Data Quality Assessment of Company’s Maintenance Reporting: A Case

Study

Manik Madhikermi

1

, Sylvain Kubler

2

, Andrea Buda

1

and Kary Fr¨amling

1

1

Aalto University, School of Science P.O. Box 15400, FI-00076 Aalto, Finland

2

University of Luxembourg, Interdisciplinary Centre for Security, Reliability & Trust, Luxembourg, Luxembourg

Keywords:

Data Quality, Multi-criteria Decision Making, Analytic Hierarchy Process, Decision Support Systems.

Abstract:

Businesses are increasingly using their enterprise data for strategic decision-making activities. In fact, infor-

mation, derived from data, has become one of the most important tools for businesses to gain competitive

edge. Data quality assessment has become a hot topic in numerous sectors and considerable research has been

carried out in this respect, although most of the existing frameworks often need to be adapted with respect

to the use case needs and features. Within this context, this paper develops a methodology for assessing the

quality of enterprises’ daily maintenance reporting, relying both on an existing data quality framework and

on a Multi-Criteria Decision Making (MCDM) technique. Our methodology is applied in cooperation with a

Finnish multinational company in order to evaluate and rank different company sites/office branches (carry-

ing out maintenance activities) according to the quality of their data reporting. Based on this evaluation, the

industrial partner wants to establish new action plans for enhanced reporting practices.

1 INTRODUCTION

Data and Information quality

1

is one of the most com-

petitive advantages for an organization in today’s dig-

ital age (e.g., with the rapid evolution of Cloud Com-

puting, Internet of Things – IoT, Big Data...) (Atzori

et al., 2010). Companies are trying hard to find out

relevant strategies to make their products (physical or

virtual products) standout with respect to their com-

petitors. In such environments, companies need to

provide after sales services such as maintenance, and

warranty services, in order to ensure that the delivered

product is reliable and in full accordance with the cus-

tomer requirements. Nonetheless, providing such ser-

vices inevitably generate costs for businesses; within

many industries, maintenance costs can account for

up to 40% of the operational budget (Dunn, 1998).

Some surveys indicate that one third of every dol-

lar of maintenance costs is wasted due to inappro-

priate or unnecessary maintenance practices (Mob-

ley, 2002). In fact, data quality practices (including

1

The terms Data and Information are often used syn-

onymously; in practice, managers differentiate information

from data intuitively, and describe information as data that

has been processed and enriched in some manner but, un-

less specified otherwise, this article will use “information”

interchangeably with “data”.

maintenance reports) has a considerable impact on

these costs since poor data quality impacts the down-

stream part of the maintenance process, and recipro-

cally, high data quality fosters enhanced business ac-

tivities and decision making.

Data quality has been intensively studied over the

last two decades, and various relevant frameworks

for assessing data quality have since then emerged

(Krogstie et al., 1995; Wang and Strong, 1996; Jarke

and Vassiliou, 1997), and continue to emerge (Batini

et al., 2009; Price and Shanks, 2009). Although most

of the conceptual data quality frameworks can be ap-

plied regardless of the application area, they often re-

quire some tuning/adaptation to each use case needs

and peculiarities, e.g. when dealing with healthcare,

environmental, governmental, business, or still engi-

neering applications (Berndt et al., 2001; Peabody

et al., 2004). The present article is set within this con-

text of ‘existing framework adaptation’, whose ulti-

mate goal of our study is to assess company’s main-

tenance reporting quality considering different office

branches of a Finnish multinational Original Equip-

ment Manufacturer (OEM). In light of the Multi-

Criteria Decision Making (MCDM) nature of the

problem (further described in Section 2), our study

proposes to combine a conceptual data quality frame-

work, namely Krogstie’s framework (Krogstie et al.,

162

Madhikermi M., Kubler S., Buda A. and Främling K..

Data Quality Assessment of Company’s Maintenance Reporting: A Case Study.

DOI: 10.5220/0005518401620172

In Proceedings of 4th International Conference on Data Management Technologies and Applications (DATA-2015), pages 162-172

ISBN: 978-989-758-103-8

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

1995), with a simple and effective MCDM technique

aiming at aggregating the different data quality di-

mensions so as to come up with a ranking of the dif-

ferent company’s sites in order of maintenance report-

ing quality.

To this end, section 2 introduces both the

Krogstie’s framework and to what extent it is adapted

to our maintenance use case. Section 3 provides

greater detail about the adaptation steps and its com-

bination with the MCDM technique. Section 4

presents the use case results related to the OEM com-

pany, along with the conclusions.

2 DATA QUALITY FRAMEWORK

AND ADAPTATION

Data quality is a well explored domain, in which

many frameworks have emerged. One of the ear-

lier framework was developed by Wang and Strong

in (Wang and Strong, 1996), followed by many other

scholars (Jarke and Vassiliou, 1997; Kahn et al., 2002;

Batini et al., 2009; Price and Shanks, 2009). Despite

differences in methods and contexts, yet they share

a number of characteristics regarding their classifi-

cations of the quality dimensions (see e.g. the six-

teen dimensions introduced by Wand and Strong). It

is difficult to state in what respects one framework

is better than another since data quality is commonly

thought of as a multi-dimensional concept with vary-

ing attributed characteristics, which depend on the au-

thor’s philosophical viewpoint, past experience, ap-

plication domains, and so forth (Knight and Burn,

2005). Within this context, the scientific contribu-

tion of this paper is not to define a new data qual-

ity framework, but rather to apply and adapt a tradi-

tional one so as to cope with the company’s needs,

expectations and application features. Accordingly,

section 2.1 provides a brief introduction of the con-

sidered framework, followed by section 2.2 that de-

tails to which extent this framework is used/extended

to our needs.

2.1 Reference Data Quality Framework

The data quality framework considered in our study

is the one defined by Krogstie et al. (Krogstie et al.,

1995), which is an extension of the framework de-

fined by (Lindland et al., 1994). The different con-

cepts and relationships of the Krogstie’s framework

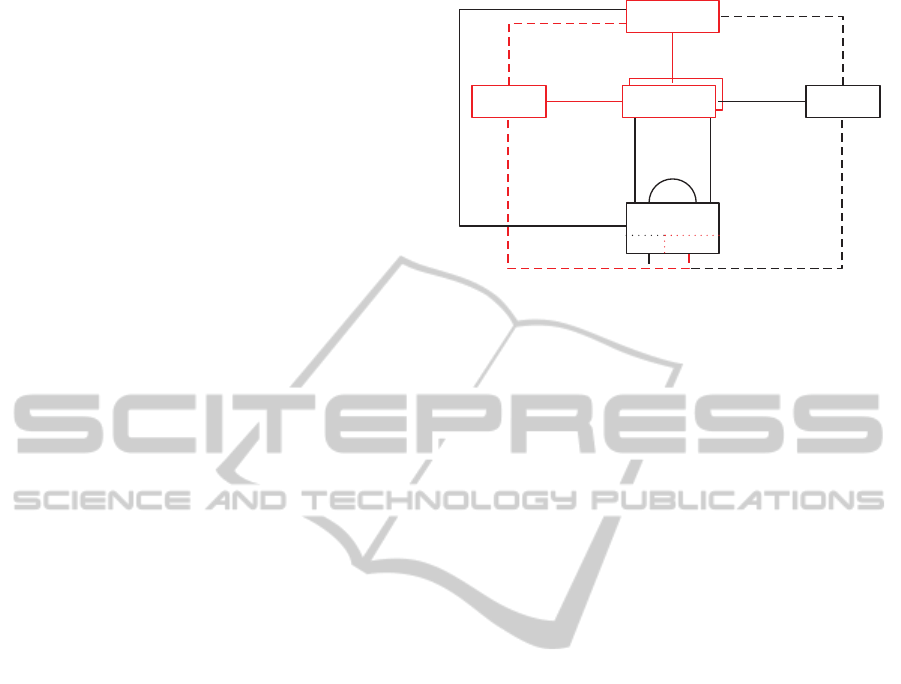

are illustrated in Figure 1, which consists of:

• Physical Quality: about externalizability (i.e., the

knowledge of some social actors have been exter-

Modeling

Domain

Knowledge

Quality

Model

Externalization

Semantic

Quality

Syntactic

Quality

Physical

Quality

Language

Extension

Language

Quality

Participant

Knowledge

Audience

Interpretation

Social Technical

Language Quality

Social

Quality

Perceived

Semantic

Quality

Pragmatic

Quality

Pragmatic

Quality

Figure 1: Krogstie’s data quality framework.

nalized by the use of a conceptual modeling lan-

guage) and internalizability (i.e., the externalized

model is persistent and available enabling partici-

pants to make sense of it);

• Syntactic Quality: correspondence between the

model and the language extension of the language

in which the model is written;

• Semantic Quality: correspondence between the

model and the domain, where the domain is con-

sidered as the ideal knowledge about the situation

to be modeled. Krogstie’s framework contains

two semantic goals: Validity and Completeness;

• Perceived Semantic Quality: correspondence be-

tween the actor interpretation of a model and

his/her current knowledge of the domain. In line

with the semantic quality, two goals are defined

by the authors: Perceived Validity and Perceived

Completeness;

• Pragmatic Quality: correspondence between the

model and the “Audience Interpretation” of it (cf.

Figure 1);

• Social Quality: about people “agreement”;

• Knowledge Quality: from a pure standpoint of

social construction, and as stated by Krogstie et

al., it is difficult to talk about the quality of ex-

plicit knowledge. On the other hand, within cer-

tain areas such as mathematics, what is regarded

as ‘true’ is comparatively stable, and it is inter-

subjectively agreed that certain people have more

valid knowledgeof an area than others. The ‘qual-

ity’ of the participant knowledge can thus be ex-

pressed by the relationships between the audience

knowledge and the domain.

• Language Quality: appears as means for model

quality in the framework. Krogstie et al. have

regrouped factors from earlier discussions on lan-

guage quality as follows:

DataQualityAssessmentofCompany'sMaintenanceReporting:ACaseStudy

163

Table 1: Criteria and its sub-criteria description related to the data quality dimensions.

Criteria Sub-Criteria Description Type

Believability (C

B

)

Length of Work Description (C

B1

) Length of the work description related to a work order. I

c

avg

(i)

Work Log Variation (C

B2

) Work Description variation among the different operator reports I

c

sim

(i)

Technician Log Variation (C

B3

) Technical log variation among the different operator reports I

c

sim

(i)

Completeness (C

C

)

Asset Location reported (C

C1

) Location of asset within product where maintenance has been done. I

c

sim

(i)

Description reported (C

C2

) Description of work to be done in particular maintenance work. I

c

sim

(i)

Actual Finish Date reported (C

C3

) Actual Finish date and time of work completed. I

c

sim

(i)

Target Start Date reported (C

C4

) Targeted start date of the maintenance work. I

c

sim

(i)

Target Finish Date reported (C

C5

) Targeted finish date of the maintenance work. I

c

sim

(i)

DLC Code reported (C

C6

) Actual location of the defect within product. I

c

sim

(i)

Schedule Start Date reported (C

C7

) Scheduled start date of the maintenance work. I

c

sim

(i)

Schedule Finish Date reported (C

C8

) Scheduled Finish date of the maintenance work. I

c

sim

(i)

Timeliness (C

T

) This is average delay of reporting on individual site I

c

avg

(i)

– Domain Appropriateness;

– Participant Knowledge Appropriateness;

– Technical Actor Interpretation Enhancement.

2.2 Krogstie’s Framework Adaptation

Given the above definitions, and based on the

OEM company’s requirements, three key con-

cepts/relationships and one assumption lay the

groundwork of our study for Krogstie’s framework

adaptation. First, the study assumption is that the

Physical Quality (cf. Figure 1), and particularly the

externalized model, is 100% persistent and available,

thus enabling participants to make sense of it. In-

deed, the OEM company designed its own mainte-

nance models, report templates, databases, etc., and

is not willing (at a first stage) to assess/study how

persistent their implementations are compared with

the initial expert statements, expressed knowledge,

etc. The OEM company then expressed require-

ments regarding three of the Krogstie’s framework

concepts/relationships, namely:

1. Semantic Quality: one of the OEM company’s re-

quirement matches – to a certain extent – with

the semantic quality dimension since the company

would like to know to which extent the service

data reported by each operator (on each site) can

be trusted, or more exactly can be considered as

“true”, “real” and “credible”, in order to carry out

the planning activities. This is referred to as the

“Believability” criterion (C

B

) in this paper, whose

various facets of the Believability are formalized

in the form of sub-criteria (or Believability quality

indicators) denoted by {C

B1

..C

B3

} in Table 1;

2. Language Quality: one of the OEM company’s

requirement matches – to a certain extent – with

the language quality dimension since the com-

pany would like to know to which extent the ser-

vice data reported by each operator is complete,

or is of sufficient depth and breadth for the task at

hand (Wang and Strong, 1996). To put it another

way, this criterion, referred to as Completeness

(C

C

), reflects the level of details reported by each

operator with regard to each report field that needs

to be entered (in accordance with the company’s

business logic) in the report. Similarly to C

B

, the

facets of Completeness are denoted {C

C1

...C

C8

}

(see Table 1);

3. Knowledge Quality: one of the OEM company’s

requirement matches – to a certain extent – with

the semantic quality dimension since the company

would like to know to which extent the service

data reported by each operator is sufficiently “up

to date”, which is depending on the time differ-

ence between the maintenance work and the work

reporting. This criterion, referred to as Timeliness

C

T

, is based on the assumption that the longer

the time spent to submit the report, the lesser the

quality of the reporting (operator are likely to for-

get key details of the maintenance task over time).

No sub-criterion is defined for this dimension, as

shown in Table 1 (C

T

);

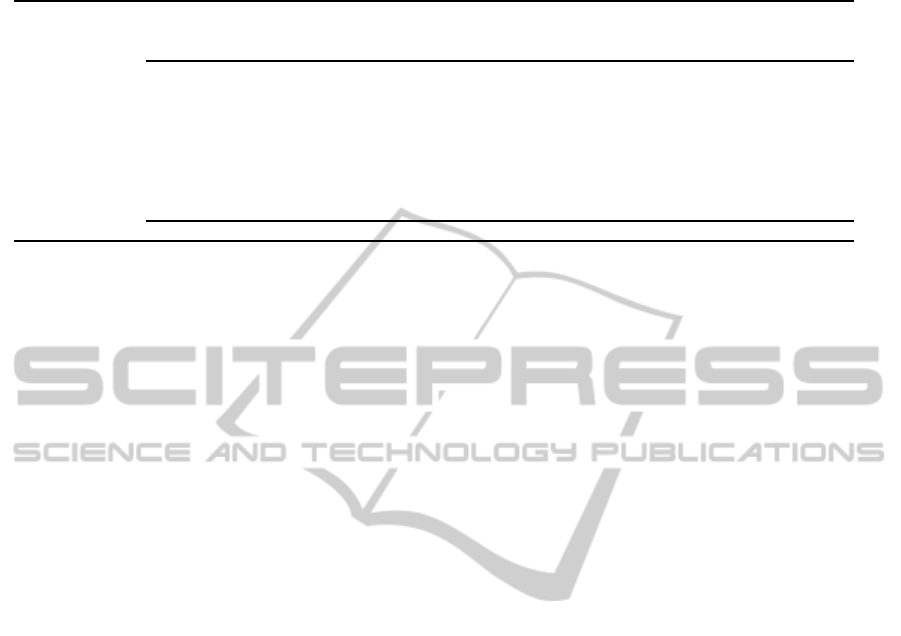

In order to ease the understanding of these three

data quality dimensions, and associated sub-criteria,

we propose to illustrate through Figure 2 the differ-

ent stages that compose our adapted framework. This

figure highlights that maintenance operators carry out

maintenance work/tasks on each OEM site (sites de-

noted by Site 1... Site z) and generate multiple re-

ports. A zoom on reports from Site 1 and n is pro-

posed in Figure 2 so as to compare both sets of re-

ports based on the criteria defined in Table 1. It al-

lows for an understanding of when a report, or field

content, impacts positively on the company’s mainte-

nance reporting quality, and when it does impact neg-

atively (see “smileys” and associated explanation in

Figure 2).

In this paper, a simple and effective MCDM tech-

nique is used as support of the arithmetic framework

to handle the integration/aggregation of the various

DATA2015-4thInternationalConferenceonDataManagementTechnologiesandApplications

164

SITE 1 SITE 2

. . .

SITE n

x

x

x

x

y

x

x

x

x

y

x

x

x

y

y

OEM

Database

Maintenance Operator (Site 1)

Report ID : 1D

Asset Location

Description

Actual End-Date

Target Start Date

. . .

Scheduled Start Date

Scheduled End Date

Maintenance Operator (Site 1)

ID : 1389706

Asset Location

Description

Actual End-Date

Target Start Date

. . .

Scheduled Start Date

Scheduled End Date

Maintenance Operator (Site 1)

ID : 1389706

Asset Location

Description

Actual End-Date

Target Start Date

. . .

Scheduled Start Date

Scheduled End Date

Maintenance Operator (Site 1)

Report ID : 1A

Asset Location

Description

Actual End-Date

Target Start Date

. . .

Scheduled Start Date

Scheduled End Date

Power Controller 4v

Done

28/08/20 14

23/08/20 14

24/08/20 14

27/08/20 14

Front axle 34.8YH

Done

02/05/20 14

07/06/20 14

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 1)

ReportID : 1 A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site 2)

ReportID : 2A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocation

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocation

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocation

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocation

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocation

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocation

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocation

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocation

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

ReportID : n A

AssetLocatio n

Description

ActualEnd-Date

TargetStart Date

. ..

Scheduled Start Date

Scheduled EndDate

Maintenance Operator (Site n)

Report ID : nD

Asset Location

Description

Actual End-Date

Target Start Date

. . .

Scheduled Start Date

Scheduled End Date

Maintenance Operator (Site 1)

ID : 1389706

Asset Location

Description

Actual End-Date

Target Start Date

. . .

Scheduled Start Date

Scheduled End Date

Maintenance Operator (Site 1)

ID : 1389706

Asset Location

Description

Actual End-Date

Target Start Date

. . .

Scheduled Start Date

Scheduled End Date

Maintenance Operator (Site n)

Report ID : nA

Asset Location

Description

Actual End-Date

Target Start Date

. . .

Scheduled Start Date

Scheduled End Date

Fuel System 01X.2

System changed by...

28/08/20 14

23/08/20 14

24/08/20 14

27/08/20 14

Chassis has been re...

28/08/20 14

23/08/20 14

24/08/20 14

27/08/20 14

Maintenance

Operators per

OEM’s Site

Example when comparing operator

reports between Site 1 and Site n

Data Quality Ass essment

of OME’s Maintenance Reporting

C

B1

: L ength of Work Description

One world (”Done”) is too short to properly

describe the maintenance opration

The description seems to be long enough

in reports nA & nD

C

B2

: Work Log Variation

No variation between the operator reports,

i.e. between report 1A & 1D in that example

The content of the work description

reported by the operator often vary

C

C1

: Asset Location Reported

Field “Asset Location” filled out in report 1A

as well as in report 1D

Field “Asset Location” filled out in

report nA but not in report nD. . .

. . .

C

T

: Average Delay of Reporting

Reports 1A was made 1h after the task, while

report 1D was made with a delay of 3 weeks

Both Reports nA and nD have been

made with a delay inferior to 2h

MCDM technique

Site ranking considering all reports, from all operators, from

all sites : {Site 1, Site 2, Site 3. . . Site n}

2 3

S

ITE

1

1

S

ITE

2

S

ITE

n

Figure 2: Stages composing the maintenance reporting quality assessment framework.

criteria preferences, report contents, etc. as empha-

sized in Figure 2 (see the podium that is the result

of the “MCDM technique”). The reason of using a

MCDM technique is threefold:

• the human brain is not reliable for decision-

making when there are many factors/criteria to

consider simultaneously, which is even more true

when the problem is structured in several lay-

ers (i.e., objective depending on several crite-

ria, which themselves can be declined into sub-

criteria...), as it is the case in our use case;

• MCDM techniques help reasoning about inter-

dependencies among criteria, alternatives, etc.,

which inevitably results in better decision-

making, or assessment outcomes;

• Experts from the OEM company can easily re-use

and adapt the MCDM parameters as they see fit

(e.g., criteria preferences, integration of new data

quality dimensions);

There is a number of MCDM techniques in the

literature such as AHP (analytic hierarchy process),

ANP (analytic network process), TOPSIS (technique

for order preference by similarity to ideal situation),

ELECTRE to solve MCDM problems (Figueira et al.,

2005). In our study, we do use AHP (Saaty, 1996)

for the reason that it is very simple and effective tech-

nique to integrate expert opinions and requirements.

For instance, decision makers use linguistic variables

in AHP rather than expressing their judgments in the

form of exact numeric values; adding that AHP does

not involve complex mathematics. These characteris-

tics are probably the main reasons for the success of

this technique, which is the second most used MCDM

DataQualityAssessmentofCompany'sMaintenanceReporting:ACaseStudy

165

Site 1 Site 2 Site 3 Site 4

. . . . . . . . . . . . . . .

Site 54

C

B1

C

B2

C

B3

C

C1

C

C2

C

C3

C

C4

C

C5

C

C6

C

C7

C

C8

C

T

Believability Completeness

Timeliness

Reporting Quality Assessment and Ranking of OEM Sites

Level 1

Level 2

Level 3

Level 4

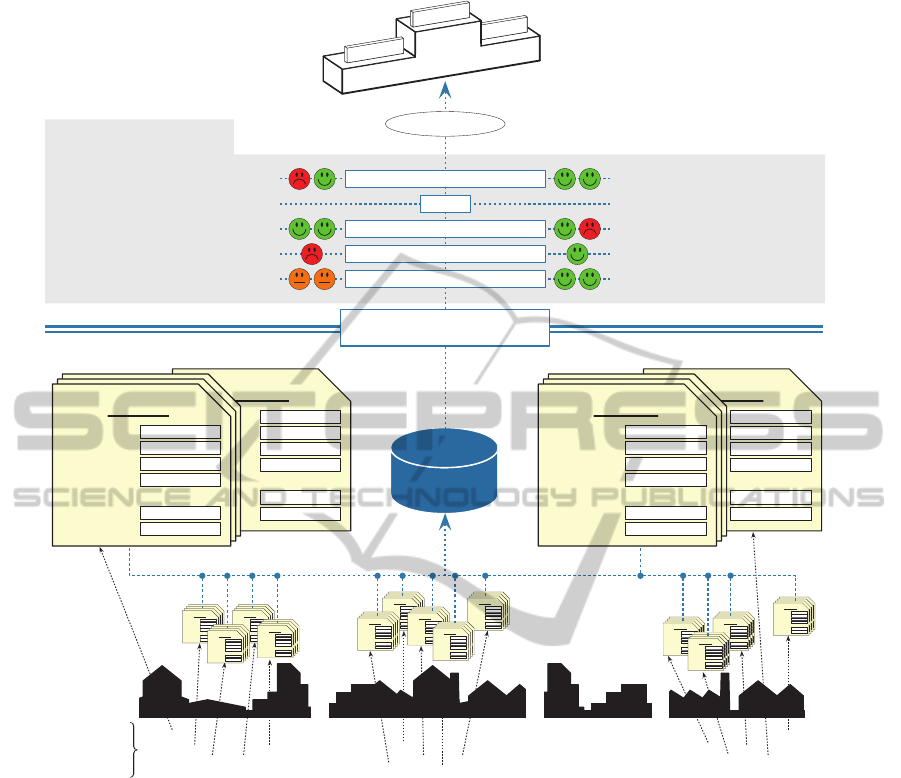

Figure 3: AHP structure related to the maintenance reporting quality assessment problem.

methods according to a recent survey

2

(Mardani et al.,

2015). Nonetheless, it is important to note that there

are no better or worse techniques, but some tech-

niques are better suited to particular decision prob-

lems than others (Zheng et al., 2012); for instance,

AHP only deals with linear preferences (this is the

case in our study), not with contextual preferences

where the value of one or several criteria may affect

the importance or utility of other criteria (Fr¨amling,

1996).

3 DATA REPORTING

ASSESSMENT

AHP, originally introduced by (Saaty, 1996), has the

advantage of organizing critical aspects of the prob-

lem in a manner similar to that used by the human

brain in structuring the knowledge, i.e. in a hierar-

chical structure of different levels consisting of the

overall goal, the criteria and sub-criteria, as well as

the alternatives. In this regard, our MCDM ranking

problem is brokendown into the hierarchical structure

depicted in Figure 3, and particularly in four distinct

levels:

• Level 1: the overall goal of the study is to rank the

different OEM company sites in terms of mainte-

nance reporting quality;

• Levels 2 and 3: the set of data quality dimensions,

and sub-criteria, used to assess the maintenance

reporting quality (derived from Krogstie’s frame-

work and listed in Table 1);

• Level 4 the alternativesthat are the OEM company

sites;

Given this hierarchy, AHP does perform the fol-

lowing computation steps for identifying the final

2

Frequency of application being 15.82% for AHP, while

Hybrid Fuzzy MCDM (1

st

position) are applied with a fre-

quency of 19.89% and Fuzzy AHP (3

rd

position) with a fre-

quency of 9.53%.

ranking of the alternatives with respect to the overall

goal:

1. Compare each element in the corresponding level

and calibrate them on the numerical scale. This

requires

(n−1)

2

pairwise comparisons, where n is

the number of elements with the consideration

that diagonal elements are equal to “1” and the

other elements will be simply the reciprocal of the

earlier comparisons;

2. Perform calculation to find the maximum eigen

value, consistency index (CI), consistency ra-

tio (CR), and normalized values for each crite-

ria/alternatives;

3. If the computed eigen value, CI and CR are sat-

isfactory, then decision/ranking is done based on

the normalized values.

Stages 1 and 2 are detailed in sections 3.1 and 3.2,

which respectively deal with expert preference-based

pairwise comparisons and ratio scale-based pairwise

comparisons (Saaty, 1990), and Stage 3 is described

in section 3.3. In order to make the understanding

easier, a scenario is considered throughout section 3,

whose parts are preceded by the symbol “➫”.

3.1 Pairwise Comparison based on

Expert Preferences

This section details how a decision maker evaluates

the importance of one criterion (or sub-criterion) with

respect to the others. To this end, OEM experts per-

form pairwise comparisons among criteria, as formal-

ized with P

C

in Eq. 1, with m the number of cri-

teria at a specific hierarchy level and from a same

“parent criterion”, e.g. m = 3 at level 2 of the AHP

structure (i.e., m = |{C

B

,C

C

,C

T

}|), m = 3 at level 3

with regard to the parent criterion ‘Believability’ (i.e.,

m = |{C

B1

,C

B2

,C

B3

}|), m = 8 at level 3 with regard

to the parent criterion ‘Completeness’, etc. The ex-

pert evaluation is carried out based on the 1- to 9-point

Saaty’s scale: {1, 3, 5,7,9}; w

ij

= 1 meaning that C

i

and C

j

are of equal importance and w

ij

= 9 meaning

DATA2015-4thInternationalConferenceonDataManagementTechnologiesandApplications

166

C

C1

C

C2

C

C3

C

C4

C

C5

C

C6

C

C7

C

C8

C

C1

1 3 1 3 7 3 9 3

C

C2

1/3 1 1/3 3 5 3 5 3

C

C3

1 3 1 3 5 3 5 3

C

C4

1/3 1/3 1/3 1 5 3 5 1

C

C5

1/7 1/5 1/5 1/5 1 1/3 3 5

C

C6

1/3 1/3 1/3 1/3 3 1 5 1/3

C

C7

1/9 1/5 1/5 1/5 1/3 1/5 1 1/5

C

C8

1/3 1/3 1/3 1 1/5 3 5 1

➠

W

C

C1

0.240

W

C

C2

0.165

W

C

C3

0.191

W

C

C4

0.128

W

C

C5

0.081

W

C

C6

0.085

W

C

C7

0.019

W

C

C8

0.089

(4)

that C

i

is strongly favored over C

j

.

P

C

=

C

1

... C

m

C

1

w

11

... w

1m

.

.

.

.

.

.

.

.

.

.

.

.

C

m

w

m1

... w

mm

(1)

The computation of the normalized eigenvector of

P

C

then enables to turn qualitative data into crisp ra-

tios. Although several approaches exist in the litera-

ture for normalized eigenvector compution, the Sim-

ple Additive Weighting (SAW) method (Tzeng and

Huang, 2011) is used in our study, as formalized in

Eq. 2.

W

i

=

∑

m

j=1

w

ij

∑

m

k=1

∑

m

j=1

w

kj

, w

ji

=

(

1 i = j

1

w

ij

i 6= j

(2)

W = [W

C

1

,...,W

C

i

,...,W

C

m

]

Finally, a P

C

matrix is characterized as consistent

if, and only if:

w

ij

= w

ik

× w

kj

∀i,k ∈ N |i 6= k; j ∈ N − {i,k}

However it is often hard to fulfill such a pre-requisite

when dealing with real expert preferences, which is

all the more true when the number of criteria to be

compared increases. Consistency of any matrix is cal-

culated through the Consistency Ratio (CR), as given

in Eq. 3, where RI is the Consistency index of a pair-

wise matrix generated Randomly (Saaty, 1980).

CR =

CI

RI

(3)

➫ In our case, pairwise comparisons are filled out

with the OEM’s executive officer. Eq. 5 provides in-

sight into the expert specifications regarding criteria

at Level 2 of the AHP structure. The computed nor-

malized eigenvector highlights that the officer judges

all criteria at this level of equal importance.

C

B

C

C

C

T

C

B

1 1 1

C

C

1 1 1

C

T

1 1 1

➠

W

C

B

0.33

W

C

C

0.33

W

C

T

0.33

(5)

CI=0; CR=0

Eq. 6 shows the pairwise comparisons carried out

at Level 3 of the AHP structure, with regard to the

parent criterion ‘Believability’ (to facilitate under-

standing, the calculation of the normalized eigenvec-

tor value W

C

B1

is detailed in Eq. 7). The eigenvector

values (cf. Eq. 6) highlight that the officer judges the

“Length of Work Description” slightly more impor-

tant (or critical) in the maintenance reporting quality

than the “Work Log Variation” (C

B1

), and far more

important than the “Technician Log Variation” (C

B3

).

C

B1

C

B2

C

B3

C

B1

1 3 5

C

B2

1

3

1 5

C

B3

1

5

1

5

1

➠

W

C

B1

0.54

W

C

B2

0.38

W

C

B3

0.08

(6)

CI=0.168; CR=0.289

W

C

B1

=

1+ 3 + 5

1+ 3 + 5 +

1

3

+ 1+ 5+

1

5

+

1

5

+ 1

(7)

=

9

16.74

= 0.54

Similarly, the experts carry out pairwise compar-

isons in Eq. 4 considering the sub-criteria of ‘Com-

pleteness’ (i.e., C

C1

to C

C8

); W

C

C1

is the most impor-

tant sub-criteria, followed by W

C

C3

and W

C

C2

respec-

tively. Regarding C

T

, there is no pairwise comparison

be performed since no sub-criterion has been defined.

The pairwise comparison approach introduced in

this section allows for taking into consideration ex-

pert know-how and judgments, and to turn them into

crisp ratios. However, pairwise comparison evalua-

tion is not always based on expert elicitation, some-

times them is necessary to take into consideration

monitoring system parameters such as: how many

times the field “DLC Code reported” (C

C6

) has been

left empty in the maintenance reports on Site i com-

pared with the other Sites. In this case, Saaty intro-

duced the concept of ‘relativescale’ or ‘pairwise com-

parison as ratios” (Saaty, 1990), which allows for con-

sidering various types of data and metrics. Section 3.2

provides greater detail about the types of data and

metrics that underly our pairwise comparisons as ra-

tios that mostly concern pairwise comparisons among

DataQualityAssessmentofCompany'sMaintenanceReporting:ACaseStudy

167

alternatives (i.e., level 4 of the AHP structure) with

respect to a each criterion taking place at the upper

level (i.e., at Level 3).

3.2 Pairwise Comparison as Ratios

Pairwise Comparison as ratios is a tool that allows

for comparing criteria (or alternatives with respect to

criteria) based upon a relative scale rather than us-

ing preference scales (e.g., the 1- to 9-point Saaty’s

scale). Eq. 8 provides insight into the pairwise com-

parison as ratio matrix considering the set of alterna-

tives A

i

(i.e., i referring to a OEM site), with I

c

x

(i) the

digital indicator (or metric) that enables us to quan-

titatively assess the alternative A

i

with respect to the

monitored system parameter c (i.e., with respect to

criteria defined at Level 3), and x referring to the fact

that several digital indicators can be used according to

the monitored system parameter/criterion c, as will be

discussed below. Note that the normalized eigenvec-

tor values of the pairwise comparison as ratios with

respect to criterion c are denoted by W

A

c

i

in Eq. 8.

A

1

A

2

... A

z

A

1

1

I

c

x

(1)

I

c

x

(2)

...

I

c

x

(1)

I

c

x

(z)

A

2

I

c

x

(2)

I

c

x

(1)

1 ...

I

c

x

(1)

I

c

x

(z)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

A

z

I

c

x

(z)

I

c

x

(1)

I

c

x

(z)

I

c

x

(2)

... 1

➠

W

A

c

1

W

A

c

2

.

.

.

W

A

c

z

(8)

Two digital indicators I

c

x

(i) are defined:

• I

c

sim

(i) (Empty Indicator – Eq. 9): used to calcu-

late the number of times a “field” was left empty

in reports carried out on Site i, with k the total

number of reports performed on Site i:

I

c

sim

(i) =

Number of empty fields on Site i

k

(9)

➫ Let us consider the example of pairwise com-

parison as ratios with regard to C

C6

and Site 1 and

2. On Site 1, 76 maintenance reports have been

carried out and 45 of these reports contain the

DLC code (meaning that 59% of all the reports

contain the requested information, see Eq. 10),

while on Site 2 only 44% of the reports contain

the requested information (see Eq. 11).

I

C

C6

sim

(1) =

45

76

= 59% (10)

I

C

C6

sim

(2) =

49

88

= 44% (11)

The pairwise comparison as ratios is then com-

puted using all I

c

x

(i) indicators and considering all

alternatives (i.e., the 54 sites). Eq. 12 provides in-

sight into such pairwise comparison as ratios with

respect to C

C6

, in which I

C

C6

sim

(1) and I

C

C6

sim

(2) (com-

puted above) are used.

A

1

A

2

... A

54

A

1

1

59

44

... 0.15

A

2

44

59

1 ... 0.67

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

A

54

6.64 1.50 ... 1

➠

W

C

C6

A

1

0.187

W

C

C6

A

2

0.002

.

.

.

.

.

.

W

C

C6

A

54

3E-06

(12)

• I

c

avg

(i) (Average Indicator – Eq. 13): used to cal-

culate the average delays for reporting the main-

tenance reports per site (i.e., regarding C

T

) or the

average length of work description (i.e., C

B1

) per

site. Mathematically, I

c

avg

(i) is computed based on

Eq. 13, where q is either the reporting delay value

or the description length value of one of the k re-

ports carried out on Site i.

I

c

avg

(i) =

k

∑

q=1

q

k

(13)

➫ Let us assume that 4 maintenance reports have

been carried out on Site 1, and that the work de-

scription length is equal to 44, 5, 13 and 101 re-

spectively. In that case, the average indicator with

regard to C

B1

and Site 1 will be equal to 40.75

(see Eq. 14). Similarly to Eq. 12, the pairwise

comparison as ratios is computed considering all

I

c

x

(i) indicators and all alternatives. The final ma-

trix is not presented here due to the similarity with

the one presented in Eq. 12.

I

C

B1

avg

(1) =

44+ 5+ 13+ 101

4

= 40.75 (14)

Note that we highlighted in Table 1 (see last col-

umn) what indicators – I

c

sim

(i) or I

c

avg

(i)) – is used with

regard to each criterion.

3.3 Alternative Ranking

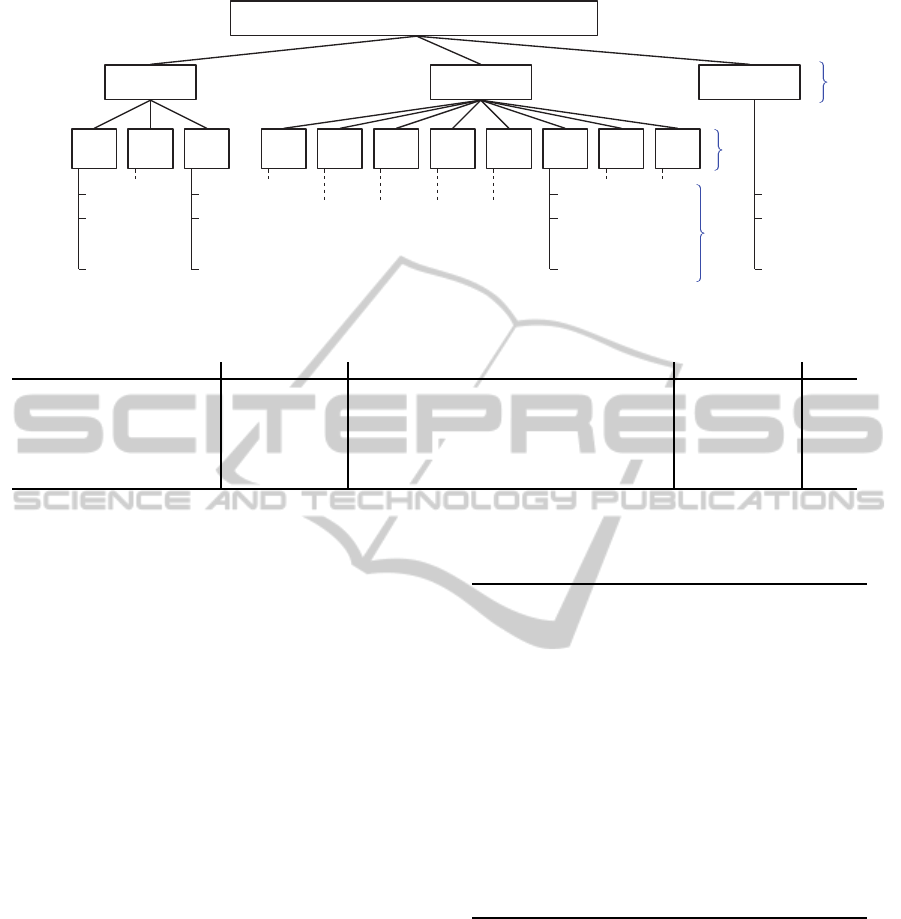

Figure 4 sums up all variables and related weights

computed in the previous sections. It is now neces-

sary to aggregate the different weights in order to con-

verge towards a final ranking of the alternatives/sites.

To this end, the global weight of each alternative with

respect to all criteria C

x

is computed based on Eq. 15.

GW

C

x

A

i

= W

C

x

A

i

×W

C

x

×W

C

x(parent)

(15)

Let us apply this formula in Eq. 16 considering

alternative A1 (i.e., Site 1) and criterion C

C6

, whose

DATA2015-4thInternationalConferenceonDataManagementTechnologiesandApplications

168

W

C

B1

0.540

W

C

B2

0.380

W

C

B3

0.080

W

C

C1

0.240

W

C

C2

0.165

W

C

C3

0.191

W

C

C4

0.128

W

C

C5

0.081

W

C

C6

0.085

W

C

C7

0.019

W

C

C8

0.089

W

C

B

= 0.33

W

C

C

= 0.33

W

C

T

= 0.33

Reporting Quality Assessment and Ranking of OEM Sites

1.00

Site 1 : W

C

B1

A

1

Site 2 : W

C

B1

A

2

Site 54 : W

C

B1

A

54

Site 1 : W

C

B3

A

1

Site 2 : W

C

B3

A

2

Site 54 : W

C

B3

A

54

Site 1 : W

C

C6

A

1

= 0.187

Site 2 : W

C

C6

A

2

= 0.002

Site 54 : W

C

C6

A

54

= 3E-06

Site 1 : W

C

T

A

1

Site 2 : W

C

T

A

2

Site 54 : W

C

T

A

54

Level 1

Level 2

Level 3

Level 4

See Eq. 5

See Eq. 4 & 6

See Eq. 12

Figure 4: AHP structure and associated weights.

Table 2: Global Weight Computation of all Alternatives with respect to all Criteria.

C

B1

C

B2

C

B3

∑

C

Bx

C

C1

C

C2

C

C3

C

C4

C

C5

C

C6

C

C7

C

C8

∑

C

Cx

∑

C

T

Site 1 GW

C

B1

A

1

... GW

C

B3

A

1

∑

x={1..3}

GW

C

Bx

A

1

... ... ... ... ... GW

C

C6

A

1

... ...

∑

x={1..8}

GW

C

Cx

A

1

GW

C

T

A

1

Site 2 GW

C

B1

A

2

... GW

C

B3

A

2

∑

x={1..3}

GW

C

Bx

A

2

... ... ... ... ... GW

C

C6

A

2

... ...

∑

x={1..8}

GW

C

Cx

A

2

GW

C

T

A

2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Site 54 GW

C

B1

A

54

... GW

C

B3

A

54

∑

x={1..3}

GW

C

Bx

A

54

... ... ... ... ... GW

C

C6

A

54

... ...

∑

x={1..8}

GW

C

Cx

A

54

GW

C

T

A

54

“parent criterion” is logically C

C

.

GW

C

C6

A

1

= W

C

C6

A

1

×W

C

C6

×W

C

C

(16)

= 0.187 × 0.085× 0.333

= 0.053

The global weight related to each alternative is

then computed as summarized in Table 2. It is thus

possible to aggregate those global weights per “par-

ent criterion”, i.e. regarding Believability (C

B

) Com-

pleteness (C

C

) and Timeliness (C

T

) as formalized in

the columns detoned by

∑

C

Bx

,

∑

C

Cx

and

∑

C

T

in Ta-

ble 2.

We do not further detail the calculations, we rather

provide (in Table 3) the final alternative/site ranking

with regard to each “parent criterion”; e.g., Site 1 is

ranked 17

th

out of the 54

th

sites in terms of ‘Believ-

ability’, 3

rd

out of the 54

th

sites in terms of ‘Com-

pleteness’, and 2

nd

in terms of ‘Timeliness’. Based

on these first results, first conclusions can be drawn:

Figure 5 provides a comparison view (using a spi-

der chart) among different alternatives/sites (we vol-

untary did not include the 54 alternatives for clarity

purposes) that helps us to see how good each com-

pany’s site is with regard to each data quality dimen-

sion. Note that in this case, the wider the shape (e.g.,

Site 11 and 32 have the widest/biggest shapes), the

better the company’s site.

In order to obtain the final ranking of the alterna-

tives, i.e. aggregating all alternative global weights

into a single and final score, it is necessary to sum

∑

C

Bx

,

∑

C

Cx

and

∑

C

T

regardingeach alternative/site.

Such results are presented and discussed in section 4.

Table 3: Site ranking with respect to each data quality di-

mension (i.e., parent criteria).

Believability Completeness Timeliness

Site 1 30

th

3

rd

2

nd

Site 2 4

th

15

th

27

th

Site 3 7

th

37

th

31

st

.

.

.

.

.

.

.

.

.

.

.

.

Site 11 33

rd

7

th

1

st

.

.

.

.

.

.

.

.

.

.

.

.

Site 32 2

nd

4

th

18

th

.

.

.

.

.

.

.

.

.

.

.

.

Site 37 46

th

52

th

37

th

.

.

.

.

.

.

.

.

.

.

.

.

Site 47 19

th

35

th

31

th

.

.

.

.

.

.

.

.

.

.

.

.

4 USE CASE RESULTS

This section presents the results of one experiment of

the maintenance reporting quality assessment.

In practice, our tool has been developed with Mat-

lab, which enables the executive officer to assess, at a

given point in time, the quality of the different com-

pany’s sites considering historical data/reports. The

assessment period can be adjusted by the officer as

he/she sees fit (e.g., to assess/compare sites over the

previous days, weeks or months). The user interface

(UI) provides the executive officer with the possibil-

DataQualityAssessmentofCompany'sMaintenanceReporting:ACaseStudy

169

Timeliness

1

st

12

th

23

th

34

th

1

st

12

th

23

th

34

th

45

th

54

th

45

th

34

th

23

th

12

th

1

st

Site 32

Site 11

Site 47

Site 37

Completeness

Believability

Figure 5: Comparison of sites 11, 32, 37 and 47.

ity to modify his/her preferences regarding the “pair-

wise comparison based on expert preferences”. For

example, if for some reasons he/she wants to give

further importance to the “Completeness” dimension

over Believability and Timeliness. Considering the

pairwise comparison as ratios, such rations are com-

puted by performing SQL queries against the OEM’s

information system that contains the maintenance re-

ports (cf. Figure 2).

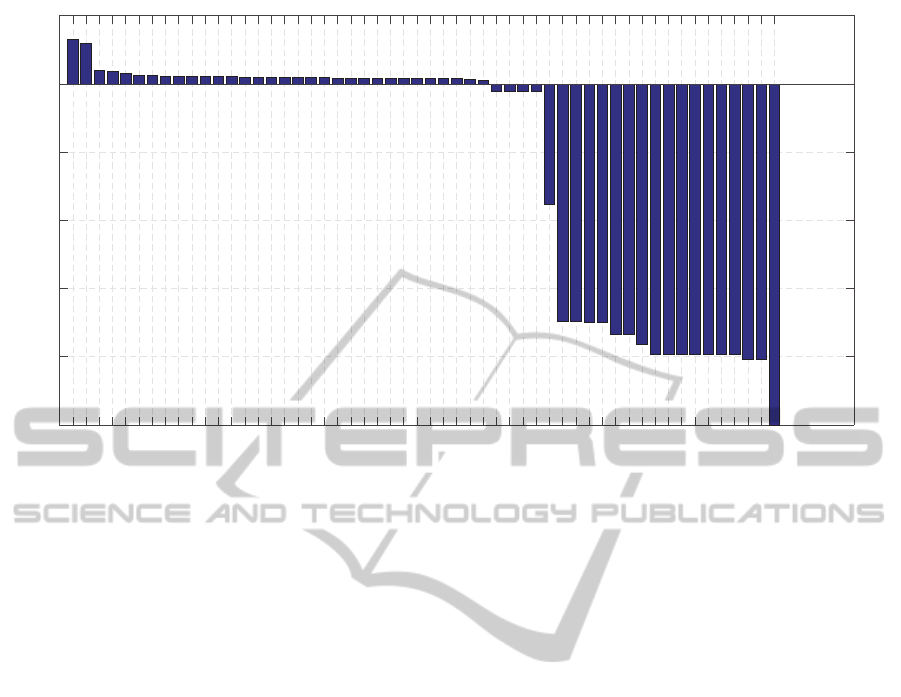

Based upon the executive officer preferences (the

ones specified throughout section 3), the histogram

in Figure 6 gives insight into the maintenance report-

ing quality assessment results: x-axis referring to the

54 sites, y-axis giving the quality maintenance report-

ing quality score. In total (considering all reports,

from all sites), 275.585 reports have been processed

and analyzed. The histogram shows that some qual-

ity scores dropped below “0”; the reason being that

a penalty score has been introduced when a report

field was left empty

3

. The histogram thus provides the

overall ranking: Site 11 has the better quality score,

followed by Site 1, Site 18... ; Site 15 has the low-

est quality score. Although the histogram does not

provide enough information to identify the reasons

for a good or non-standard reporting, it nonetheless

provides first insights into qualitative results that may

help to understand some of the reasons (e.g., a lack

of training, insufficient manpower, . ..). These results

also offer the opportunity to identify and understand

the good reporting practices from the best sites so as

to learn and apply those practices on the less perfor-

3

Although other penalty strategies could be applied, we

propose as a first step to define the penalty as (−1 × K)

with K the criterion importance (signifying that the higher

the criterion importance, the higher the penalty score for not

having filled out the report field)

mant sites. Another action from the executive officer

perspective is to cluster the sites based on reporting

quality, thus enabling easier implementation of cor-

rective actions driven by the clustering.

Again, let us remember that the executive officer

has the possibility to customize his/her own UI dash-

board by selecting different views, e.g. the histogram

view (Figure 6), the spider chart view (Figure 5), etc.,

each of them providing more or less detailed and ag-

gregated information (the level of aggregation of the

results varies depending upon the selected view).

5 CONCLUSIONS

In recent years, implementation of effective mainte-

nance strategies proved to be a significant source for

financial savings and enhanced productivity. At the

heart of those strategies is the quality of data that

includes, among other things, maintenance reporting

activities. Indeed, maintenance data has directs im-

pact on other company activities such as on:

• after-sales services: the quality of maintenance

reports makes it possible to assess the mainte-

nance work, thus helping to reach a higher quality

after-sales services;

• on the design of future generations of products:

processing and analyzing ‘relevant’ maintenance

reports help to better understand how the products

from the company behave throughout their prod-

uct lifecycle, thus helping to enhance the design

of the next product generations (Fr¨amling et al.,

2013);

• predictive maintenance strategies: providing real-

time and remote predictivemaintenance is becom-

ing a very promising area in the so-called IoT

(Buda et al., 2015), whose objective is to provide

systems with the capability to discover and pro-

cess real-time data and contexts so as to make

pro-active decisions (e.g., to self-adapt the sys-

tem before a possible failure). Although real-time

data is of the utmost importance in the predictive

maintenance process, combining such data with

historical maintenance reporting data (regarding a

specific product item) has the potential to gener-

ate new knowledge, thus leading to more effective

and product-centric decisions;

• government regulation compliance: in some do-

mains, it is mandatory to comply with govern-

ment regulations (e.g., in automotive, avionics, or

healthcare domains). In this respect, assessing the

quality of maintenance reporting can prevent the

company from having regulation non-compliance

DATA2015-4thInternationalConferenceonDataManagementTechnologiesandApplications

170

Site 11

Site 1

Site 18

Site 34

Site 25

Site 33

Site 10

Site 43

Site 42

Site 49

Site 32

Site 4

Site 35

Site 9

Site 12

Site 5

Site 22

Site 52

Site 39

Site 21

Site 2

Site 46

Site 36

Site 38

Site 51

Site 40

Site 16

Site 50

Site 27

Site 13

Site 41

Site 23

Site 3

Site 28

Site 47

Site 20

Site 26

Site 44

Site 6

Site 7

Site 29

Site 24

Site 17

Site 19

Site 14

Site 8

Site 30

Site 31

Site 45

Site 53

Site 54

Site 37

Site 48

Site 15

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

Overall Data Quality Score

Figure 6: Site ranking according to the maintenance reporting quality assessment study.

issues, e.g. by carefully following the data qual-

ity on each company’s site and identifying when

the quality is too poor, or when a key data quality

dimension is not of sufficient quality;

Given the above statements, a methodology for as-

sessing the quality of enterprises’ daily maintenance

reporting is developed in this paper, which relies, on

the one hand, on the Krogstie’s data quality frame-

work and, on the other hand, on a simple arithmetic

MCDM framework (AHP) in order to handle the ag-

gregation of the expert preferences, application fea-

tures, etc. (the reason for combining both techniques

being given in sections 2 and 3). An important as-

pect of our methodology, and adapted framework, is

that this framework can further be extended in two re-

spects:

• Data quality framework extension: as highlighted

in Figure 1, only a few concepts and relation-

ships from the Krogstie’s framework were con-

sidered (semantic quality, knowledge quality... ),

which is mainly due to the company’s expecta-

tions and needs. Accordingly, the framework can

be further extended considering the other con-

cepts/relationships (not used yet) such as Lan-

guage Quality (e.g., for domain appropriateness,

participant knowledge appropriateness...), Syn-

tactic Quality (e.g., for syntactical correctness

purposes, meaning that all statements in the model

are according to the syntax of the language), and

so forth;

• AHP structure extension: as described in sec-

tion 2.2, a first set of criteria and sub-criteria

have been considered, but further data quality di-

mensions can easily be added to the overall AHP

structure (see Figure 3).

Our maintenance reporting quality assessment

framework has been developed and applied in cooper-

ation with a Finnish OEM company in order to eval-

uate and rank 54 office branches, which are spread

in different countries. Based on this initial evaluation

(cf. section 4), the OEM partner has since then es-

tablished adapted action plans for enhanced reporting

practices, and is now interested in extending this ini-

tial framework.

ACKNOWLEDGEMENT

This research was conducted in the Future Industrial

Services (FutIS) research program, managed by the

Finnish Metals and Engineering Competence Clus-

ter (FIMECC), and funded by the Finnish Funding

Agency for Technology and Innovation (TEKES), re-

search institutes.

REFERENCES

Atzori, L., Iera, A., and Morabito, G.(2010). The internet of

things: A survey. Computer networks, 54(15):2787–

2805.

Batini, C., Cappiello, C., Francalanci, C., and Maurino, A.

(2009). Methodologies for data quality assessment

DataQualityAssessmentofCompany'sMaintenanceReporting:ACaseStudy

171

and improvement. ACM Computing Surveys (CSUR),

41(3):16.

Berndt, D. J., Fisher, J. W., Hevner, A. R., and Studnicki,

J. (2001). Healthcare data warehousing and quality

assurance. Computer, 34(12):56–65.

Buda, A., Kubler, S., Borgman, J., Fr¨amling, K., Mad-

hikermi, M., and Mirzaeifar, S. (2015). Data supply

chain in industrial internet. In Proceedings of the 11th

IEEE World Conference on Factory Communication

Systems.

Dunn, S. (1998). Reinventing the maintenance process: to-

wards zero downtime. In Queensland Maintenance

Conference Proceedings, Queensland, Australia.

Figueira, J., Greco, S., and Ehrgott, M. (2005). Multiple

criteria decision analysis: state of the art surveys, vol-

ume 78. Springer Science & Business Media.

Fr¨amling, K. (1996). Mod´elisation et apprentissage des

pr´ef´erences par r´eseaux de neurones pour l’aide `a la

d´ecision multicrit`ere. PhD thesis, INSA Lyon.

Fr¨amling, K., Holmstr¨om, J., Loukkola, J., Nyman, J., and

Kaustell, A. (2013). Sustainable plm through intelli-

gent products. Engineering Applications of Artificial

Intelligence, 26(2):789–799.

Jarke, M. and Vassiliou, Y. (1997). Data warehouse quality:

A review of the dwq project. In IQ, pages 299–313.

Kahn, B. K., Strong, D. M., and Wang, R. Y. (2002). Infor-

mation quality benchmarks: product and service per-

formance. Communications of the ACM, 45(4):184–

192.

Knight, S.-A. and Burn, J. M. (2005). Developing a frame-

work for assessing information quality on the world

wide web. Informing Science: International Journal

of an Emerging Transdiscipline, 8(5):159–172.

Krogstie, J., Lindland, O. I., and Sindre, G. (1995). Defin-

ing quality aspects for conceptual models. Proceed-

ings of the IFIP8.1 Working Conference on Informa-

tion Systems Concepts: Towards a Consolidation of

Views, 1995:216–231.

Lindland, O. I., Sindre, G., and Solvberg, A. (1994). Un-

derstanding quality in conceptual modeling. Software,

IEEE, 11(2):42–49.

Mardani, A., Jusoh, A., and Zavadskas, E. K. (2015).

Fuzzy multiple criteria decision-making techniques

and applications–two decades review from 1994 to

2014. Expert Systems with Applications.

Mobley, R. K. (2002). An introduction to predictive main-

tenance. Butterworth-Heinemann.

Peabody, J. W., Luck, J., Jain, S., Bertenthal, D., and Glass-

man, P. (2004). Assessing the accuracy of administra-

tive data in health information systems. Medical care,

42(11):1066–1072.

Price, R. J. and Shanks, G. (2009). A semiotic information

quality framework: Theoretical and empirical devel-

opment.

Saaty, T. L. (1980). The analytic hierarchy process: plan-

ning, priority setting, resources allocation. New York:

McGraw.

Saaty, T. L. (1990). How to make a decision: the analytic

hierarchy process. European journal of operational

research, 48(1):9–26.

Saaty, T. L. (1996). Decision making with dependence

and feedback: The analytic network process, volume

4922. RWS publications Pittsburgh.

Tzeng, G.-H. and Huang, J.-J. (2011). Multiple attribute de-

cision making: methods and applications. CRC Press.

Wang, R. Y. and Strong, D. M. (1996). Beyond accuracy:

What data quality means to data consumers. Journal

of management information systems, pages 5–33.

Zheng, G., Zhu, N., Tian, Z., Chen, Y., and Sun, B. (2012).

Application of a trapezoidal fuzzy ahp method for

work safety evaluation and early warning rating of hot

and humid environments. Safety Science, 50(2):228–

239.

DATA2015-4thInternationalConferenceonDataManagementTechnologiesandApplications

172