Experimental/FEM Optimization of Medium Voltage Rubber

Insulated Electric Cables Vulcanized with Steam Water

Differential Scanning Calorimetry (DSC) and Rheometer Experimental Results

Gabriele Milani

1

and Federico Milani

2

1

Technical University in Milan, Piazza Leonardo da Vinci 32, 20133, Milan, Italy

2

CHEM.CO Consultant, Via J.F.Kennedy 2, 45030, Occhiobello (RO), Italy

Keywords: Power Cables Production Lines, EPDM Elastomers, Peroxide Vulcanization, Steam Curing, DSC

Characterization, Experimental Rheometer Curves.

Abstract: The standard industrial process to produce medium voltage electric cables based on EPDM consists of

crosslinking by peroxides with high temperature steam (pressurized water vapor). Suboptimal material

crosslinking is usually due to a decrease of the temperature along the vulcanization pipe. Temperature

variations are connected to variations in steam pressure into pipe system. In the present paper a combined

numerical and experimental approach to optimize the production process of medium voltage rubber

insulated electric cables vulcanized with steam water is presented. The numerical part, discussed in an

accompanying paper, is based on the utilization of Finite Elements and an optimization Genetic Algorithm

(GA) approach. Here, attention is focused on the experimental investigation. In particular, the final

crosslinking degree is experimentally obtained by means of a DSC determination of non-decomposed

peroxide from the external layer to the core of the cable insulation. The final task is to minimize the

difference between numerically predicted and experimentally determined crosslinking degree using a steam

temperature profile along the pipe to explain the variations. A preliminary evaluation of kinetic reaction

constants of rubber cured with peroxides is here provided by means of a previously presented kinetic model.

1 INTRODUCTION

The continuous vulcanization process of cables has

been developed more than fifty years ago.

Nevertheless, the use of advanced mathematic

studies to predict polymer compounds performance

is not commonly applied, despite the fact it could

play an important role in industrial technical

development.

In the last few years, high voltage cables have

been produced by using ethylene propylene co- and

ter-polymers EPM/EPDM, Milani and Milani

(2008), due to their good dielectric strength, aging

resistance and partial discharges resistance. The

capability to set up and to tune the plant conditions

according to cable structure and compound

properties plays a critical role in cable production

and quality.

The industrial process of crosslinking, Roberts

and Verne (1984), of power cables is usually

obtained by means of horizontal (catenary

continuous vulcanization CCV) systems, Figure 1.

In Figure 1 the CCV plant considered in the present

paper is described.

Pressure, temperature and production speed

should be kept under severe control in order to

guarantee a designed crosslinking degree.

In order to prevent undesirable low level of

crosslinking of the cable, authors conducted an

experimental campaign crosslinking a medium

voltage electric cable in four different conditions.

Preliminary rheometer characterizations at

different temperatures and concentrations of the

curing agents were performed to find out the most

suitable crosslinking conditions. Several meters of

cured samples were produced in order to measure

the crosslinking degree. The level of crosslinking

was evaluated through differential scanning

calorimetry DSC, i.e. by the content of the unreacted

peroxides, on five different radial positions of the

cable, from the core to the external layer.

Experimental results of DSC analysis are reported in

the paper.

The determination of the unreacted quantity of

63

Milani G. and Milani F..

Experimental/FEM Optimization of Medium Voltage Rubber Insulated Electric Cables Vulcanized with Steam Water - Differential Scanning Calorimetry

(DSC) and Rheometer Experimental Results.

DOI: 10.5220/0005502900630068

In Proceedings of the 5th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2015),

pages 63-68

ISBN: 978-989-758-120-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

peroxide is not evaluable by the well-known relation

between temperature and half time life of peroxide (

2/1

t

) because the curing agent used is a mixture of

peroxides. To overtake this limitation, authors

applied a recently proposed quite robust kinetic

model based on multiple rheometer characterization,

which has been integrated in the thermal analyses.

2 PEROXIDE CURING PROCESS,

KINETIC MODEL FOR

PEROXIDE MIXTURES

This section provides a numeric assessment of the

results obtained experimentally and a brief

description of the numeric model used to fit

experimental data. The model is based on the kinetic

of the reactions occurring in EPDM cured by

peroxide through the following steps:

Translation of chemical reactions into

mathematical differential equations (set of first

order ordinary differential equations, ODE

system);

Manipulation of the ODE system to reduce the

problem to a single nonlinear ODE;

Solving of the nonlinear equation through a

standard numeric tool;

Estimation of the kinetic constants entering into

the model by means of standard least squares

fitting of the experimental rheometer curves.

The basic chemistry of peroxide curing of EPDM

has been reviewed by van Duin and co-workers

(2002) and could be summarized by the following

partial reactions that occur in series and parallel:

1

ROOR RO R'

2

initiation

EP(D)M-H RO /R' EP(D)M ROH/R'H

H-abstraction

2EP(D)M EP(D)M-EP(D)M

(combination)

EP(D)M EP(D)M EP(D)M EP(D)M EP(D)M EP(D)M H

(addition)

(1)

Where the exact meaning of the symbols can be

found in e.g. Milani et al., 2014, where the reader is

referred to.

In the numeric model we adopted the kinetic

scheme for the peroxide crosslink reactions

summarized previously because it reproduces the

most important steps occurring during peroxide

curing and it is simple to handle.

It can be proved that polymer concentration (P)

vs time (t) can be estimated using xyz method after

suitable mathematical manipulation:

02

1

1

0212

2

2

2

o

ttK

PeIKK

dt

dP

PK

dt

dP

P

dt

Pd

(2)

Further details on equation derivation (2) could be

found in Milani et al., (2014).

The nonlinear differential equation (2) may be

solved numerically with a standard Runge-Kutta

algorithm to find concentration P(t).

The knowledge of P(t) allows the determination

of quantity R(t) and

*

P

(residual polimer after de-

vulcanization):

*

4

2

*

32

*

)()( PKPKtPtRK

dt

dP

(3)

Equation (3) is again solved using a Runge-Kutta

numeric approach.

The combined application of equation (2) and (3)

with least squares minimization allows to estimate

the kinetic constants entering into reaction scheme.

Figure 1: Real industrial production line considered.

=270 mm

2

m

extruder

P

=210 mm

slope 11°

slope 3°

1

3

t

o

t

a

l

l

e

n

g

t

h

5600 mm

t

o

t

a

l

l

e

n

g

t

h

o

f

t

h

e

l

i

n

e

:

1

0

3

m

Free surface water level

T

4

4

m

T

3

4

m

T

2

5

m

capstan

P: vapour pressure measure T evaluation

T

1

1

T , if not submerged normally 10-20°C less than T

21

T and T always submerged: from 70°C to 35°C

34

C

o

o

l

i

n

g

p

h

a

s

e

H

e

a

t

i

n

g

p

h

a

s

e

Suspended cable for 30-35 meters, then resting on the lower part of the tube

H

e

a

t

i

n

g

p

h

a

s

e

Water pool

diameter change

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

64

3 DETERMINATION OF

TEMPERATURE PROFILES IN

THE VULCANIZATION TUBE

A short overview of the mathematical basis of the

numeric approach employed for the determination of

cable temperature profiles under curing is reported.

The production line is supposed to be constituted by

a vulcanization pipe (with water steam at high

temperatures) followed by a water cooling phase (at

lower temperature) as reported in Figure 1.

Steam temperature adopted by manufacturers

usually depends on the peroxide employed for the

EPDM crosslinking. Linear speed of the cable

determines the exposition time at fixed pipe length.

At fixed exposition time and temperature

crosslinking degree of each layer can be numerically

estimated applying standard heat transmission

physical laws.

The analyses hereafter conducted refer to a real

CV line. Its basic scheme is sketched in Figure 1.

The head of the extruder is connected to the

vulcanization pipe. After extrusion, the cable passes

into a pipe containing water steam under pressure.

Finally the tube is connected with a submerged

equipment with cooling water. Linear speed of the

cable is controlled by the capstan at the end on the

line.

The CV pipe considered in this work is 103

meters long and exhibits an initial inclination of 11°

for approximately one third of its length. After this

zone, the pipe shows a slight residual slope of 3°.

Diameter of the pipe is initially equal to 270 mm and

reduced to 210 mm starting from one half of the

length.

Two meters after the head of the extruder is

located an analogic manometer used to measure the

steam pressure acting during the vulcanization

process. In the last 15 meters of the pipe, the cable is

cooled by a water-pool at 35-40°C. Also the capstan

is partially submerged. Considering as reference the

free surface of the water in the pool the depth of the

extruder head is equal to 5.6 meters. In the initial

part the cable is suspended inside the pipe, but after

30-35 meters it rests on the lower part of the

vulcanization device because of the combined action

of gravity and slope change, posing also doubts on

the effective symmetric crosslinking of the item

under such physical conditions. Since the cable

enters into the last portion of the line in

correspondence of the lower part of the pipe, it

immediately comes in contact with the cooling

water-pool. Water level has therefore to be checked

with particular care in order not to vary significantly

the length of heating zone.

Three thermometers are placed in the last 15

meters at a mutual distance of 5 meters and labeled

in Figure 1 as T

2

, T

3

and T

4

respectively.

Theoretically, T

2

should measure the same

temperature deduced from the pressure measure at

the beginning of the line (i.e. T

1

), but in practice this

never occurs, because T

2

is usually 10-20 °C lower

than T

1

near the surface of the water. This issue

depends intrinsically on the design of the plant and

partially on initial temperature imposed. In some

cases, it occurs that T

2

section is submerged

vanishing the temperature check at the end of the

heating phase. No thermometer probes are installed

in intermediate position from the begging to the end

of the heating phase. T

3

and T

4

thermometers have

the role to monitor the temperature of the water-

pool.

The experimental campaign has been conducted

under the following four different crosslinking

conditions:

Test #1: temperature T

1

=202°C, total curing time

t

c

=5.6 minutes;

Test #2: temperature T

1

=212°C, total curing time

t

c

=5.6 minutes;

Test #3: temperature T

1

=202°C, total curing time

t

c

=7.7 minutes;

Test #4: temperature T

1

=212°C, total curing time

t

c

=7.7 minutes.

Table 1: Experimental data set analyzed, EPDM

composition in grams.

Polymer

(Exxon)er Manufactur

35.3 100°C 4)+(1 MLMooney

0.9 % in wt. rnenevinylnorbo-VNB

76.2 % in wt. Ethylene

1703P VISTALON

100

Silane treated calcinated kaolin 55.5

Antioxidants 14.8

LDPE Riblene MR 10 MFI= 18.7

(ASTM D1238)

11.1

PE WAX 1.8

Peroxide mixture M3 1.1

4 EXPERIMENTAL

RHEOMETER CURVES AND

KINETIC MODEL

The polymer used is a commercial EPDM, with

properties furnished by the provider and summarized

Experimental/FEMOptimizationofMediumVoltageRubberInsulatedElectricCablesVulcanizedwithSteamWater-

DifferentialScanningCalorimetry(DSC)andRheometerExperimentalResults

65

in Table 1. The mixture (M3) of peroxides used as

curing agent is a composition of three different

peroxides: Trigonox T, Perkadox BC-FF and

Perkadox 14S. For the composition and use of the

mixture of peroxides M3 the reader is referred to

Milani and co-workers (2014).

The amount of peroxide, referred to 100 grams

of polymer, is variable. The chosen standard

concentration, labeled as “+/-0%”, is equal to 5.037

millimoles per 100 g of polymer. It was considered

as “reference” because this was the concentration

used in the standard industrial production of the

compound.

M3 +150% 160°C

-a

M3 +150% 180°C

-b

M3 +150% 200°C

-c

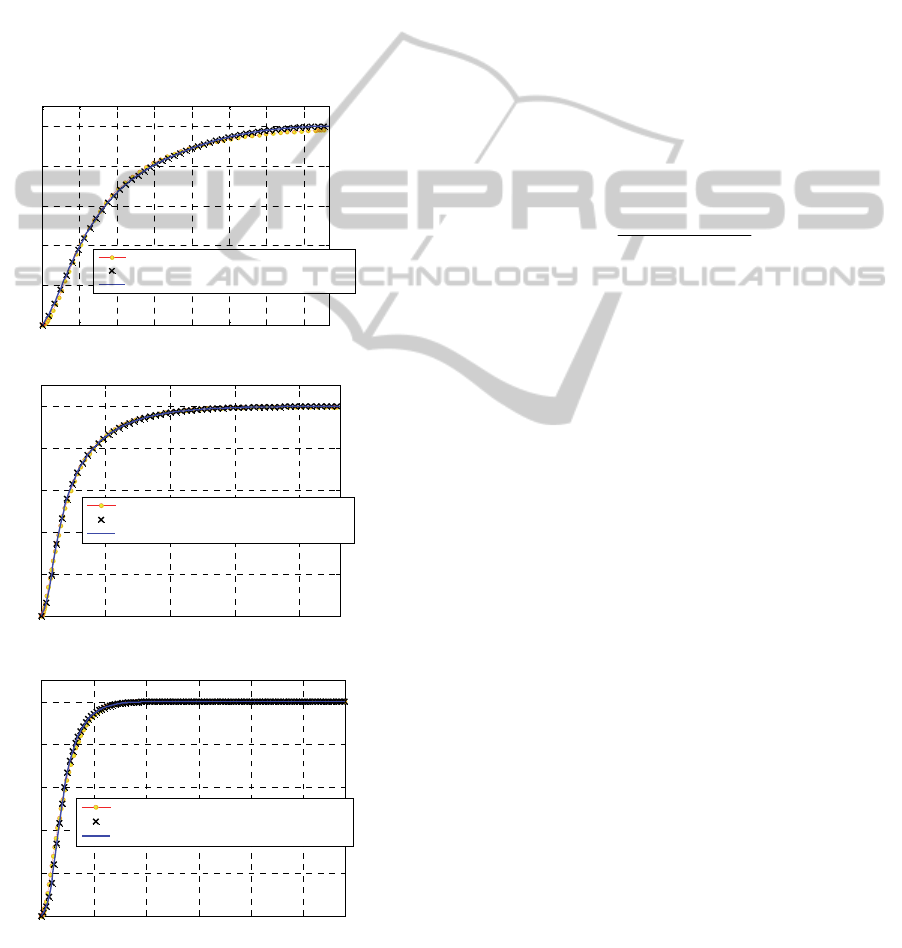

Figure 2: M3 curing agent. Comparison between

normalized experimental rheometer curve and numeric

model predictions. –a: 160°C. –b: 180°C. –c: 200°C.

Four additional concentrations were tested,

called -50%, +50%, +100% and +150%. Labels

indicate the molar concentration of the curing agent

with respect to the standard concentration. For

instance, a +50% concentration indicates that 1.5

moles with respect to the standard one were used.

Three different vulcanization temperatures where

inspected, typical for the curing of medium/high

voltage electric cables, namely 160°C, 180°C and

200°C.

DSC analysis are used to quantify the unreacted

crosslinking agents and Rheometer curves to obtain

an indirect information on the state of cure or cure

efficiency of the crosslinking agent, as extensively

demonstrated by Sun and Isayev (2009).

The average M(t) curves obtained may indeed be

used to calculate the evolution of the crosslinking

degree exp(t) using Sun and Isayev (2009) relation:

00

minmax

min

exp

TT

T

MM

MtM

t

(4)

where:

M

minT

is the minimum value of torque S’ during a

cure experiment at temperature T. Before

reaching this minimum value, exp is considered

equal to zero.

M

minT0

and M

maxT0

are the minimum and

maximum torque values, obtained for a cure

experiment at a temperature T

0

low enough to

allow neglecting reversion. In this way,

rheometer curves to fit always range between 0

and 1, with a maximum torque sensibly lower

than 1 for high vulcanization temperatures.

Experimental results rely into a thermal

characterization to determine the state of cure of

each sample conducted by means of a standard ODR

(oscillating disc rheometer), and mechanical

characterizations, in particular tear and tensile

strength tests.

5 THE NEW SIMPLIFIED

MECHANISTIC MODEL

PROPOSED

Experimental data exhibit a maximum torque close

to 55 dNm that lowers at low concentrations

(especially at -50%), whereas a concentration

increase results in a beneficial effect.

The absence of reversion (decrease of torque

after reaching the maximum) and the homogeneity

0 5 10 15 20 25 30 35

0

0.2

0.4

0.6

0.8

1

Time [min]

Normalized torque M

t

/M

tmax

Present model solution

Experimental data utilized to set numerical model

Full experimental data curve

0 5 10 15 20

0

0.2

0.4

0.6

0.8

1

Time [min]

Normalized torque M

t

/M

tmax

Present model solution

Experimental data utilized to set numerical model

Full experimental data curve

0 2 4 6 8 10

0

0.2

0.4

0.6

0.8

1

Time [m i n]

Normalized torque M

t

/M

tmax

Present model solution

Experimental data utilized to set numerical model

Full experimental data curve

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

66

M3

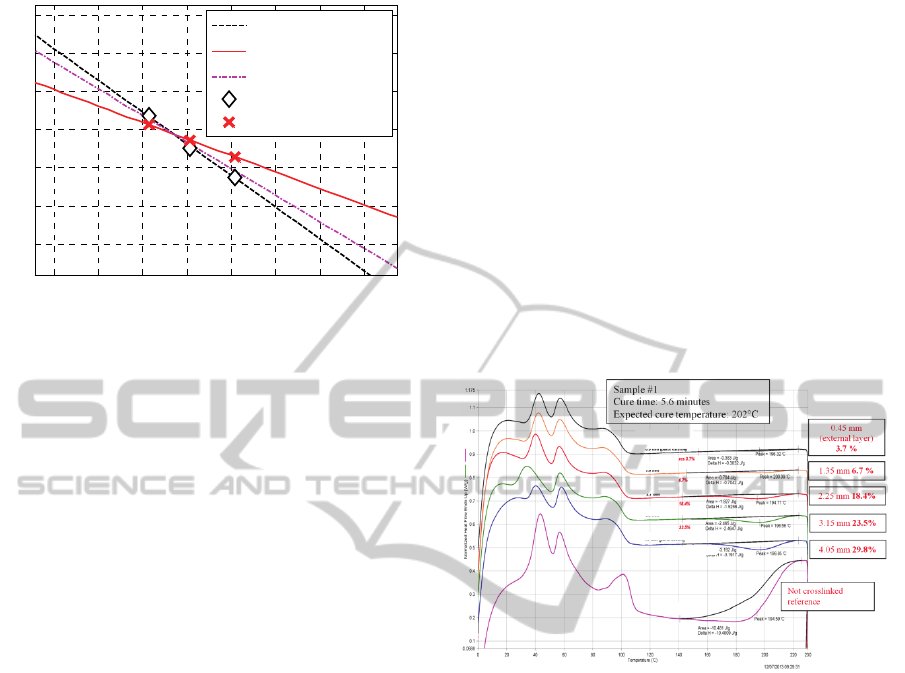

Figure 3: Linear regression interpolation of the kinetic

constants

1

K

and

2

K

provided by the single differential

equation model and the resultant linear regression

obtained as weighted sum of

1

K

and

2

K

of minimum and maximum values of the torque at

the three temperatures allow the normalization of the

analysis simply dividing each value of the torque by

the maximum torque, measure during the test. For

the cases where reversion is present, the reader is

referred to Milani (2013).

Experimental evidences show that maximum

crosslinking density could be obtained with at

double amount of peroxide in comparison to the

standard one (+100% concentrations).

Kinetic constants of the mixture M3 are

evaluated numerically with the kinetic model

previously discussed. Numerically predicted

rheometer curves resulting from the fitting process

are depicted and compared with experimental ones

in Figure 2 (-a: 160°C, -b: 180°C and –c: 200°C).

The numeric fitting overlaps almost perfectly the

experimental curves. Numeric curves were obtained

using a nonlinear least square procedure. As

extensively demonstrated in Milani and co-workers

(2014), the fitting of experimental response is rather

satisfactory by superposition of calculated curves

with experimental data.

Considering the numeric values obtained for the

two constants

1

K

and

2

K

at three distinct

temperatures (the other constants are close to zero,

indicating that no reversion is experienced), the lines

passing from such values in the Arrhenius plane was

plotted. In this space, the horizontal axis is

represented by the inverse of the absolute

temperature,

T/1 , whereas the vertical axis is

i

Klog

, where

i

K

is the ith kinetic constant. The

calculated lines are plotted in Figure 3.

6 DIFFERENTIAL SCANNING

CALORIMETRY (DSC)

The differential scanning calorimetry (DSC) has

become the most used thermal analyzing technique.

We have used this technique in order to quantify the

vulcanization degree and hence the unreacted

peroxide after the crosslinking process recovering

samples across the sample section.

Five samples were cut at 1 mm of distance along

the cross section (0.9 mm external surface, 1.8, 2.7,

3.6, 4.7 mm internal surface). The analyses were

carried out on 10-15 mg samples in the temperature

range from 0 to 230°C at the scanning rate of

20°C/min under inert atmosphere (N

2

) in punched

aluminum pans.

Figure 4: sample #1, DSCs on different positions from the

external layer compared with DSC of the not crosslinked

sample.

The residual unreacted peroxide has been

calculated in order to evaluate the crosslinking

degree according to the equation:

Res = H

r

/ H

0

(5)

where H

r

is referred to the peroxide in the sample

and H

0

to the peroxide in the not crosslinked

compound used as reference (100% of crosslinking

residue).

In Figure 4 the results of the DSC performed for

Sample #1 with the corresponding evaluation of the

unreacted peroxide concentration are represented. In

each figure six curves are reported. Five refer to the

different positions across the cable section whereas

the last one is the reference curve for the sample

before crosslinking. The representation refers to the

measured normalized heat flow plotted against

temperature.

1.9 2 2.1 2.2 2.3 2.4 2.5 2.6

x 10

-3

-3

-2

-1

0

1

2

3

1/T [K]

l

og

(

K

i)

K

1

=K

10

e

E

a

/R

g

T

K

2

=K

20

e

E

a

/R

g

T

1/3[2*log(K

1

)+log(K

2

)]

Numerical data K

1

Numerical data K

2

Experimental/FEMOptimizationofMediumVoltageRubberInsulatedElectricCablesVulcanizedwithSteamWater-

DifferentialScanningCalorimetry(DSC)andRheometerExperimentalResults

67

7 CONCLUSIONS

The experimental study on CV line crosslinked

EPDM allows drawing the following considerations:

1. Optimization of final mechanical properties

could be obtained with a detailed mechanical

characterization at different concentrations of the

curing agent;

2. A mixture of peroxides shows the interesting

feature to reduce the gap between tensile and tear

strength performances.

DSCs and classical rheometric curves are key tools

to double check the unreacted peroxide

concentration and the efficiency of the used curing

agent. In an accompanying paper (Milani and Milani

2015) a comprehensive numerical investigation

basing on the kinetic mathematical approach here

presented and coupled with Finite Element

computations will be presented and applied to the

experimental case study here discussed, assuming in

the numerical model a drop of the steam temperature

along the length of the pipe to minimize the error

between experimentally obtained data and

numerically predicted output.

Residual values of peroxide are collected in

Table 2 and Table 3, where the results of the DSC

experimental campaign are synoptically represented.

Table 2: experimentally determined quantity of unreacted

peroxide, test #2 and #4, temperature equal to 202°C.

Curing time Distance from the surface

0.9 mm 1.8 mm 2.7 mm 3.6 mm 4.7 mm

5.6 min (#1) 3.7 6.7 18.4 23.5 29.8

7.0 min (#3) 0 0 0 2.1 3.7

Table 3: experimentally determined quantity of unreacted

peroxide, test #2 and #4, temperature equal to 212°C.

Curing time Distance from the surface

0.9 mm 1.8 mm 2.7 mm 3.6 mm 4.7 mm

5.6 min ( #2) 0 0 0.9 3.6 11.4

7.7 min (#4) 0 0 0 0 0

REFERENCES

Ding R., Leonov I., J. Appl. Polym. Sci., 61, 455 -1986.

Isayev A.I., Deng J.S., Rubber chemistry and technology,

61(2), 340-361 -1988.

Milani G., Galanti A., Cardelli C., Milani F., Journal

Appl. Polym. Sci., 131(8) 2014, paper #40075. DOI:

10.1002/app.40075.

Milani G., Journal of Mathematical Chemistry, 51(8),

2038 -2013.

Milani G., Milani F., Computers and Chemical

Engineering, 32, 3198 – 2008.

Milani G., Milani F., Experimental/FEM optimization of

medium voltage rubber insulated electric cables

vulcanized with steam water. Numerical simulations

and inverse analyses. In Proc. 5

th

International

Conference on Simulation and Modeling

Methodologies, Technologies and Applications

SIMULTECH2015, Colmar, France, 21-23 July 2\015.

Roberts B. E., Verne S., Plastic and Rubber Processing

and Applications, 4(2), 135 – 1984.

Van Duin M., Kautsch. Gummi Kunstst., 55, 150 – 2002.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

68