Parametric Study of Liquid Flow in Five- and Six-stage Centrifugal

Pumps

Lahbib Kerbouci and Guyh Dituba Ngoma

University of Quebec in Abitibi-Témiscamingue, School of Engineering’s Department, 445, Boulevard de l’Université,

Rouyn-Noranda, Quebec, J9X 5E4, Canada

Keywords: Multistage Centrifugal Pump, Impeller, Diffuser, Computational Fluid Dynamics (CFD), Modeling and

Simulation.

Abstract: Two models of a multistage centrifugal pump using a five- and six-stage centrifugal pumps were developed

and numerically investigated. The continuity and Navier-Stokes equations with the k- turbulence model

and standard wall functions were used by means of the ANSYS-CFX code. To enhance the design of the

multistage pump, the concept consisting of varying three parameters at a time was used. Thus, the combined

effects of the impeller blade angle, the impeller blade number and the impeller blade width on the

performance of the five- and six-stage centrifugal pumps was analyzed. The results obtained reveal, among

other things, that the highest pump efficiency was reached for the outlet impeller blade angle of 25.38°, the

number of impeller blades of 7, and the impeller blade width of 7 mm.

1 INTRODUCTION

Multistage centrifugal pumps are widely used in

industrial and mining enterprises (Gülich, 2010). For

a more performing multistage pump, its design

parameters, such as the number of stages, impeller

blades, diffuser vanes and diffuser return vanes,

angle of the impeller blade, height of the impeller

blade and diffuser vane, the width of the impeller

blade and diffuser vane, the impeller and diffuser

diameter, the rotating speed of the impeller and the

casing geometry must be determined accurately.

Many experimental and numerical studies have been

conducted on the liquid flow through a multistage

centrifugal pump varying one key parameter at a

time (Among other things, La Roche-Carrier et al.,

2013; Miyano et al., 2008; Kawashima et al., 2008,

Gantar et al., 2002). In this study, a concept

consisting of varying three key parameters of

multistage centrifugal pumps at a time was used to

identify parameters to lead to the best design and

performances of multistage centrifugal pumps. Thus,

the following parameters were varied at a time for

the five- and six-stage centrifugal pumps: a) the

numbers of impeller blades (6, 7 and 8), b) the outlet

angle of the impeller blade (19.81°, 21.24° et

25.38°), and c) the impeller width blade (4 mm, 5

mm and 7 mm).

2 GOVERNING EQUATIONS

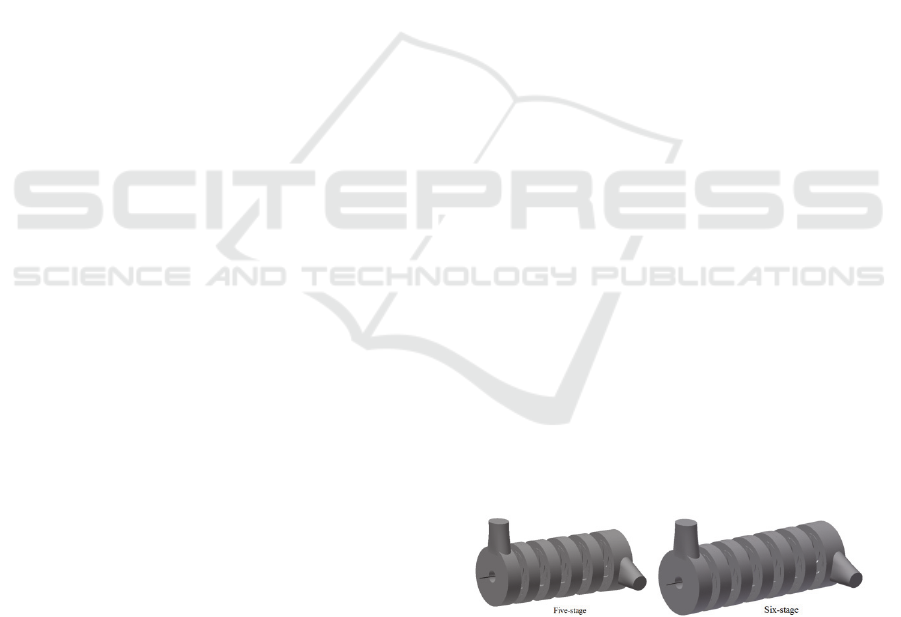

Fig. 1 shows the domain fluids of five- and six-stage

centrifugal pumps considered in this research work

to run the numerical simulations.

Figure 1: Domain fluids of five- and six-stage pumps.

The following assumptions were made for the

governing equations for liquid flow in the five- and

six-stage centrifugal pumps: (i) a steady state, three-

dimensional and turbulence flow using the k-

model was assumed; (ii) it was an incompressible

liquid; (iii) it was a Newtonian liquid; and (iv) the

liquid’s thermophysical properties were constant

with the temperature.

To account for these assumptions, the theoretical

analysis of the liquid flow in the impeller passages,

diffuser vane passages and diffuser return vane

passages was based on the continuity and

Navier-Stokes equations (Ansys inc., 2011). For the

three-dimensional liquid flow through these five-

and six-stage centrifugal pumps as shown in Fig. 1,

178

Kerbouci L. and Dituba Ngoma G..

Parametric Study of Liquid Flow in Five- and Six-stage Centrifugal Pumps.

DOI: 10.5220/0005543601780182

In Proceedings of the 5th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2015),

pages 178-182

ISBN: 978-989-758-120-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

the continuity equations are expressed by:

0

z

w

y

v

x

u

(1)

and the Navier–Stokes equations are given by:

z

2

2

2

2

2

2

eff

y

2

2

2

2

2

2

eff

x

2

2

2

2

2

2

eff

B

z

p

z

w

y

w

x

w

z

w

w

y

w

v

x

w

u

B

y

p

z

v

y

v

x

v

z

v

w

y

v

v

x

v

u

B

x

p

z

u

y

u

x

u

z

u

w

y

u

v

x

u

u

(2)

where p is the pressure, is the density,

eff

is the

effective viscosity accounting for turbulence, and

B

x

, B

y

and B

z

are the source terms. They can be

expressed by:

.0B and u2rB ,v2rB

zzy

2

zyzx

2

zx

(3)

Furthermore,

eff

is defined as

teff

, where

is the dynamic viscosity and

t

is the turbulence

viscosity, it

is linked to turbulence kinetic energy k

and dissipation ε via the relationship:

12

t

kC

,

where C

is a constant. The values of k and tem

directly from the differential transport equations for

turbulence kinetic energy and turbulence dissipation

(Ansys inc., 2011). Additionnally, for the flow

modeling near the wall, the logarithme wall function

is used to model the viscous sub-layer (Ansys inc.,

2011).

To solve equations 1 and 2 numerically while

accounting for the boundary conditions and

turbulence model k-, the computational fluid

dynamics ANSYS-CFX code, based on the finite

volume method, was used to obtain the liquid flow

velocity and pressure distributions. Pressure velocity

coupling is calculated in ANSYS-CFX code using

the Rhie Chow algorithm (Ansys inc., 2011).

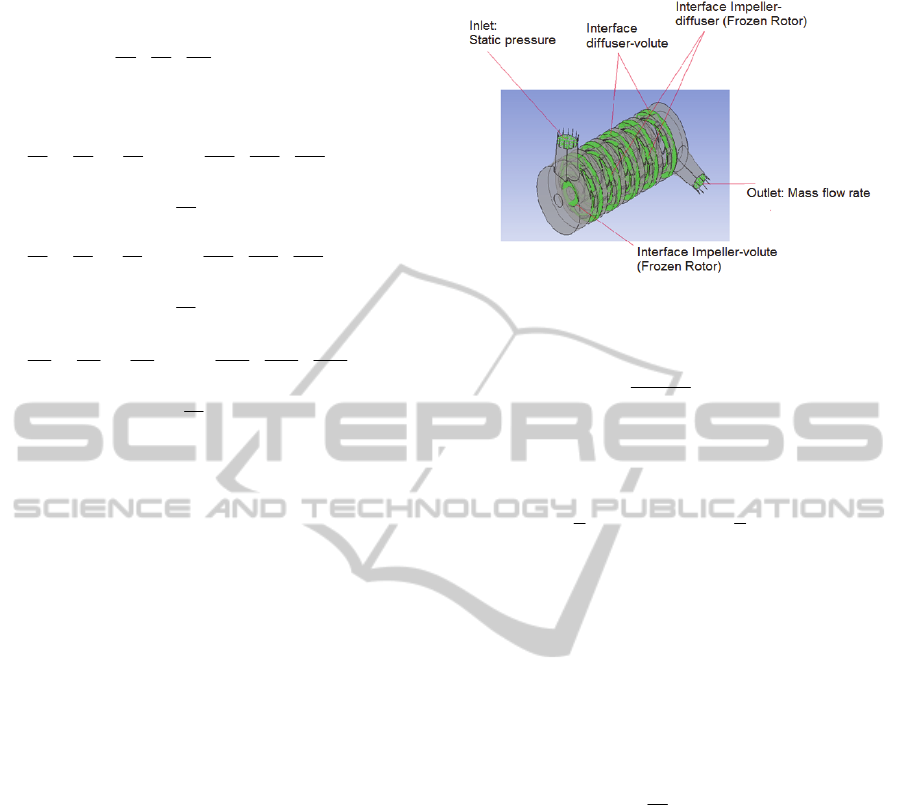

In the cases examined involving the five- and

six-stage centrifugal pumps, the boundary conditions

were formulated as follows (figure 2): the static

pressure provided was given at the pump inlet, while

the flow rate provided was specified at the pump

outlet. The frozen rotor condition was used for the

impeller-diffuser interfaces. A no-slip condition was

set for the flow at the wall boundaries.

Figure 2: Boundary conditions.

The pump head is determined as follows:

g

pp

H

tito

(4)

where p

ti

is the total pressure at the pump inlet and

p

to

the total pressure at the pump outlet. They are

expressed as:

2

vel

iti

i

V

2

pp

and

2

vel

oto

o

V

2

pp

(5)

Moreover, the hydraulic power of the pump is given

by

QgHP

h

, where Q is the flow rate and H is the

pump head.

Furthermore, the brake horsepower of the pump

stage is expressed as

CP

s

, where is the angular

velocity and C is the impeller torque.

From the hydraulic power and the brake

horsepower, the efficiency of the pump can be

written as

s

h

P

P

(6)

3 RESULTS AND DISCUSSION

The main reference data used for the impeller were

89 mm for the inner diameter, 175 mm for the outer

diameter and 2800 rpm for the rotating speed. For

the diffuser, the main reference data were 176 mm

for the inner diameter, 234 mm for the outer

diameter, 6 for the number of vanes and 8 for the

number of return vanes. The numerical simulation

results presented in this work were obtained with the

highest accuracy by conducting mesh-independent

solution tests in each case study using different

numbers of mesh elements.

ParametricStudyofLiquidFlowinFive-andSix-stageCentrifugalPumps

179

3.1 Combined Effect of the Impeller

Blade Angle, Impeller Blade

Number and Impeller Blade Width

To investigate the influence of the combined effect

of the impeller blade angle, the impeller blade

number and the impeller blade width on the pump

head, brake horsepower and efficiency, the values of

the blade angle, the blade number and the blade

width were varied at a time while the other

parameters were kept constant, as indicated in Tab. 1

for the five- and six-stage centrifugal pumps.

Table 1: Selected parameters for simulations.

Impeller blade number; Impeller blade angle [°];

Impeller blade witdh [mm]

Case 1 6; 21.24; 7

Case 2 7; 19.81; 4

Case 3 8;25.38°;5

Figs. 3 and 4 represent the variation of the head

as a function of the flow rate for the five- and six-

stage centrifugal pumps respectively. There, it is

observed that the lowest head was achieved with the

combined of the values of the blade number of 6, the

blade angle of 25.34° and the blade width of 4 mm.

Figure 3: Head versus volume flow rate (five-stage pump).

Figure 4: Head versus volume flow rate (six-stage pump).

Additionally, as shown in Figs. 5 and 6, the

lowest brake horsepower was reached using the

blade number of 7, the blade angle of 25.38° and the

blade width of 7 mm for the five- and six-stage

centrifugal pumps.

Figure 5: Brake horsepower versus volume flow rate (five-

stage pump).

Figure 6: Brake horsepower versus volume flow rate (six-

stage pump).

Furthermore, Figs. 7 and 8 represent the

efficiency curves, showing that the highest

efficiency was achieved for the flow rate about of 33

m³/h.

Figure 7: Efficiency versus volume flow rate (five-stage

pump).

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

180

Figure 8: Efficiency versus volume flow rate (six-stage

pump).

3.2 Parameters of Improved Five- and

Six-centrifugal Pumps

Taking account of the accomplished simulations in

section 3.1, an analysis was performed to identify

the parameters which improve the efficiency of the

five- and six-centrifugal pumps. Thus, the following

values were found for the five- and the six-stage

centrifugal pumps:

Impeller blade number: 7

Impeller blade angle: 25.38°

Impeller blade width: 7 mm

4 CONCLUSIONS

In this study, a liquid flow in a five- and six- stage

centrifugal pumps was umerically investigated using

a ANSYS- CFX code. The combined effects of the

outlet blade angle, the impeller blade number and

impeller width on the on the five- and –six

centrifugal pump head, efficiency and the brake

horsepower were performed. The results obtained

demonstrate, among other things, that a multistage

centrifugal pump can be improved selecting

adequately three key parameters. Further research

work is planned to complete this study finding a

general appropriated to enhance the performances of

a multistage centrifugal pump of any size.

NOMENCLATURE

B source term (Nm

-3

)

C torque (Nm)

g acceleration of gravity (ms

-2

)

H head (m)

P power (W)

p pressure (Nm

-2

)

p

turbulence production due to viscous and

buoyancy forces

Q flow rate (m

3

s

-1

)

r radial coordinate (m)

V velocity (ms

-1

)

u flow velocity in x direction (ms

-1

)

v flow velocity in y direction (ms

-1

)

w flow velocity in z direction (ms

-1

)

x x-coordinate (m)

y y-coordinate (m)

z z-coordinate (m)

Greek symbols

difference

turbulence dissipation (m

2

s

-3

),

efficiency

turbulence kinetic energy (kg m

-2

s

-2

)

fluid density (kg m

-3

)

dynamic viscosity (Pa s)

eff

effective viscosity (Pa s)

t

turbulence viscosity (Pa s)

ω angular velocity (rad s

-1

)

Subscripts

1 inlet

2 outlet

h hydraulic

i inlet

m mechanical

o outlet

s shaft

t total

v volumetric

vel velocity

ACKNOWLEDGEMENTS

The authors are grateful to the Foundation of

University of Quebec in Abitibi-Temiscamingue

(FUQAT) and the Company Technosub inc.

REFERENCES

Gülich, J. F., 2010. Centrifugal Pumps, second Edition,

Springer.

Miyano M., Kanemoto T., Kawashima D., Wada A., Hara

T., Sakoda K., 2008. Return Vane Installed in

Multistage Centrifugal Pump. International Journal of

Fluid Machinery and Systems, Vol. 1, No. 1.

ParametricStudyofLiquidFlowinFive-andSix-stageCentrifugalPumps

181

Kawashima D., Kanemoto T., Sakoda K., Wada A., Hara

T., 2008. Matching Diffuser Vane with Return Vane

Installed in Multistage Centrifugal Pump.

International Journal of Fluid Machinery and

Systems, Vol. 1, No. 1.

Gantar M., Florjancic D., and Sirok B., 2002. Hydraulic

Axial Thrust in Multistage Pumps - Origins and

Solutions. Journal Fluids Engineering, Vol. 124, Issue

2, 336-341.

La Roche-Carrier N., Dituba Ngoma G., and Ghie W.,

2013. Numerical investigation of a first stage of a

multistage centrifugal pump: impeller, diffuser with

return vanes, and casing. ISRN Mechanical

Engineering, Volume 2013, Article ID 578072, 15

pages.

Ansys inc. 2011. ANSYS-CFX (CFX Introduction, CFX

Reference Guide, CFX Tutorials, CFX-Pre User's

Guide, CFX-Solver Manager User's Guide, CFX-

Solver Modeling Guide, CFX-Solver Theory Guide),

release 14.0, USA.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

182