Web of Things in an Industrial Environment

Leandro F. Rojas-Peña and Reinhard Langmann

University of Applied Sciences Düsseldorf, Josef-Gockeln-Straße 9, 40470, Düsseldorf, Germany

Keywords: Web of Things, WoT, Websocktes, Web-automation, WOAS, Automation Services.

Abstract: This paper summarizes the work around enhancing an existing Web-oriented Automation System (WOAS)

that provides automation services; to support Virtual Devices (VD) that communicate directly with automa-

tion components like industrial controllers via Websockets. The presented architecture is a Cyber Physical

System (CPS) oriented to production environments in the industry. After a short introduction a quick over-

view about the currently used technologies is presented. The central part of the work focuses on the imple-

mentation of the required interfaces on both sides of the system. The physical side uses a Programmable

Logic Controllers (PLCs) as automation device. In the other side JavaScript and PHP are used to develop

the client and server modules respectively. A simple demo application was created for the first tests and at

the time, some basically delay measurements were realized.

1 INTRODUCTION

In the last years the concepts and paradigms of Web

of Things (WoT), Internet of Things (IoT), and In-

dustry 4.0 has been quickly grown and expanded

challenging the technology and its applications. At

present, we find ourselves at the beginning of a

stage, which is characterized by so-called “Cyber-

Physical Systems” (CPS). These systems are a con-

sequence of the far-reaching integration of produc-

tion, sustainability and customer-satisfaction form-

ing the basis of intelligent network systems and

processes (Bloem, 2014).

Automation technologies are confronting big

challenges due to the increasing penetration of such

tendencies. The emphasis on the product portfolio of

industrial automation is expected to decline over the

next few years in the factory of the future. In con-

trast, the requirement for globalized service & sup-

port is set to gain importance, together with the cost

factors. The introduction of secure Cloud computing

technology enables access to relevant strategic data

via the Internet, which can be used to make deci-

sions in real time as well as boost the operational

efficiency (Langmann, 2013).

Many companies and projects has been focus on

developments to fulfil the new requirements regard-

ing to the Web-based control applications. Since a

few years many alternatives have been used to guar-

antee the short response time required in such appli-

cations using HTTP as standard protocol. HTML-5

brings improvements to the development of Web

applications; one of them is the Websockets (WS)

specification. WS provide an enormous reduction in

unnecessary network traffic and latency compared to

other technologies. It accounts for network hazards

such as proxies and firewalls, making streaming

possible over any connection, and with the ability to

support upstream and downstream communications

over a single connection. HTML5 WebSockets-

based applications place less burdens on servers,

allowing existing machines to support more concur-

rent connections (Kaazing). This makes it suitable

for many applications requiring fast and frequent

action in both direction client/server/client; like

those which involve multiple users communicating

with each other, or those where the server-side data

constantly change (Freeman, 2013).

As consequence, Ethernet is nowadays used as a

standard protocol for the factory floor and other

industrial applications. But it is important to note

that the timing is a quite critical in the industrial

environments networks. “Time critical” refers to a

system’s dependency on a deterministic latency - or

better, absolute knowledge of time to a very high

degree of accuracy. This is the major difference

between information exchange and control applica-

tions (Zarr, 2014).

The main objective of this development was to

upgrade the WOAS system to support Virtual De-

533

F. Rojas-Peña L. and Langmann R..

Web of Things in an Industrial Environment.

DOI: 10.5220/0005491105330539

In Proceedings of the 11th International Conference on Web Information Systems and Technologies (WEBIST-2015), pages 533-539

ISBN: 978-989-758-106-9

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

vices that communicate directly with automation

components like PLCs via Websockets. The test and

demo scenarios as well a simple real application

were also part of the initial objectives.

2 RELATED TOPICS

This section will briefly introduce some related

concepts and technologies and its state of the art.

2.1 Trends on the Nowadays Web

Automation

Nowadays there are several topics that have been the

subject of numerous articles focused on this field.

These include Internet and Web of Things (IoT,

WoT), Big Data, Cloud Computing and Industry 4.0.

All of these trends involve a lot of devices net-

worked together and a lot of data available to do

things. They also include deciding whether data is

stored and applications accessed from the computer

next to you or from a server located somewhere else

(Oulton, 2014).

Industrial automation spans a wide range of con-

trol systems from simple Programmable Logic Con-

trollers (PLC) to Supervisory Control and Data-

Acquisition (SCADA) systems and distributed con-

trol systems (Joby, et al., 2011). Automation systems

frequently control multiple devices in a synchro-

nized fashion. PLCs generally are end nodes for

more complex control systems. They are simple to

program and these days; PLCs are microcontroller-

based systems that may have a procedural program-

ming interface. In any case, a typical PLC will offer

rugged I/O and real-time synchronization. Today’s

PLCs may have network connectivity as well. A

network does not affect the I/O side, but timing and

synchronization will be an issue (Wong, 2014).

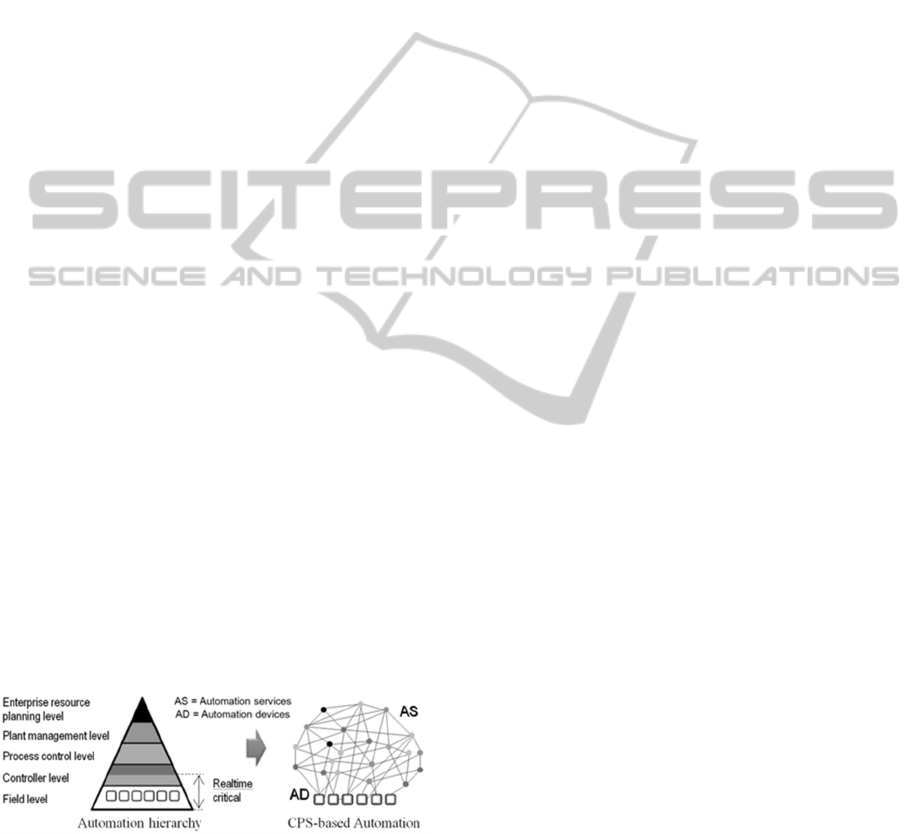

Figure 1: Decomposition of the automation hierarchy by

CPS with distributed services.

The conventional automation hierarchy is in-

creasingly transforming into a flat automation

"Cloud" as Figure 1 shows. Service-oriented archi-

tectures (SOA) provide a good solution for creating

uniform interfaces, while allowing collaboration

from the field level to the enterprise level. Cloud

computing is the provision of jointly usable and

flexibly scalable IT services using IT resources via

networks. Typical features are provision in real time

as a self-service based on Internet technologies and

charges according to use. Cloud computing enables

users to redistribute from investment to operational

expense, while paving the way for completely new

business models and their prompt implementation

(Langmann, 2014).

Current automation systems such as process vis-

ualization systems, SCADA/HMI systems and pro-

cess control systems are proprietary and manufac-

turer-specific systems that are created with conven-

tional programming languages and mostly have

manufacturer-specific internal interfaces and data

formats, making them hardly to accept as an open

industrial model. Also the increasing standardization

and opening of interfaces and description methods

(OPC UA, FDT/DTM etc.) does not change the fact

of the unity of an automation system, but comple-

ment them only in the direction of openness of a

given environment. Not the systems themselves are

more open, but rather only the interfaces and de-

scription methods are more standardized and

opened. Only the new and standardized IT technolo-

gies with Web/Internet at the forefront established

the prerequisites for a spatially unlimited distribu-

tion of functions/services and are now also increas-

ingly interesting for automation technology (Lang-

mann, 2013).

2.2 WOAS

In general all functions which are required for the

execution of an automation system could be used as

services. These can be such simple functions as a

measuring algorithm, operating or visualization of

process data, but also complex functions from higher

levels (Figure 1) could be used as AS. Looking at an

automation system from this perspective there is still

some open points; the new automation structure is a

vision for the future. At present, no application-wide

systems are available on the market, which imple-

ment a CPS-based and service-oriented automation.

Between 2011 and 2014, however, the prototype

of a Web-based platform was created, which can

integrate worldwide distributed services also with

worldwide distributed CPS components (device

components) into a functional system (Langmann,

2013). This was within the framework of the R&D

project "Architecture and Interfaces of a Web-

Oriented Automation System (WOAS)" and in-

volved the participation of 10 industrial companies.

WEBIST2015-11thInternationalConferenceonWebInformationSystemsandTechnologies

534

The WOAS platform can also be referred to as CPS

integration platform. On the client side (browser) the

platform is completely implemented in HTML5 and

JavaScript runnable in each browser and device.

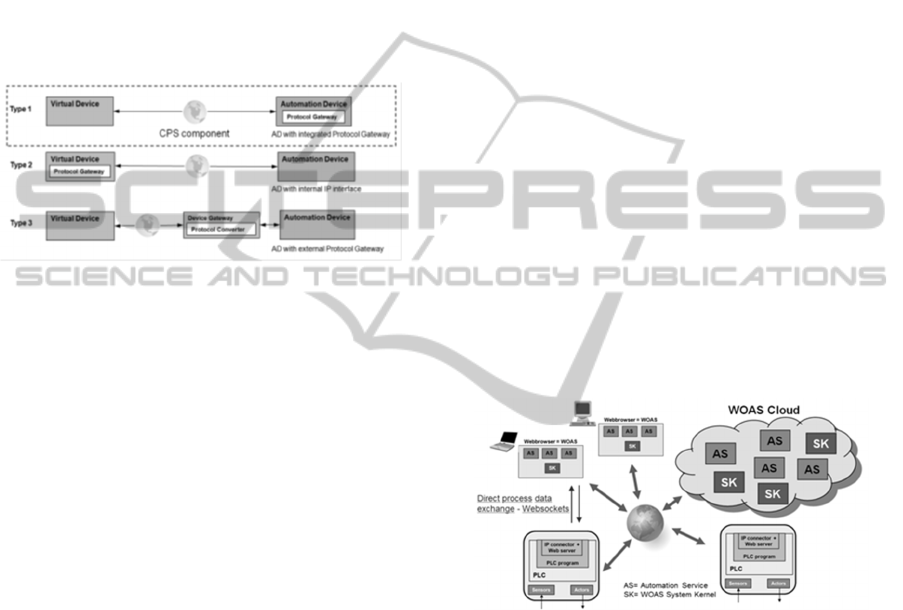

For the CPS-based automation, the automation

devices (AD) like controls, sensors, actuators etc.,

can be considered as CPS components after adding

corresponding interfaces to the IP network. This

results in the CPS structures as shown in Figure 2

for different AD. A Virtual Device (VD), which

maps the real device in the virtual world, functions

as an interface from the CPS components to services

distributed in the network (Langmann, 2014, p. 133).

Figure 2: Automation Devices as a CPS components.

The VD is used to map the process data of an au-

tomation device via event-based channels onto Web-

or Internet-suitable objects in a uniform manner and

makes this available in a Web browser. Via integrat-

ed protocol or device gateways, any industrial inter-

faces can therefore be made available in the IP net-

work. For the process data transfer between a VD

and an AD via HTTP, a specific protocol was devel-

oped. The VD and the protocol- or device-gateway

together form a Web Connector for the AD as a CPS

interface.

This work describes the development and evalua-

tion of an integrated PLC Web Connector according

to a Type 1 VD (Figure 2) and its application in the

WOAS portal for creating Web-oriented automation

systems.

2.3 The WSS4ILC Library

Even when the Websocket (WS) protocol is not

anymore so young in the world of the standard Web

applications, it is so in the automation world, espe-

cially in the industrial controllers like PLCs. All the

more, most automation manufacturers provide a

Web server in their devices, but usually it is only for

managing purposes or simply do not support WS. To

be able to explode the benefits of the WS protocol in

the automation devices it is necessary its complete

implementation.

Fortunately, for the PLCs of the Phoenix Contact

family (ILC series) exist a library that provides a

basis implementation of the WS protocol which

main technical specifications are: data frames can be

up to 125 byte long; support the Ping/ Pong signals

and last one is a kind of limitation but enough for

this application; it allows only one client at a time.

The use of the library is a quite simple and re-

quires just to instantiate the WSS4ILC FB and set or

connects all input and output parameters properly

(Rojas-Peña, 2014).

3 SCIENTIFIC-TECHNICAL

CONTRIBUTION

Once covered a few obligatory topics around the

concepts related to this work it is possible to present

its global conceptual idea. Figure 3 shows how in-

dustrial controllers or any automation device in

general can be directly connected to the Cloud al-

lowing its control and/or supervision by any client

user using an Internet browser. Any user can access

the WOAS portal, but to access the services provid-

ed by the controller as a VD must be properly regis-

ter in the WOAS server and be subscribed to the

desired channels.

Figure 3: Conceptual idea.

3.1 The VD4PLC Concept

To be able to successfully fulfil the proposed objec-

tives it is necessary to properly understand the com-

plete structure of the architecture and its functionali-

ties. Figure 4 shows the connections between the

different parts of the automation system and the used

protocols. Note this corresponds to a single automa-

tion device, in this case, the industrial controller

used for the test, an ILC 150 ETH PLC. In this

sense, VD4PLC is the VD developed to allow

WOAS connects directly with industrial controllers.

Let’s take a closer look to each part of the sys-

tem and decide how to realize its implementation. In

one side is the automation device (AD) and in the

WebofThingsinanIndustrialEnvironment

535

other side the Virtual Device (VD) which is a JavaS-

cript dynamic Web page created by the WOAS sys-

tem kernel. Once a user logs in to the WOAS client,

an instance of the registered VDs is created. In this

process a WS communication is established between

both entities allowing the bidirectional data ex-

change. As a particularity for PLCs must be consid-

ered that the programming standard IEC 61131-3 do

not allows using the device’s Ethernet interface with

unknown entities. For this reason it was necessary to

find a way how to set the client's IP that is starting a

session in the PLC.

Figure 4: Structure of the system.

3.2 VD4PLC Interfaces

Implementation

To communicate both sides of the system correctly it

is necessary not only to use the WS protocol for the

communications between the PLC and the VD in the

WOAS client but also to implement a higher level

protocol to properly perform the data exchange ac-

cording to the WOAS specifications.

To be congruent with WOAS it is necessary to

process the commands Subscribe, Unsubscribe,

Read and Write (CCAD-VD, 2013) as they will be

sent by the WOAS server, or a test client during the

development phase. This process is implemented

very simple; the first byte in the sent/received data

string is a command field and codifies this function-

ality as Table 1 shows.

Table 1: WOAS commands.

Command Description

Subscribe

Data can be sent when they change or be

explicitly requested

Unsubscribe No data will be sent (stops sending)

Read

Explicit data update requested. A frame

should be sent with current value of one

or all subscribed channels

Write

Contains the updated/new values of one

or all subscribed channels

Also note that the frames with the commands

Subscribe, Unsubscribe and Read are considered

command frame’s that contains no process data,

while frames with de command Write are considered

as data frames and should contain process data.

With the use of the library WSS4ILC the heavy

work is already guaranteed in the side of the AD

because it provides the required WS server as basic

unit for the communication. It is only necessary to

implement the protocol previously described in the

AD or PLC and to interact with the process I/O as

the automation function requires.

The WOAS protocol was programed as a modu-

lar function block (FB), which in correspondence

with the WSS4PLC, use parameters for its configu-

ration, facilitating its portability. The used develop-

ment environment was PC WORX from the Phoenix

Contact company. At this point the interface with the

WOAS VD is ready to be used.

In the client side, the VD4PLC is programmed in

JavaScript and of course implement the above de-

scribed protocol as the other edge of the communi-

cation channel. Its main module is the file

vd4plc.js, including functions for sending and

processing messages to or from the industrial con-

troller. Those functions are:

sendToPLC: Prepares the messages (strings)

to be sent to the PLC when commands are

generated. Write commands with process da-

ta; the others without.

getFromPLC: Decode the messages (strings)

received from the PLC when an explicit read

command is generated or the automation de-

vice sends new process data automatically

due to its own functionality or data updates.

A third function has an important role in this

main module; it is the initialization function which

by means of Ajax requests to the WOAS server

setting the client IP in the PLC.

An IEC 61131-3 programmable industrial con-

troller needs to know the IP of its partner before

starting a connection. To overcome this problematic

or limitation it is necessary to fetch the client IP at

the moment the user logs in to the WOAS portal and

send it to the PLC. After, the WS library can connect

with the VD allowing direct data exchange between

the user somewhere in the Cloud and the automation

device (AD) in a certain physical process. Two

things must be done in this direction; the VD4PLC

also includes a PHP module (vd4plc.php) which

at the proper time fetches the client IP and sends it to

the PLC (function sendCmdToPLC) via HTTP.

Therefore the AD also requires a Web server; it was

also part of this development and with quite rudi-

mentary functionalities allows setting the IP for the

WOAS server

VD4PLC

JavaScript

PHP

WOAS client

VD4PLC instance

Java

Script

IOs

HTTP

HTTP

WS

PLC

Process

Web browser

WEBIST2015-11thInternationalConferenceonWebInformationSystemsandTechnologies

536

proper WS communication and also to know the stay

of the WS server in the WSS4ILC library.

4 TEST-DEMO APPLICATION

For the initial test a Phoenix Contact EduNet devel-

opment kit was used as an automation device. This

kit has a PLC of the low range ILC (150 ETH) series

of the same company. The digital inputs (DIs) are

connected to a block of switchers allowing its manu-

al operation. The analog input is connected to a

linear potentiometer and the analog output to a led

bar with 12 indications levels. To have a direct feed-

back of the hardware functionalities one of the DOs

is physically connected to one of the DI's.

A simple program was written to combine the

WSS4PLC library, the developed WOAS FB written

in the IEC 61131-3 programming language and a

dummy automation function that basically forward

the values of the inputs every time they change and

in the other direction reflex the received values to

the outputs. The idea was to simply show how to

create automation services that will be available for

the WOAS users in the Cloud.

Figure 5: Test Web page.

To test the WOAS client was used a standalone

Web page. This is possible because WOAS is com-

plete modular and the VD4PLC implementation can

be used out of it. This has a big advantage allowing

control automation developers to easily access its

process from the Web. The unique requirement is to

use Web server to host the PHP component of the

VD.

The Web page used as user interface to test the

developed system is a quite simple, see Figure 5.

Note some of the VD properties are shown in the

upper tables while the data channels equivalent to

the automation services provided by WOAS are in

the lower table. The two controls at the bottom facil-

itate the tests; a Status field indicating if the WS is

connected to the server or not and a Disconnect

button to close the connection explicitly.

In the middle there are three buttons which are

equivalent to the WOAS commands Read, Subscribe

and Unsubscribe respectively. Note that the Read

command is also triggered with a mouse click over

the channel Value column in the bottom table. For

the Write command it is necessary to click over the

button ‘W’ in the Channel Type column.

During the days of WEBIST‘2015 the link

http://vd4plc.ccad.eu will be available for online

tests with this demonstration application.

5 DELAY TEST

A delay test was performed to have an idea about the

time performance of the implemented system. This

test was realized in two different environments, the

first one in local closed scenario in intranet and a

second one in an open scenario in the Internet. In

both cases was used the same web page on the PC

and the same program on the PLC. The physical

measurements were based on the loopback connec-

tion of one output and one input on the automation

device which guarantees that certain information

received will be automatically echoed. Around 2500

messages (pulses) were sent; while some values

were computed: maximum and minimum delay, total

of pulses lost (no pulse confirmation received), and

the frequency distribution of the delay according to

the number of pulses with a same delay.

Figure 6: Delay analisys.

Figure 6 shows the results of both tests graph

WebofThingsinanIndustrialEnvironment

537

ically in different interesting time windows accord-

ing to the delay range in the abscise axis. The blue

curve (left) represents the obtained values for the

test realized in the intranet with a very good time

response. Most measured delays were between 23

and 37 milliseconds for a 72% of the total sent puls-

es. The minimum value is really small and can be

considered ideal for some applications. The maxi-

mum value is still acceptable for some applications

but has not so important significance because it is

just a punctual value.

The green curve (right) depict the values for the

test realized in the Internet with bigger delays and

also minor repetitions for smaller delays but also

acceptable for the used scenario. In this case, most

of the values were between 42 and 54 milliseconds

for a 56,4% of the total sent pulses. Here is also

interesting to note that between 55 and 79 millisec-

onds there is an important amount of values equiva-

lent to the 24,8% of the total sent pulses. The mini-

mum value is not so small like in the intranet test but

can be also considered ideal for some applications.

The maximum value is much bigger than in the other

test and should be considered significant depending

on the application to be used.

In both cases the values are considered very well

for “soft” real time applications in automation

(Home, 2014). The percent of delay values above

180 ms is only 0,9% in the intranet test and a 2.1%

in the Internet test. The lost pulses in both cases are

around 0.2 percent.

6 CONCLUSIONS AND FUTURE

WORK

The present work describes the implementation and

test of an automation system which is services ori-

ented and CPS-based to be used in the WoT as an

enhancement of the WOAS project.

The new developed Web connector for the PLC

(Virtual Device and WOAS Function Block) allows

to connect automation devices directly to the Cloud,

and therefore to be controlled and supervised by a

user with the valid and with the required rights from

the Cloud. The tests realized with a demo applica-

tion show the feasibility of the implementation to be

used in the production environments in the industry.

On the other hand the time measurements results are

very promising in comparison with previously tech-

nologies, suggesting this architecture to be used in

control automation Web-based applications where

the time constraints are considered soft with relative

small jitter on medium-low network's load.

There are still a lot to do in this direction. The

first steps are directed to allow the WSS to support

more clients simultaneously and at the same time

improve the WOAS protocol designed for the

VD4PLC allowing longer frames and better han-

dling of the modified or read data. As a generaliza-

tion both, the WSS library and the VD should be

extended to other types of industrial controllers with

the respective tests.

Cloud-based Industrial Control Services (CICS)

is a new R&D project focused to a complete Web-

oriented control system (see control level on Fig.1).

Industrial control programs according the standard

IEC 61131-3 should be executed as control services

from the Cloud. The described WoT solution for

PLC will be evaluated in the CICS project as one of

the possibilities for a direct connection of PLCs as

CPS component to a Cloud-based and distributed

control system.

REFERENCES

Bloem, J., 2014. The 4I Revolution: Industrial – Infor-

mation Tech – Internet – and Industrious Once More.

s.l.:SogetiLabs.

CCAD-VD, C. C. A. D., 2013. Beschreibung der Virtual

Devices. s.l.:s.n.

Freeman, J., 2013. 9 killer uses for WebSockets.

s.l.:InfoWorld.

Home, S. P. S. D. C., 2014. Design of communication

systems for networked control system running on

PROFINET. WFCS 2014, Toulouse: IEEE.

Joby, A., Mahato, B., Sharma, S. & G., C., 2011. A web

PLC using distributed web servers for data. ICISA

2011, Jeju Island: IEEE.

Kaazing, C., n.d. About HTML5 WebSockets.

s.l.:WebSocket.org.

Langmann, R., 2014. Automation services from the cloud.

Industrial Ethernet Book: s.n.

Langmann, R., 2014. Ein Interface für CPS-basierte

Automatisierungsgeräte (Interface for CPS-based

automation devices). AALE 2014: Deutscher

Industrieverlag.

Langmann, R. M. L., 2013. Architecture of a Web-

oriented Automation System. ETFA 2013,

Cagliari/Italy: IEEE.

Oulton, B., 2014. 4 Big Trends that Impact Industrial

Automation and What To Do About Them. s.l.:Belden.

Rojas-Peña, L., 2014. Making your PC WORX project

WOAS compatible, Düsseldorf: CCAD.

Wong, W., 2014. Electronic Design: Industrial Automa-

tion Relies On Ethernet. s.l.:electronic design.

Zarr, R. F., 2014. Electronic Design: Ethernet Dominates

Industrial Environments. s.l.:electronic design.

The IGF project CICS (18354 N) of the Forschungs-

WEBIST2015-11thInternationalConferenceonWebInformationSystemsandTechnologies

538

vereinigung Elektrotechnik beim ZVEI e.V. – FE, Ly-

oner Str. 9, D-60528 Frankfurt am Main is funded via

the AiF within the framework of the programme for

funding industrial community research and develop-

ment (IGF) of the Federal Ministry of Economics and

Technology based on the resolution of the German

parliament.

WebofThingsinanIndustrialEnvironment

539