRobots

9

ˆx[n] = ˆx[n− 1] + D

c

[n] ∗ sin(

ˆ

ϕ[n]) (28)

ˆy[n] = ˆy[n− 1] + D

c

[n] ∗ cos(

ˆ

ϕ[n])∗ cos(θ

a

) (29)

ˆ

ψ[n] = 0 (30)

Where θ

a

= abs(

ˆ

θ[n])

The component ˆz[n] can be calculated in state 1 by

(31) and in state 2 by (32).

ˆz[n] = ˆz[n− 1] + D

c

[n] ∗ sin(

ˆ

ϕ[n])∗ sin(θ

a

) (31)

ˆz[n] = ˆz[n− 1] − D

c

[n] ∗ sin(

ˆ

ϕ[n])∗ sin(θ

a

) (32)

3.4.3 Estimation in State 3 and 4

On the other hand, the bank angle

ˆ

ψ[n] can be calcu-

lated in state 3 by (33) and in state 4 by (34).

ˆ

ψ[n] = atan

p

a

xf

[n]

2

+ a

yf

[n]

2

−a

zf

[n]

!

(33)

ˆ

ψ[n] = atan

p

a

xf

[n]

2

+ a

yf

[n]

2

a

zf

[n]

!

(34)

In both states the components

ˆ

ϕ[n], ˆx[n], ˆy[n] and

ˆ

θ[n] have the same expressions (35) - (38)

ˆ

ϕ[n] =

ˆ

ϕ[n− 1] +

ˆ

ϕ

o

[n] (35)

ˆx[n] = ˆx[n − 1] + D

c

[n] ∗ sin(

ˆ

ϕ[n])∗ cos(ψ

a

) (36)

ˆy[n] = ˆy[n− 1] + D

c

[n] ∗ cos(

ˆ

ϕ[n]) (37)

ˆ

θ[n] = 0 (38)

Where ψ

a

= abs(

ˆ

ψ[n])

Finally, the component ˆz[n] can be calculated in

state 3 by (39) and in state 4 by (40).

ˆz[n] = ˆz[n− 1] + D

c

[n] ∗ sin(

ˆ

ϕ[n])∗ sin(ψ

a

) (39)

ˆz[n] = ˆz[n− 1] − D

c

[n] ∗ sin(

ˆ

ϕ[n])∗ sin(ψ

a

) (40)

3.5 Heading Reference System based on

Tilt Angle

The heading angle

ˆ

ϕ[n] is the most important of the

navigation parameters in terms of its influence on ac-

cumulated errors. In the proposed system, when the

robot is in the state 0 the only way to calculate this pa-

rameter is by odometry (

ˆ

ϕ[n] =

ˆ

ϕ[n−1]+

ˆ

ϕ

o

[n] where

ˆ

ϕ

o

[n] =

D

l

[n]−D

r

[n]

L

). But, when the robot is moving

on a surface with an elevation angle

ˆ

θ[n] 6= 0 or with

a bank angle

ˆ

ψ[n] 6= 0 (states 1, 2, 3 or 4), the values

of a

xf

[n] and a

yf

[n] can also be used to estimate the

heading angle of the robot.

When the FSM is in state 1, 2, 3 or 4, two estima-

tions of the heading can be obtained, one of them via

odometry

ˆ

ϕ

o

[n] and another one from the accelerom-

eter

ˆ

ϕ

a

[n] by the following equations (41)-(44).

In state 1,

ˆ

ϕ

a

[n] =

atan

|a

xf

|

|a

yf

|

if (a

xf

>0)&(a

yf

≤0)

π

2

+ atan

|a

yf

|

|a

xf

|

if (a

xf

>0)&(a

yf

>0)

π+ atan

|a

xf

|

|a

yf

|

if (a

xf

≤0)&(a

yf

>0)

3π

2

+ atan

|a

yf

|

|a

xf

|

if (a

xf

≤0)&(a

yf

≤0)

(41)

in state 2,

ˆ

ϕ

a

[n] =

π+ atan

|a

xf

|

|a

yf

|

if (a

xf

>0)&(a

yf

≤0)

3π

2

+ atan

|a

yf

|

|a

xf

|

if (a

xf

>0)&(a

yf

>0)

atan

|a

xf

|

|a

yf

|

if (a

xf

≤0)&(a

yf

>0)

π

2

+ atan

|a

yf

|

|a

xf

|

if (a

xf

≤0)&(a

yf

≤0)

(42)

in state 3,

ˆ

ϕ

a

[n] =

π

2

+ atan

|a

xf

|

|a

yf

|

if (a

xf

>0)&(a

yf

≤0)

π+ atan

|a

yf

|

|a

xf

|

if (a

xf

>0)&(a

yf

>0)

3π

2

+ atan

|a

xf

|

|a

yf

|

if (a

xf

≤0)&(a

yf

>0)

atan

|a

yf

|

|a

xf

|

if (a

xf

≤0)&(a

yf

≤0)

(43)

and finally, in state 4

ˆ

ϕ

a

[n] =

3π

2

+ atan

|a

xf

|

|a

yf

|

if (a

xf

>0)&(a

yf

≤0)

atan

|a

yf

|

|a

xf

|

if (a

xf

>0)&(a

yf

>0)

π

2

+ atan

|a

xf

|

|a

yf

|

if (a

xf

≤0)&(a

yf

>0)

π+ atan

|a

yf

|

|a

xf

|

if (a

xf

≤0)&(a

yf

≤0)

(44)

where a

xf

= a

xf

[n] and a

yf

= a

yf

[n]

Here, it is important to note that the heading es-

timation from the accelerometer

ˆ

ϕ

a

[n] is an absolute

measure of the heading angle and it does not depend

on the previous values. For this reason, this measure

is a good way to avoid the accumulated errors that the

classical odometry produces.

On the other hand, due to the acceleration signals

have to be filtered to eliminate the noise in the sen-

sor, the measurements of the acceleration have a de-

lay which depends on the parameter α of the filter (see

equation 7). In this case, if the heading estimation is

calculated as

ˆ

ϕ[n] =

ˆ

ϕ

a

[n] it would be a bad approxi-

mation, for example, when the robot is making a cir-

cular path. Nevertheless, a little time after the robot

starts to travel in straight line, the accelerations are

stable (because the values of a

xf

[n],a

yf

[n] and a

zf

[n]

do not change) and the delay does not affect.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

10

Taking in account the previous considerations,

when the robot is travelling in straight line (D

l

= D

r

)

after certain time (time > t

min

) and the FSM is in

state 1, 2, 3 or 4, the heading estimation from the ac-

celerometer

ˆ

ϕ

a

[n] can be used as a reference value for

the heading angle. In this way, the accumulated error

that the classical odometry produces in the heading

angle can be avoided. The t

min

value has to be defined

as a function of the parameter α of the filter. The ref-

erence system proposed in this paper is depicted in

Figure 8.

Heading Estimation

yes

no

Figure 8: Proposed heading reference system.

4 EXPERIMENTAL RESULTS

To check the proposed algorithm in this paper, the

low cost mOway differential wheel drive robot has

been used. This robot has wheel encoders and a

three-axis MMA7455L accelerometer from Freescale

Semiconductor. The accelerometer has a dynamic

range from −2g to 2g (where g value is 9.81m/s

2

)

in the three axis. The positioning algorithm has been

implemented in C++ language, the algorithm runs in

a laptop with Windows OS. A radio frequency link of

2.4 GHz has been used to communicate the robot and

the laptop. A flat surface without tilt angle has been

used as the world frame and a moving surface as sur-

face frame (see section 2). Finally, a video camera

has been used to capture the real path of the robot.

The test laboratory is depicted in Figure 9.

Before checking the algorithm, the sensor and

other parameters of the robot were calibrated. The re-

sults of these procedures are presented in the Table1.

On the other hand, the parameters of the algorithm

were set as it is shown in Table 2.

Next sections, show some experiments to analyse

the response of the algorithm.

4.1 Behaviour of the FSM

To check the behaviour of the FSM, the robot was

put on the moving surface (surface frame) with a con-

Surface Frame

World Frame

mOway

Robot

PC conneted via

RF to the robot

Video

camera

Figure 9: Test laboratory.

Table 1: Robot parameters.

Sampling period t

s

= 0.2s

Distance between two wheels L = 6.6cm

Bias X acceleration a

xbias

= −0.1059g

Bias Y acceleration a

ybias

= −0.3480g

Bias Z acceleration a

zbias

= 0.0927g

Table 2: Algorithm parameters.

Filter constant α = 0.9

Length of threshold calculator l = 20

Guard value H H = 0.2

◦

Guard value h h = 0.1

◦

Minimum time in reference system t

min

= 1s

stant speed of 10.3cm/s in straight line. Then differ-

ent tilts (

ˆ

θ and

ˆ

ψ) were applied and the states of the

FSM were analysed. The elevation angle was modi-

fied from −8

◦

to 8

◦

, in the same way, the bank angle

was varied from −7.5

◦

to 7.5

◦

. The result of the ex-

periment is depicted in the Figure 10.

0 20 40 60 80 100 120 140 160 180 200 220

-10

0

10

0 20 40 60 80 100 120 140 160 180 200 220

-10

0

10

0 20 40 60 80 100 120 140 160 180 200 220

0

2

4

a)

b)

c)

Figure 10: FSM’s behaviour. a) Elevation angle in blue and

t

hy

in green. b) Bank angle in blue and t

hx

in green. c) States

of the FSM.

As Figure 10 shows, the behaviourof the system is

according to the tilt angle. When tilt angles are close

to zero, the system is in the state 0. The FSM is in

3DPositioningAlgorithmforLowCostMobileRobots

11

the state 1 or 2 depending on the value of θ

tilt

as it is

presented in Figure 10 a) and 10 c). And finally, states

3 and 4 depend on the value of ψ

tilt

as it is shown in

Figure 10 b) and 10 c).

It is important to note that the system can change

between states with an error smaller than 1

◦

in the tilt

estimation as it is presented in Figure 10.

4.2 3D Positioning Estimation

Once the FSM is analysed, the next step is to check

the 3D positioning. To this end two experiments

were performed. In the first one, the robot travels in

straight line with a speed of 10.3cm/s on a surface

with a elevation angle of fifteen degrees (θ = 15

◦

).

In the second one, the robot drives a circular path

(speed of left wheel= 17.5cm/s and speed of right

wheel= 10.3cm/s) on a surface with bank angle of

minus twenty degrees (ψ = −20

◦

). The experiments

take 10 seconds in both cases. In Figure 11 some

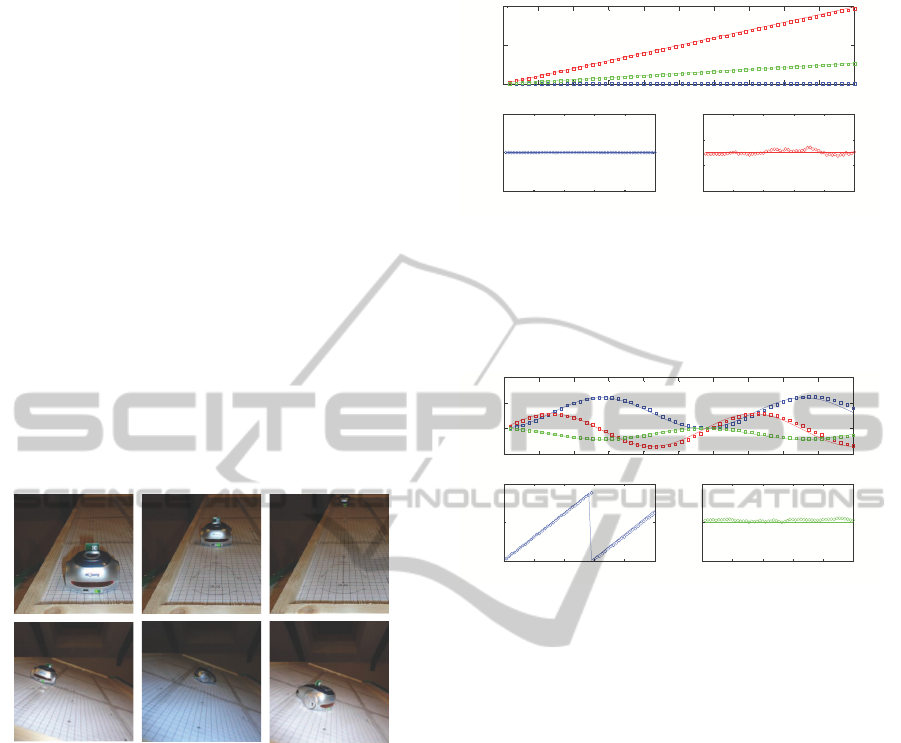

snapshots of theses experiments are presented.

a)

b)

t=0s

t=0s

t=2s

t=10s

t=1,5s t=5s

Figure 11: Experiments for checking the 3D positioning es-

timation. a) Straight line with θ = 15

◦

and ψ = 0

◦

(state 1).

b) Circular path with θ = 0

◦

and ψ = −20

◦

(state 4).

To check the accuracy of the algorithm, the real

position (x,y,z) and orientation (ϕ,θ,ψ) of the robot

is obtained from the images of the video camera. The

estimated parameters ( ˆx, ˆy, ˆz,

ˆ

ϕ,

ˆ

θ,

ˆ

ψ) are calculated by

the proposed algorithm. The results of the first exper-

iment is depicted in Figure 12 and in Figure 13 for the

second one. As it is shown in the Figures 12 and 13

the algorithm is a good 3D positioning estimator with

a low estimation error. The elevation and the bank an-

gles do not have accumulative errors because they are

obtained directly from the accelerometer. The rest of

the parameters, will have accumulative error over the

time because they are calculated by odometry.

4.3 The Heading Reference System

To analyse how the heading reference system im-

proves the 3D positioning estimation, a new exper-

0 1 2 3 4 5 6 7 8 9 10

0

50

100

0 2 4 6 8 10

-1

0

1

0 2 4 6 8 10

0

10

20

30

a)

b)

c)

Figure 12: 3D positioning estimation in a straight line. a)

Figure 12: 3D positioning estimation in a straight line. a)

Real position (x,y,z) (solid lines) and estimated position

( ˆx, ˆy, ˆz) (square line). b) Real heading ϕ (solid line) and

estimated heading

ˆ

ϕ (circle line). c) Real elevation θ (solid

line) and estimated elevation

ˆ

θ (circle line). The bank angle

ˆ

ψ is not depicted because is zero as it was defined in (30).

0 1 2 3 4 5 6 7 8 9 10

-20

0

20

40

0 2 4 6 8 10

0

200

400

0 2 4 6 8 10

-40

-20

0

a)

b)

c)

Figure 13: 3D positioning estimation in a circular path. a)

Real position (x,y,z) (solid lines) and estimated position

( ˆx, ˆy, ˆz) (square line). b) Real heading ϕ (solid line) and es-

timated heading

ˆ

ϕ (circle line). c) Real bank ψ (solid line)

and estimated bank

ˆ

ψ (circle line). The elevation angle

ˆ

θ is

not shown due to is zero according to (38).

iment has been set up. In this case, the robot has

been programmed with a trajectory as it is shown in

the Figure 14. The real path of the robot has been

recorded by the video camera and two estimations

have been calculated in the same experiment. One

of them without the heading reference system and the

another one using this system. The real heading and

its estimations by the algorithm are presented in the

Figure 15. As it can be noticed from this figure, the

error in the heading estimation without the reference

system increases over time. However when the ref-

erence system is activated, the error in the heading

estimation does not increase.

Considering the position parameters, the results of

the experiment are depicted in the Figures 16 and 17.

As it is shown in these figures, when the position

is obtained with the reference system proposed in this

paper, the estimation error is reduced considerably. If

the real position vector is defined as p = {x, y, z} and

the estimation position vector as

ˆ

p = { ˆx, ˆy, ˆz}, the po-

sitioning error can be defined as P

error

= |p−

ˆ

p|. In

Figure 18, the positioning error is presented for this

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

12

t=0s t=5s t=8s t=13s

t=16s t=21s t=29s t=32s

Figure 14: Snapshots of the experiment. In the straight line path the robot has a speed of 10.8cm/s. In the the circular path

the speed of the right wheel is 10.3cm/s and the left wheel is 17.5cm/s.

0 5 10 15 20 25 30 35

-50

0

50

100

150

200

250

300

350

400

Figure 15: Heading estimation. Solid blue line is the real

heading, solid red line is the heading estimation without ref-

erence system and solid green line is the heading estimation

with the reference system.

0

20

40

-20

0

20

40

60

80

-5

0

5

10

15

0

20

40

-20

0

20

40

60

80

-5

0

5

10

15

b)

a)

Figure 16: 3D position parameters, solid blue line is the

real path. a) Red circle is the position estimation without

reference system. b) Green circle is the position estimation

with reference system.

experiment.

Comparing the results in the figure, although both

methodologies have accumulative error over time, the

proposed reference system reduce significantly the

positioning error.

5 CONCLUSIONS

In this paper we have proposed a new 3D position-

ing algorithm for low cost robots. The architecture

presented can be applied in robots which have wheel

-10 0 10 20 30 40 50

-20

-10

0

10

20

30

40

50

60

70

-10 0 10 20 30 40 50

-20

-10

0

10

20

30

40

50

60

70

a)

b)

Figure 17: 2D position parameters (to show more clearly

the error, z has been set to zero), solid blue line is the real

path. a) Red circle is the position estimation without refer-

ence system. b) Green circle is the position estimation with

reference system.

0 5 10 15 20 25 30 35

0

2

4

6

8

10

12

14

16

18

Figure 18: Red solid line is the positioning error when the

reference system has not been used. The solid green line is

the positioning error when the reference system is used.

encoders and a three axis accelerometer. The prob-

lem formulation have been developed for two wheel

differential robots, however this algorithm is easy to

apply in other kind of robots in a simple way. The

methodology presented is based on a Finite State Ma-

chine. A threshold calculator allows to set the sys-

tem dynamically as a function of the noise in the

accelerometer. Also a new reference system is pro-

posed, this new system improves considerably the

estimation of the algorithm respect to the classical

odometry.

3DPositioningAlgorithmforLowCostMobileRobots

13

The proposed algorithm was checked in the low

cost robot mOway. In these experiments, in a simple

way, the algorithm has been set and precise estima-

tions of the 3D position were obtained. The thresh-

old calculator worked in a correct way to estimate the

states of the FSM and it sets the systems dynamically.

Finally with the new reference system the positioning

error has been considerably reduced.

As a future work, now we are considering to apply

this algorithm in robots which have also gyroscopesto

allow estimations on surface with elevation and bank

angles at the same time. On the other hand, newmeth-

ods for reference systems in low cost robots are being

explored.

REFERENCES

Abbas, T., Arif, M., and Ahmed, W. (2006). Measurement

and correction of systematic odometry errors caused

by kinematics imperfections in mobile robots. In

SICE-ICASE, 2006. International Joint Conference,

pages 2073–2078. IEEE.

Borenstein, J., Everett, H. R., Feng, L., and Wehe, D.

(1997). Mobile robot positioning-sensors and tech-

niques. Technical report, DTIC Document.

Borenstein, J. and Feng, L. (1995). Correction of system-

atic odometry errors in mobile robots. In Intelligent

Robots and Systems 95.’Human Robot Interaction and

Cooperative Robots’, Proceedings. 1995 IEEE/RSJ

International Conference on, volume 3, pages 569–

574. IEEE.

Everett, H. (1995). Sensors for mobile robots: theory and

application. AK Peters, Ltd.

Faisal, M., Hedjar, R., Alsulaiman, M., Al-Mutabe, K., and

Mathkour, H. (2014). Robot localization using ex-

tended kalman filter with infrared sensor. In Computer

Systems and Applications (AICCSA), 2014 IEEE/ACS

11th International Conference on, pages 356–360.

IEEE.

Jha, A. and Kumar, M. (2014). Two wheels differential

type odometry for mobile robots. In Reliability, Info-

com Technologies and Optimization (ICRITO)(Trends

and Future Directions), 2014 3rd International Con-

ference on, pages 1–5. IEEE.

Lee, Y.-C. and Park, S. (2014). Localization method for

mobile robots moving on stairs in multi-floor environ-

ments. In Systems, Man and Cybernetics (SMC), 2014

IEEE International Conference on, pages 4014–4020.

IEEE.

Liu, H. H. and Pang, G. K. (2001). Accelerometer for mo-

bile robot positioning. Industry Applications, IEEE

Transactions on, 37(3):812–819.

Luczak, S., Oleksiuk, W., and Bodnicki, M. (2006). Sens-

ing tilt with mems accelerometers. Sensors Journal,

IEEE, 6(6):1669–1675.

Roberson, R. E. and Schwertassek, R. (1988). Dynam-

ics of multibody systems, volume 18. Springer-Verlag

Berlin.

Seifert, K. and Camacho, O. (2007). Implementing posi-

tioning algorithms using accelerometers. Freescale

Semiconductor.

Siegwart, R., Nourbakhsh, I. R., and Scaramuzza, D.

(2011). Introduction to autonomous mobile robots.

MIT press.

Trimpe, S. and D’Andrea, R. (2010). Accelerometer-

based tilt estimation of a rigid body with only rota-

tional degrees of freedom. In Robotics and Automa-

tion (ICRA), 2010 IEEE International Conference on,

pages 2630–2636. IEEE.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

14