Low Noise Design of Regenerative Blower by Combining the

FANDAS-Regen Code, Optimization Technique and

Phase-Shift Cancellation Concept

Chan Lee, Hyun Gwon Kil and Jun Kon Kim

Department of Mechanical Engineering, University of Suwon, Hwaseong, Korea

Keywords: Regenerative Blower, FANDAS-Regen Code, Optimization Algorithm, Low Noise.

Abstract: Low noise regenerative blower is designed by combining the FANDAS-Regen code and optimization

technique. The FANDAS-Regen code used in the present study defines blower design variables on rotating

impellers and fixed side channels, and then constructs the 3-D blower design geometry. Based on the

designed blower geometry, the FANDAS-Regen code also analyzes the blower performance as well as noise

characteristics by using momentum exchange theory coupled with pressure loss and leakage models and by

incorporating the performance prediction results into discrete and broadband noise models. With the

FANDAS-Regen code as a simulation engine, design optimization is conducted for impeller and side

channel design variables to minimize overall sound pressure level of blower under the constraints of

aerodynamic design requirements on pressure rise, efficiency and power consumption. Furthermore, for

more noise reduction of blower, a staggered impeller blade arrangement as a phase-shift cancellation design

concept is also applied to the optimized impeller design. The optimized blower model is manufactured and

tested by a chamber-type performance tester and narrow-band noise measurement apparatus. The

performance measurement results agree well with the FANDAS-Regen prediction, and the noise

measurement results show a remarkable noise reduction of 26 dBA through the present design optimization.

1 INTRODUCTION

Regenerative blowers are usually operated with high

pressure rise at low flow capacity and are widely

used as the gas supply equipment of fuel cell

automotive vehicles and distributed fuel cell power

systems (Badami and Mura, 2011; 2012). However,

because the most of these fuel cell systems are

located very close to human users, when

regenerative blower is used in the fuel cell

applications, its high noise characteristics would be

main shortcoming and hurdle to be applied in the

fuel cell applications. For this reason, there are

growing industrial needs of low noise regenerative

blower design.

Through the previous research by authors(Lee et

al., 2013), the FANDAS-Regen code as design-

analysis program for regenerative blower has been

developed and showed its good prediction

accuracies on performances and noise levels of

designed regenerative blower. In the FANDAS-

Regen code, 3-D blower geometry on impeller

blades and side channel is designed, and then blower

performances are predicted by the momentum

exchange theory between the rotating impeller

blades and the fixed side channel. After the predicted

performance results are obtained and then

incorporated with the noise models of the FANDAS-

Regen code, discrete frequency noise at blade

passing frequency and its harmonics are predicted by

acoustic mode analysis, and broadband noise is also

predicted by the combination of several correlation

models for inflow turbulence, impeller turbulence

and exhaust jet mixing. The performance and noise

prediction accuracies of the FANDAS-Regen code

are verified by comparing the prediction with the

measurement results of actual regenerative blowers.

Furthermore, with the use of the present analysis

method of the FANDAS-Regen code as simulation

engine, design optimization is conducted for two

impeller and side channel design variables to

minimize overall noise level of blower, and then a

phase-shift cancellation concept of staggered

impeller blade arrangement is also applied for more

noise reduction of optimized blower. The optimized

469

Lee C., Kil H. and Kim J..

Low Noise Design of Regenerative Blower by Combining the FANDAS-Regen Code, Optimization Technique and Phase-Shift Cancellation Concept.

DOI: 10.5220/0005514304690475

In Proceedings of the 5th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2015),

pages 469-475

ISBN: 978-989-758-120-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

blower by the present study is manufactured and

tested by using chamber-type test facility and

narrow-band noise measurement apparatus and its

measurement results are favorably compared with

the prediction by the FANDAS-Regen code. The

comparison results also show the overall noise level

of optimized blower is remarkably reduced by 26

dB(A) when compared with that of initial design.

2 DESIGN, PERFORMANCE AND

NOISE ANALYSIS METHODS

OF THE FANDAS-REGEN CODE

2.1 Blower Design Method

In general, regenerative blower is composed of

impellers equipped on double sides of rotating plate

and fixed side channel covering the impellers.

Blower’s design variables and geometry are shown

in Fig.1.

Figure 1: Geometry and design variables of regenerative

blower.

The main design variables of rotating impellers and fixed

side channel are defined as follows:

- Rotation speed( N )

- Tip diameter( D

2

=2r )

- Channel height( h )

- Channel width( W )

- Impeller blade inlet angle( β

1

)

- Impeller blade outlet angle( β

2

)

- No. of impeller blades( Z )

- Impeller blade thickness( d )

- Axial clearance( c )

- Extension angle( θ

c

)

Once the blower design variables are determined by

designer, 3-D blower shape and geometry are easily

obtained and then can be used for the input data of

performance analysis and CFD simulation.

2.2 Blower Performance Analysis

Models

In the FANDAS-Regen code( Lee et al., 2013), the

performance of blower is analysed by combining the

mean line analysis method for fluid flow and the

momentum exchange theory between impellers and

side channel. As shown in Fig. 2, the gas flow inside

regenerative blower is assumed to be typically three

dimensional and helical-toroidal motion where fluid

rotates in and passes along the space between

rotating impeller blades and fixed side channel. The

present study assumes mean streamline as the

representative one of the three dimensional fluid

flow phenomena.

(a) Flow behavior inside regenerative blower

(b) Cross section view on helical-toroidal flow

Figure 2: Flow pattern of regenerative blower.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

470

Through the momentum exchange between fluid

and impeller due to this flow motion, gas pressure is

gradually raised along tangential flow path and its

overall pressure rise( ∆p

s

) is calculated by

2

21

12

2

1

2(/4)

1

2

sm uu

pf

cc

pQ CC

rr

KK

Aur r u u

u

φ

ρ

Δ

=−−+

(1)

where

22 2

2

22

1cot

ucm

c

CAQ

ru

ur u AAu

β

Δ

=− +

(2)

22

2

2

12 2

1.5 1.1(2 2 / )

[1 ( / ) ] 1.5 1.1(2 2 / )

u

uZrr

βπ

βπ

Δ+−

=

−++−

(3)

c

Q

uA

ϕ

=

1

1

u

Cr

ur

ϕ

=

(4)

2

22

2

1

21

11

2

12 12

2

11

cot cot

2sin

cm c cm

m

cc

AQ u AQ

Ar

K

AAAuruAAu

ββ

β

++ +−

(5)

Here ρ, u, Q, Q

m

and φ are fluid density, impeller

rotation speed, flow capacity, circulating flow rate

and flow coefficient. More detailed description and

variable definition about momentum-exchange

theory are referred to Badami et al( Badami and

Mura, 2012 ).

As represented in equation (1), proper models

for pressure losses and the leakage flows should be

constructed for accurate performance prediction, so

the FANDAS-Regen code uses the correlations of

Table 1, which are expressed as the functions of

blower design variables( Lee et al., 2013 ).

Table 1: Pressure loss and leakage model coefficients.

2.3 Blower Noise Modelling and

Analysis Method

Based on the blower performance prediction results,

the FANDAS-Regen code considers two kinds of

noise components. One is the discrete frequency

noise at blade passing frequency( BPF ) and another

is the broadband noise distributed over wide

frequency range, which are produced due to inflow

turbulence at blower inlet, turbulence within

impeller and side channel and turbulent jet at blower

exit.

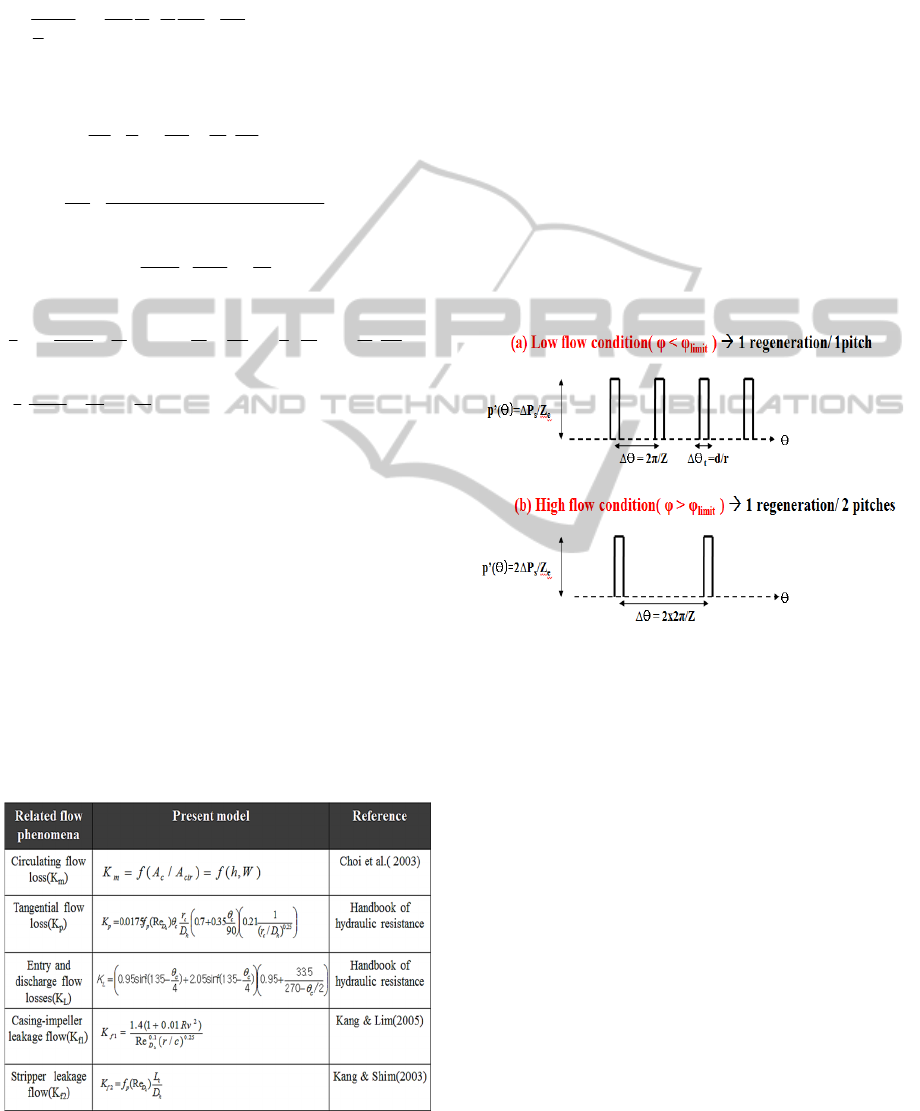

Discrete frequency noise is produced due to the

pressure difference between adjacent impeller blades

rotating at BPF. In the present study, the pressure

difference is defined by ∆p

s

/Z

e

or 2∆p

s

/Z

e

and its

pressure fluctuation can be modelled as shown in

Fig. 3:

Figure 3: Theoretical model for the pressure fluctuation

between adjacent impeller blades.

where ∆p

s

is overall blower pressure rise calculated

by the performance prediction method of section 2.2,

and Z

e

, d and r represent effective number of

impeller blades, impeller thickness and impeller tip

diameter respectively, and θ is angular coordinate in

the direction of tangential flow. As shown in Fig. 3,

fluid pressure rise is achieved through 1

regenration/1 pitch of fluid at low flow capacity( ϕ <

ϕ

lim

) while it being achieved through the 1

regeneration/ 2 pitches at high flow capacity(ϕ >

ϕ

lim

). Here ϕ is the flow coefficient as non-

dimensional flow capacity parameter, and ϕ

lim

is

assumed as 0.75 from the experiment of Badami and

Mura( Badami and Mura, 2013 ).

Under the assumption of dipole type noise

radiation, classical acoustic theory (Wright, 1975)

on the rectangular-shaped pressure fluctuation of Fig.

3 gives the following root mean square value of

acoustic pressure( p

a

’ ) as:

0

2

1

2

1

2

1

2

2

2

2

2

1

=

−

+

−

+

u

u

u

u

r

rr

c

c

LowNoiseDesignofRegenerativeBlowerbyCombiningtheFANDAS-RegenCode,OptimizationTechniqueand

Phase-ShiftCancellationConcept

471

at ϕ < ϕ

lim

at ϕ > ϕ

lim

(6)

where m= 1 means fundamental mode, m=2,3, …

mean its harmonic modes, and θc, θ and R are side

channel extension angle, noise measuring angle and

radius.

Broadband noise is produced from three main

noise sources of inflow turbulence, impeller

turbulence and exhaust turbulent jet. The present

study employs well-verified correlation model

corresponding to each noise sources (Mugridge,

1976; Goldstein, 1976), and their noise prediction

results are superimposed over frequency range. It is

noted that all the present broadband noise models

are expressed in terms of blower design variables

and performance parameters.

Figure 4: Performance and noise measurements.

2.4 Verification of the FANDAS-Regen

Code Prediction Method

The FANDAS-Regen code is applied to two existing

blower models for verifying its prediction accuracies

of performance and noise. The performance and

noise measurements on two Hwang-Hae blower

models (Hwang-Hae, 2012) are made by chamber-

type test facility and by the precision sound level

meter or the PULSE, a FFT analyser, as shown in

Fig. 4.

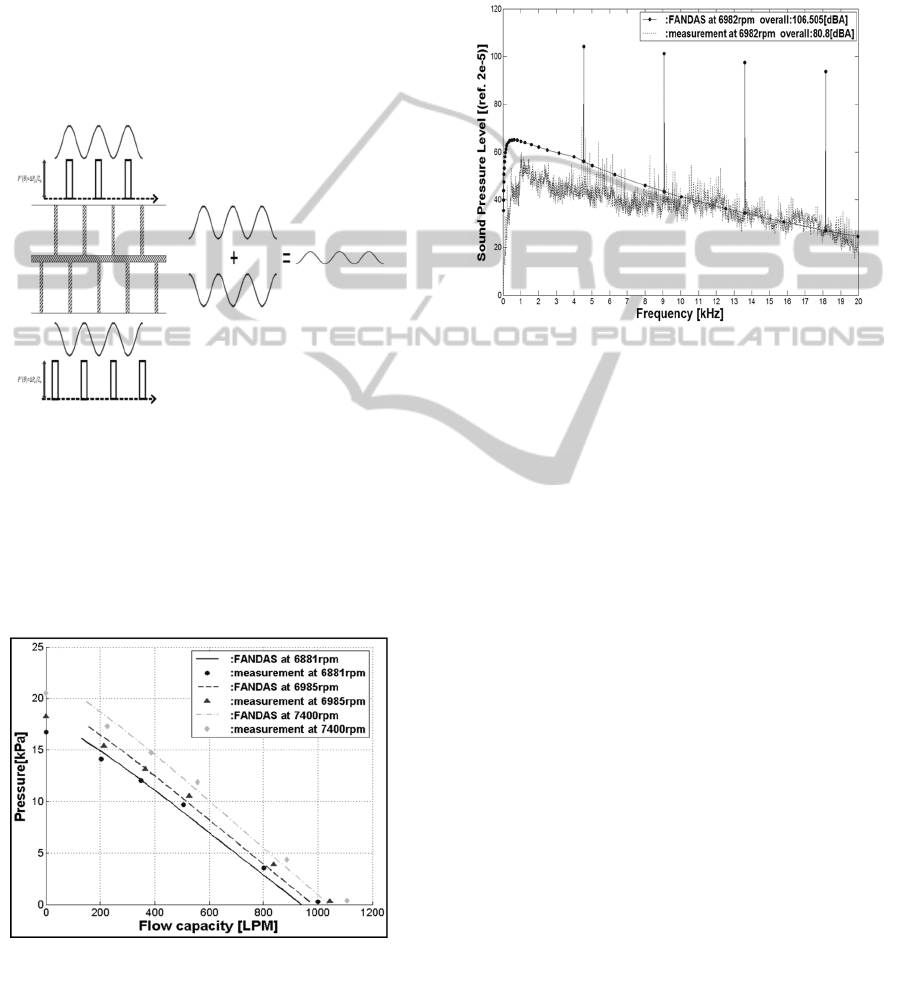

Figs. 5 and 6 show the performance and the

noise prediction results of Mini H-200

model( Hwang-Hae, 2012 )by the FANDAS code.

The performance prediction results are well-agreed

with the measurement over entire flow capacity

range, and the noise spectrum analysis result derived

from the performance prediction is also verified

through the good comparison between the prediction

and the measurement at blade passing frequency and

over wide frequency range. It is noted the noise

measurement of Mini H-200 at maximum flow

capacity is made from octave band analysis at 1.5 m

from blower inlet.

Fig. 7 and 8 represent the comparison between

the FANDAS-Regen code and the measurement

results of Mini H-100 model( Hwang-hae, 2012 ).

As shown in Fig. 7, the predicted performances by

the FANDAS-Regen code are well-agreed with the

measurement. Fig. 8 shows the predicted noise

spectrum at maximum flow capacity is reasonably

agreed with the 1/3 octave band measurement.

Figure 5: Aero-acoustic performance map of Mini H-200.

Figure 6: Noise spectrum of Mini H-200.

R

mZ

r

mZd

mZ

rp

Rp

c

s

a

)cos(

2

sin22),(

'

θ

θ

θ

Δ

=

R

mZ

r

mZd

mZ

rp

Rp

c

s

a

)cos(

2

sin24),(

'

θ

θ

θ

Δ

=

Flow capacity[LPM]

0 50 100 150 200 250 300 350

Efficiency[%], Power[kW] and OASPL[dB]

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

Static pressure[mmAq]

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

: Static pressure[mmAq]-Pred.

: Efficiency[%]-Pred.

: Power[kW]-Pred.

: OASPL[dBA]-Pred.

: Static pressure[mmAq]-Exp.

: OASPL[dBA]-Exp.

Frequency[Hz]

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000

Noise level

0

10

20

30

40

50

60

70

80

90

100

: SPL[dB]-Pred.

: SPL[dBA]-Pred.

: SPL[dBA]-Exp.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

472

Figure 7: Aero-acoustic performance map of Mini H-100.

Figure 8: Noise spectrum of Mini H-100.

From the comparison results of Figs. 5-8, the

performance and noise prediction method of the

FANDAS-Regen code is expected to be used as

reliable simulation engine suitable for blower design

optimization.

3 BLOWER NOISE REDUCTION

BY DESIGN OPTIMIZATION

The present study conducts design optimization for

noise minimization of the blower with the following

design parameters:

- Rotation speed = 7400 rpm

- Side channel height( h ) = 20 mm

- No. of impellers( Z ) = 39

- Axial clearance( c ) = 0.2 mm

- Impeller blade thickness( d ) = 1 mm

- Tip diameter( D

2

) = 100 ∼ 200 mm

- Side channel width( W ) = 5 ∼ 15 mm

As mentioned above, tip diameter( D

2

) and side

channel width (W) are treated as the design variables

of optimization study while the other parameters

being as fixed values.

Therefore, the present optimization problem can

be formulated with the constraints for design

requirements as follows:

Find D

2

and W to minimize OASPL[ dBA ]

Subject to design flow capacity( Q

d

) = 350[ LPM ]

design pressure( ΔP

s

) ≥ 13 [ kPa ]

design-pt. efficiency( η

s

) ≥ 25 [%]

design-pt. power ≤ 500 W

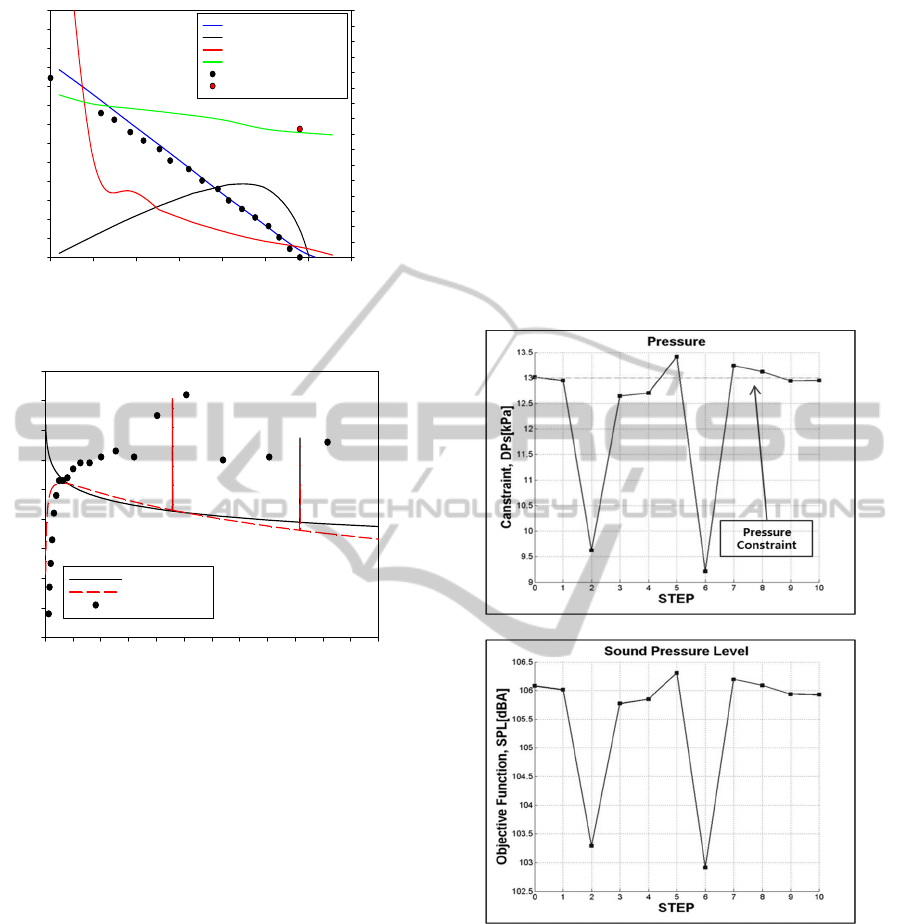

(a) Static pressure

(b) Overall sound pressure level

Figure 9: Solution-finding histories.

The above optimization problem is solved by the

STQDAO algorithm of gradient-based sequential

approximate optimization technique in the PIAno

code (PIDOTECH, 2013) and its solution-finding

histories are shown in 9. After 10 iterations from

initial design condition, with satisfying pressure

constraint, optimum design is obtained as D

2

= 144

mm, W = 12 mm and results in the noise reduction

by 2.78 dBA compared with the initial design.

In addition to the optimization mentioned before,

for more noise reduction, the present study also

Flow capacity[LPM]

0 50 100 150 200 250 300 350

Efficiency[%], Power[kW] and OASPL[dB]

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

Static pressure[mmAq]

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

: Static pressure[mmAq]-Pred.

: Efficiency[%]-Pred.

: Power[kW]-Pred.

: OASPL[dBA]-Pred.

: Static pressure[mmAq]-Exp.

: OASPL[dBA]-Exp.

Frequency[Hz]

0 100020003000400050006000700080009000100001100012000

Noise level

0

10

20

30

40

50

60

70

80

90

: SPL[dB]-Pred.

: SPL[dBA]-Pred.

: SPL[dBA]-Exp.

LowNoiseDesignofRegenerativeBlowerbyCombiningtheFANDAS-RegenCode,OptimizationTechniqueand

Phase-ShiftCancellationConcept

473

employs a phase-shift cancellation concept on

impeller blade arrangement design. As known from

Fig. 3 of section 2.3, acoustic pressure is radiating

from each impeller blade in the form of sinusoidal

wave with the period of blade pitch. Thus, because

impeller blades are equipped and arranged along

angular direction on double sides of rotating plate, if

the impeller blades are arranged with staggered type

as shown in Fig. 10, the acoustic pressure radiating

from impeller on one side could be cancelled by that

from impeller on another side (Lee and Kil, 2014;

Kim et al., 2014 ).

Figure 10: Phase-shift cancellation concept.

Fig. 11 shows the pressure rise curves of the blower

model obtained through the applications of design

optimization and phase-shift cancellation concept.

The predicted pressure curves are well agreed with

the test ones at various RPM conditions, and the

optimized model satisfies its design requirement of

static pressure at design point.

Figure 11: Pressure rise curves of optimized blower.

Fig. 12 shows the comparison of the predicted noise

spectrum of initial blower model with the measured

one of the optimized blower model. As shown in Fig.

12, remarkable noise reductions of discrete

frequency noise components can be found at BPF

and its harmonics. These noise reduction effects

might be due to both the design optimization of 2.78

dBA and the phase-shift cancellation of 22.9 dBA.

The overall sound pressure level of the optimized

blower is significantly reduced by about 26 dBA

compared with the initial design case.

Figure 12: Noise spectrum of optimized blower.

4 CONCLUSIONS

The present study conducts noise reduction design of

regenerative blower by combining the FANDAS-

Regen code, optimization technique and phase-shift

cancellation concept. The FANDAS-Regen code, as

simulation engine of optimization problem, can

predict blower performances as well as noise levels

and its prediction results are well agreed with the

measurements. The optimization process by

STQDAO algorithm is carried out for low noise

blower design and then phase-shift cancellation

concept of staggered impeller arrangement is also

applied to the optimized blower. The present design

optimization gives the final design with 26 dBA

noise reduction compared with the initial design.

ACKNOWLEDGEMENTS

This work was supported by the Development of the

Regenerative Blower for fuel cell application of the

Korea Institute of Energy Technology Evaluation

and Planning (KETEP) grant funded by the Korea

government Ministry of Knowledge Economy.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

474

REFERENCES

M. Badami, and M. Mura, Comparison between 3D and

1D Simulations of Regenerative Blower for Fuel Cell

Applications, 2012, Energy Conversion and

Management, 55, 93-100.

C. Lee, H.G. Kil, G.C. Kim, J.G. Kim, J.H. Ma, and K.H.

Chung, 2013, Aero-acoustic Performance Analysis

Method of Regenerative Blower, J. of Fluid

Machinery( in Korean ), 16(2).

M. Badami and M. Mura, 2011, Setup and Validation of a

Regenerative Compressor Model Applied to Different

Devices, Energy Conversion and Management, 52,

2157-2164.

S. E. Wright, 1976, The Acoustic Spectrum of Axial Flow

Machines, J. of Sound & Vibration 45(2), 165-223.

B. D. Mugridge, 1976, Noise Characteristics of Axial and

Centrifugal Fans as Used in Industry, Shock and

Vibration Digest, 45(3).

M. E. Goldstein, 1976, Aeroacoustics, McGraw-Hill.

Regenerative Blower Performance and Noise Test

Report, 2012, Hwang Hae Electric Co.

PIAnO(Process Integration, Automation and Optimization

user’s Manual, Ver.3.5, 2013, PIDOTECH, INC.

C. Lee and H.G. Kil, 2014, Impeller for reducing noise

and regenerative blower with the same impeller,

Korean Patent No.1014593790000.

J. K. Kim, K. Y. Lee, C. Lee

, H. G. Kil, K. H. Chung and

S. M. Hwang, 2014, Development of a low-noise

regenerative blower for fuel cell application, The

KSFM Journal of Fluid Machinery, 17(2), 48-53.

LowNoiseDesignofRegenerativeBlowerbyCombiningtheFANDAS-RegenCode,OptimizationTechniqueand

Phase-ShiftCancellationConcept

475