Neural Modeling and Control of a

13

C Isotope Separation Process

Vlad Muresan

1

, Mihail Abrudean

1

Honoriu Valean

1

, Tiberiu Colosi

1

, Mihaela-Ligia Ungureşan

2

,

Valentin Sita

1

, Iulia Clitan

1

and Daniel Moga

1

1

Automation Department, Technical University of Cluj-Napoca, Bariţiu Street, Cluj-Napoca, Romania

2

Physics and Chemistry Department, Technical University of Cluj-Napoca, Bariţiu Street, Cluj-Napoca, Romania

Keywords: Separation Column,

13

C Isotope, Internal Model Control Strategy, Neural Networks, Distributed Parameter

Process, Approximating Analytical Solution.

Abstract: The paper presents a solution for the

13

C isotope concentration control inside and at the output of a

separation column, solution based on the Internal Model Control strategy. The

13

C isotope results from a

chemical exchange process carbon dioxide – carbamate, which is a distributed parameter process. In order

to model the mentioned process, an original form of the approximating analytical solution which describes

the process work in transitory regime is determined. The evolution of the approximating solution depends

both on time and on the position from the column height. The reference model of the fixed part of the

control structure is implemented using neural networks, representing an original solution due to the fact that

a neural model is determined for a distributed parameter process. The controller is, also, implemented using

neural networks, its main parameter being adapted in relation to the transducer position change in the

separation column. The advantages of using the proposed concentration control strategy consist of: the

possibility of controlling the value of the

13

C isotope concentration in any point from the separation column

height; the improvement of the system performance regarding the settling time; the possibility to reject the

effect of the disturbances.

1 INTRODUCTION

The plant used for the separation of the

13

C isotope

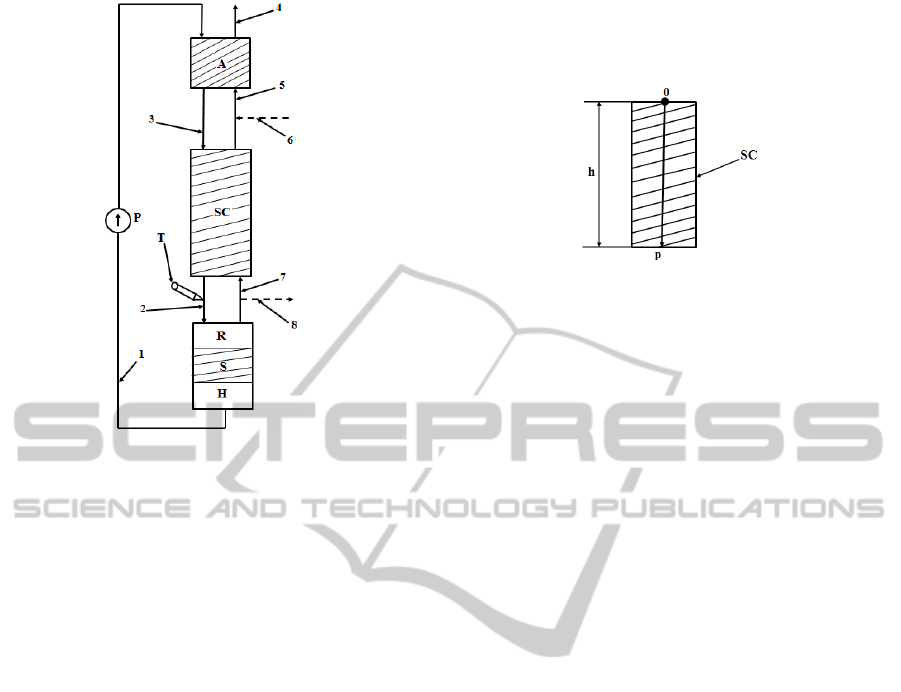

is presented in Figure 1. The absorber A is supplied

with ethanolamine using the pump P through the

pipe 1 and with carbon dioxide (CO

2

) at

approximately 99.98% concentration through the

pipe 5. In A the absorption (Dang and Rochelle,

2003; Dugas and Rochelle, 2009) of CO

2

in

ethanolamine takes place (the two chemical

elements circulating in counter current), resulting the

carbamate in the lower part of A (pipe 3) and a gas

phase (containing CO

2

at a concentration lower than

0.1%) in its upper part (pipe 4). The carbamate is

used to supply the separation column SC through the

pipe 3, respectively the gaseous phase is evacuated

from the plant through pipe 4. Also, the CO

2

resulted

after the carbamate decomposition enters in SC

through the pipe 7, in this system element the

chemical exchange between the carbamate and CO

2

taking place (in SC the two mentioned chemical

elements circulate in counter-current, too). During

the chemical exchange process, the enrichment of

the

13

C isotope is accomplished, it concentrating in

liquid phase in the lower part of the SC (Axente et.

all, 1994). The most important parameter which has

to be monitored and controlled is the

13

C isotope

concentration. The concentration value can be

measured using the concentration transducer (mass

spectrometer) T placed on the pipe 2 at the output

from SC. Through the pipe 2, the carbamate is sent

to the reactor R, where the thermal decomposition of

this solution is made. The resulted CO

2

(with a

higher concentration of the

13

C isotope comparing

with the initial conditions values) is returned to the

SC through the pipe 7. Also, the CO

2

is completely

removed after the stripping procedure (in the stripper

S), resulting the ethanolamine. The ethanolamine is

reheated in the heater H and circulated again through

the plant using the pump P and the pipe 1. The CO

2

quantity which passes through the SC is sent to the

absorber through the pipe 5.

In production regime, the pipe 6 is used to supply

the plant with CO

2

, the product being extracted in

gaseous phase (CO

2

with a certain concentration of

13

C through the pipe 8). Obviously, in production

254

Muresan V., Abrudean M., Valean H., Colo¸si T., Unguresan M., Sita V., Clitan I. and Moga D..

Neural Modeling and Control of a 13C Isotope Separation Process.

DOI: 10.5220/0005549002540263

In Proceedings of the 12th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2015), pages 254-263

ISBN: 978-989-758-122-9

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

Figure 1: The separation plant.

regime, some connecting pipes are used to connect

pipes 6 and 8.In Figure 1, the hachured zones signify

that the corresponding elements present steel pack of

Helipack type. The steel pack has a determinant

contribution in the plant working, making possible

the

13

C isotope separation (Axente et. all, 1994).

The problem of

13

C separation is treated in a few

papers from the technical literature, for example in

(Li et. all, 2010), but the proposed solutions for

improving the separation process are not based on

using an advanced control strategy. Also, all the

control solutions are referring only to the

13

C isotope

concentration control at the base of SC (associated

to the position of T from Figure 1). At this moment,

the treated separation plant is controlled using an

on-off concentration controller which does not

ensure the necessary control accuracy and it

introduces undesired fluctuations in the system.

2 PROCESS MODELING

The

13

C isotope separation process is a distributed

parameter process (Li and Qi, 2011), the output

signal y (the

13

C concentration) depending both on

the independent variable time (t) and on the position

in the SC in relation to its height. The concentration

variation in relation to the position in the transversal

section of SC is insignificant and it is not considered

in the process model. In order to highlight the

second independent variable “length” notated with p,

the 0p axis from Figure 2 is defined. The origin 0 of

the 0p axis is the centre of the transversal section of

the SC from its upper part (the term transversal

section is referring to a section on which the height

direction (for example the 0p axis) is a vertical line).

Figure 2: The 0p axis.

Due to the fact that SC has a cylindrical form,

each transversal section is a circle. The diameter of

the transversal section is d = 2.5cm and the column

height is h = 300cm (Axente et. all, 1994).

Considering the previous aspects, the p independent

variable has the definition domain p

{[p

0

, p

f

] = [0,

h]}. The y(t,p) signal has an increasing evolution in

relation to the both independent variables, implying

that the approximating analytical solution which

describes the process work in transitory regime

contains two functional terms that have to be

determined, one in relation to t (F

t

(t)) and the second

one in relation to p (F

p

(p)). The modelling procedure

is valid for all working regimes, but only after the

CO

2

enters the first time in the SC through the pipe

8. First, the expression of the F

t

(t) function is

determined. The height equivalent to a theoretical

plate (HETP) is a function depending on the input

ethanolamine flow. Knowing that the dependence

between HETP and ethanolamine input flow F

in

is a

linear one (Axente et. all, 1994), the following

relation can be written:

HETP(t) = HETP

0

+ K

H

·(F

in

(t) – F

in0

), (1)

where HETP(t) is the instantaneous value of the

height of the equivalent plate, HETP

0

is the steady

state value of the height of the equivalent plate for

the ethanolamine input flow F

in0

= ct., K

H

is a

proportionality constant which makes the connection

between the ethanolamine input flow and HETP and

F

in

(t) is the instantaneous value of the ethanolamine

input flow. The proportionality constant K

H

is

determined using some experimental data resulted

from the plant. Each experiment is made measuring

the evolution in time of the output signal y(t,p) for

different step type variations of the input signal

F

in

(t). The value of the reference input flow is

chosen from the experimental data F

in0

= 367ml/h,

its corresponding HETP

0

having the value 4.64cm.

In (Axente et. all, 1994) it was proved that K

H

is

the gradient of the ramp resulted after the graphical

NeuralModelingandControlofa13CIsotopeSeparationProcess

255

representation of the function HETP

st

(F

in

), where

HETP

st

represents the steady state values of HETP

corresponding to different F

in

step signals.

Determining, also experimentally, that for F

in1

=

=460ml, HETP

st1

= 5.43, K

H

can be computed using

the relation:

in0in1

0st1

H

F -F

HETP - HETP

K

,

(2)

resulting after computation K

H

= 0.0085(cm·h)/ml.

The instantaneous value of the number of the

theoretical plates is given by:

n(t) = h/HETP(t). (3)

Also, the isotope separation can be computed

using relation (4):

S(t) = α

n(t)

, (4)

where α = 1.01 is the elementary separation factor of

the

13

C isotope for the carbamate – CO

2

chemical

exchange procedure. Considering (1), the positive

value obtained for K

H

constant implies the increase

of HETP(t) at the increase of F

in

(t). Also, from (3)

and (4) the decrease of the number of theoretical

plates, respectively of the isotope separation value,

results. The main consequence of the last two

remarks is the fact that the y(t,p) signal decreases at

the F

in

(t) increasing, respectively the y(t,p) signal

increases at the F

in

(t) decreasing. From the physical

point of view, this phenomenon is explained due to

the fact that lower the value of the input

ethanolamine flow F

in

(t) is, the longer the contact

duration between the carbamate and CO

2

in SC is,

the chemical exchange between the two chemical

elements being a more efficient one.

Also, the isotope separation is given by the

relation:

0

inff

y

)(t)F)(p,y(t

S(t)

,

(5)

where y

0

= 1.108% represents the natural abundance

of the

13

C isotope and y(t

f

,p

f

)(t) is the steady state

value of the output signal for a certain input step

type signal which would have the instantaneous

value of the signal F

in

(t), considering that

p = p

f

=300cm. From (4) and (5), it results that:

n(t)

0inff

αy)(t)F)(p,y(t

,

(6)

or

)t(Sy)(t)F)(p,y(t

0inff

.

(7)

The

13

C concentration increase over the initial

value y

0

, in steady state regime, is given by:

)1)t(S(y

)1α(yy)(t)F)(p,y(t

0

n(t)

00inff

.

(8)

The final input signal in the process is defined

by:

)1)t(S(y(t)u

0f

.

(9)

Obviously, if F

in

(t) is a step type signal it results

that the u

f

(t) signal is a step type signal, too.

The isotope separation process is a first order

one, being characterized by only one time constant.

The time constant of the process is experimentally

determined and if the experiment based on a step

type variation of the input signal F

in

(t) is made for

p = p

f

, it can be determined using the tangent

method, resulting the value T

pf

= 14h. If the same

experiment is repeated, but the measurement of the

output signal y(t,p) is made in the close

neighbourhood of the origin 0 on the 0p axis (for the

value p = 0

+

), after applying the tangent method, it

results for the process time constant the value

T

p0

= 2h.

From these experimental identifications of the

two time constants, it results that the process time

constant increases progressively from the upper part

to the lower part of SC along the 0p axis. Next, in

this paper, a linear increasing evolution of the T time

constant of the process along the 0p axis is

considered, given by the relation:

f

p0pfp0

p

p

)TT(TT

,

(10)

where p

f

= h. From (10) it can be remarked that

T = T(p), but the changing of the value of the p

independent variable is not made continuously. The

p value changing is made at discrete time moments

through the changing of the transducer T position

inside the SC along the 0p axis. The commutations

of the p independent variable can be viewed as step

type signals.

The first order differential equation which

describes the relation between the final input signal

u

f

(t) and the function F

t

(t) (F

t

(t) being the solution of

this equation) is:

)t(u

T(p)

1

)t(F

T(p)

1

dt

)t(dF

ft

t

.

(11)

In the previous equation, the p independent

variable change implies the value changing of the

process time constant T(p), the effect of such a

variation influencing the F

t

(t) function only in

transitory regime. Consequently, F

t

depends on both

independent variable F

t

(t,p) only in the commutation

moments of the p independent variable and only

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

256

when this commutation takes place in transitory

regime. Also, the F

t

(t) function represents the

13

C

concentration evolution in time over the value y

0

until the value y(t

f

,p

f

) for a certain value of F

in

(t). If

the value of the p variable is changed, the speed

evolution of the F

t

(t) function is adapted, but its

steady state value remains at y(t

f

,p

f

). This problem is

solved introducing in the approximating analytical

solution the F

p

(p) function.

The F

p

(p) function can be determined in two

stages. Firstly, the F

p1

(p) function is determined. The

y(t,p) evolution in relation to the p independent

variable for t = t

f

and for a certain constant value of

the F

in

signal is given by the relation:

)n(t

0f

f

α · y = p),y(t ,

(12)

As it results from (12), the evolution in time of

the y(t

f

,p

f

) signal has a hyperbolic form. Using a

mathematical procedure based on an interpolation

method, the y(t

f

,p) signal can be approximated by a

F

p1

(p) function of the form:

)F)t(F(K430

p

0p1

in0inP

e1)-α(y = (p)F

,

(13)

where C = 430cm is a SC constant determined

through interpolation and K

P

= 0.7527(cm·h)/ml

results using two consecutive determined sets of

values {F

in

, P}. The “length” constant P is:

P = 430 + K

P

·(F

in

(t) – F

in0

). (14)

As it can be remarked, the F

p1

(p) function can be

modelled using only one “length” constant P. Also,

from (14), it results that P is a function of the input

ethanolamine flow P(F

in

(t)), implicitly a function of

time P(t). It results that F

p1

is a function depending

on F

in

(t) (F

p1

(F

in

(t),p) and implicitly on both

independent variables t and p (F

p1

(t,p)).

Secondly, the function F

p2

= F

p1

(F

in

(t),p

f

) is

determined. The final form of the F

p

(p) function

results using the relation:

0finp1

0inp1

0p2

0inp1

inp

y-)p(t),(FF

y-p)(t),(FF

y-F

y-p)(t),(FF

= (t))F(p,F

,

(15)

this function depending on the input flow F

in

(t), too.

Also, the final form of the approximating

analytical solution is given by:

y

AN

(t,p) = y

0

+ F

t

(t)·F

p

(p,F

i

n

(t)) . (16)

Due to the facts that, F

p

= F

p

(F

in

(t),p), it results as

ratio between two other functions ((F

p1

– y

0

) and

(F

p2

– y

0

)) and for some particular cases F

t

= F

t

(t,p),

getting to the conclusion that the treated separation

process is a strong non-linear one.

3 LEARNING THE PROCESS

BEHAVIOUR USING NEURAL

NETWORKS

The approximating analytical solution from (16)

which describes the working of the separation

process, the process being a distributed parameter

one (Smyshlyaev and Krstic, 2005), has a very

complex structure. Considering this aspect, the

analytical solution is decomposed in some more

simple mathematical components. Each resulted

mathematical component is modelled using a neural

network and, after that, in order to obtain the model

of the entire analytical solution, the resulted neural

networks are properly interconnected between them.

The two types of neural structures used to learn

(Borges, 2011) the behaviour of the components of

the analytical solution are the forward fully

connected neural networks and the autoregressive

fully connected networks with exogenous inputs

(Haykin, 2009). The two types of neural networks

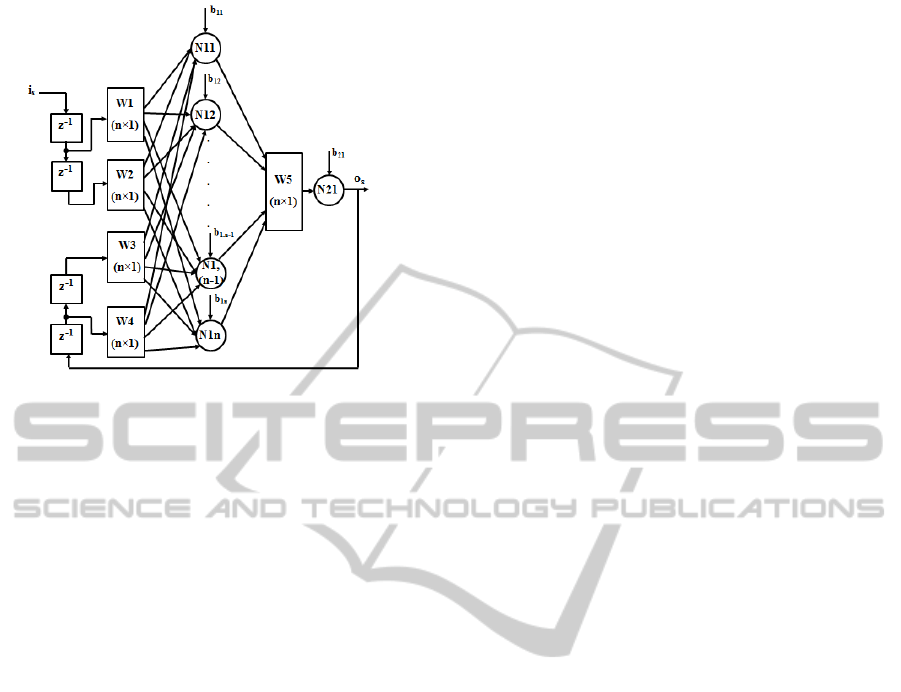

are presented schematically in Figures 3 and 4. In

both cases, i

s

represents the input signal in the neural

network and o

s

represents the output signal from the

neural network. In all the cases from this paper, the

network from Figure 3 contains non-linear neurons

in the hidden layer (N

1i

neurons, where i = 1,…,n)

having hyperbolic tangent activation functions).

Also, in all the cases, the N21 neuron is linear

(having linear activation function (Maren et. all,

1990; Norgaard et. all, 2000)).

Figure 3: The forward fully connected network.

NeuralModelingandControlofa13CIsotopeSeparationProcess

257

Figure 4: The autoregressive fully connected network with

exogenous inputs.

The W1 and W2 vectors are column vectors

containing the weights that make the connection

between the input layer and the hidden layer,

respectively between the hidden layer and the output

layer. The n dimension (the dimension of the hidden

layer) can be singularized for each application in

part. The output signal o

s

, for the general structure

from Figure 3 is given by the relation:

o

s

= [tanh(i

s

·W1

T

+ B1

T

]·W2 + b21, (17)

where B1 is a column vector containing the bias

values of the neurons from the hidden layer, b21 is

the bias value of the N21 neuron, the superscript

T

signifies that the corresponding vector is considered

in transposed form and the notation “tanh” signifies

the application of the hyperbolic tangent functions to

all the elements of the corresponding vector.

The structure from Figure 4 is used in the case

when the work of the components is expressed using

differential equations. The elements z

–1

represent

delay lines used both on the input and on the

feedback signal, in order to memorize the previous

values of the two signals. The connection between

the input layer (formed by the input signal and the

feedback signal) and the hidden layer is made

through the column vectors W1 and W2,

respectively W3 and W4, all of them containing

weights. W5 has the same significance as W2 in the

case of Figure 3 and the dimension n is singularized,

also, for each application in part. In the case of the

network from Figure 4, all the neurons are linear.

The o

s

signal is given by the relation:

o

s

(k) = [W1

T

·i

s

(k–1)+ W2

T

·i

s

(k–2)+ W3

T

·

·o

s

(k–2)+ W4

T

·o

s

(k–1)+ B1

T

]·W5 + b21,

(18)

where B1, b21 and

T have the same significance as

in the case of relation (17), respectively the sequence

(k) represents the current value of the signals, and

the sequences (k–1) and (k–2) represent the previous

two values of the signals. If only one unit line is

necessary for a certain application both on the input

and on the feedback signals, the same presented

structure can be used considering the elements of the

matrices W2 and W3 equal to 0 (Vălean, 1996).

The implementation of the approximating

analytical solution from (16) using neural networks

is presented in Figure 5. The neural networks noted

with NN are trained in order to learn the functional

dependence between the corresponding input and

output signals. Practically, the neural structure from

Figure 5 resulted following the relations (1)-(16) and

interconnecting the component neural networks,

obviously processing mathematically the signals that

occur in the structure. All the neural networks from

Figure 5, instead of NN4 are forward fully

connected ones with n = 10. They are trained using

1000 input-output data pairs and considering, also, a

ramp type variation of the corresponding input

signals. In all cases, as training algorithm, the

Levenberg-Marquardt back-propagation algorithm is

used. The maximum number of training epochs was

fixed to 20000, obtaining in all cases very small

error values (values proportional with 10

-13

; the

quality indicator is considered the mean square

error). The neural network NN4 implements the

integration function.

In this case the autoregressive fully connected

network with exogenous inputs structure from

Figure 4 is used, considering all the elements of the

vectors W2 and W3 equal to 0 (only 1 unit delay

both on the input and on the output signals). Also, in

this case n = 7. The same number of input-output

data pairs and the same training algorithm are

considered as in the case of the other Neural

Networks from Figure 5, but a white noise variation

of the input signal. The imposed value of the mean

square error is reached after 15 training epochs. The

neural model implemented in Figure 5 and

associated to the analytical solution from (16) will

be used as the process Reference Model in the IMC

control structure.

4 THE PROPOSED CONTROL

STRUCTURE

The control structure based on the Internal Model

Control (IMC) strategy (Love, 2007; Golnaraghi et.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

258

Figure 5: The implementation of the approximating analytical solution using neural networks.

Figure 6: The proposed IMC structure.

all, 2009), proposed to be used for the concentration

control of the

13

C isotope, is presented in Figure 6.

The elements from the direct physical channel of

the structure are: the actuator A (the pump P from

Figure 1), the distributed parameter (DPP)

technological process (TP) and the transducer T (the

same transducer as in Figure 1). Also, the elements

from the direct reference channel represent the

neural networks that describe the work of the

elements from the physical direct channel: NN7 for

A, NS (neural structure from Figure 5) for the TP

(DPP) and NN8 for T. The three neural models

connected in series represent the Neural Reference

Model of the Fixed Part of the system. Also the

element NAC is the Neural Adaptive Controller

modelled using the neural structure NN9. From the

mathematical point of view, the NAC controller is a

distributed parameter controller. The term

“distributed parameter controller” is referring to the

fact that one of the controller parameters (the main

parameter) depends on the value of the p

independent variable. This term does not have the

meaning of a spatial distribution of the generated

control signal. Also the significance of the notations

regarding the signals from Figure 6 is: w(t) –

reference signal, c(t) – control signal, F

in

(t) –

– actuating signal (the input flow of ethanolamine),

d

1

(t) – disturbance signal which affects directly the

actuating signal, F

inf

(t) – disturbed actuating signal

(the final value of the ethanolamine input flow),

y(t,p) – output signal (the

13

C isotope concentration),

d

2

(t) – disturbance signal which affects directly the

output signal, y

f

(t,p) – disturbed output signal due to

the effect of d

2

(t), respectively r(t) – feedback signal.

Also, the F

inN

(t), y

N

(t,p), and r

N

(t) signals have

the same significance as the signals F

in

(t), y(t,p) and

r(t), but represent output signals from the

corresponding elements of the Reference Model of

the Fixed Part. These signals are not disturbed, the

disturbances not affecting the reference direct

channel of the system. The final feedback signal

r

f

(t) = r(t) – r

N

(t) represents a measure of all

disturbances effects that affect in a negative manner

the work of the physical direct channel (d

1

(t), d

2

(t),

but also the parametric disturbances (variations in

time of the parameters of the elements A, TP and

T)). Also a(t) = w(t) – r

f

(t) is the error signal. It can

be remarked that the value of the p independent

NeuralModelingandControlofa13CIsotopeSeparationProcess

259

variable is transmitted to both direct channels and to

the controller.

The structure from Figure 6 can work, in the case

the p variable value is not transmitted to the

reference direct channel, but this case is not treated

in this paper. Also, the structure can be adapted for

the case when the automatic determination of the p

value is necessary (Muresan and Abrudean, 2010),

case which also, is not treated in this paper. The

work of the actuator A, it having a linear behaviour,

is expressed using a second order transfer function.

The values of the time constants of the actuator are:

T

A

= 0.1min (the time constant of the actuator) and

T

1

= 2min (the time constant introduced using an

electronic equipment in order to “delay” the

propagation of the control signal to the actuator).

Also, the proportionality constant of the actuator

K

A

= -56.25 ml/(h·mA). The generated output signal

represents the value of the ethanolamine flow which

has to be subtracted from F

inmax

in order to obtain the

F

in

signal. This adjustment is necessary due to the

fact that the plant technological start is made using

F

inmax

. The A element is modelled using the neural

network 7 (NN7). NN7 has exactly the structure

from Figure 4, for n = 10. Also all the delay lines

from Figure 4 are necessary due to the fact that the

actuator model is of second order. The network NN7

is trained using the same training algorithm as in the

case of NN4, the same type of input signal and 500

pairs of input-output data. The imposed mean square

error of is reached after 17 training epochs. The used

sampling time, in this case, has the value

T

s

= 0.036 min. This value is much smaller than the

value of the sampling time used for the training of

all neural networks from the previous Paragraph (3)

(T

s

= 30 min) due to the much smaller time constants

values of the actuator comparing to the value of the

time constant of the technological process.

The transducer T model is expressed using a first

order transfer function with K

T

= 5.7143mA/% (the

proportionality constant of the transducer) and

T

T

= 6min (the time constant of the transducer). The

computation of K

A

and K

T

proportionality constants

is made taking in consideration the fact that the

automation equipment used for this application

works with unified current signals. This model is

learned using the NN8 neural network from

Figure 6. The network parameters and the training

parameters are the same as in the case of the NN4

training, with the exception that T

s

= 0.09min.

The controller is tuned in order to compensate

the main time constant of the process T(T(p)). The

mathematical model which describes the controller

work in time domain is expressed using the

following differential equation:

a(t)

d

t

da(t)

T(p)c(t)

d

t

dc(t)

T

f

,

(19)

where T

f

is the time constant of the first order filter

used in order to obtain the controller feasibility

(T

f

< T(p)). The control signal c(t) represents the

solution of the equation (19). At the changing of the

p independent variable value, the value of the

process time constant is modified and from (19) it

results that the value of the T(p) time constant of the

controller is modified, too, in order to be adapted to

the new time constant of the process. This

explanation implies the term “adaptive controller”.

Also the modification of the T(p) value is made

through the value of p independent variable, being

justified the abstract term of “distributed parameter

controller”. The implementation of the controller

using three neural networks interconnected between

them using mathematical operators, is presented in

Figure 7. The NN31 has the same structure as NN3

from Figure 5, generating at the output the value

T(p). Also, the NN41structures have the same

structure as NN4 from Figure 5, implementing the

integration operation. The training procedures and

parameters for the two types of neural networks

from Figure 7 are the same as in the case of NN3

and NN4 from Figure 5, with the exception of the

sampling time (in this case T

s

= 3min). In the case

when the

13

C isotope concentration control is made

in the point p = p

f

, the value T

f

= 8h represents a

good compromise between the system stability and

the structure performances. Also, for this value, the

usage of the control signal is feasible from its

saturation values avoidance point of view.

Having the neural models of the elements A, TP

and T, practically the model of the Reference Model

of the Fixed Part can be implemented, for example,

on a process computer and the structure from

Figure 6 can be used. The model of the controller,

also expressed using a neural networks structure, can

be implemented on a computation equipment, too.

5 SIMULATION RESULTS

The simulations (Colosi et. all, 2013) are made in

MATLAB/Simulink. First the validity of the

analytical solution from (16) is verified. In Figure 8

is presented the comparative graph between 5 step

responses of the separation column model expressed

through the mentioned analytical solution, if the

simulation is made for p = p

f

. The values of the

considered input step type variations are F

in

{200;

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

260

280; 367; 416; 600}ml/h. The steady state values of

the

13

C concentration isotope (y(t

f

,p

f

)) are

centralized in Table 1.

0 20 40 60 80 100 120 140 160 180

1

1.5

2

2.5

3

TIME [h]

y(t,p) [% ]

Fin = 280ml/h

Fin = 367ml/h

Fin = 416ml/h

Fin = 600ml/h

Fin = 200ml/h

Figure 8: Open loop responses of the determined process

model for different values of the input signal.

Table 1: The simulation results associated to Figure 8.

F

in

[ml/h] y(t

f

,p

f

) [%]

200 2.8

280 2.3818

367 2.1083

416 2

600 1.7392

Comparing to the experimental data from

(Axente et. all, 1994), it results that the determined

approximating analytical solution describes the

process work with high accuracy, the differences

occurring only at the third decimal. Also, in Table 1

and Figure 8 the increasing evolution of the

13

C

isotope concentration at the decrease of the value of

the input ethanolamine flow is highlighted.

In Figure 9 is presented the comparative graph

between 4 step responses of the separation column

model expressed through the mentioned analytical

solution, if the input flow of ethanolamine presents a

step type variation with the value F

in

= 300ml/h, for

different values of the p independent variable

p

{p

f

/4; p

f

/2; p

f

/4·3; p

f

}[cm]. The steady state

values of the

13

C isotope concentration (y(t

f

,p)) from

Figure 9 are centralized in Table 2.

0 20 40 60 80 100 120 140 160 180

1

1.5

2

2.5

TIME [h]

y(t,p) [% ]

ts1

ts2

ts3

ts4

p = pf

p = pf/4*3

p = pf/4

p = pf/2

Figure 9: Open loop responses of the determined process

model for different values of the p independent variable.

Table 2: The simulation results associated to Figure 9.

p [cm] y(t

f

,p) [%]

p

f

/4 1.3345

p

f

/2 1.5971

p

f

/4·3 1.917

p

f

2.3069

From Figure 9 and Table 2, the decreasing

evolution of the process response in relation to the

decrease of the p independent variable is

highlighted. From the mathematical point of view,

this aspect is explained due to the increasing

evolution of the F

p

function in relation to the

increase of p. From the physical point of view, this

aspect is explained due to the increase evolution of

the number of the theoretical plates in relation to the

increase of p. Also, from Figure 9 it can be remarked

that lower the value of p is, lower the value of the

process settling time is (t

s1

< t

s2

< t

s3

< t

s4

). This

phenomenon is explained due to the decreasing

evolution of the T(p) process time constant at the

decrease of p.

Figure 7: The implementation of the controller using neural networks.

NeuralModelingandControlofa13CIsotopeSeparationProcess

261

In Figure 10, the comparative graph between the

process response (modelled through the analytical

solution) and the process response (modelled

through the neural structure implemented in Figure

5) is presented. Practically, the differences between

the two curves from Figure 10 cannot be

distinguished, resulting the high validity of the

Neural Reference Model of the Fixed Part of the

control system from Figure 6 (the NS element from

the Reference Model has the main weight in it). The

square mean error between the two curves from

Figure 10, computed for 453 pairs of values

associated to the two responses, has the value

E

mp

= 0.0023%, considered insignificant for this

application.

0 10 20 30 40 50 60 70 80 90

1

1.2

1.4

1.6

1.8

2

2.2

TIME [h]

y(t,p) [% ]

Output generated by the analytical solution

Output generated by the neural network

Figure 10: The validation of the neural model associated

to the technological process.

In Figure 11, the response of the control system

from Figure 6 is presented. Firstly, between the time

moments t

1

= 30h and t

2

= 120h, the plant works in

starting regime, the ethanolamine flow being

maintained at F

inmax

. After the

13

C isotope

concentration (the output signal) gets steady to the

value 1.492%, the structure can be used to assure a

certain value of the y(t,p) signal. The simulation

from Figure 11 is made for p = p

f

. After the moment

t

2

, the concentration reference is set to the value

1.795%. From the Figure it can be remarked that this

value is reached after approximately 40h, much

faster than in open loop regime (case of t

s4

from

Figure 9 which has the value approximately equal to

78h). Also it can be remarked that the steady state

error a

st

= 0% and the overshoot %0σ (a very

important constrain imposed to the treated type of

system).

In Figure 12, the simulation from the Figure 11 is

repeated until the time moment t

3

= 190h. In this

moment the disturbance d

2

(t) of step type with the

value –0.1% occurs in the system. From Figure 12, it

results that the effect of the disturbance is efficiently

rejected by the controller after 50h the concentration

value being brought back to the value imposed

through the reference signal.In both the cases of the

simulations from Figures 11 and 12, the saturation

limits of the control respectively of the actuating

signals (both the minimum and maximum limits) are

not reached, the usage of the controller being

feasible.

0 20 40 60 80 100 120 140 160 180 200

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

TIME [h]

y(t,p) [% ]

Automatic control system response

Figure 11: The automatic control system response.

0 50 100 150 200 250 300

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

TIME [h]

y(t,p) [% ]

The automatic control system response

Figure 12: The automatic control system response, for the

case when a disturbance signal occurs in the system.

6 CONCLUSIONS

An original solution for the mathematical modelling

of a separation technological is presented in this

paper. Also, a solution for the automatic control of

the

13

C isotope concentration is presented based on

the IMC strategy.

In order to implement the Reference Model of

the system Fixed Part, the neural networks are used.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

262

These elements are original ones, too, due to the fact

that a distributed parameter technological process is

included in an IMC control structure and the model

of this type of process is learned using neural

networks. The work of A and T elements (Figure 6)

is learned using neural networks in order to preserve

the unitary character of the solution and the high

accuracy of the Fixed Part mathematical model.

The neural networks are used, also, for

implementing the adaptive controller, respectively

the term “distributed parameter controller” is

introduced and defined.

The process model validity and the high

performances of the proposed control structure are

proved through the simulations from Paragraph 5.

The control structure is tested in the case when a

disturbance signal occurs in the system. As it can be

remarked from Figure 12, the effect of the

disturbance is rejected with high efficiency.

ACKNOWLEDGEMENTS

The research activity that helped the authors to

elaborate the paper is supported through the research

projects no. 30141/12.12.2014 and no. 30104/2014,

financed by the Technical University of Cluj-

Napoca.

REFERENCES

Axente, D., Abrudean, M., Bâldea, A., 1994.

15

N,

18

O,

10

B,

13

C Isotopes Separation trough Isotopic

Exchange, Science Book House.

Borges, R. V., 2011. Learning and Representing Temporal

Knowledge in Recurrent Networks. In IEEE

Transactions on Neural Networks, Vol. 22, Issue 12,

pp. 2409 – 2421.

Coloşi, T., Abrudean, M., Ungureşan, M.-L., Mureşan, V.,

2013. Numerical Simulation of Distributed Parameter

Processes, Springer.

Dang, H., Rochelle, G. T., 2003. CO2 absorption rate and

solubility in monoethanolamine/ piperazine/ water. In

Separation Sci. & Tech., Vol. 38 (2), pp. 337–357.

Dugas, R., Rochelle, G., 2009. Absorption and desorption

rates of carbon dioxide with monoethanolamine and

piperazine. In Energy Procedia, Vol. 1 (1), pp. 1163–

1169.

Golnaraghi, F., Kuo, B. C., 2009. Automatic Control

Systems, 9

th

edition, Wiley Publishing House.

Haykin, S., 2009. Neural Networks and Learning

Machines, Third Edition, Pearson Int. Edition.

Li, H.-L., Ju, Y.-L., Li, L.-J., Xu D.-G., 2010. Separation

of isotope

13

C using high-performance structured

packing. In Chemical Engineering and Processing:

Process Intensification, Vol. 49 (3), pp. 255–261.

Li, H.-X., Qi, C., 2011. Spatio-Temporal Modeling of

Nonlinear Distributed Parameter Systems: A

Time/Space Separation Based Approach, 1st Edition,

Springer.

Love, J., 2007. Process Automation Handbook, 1 edition,

Springer.

Maren, A., Harston, C., Pap, R., 1990. Handbook of

Neural Computing Applications, Academic Press.

Mureşan, V., Abrudean, M., 2010. Temperature Modelling

and Simulation in the Furnace with Rotary Hearth. In

Proc. of IEEE AQTR–17

th

ed., Cluj-Napoca,

Romania, pp. 147-152.

Norgaard, M., Ravn, O., Poulsen, N.K., Hansen, L.K.,

2000. Neural Networks for Modelling and Control of

Dynamics Systems, Springer.

Smyshlyaev, A., Krstic, M., 2005. Control design for

PDEs with space-dependent diffusivity and time-

dependent reactivity. In Automatica, Vol. 41, pp.

1601-1608.

Vălean H., 1996. Neural Network for System

Identification and Modelling. In Proc. of Automatic

Control and Testing Conference, Cluj-Napoca,

Romania, 23-24 May, pp. 263-268.

NeuralModelingandControlofa13CIsotopeSeparationProcess

263