Optimizing Construction Sequences for Secant Pile Walls

Rong-Yau Huang, Ping-Fu Chen and Jieh-Haur Chen

Graduate Institute of Construction Engineering and Management, National Central University,

No. 300, Jhongda Rd., 32001, Jhongli District, Taoyuan City, Taiwan

Keywords: Pile Sequence, Optimization, Genetic Algorithm (GA).

Abstract: Secant pile walls are crucial in the construction of fossil-fuel power plants for water exclusion purposes.

The construction time is the most critical factor that influences the entire construction project. Thus,

shortening the time needed for building secant pile walls requires further investigation. Secant pile walls are

not required to be constructed in any particular order; typically, site engineers assign construction crews to

first build several primary bored piles, and then build secondary bored piles. However, building secant pile

walls in this sequence generally requires the primary bored piles to be excessively cured and hardened. The

construction of secondary bored piles in this manner thus results in construction difficulties, wasted

construction time, and poor construction quality. To address this practical problem, this study adopted a

genetic algorithm to investigate the optimal number of primary bored piles, the curing time, and the number

of daily working hours for the construction crew. In addition, the relationship between the curing time for

the primary bored piles and the construction time for the secondary bored piles was investigated by using a

case study, to ensure the overall research results corresponded to practical operation. The findings of this

study can facilitate the saving of construction time in the future construction of secant pile walls, enabling

the whole construction project to be completed successfully and improving public welfare.

1 INTRODUCTION

Construction time matters for activities. The

building of a secant pile wall requires the rental of

equipment and finding the optimal sequence to

minimize the construction time is one way to save

construction costs. Secant pile walls are necessary in

the fossil-fuel power plants construction project for

water exclusion purposes.

This research scope is

limited to finding the optimal construction sequence

of the work activities needed to build a secant pile

wall, which include grading, positioning of the site,

positioning of the equipment, driving the first 8-

meter casing into the ground, boring and cutting (0

–6 m),boring and cutting (6–12 m), driving the

second 8-meter casing into the ground, boring and

cutting (12–17 m), measuring the center of the pile,

measuring the altitude, ultrasound measurements,

placing of the steel cage, removal of bottom soil,

application of Bentonite slurry, pouring the concrete,

and removing the casing. Activities other than these

16 are not included. Such other activities could

include, for example, time for equipment

preparation, adjusting, relocating, and idle time.

Human effects such as the how the operator's skill

level and physical condition contribute to operations

are also excluded. In this study we try to develop an

effective and efficient model with Genetic

Algorithm to minimize the construction time. The

algorithm is applied to a case study to obtain the

optimal sequences for both primary and secondary

bored piles for a secant pile wall. Some factors

affect the total construction time are discussed with

sensitivity analysis, like the cement setting time of

the primary bored piles, the quantity of the primary

bored piles be done in a round and the working-

hour/ per day of the crew. The optimal sequences for

both primary and secondary bored piles are also

determined.

Previous studies on optimal solutions for

repetitive project scheduling have shown that when

problems are complex and large-scale, the efficiency

of analytical methods is considerably reduced;

determining optimal solutions may thus be hindered

by the excessively large amount of calculations and

time required (Al-Harbi et al., 1996). In the problem

of nonlinear optimization, the application of

analytical methods is typically difficult if not

impossible. A genetic algorithm (GA) is a direct

stochastic search technique that has been applied

widely in recent years. GA is used to determine

145

Huang R., Chen P. and Chen J..

Optimizing Construction Sequences for Secant Pile Walls.

DOI: 10.5220/0005553201450150

In Proceedings of the 10th International Conference on Software Engineering and Applications (ICSOFT-EA-2015), pages 145-150

ISBN: 978-989-758-114-4

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

optimal solutions based on the mechanism of natural

selection and the principle of survival-of-the-fittest.

GA generally yields satisfactory outcomes in a

relatively short amount of time. Therefore, this study

used the GA concept as basis to develop an

algorithm for optimizing the scheduling of a full-

casing secant pile wall.

2 PILE SEQUENCE

OPTIMIZATION MODEL

2.1 Model Assumption

To reduce the number of variables, the research

scope of this study was narrowed under several

assumptions, as follows:

(a) Construction crew (resource) = 1

Only one construction crew was assumed

to engage in the construction of the primary

and secondary bored piles, which were

assumed to be built at different times.

(b) Construction machinery (resource) = 1

Only one set of machines, including the

boring machine and spreader, were assumed in

the construction of the primary and secondary

bored piles. Every pile was assumed to be

constructed separately.

(c) The machinery transport time is excluded.

According to on-site observations, the time

required to transport machinery is

approximately 5 minutes. This was negligible

and consequently, the effect of transportation

time was not taken into account.

(d) The secondary bored piles were assumed to be

constructed after the primary bored piles were

constructed, in sequence.

The construction of primary bored piles is

affected by the geology of the area in which

they are being built. This study assumed that

the construction sequence for primary bored

piles did not influence the overall construction

time; only combinations to the construction

sequence for secondary bored piles were

considered.

(e) The drilling time for the secondary bored piles

is related to the curing time of the primary

bored piles.

Secant piles are composed of concrete, and

their curing time and strength is identical to that

of concrete generally. Increased curing time

results in increased curing strength, but the

strength plateaus after a specific time period.

(f) The secondary bored piles were assumed to be

constructed the day after all the primary bored

piles were built.

According to on-site observations, after the

construction of primary bored piles, the

construction site requires cleaning before

machinery for the construction of the secondary

bored piles can be brought in. Thus, the

construction of secondary bored piles is

generally initiated on the next day after the

construction of primary bored piles is

completed.

(g) The construction time was limited by the

working hours of the construction crew each

day.

If the construction time for the j

th

pile on the

i

th

day is T

ij

, then when ΣT

ij

is larger than the

construction time worked each day (T

k

), the

time spent on construction within one day is T

ij-

1

, and that of the next day is T

ij

.

(h) The time required to construct the secondary

bored piles was based on the curing time for

the preceding primary bored piles.

Because the construction of secondary bored

piles involves the drilling of primary bored piles to

form a watertight surface, the time required for

drilling is determined by the longest time needed to

cure the preceding primary bored pile. For example,

the time necessary to construct the sixth secondary

bored pile is based on the curing time for the fifth

secondary pile.

2.2 The Relationship Between the

Construction Time for Secondary

Bored Piles and the Curing Time

for Primary Bored Piles

Because of the properties of secant piles, the primary

bored piles must be established for a certain period

of time before pile driving of secondary bored piles

could be initiated, thereby achieving the goal of

water exclusion. However, no specifications for the

length of this waiting time are available. If the time

period is overly short, the concrete strength is

insufficient for construction processes. If the time

period is excessively long, the time spent on pile

driving may be considerable, or the machinery may

be damaged, resulting in extensions to the total

construction time. This study reviewed records of

the construction of primary and secondary bored

piles to understand the functional relationship

between the curing time for primary bored piles and

ICSOFT-EA2015-10thInternationalConferenceonSoftwareEngineeringandApplications

146

the construction time for secondary bored piles. This

relationship can then be used to estimate the

construction time needed for building secondary

bored piles. Based on 104 on-site records, the

maximum and minimum numbers of hours for the

construction of primary bored piles were obtained to

facilitate subsequent simulations, in which random

numbers corresponding to the uncertainties existing

in actual construction process were used. The

minimum number of hours required to construct

primary bored piles was 2.55, and the maximum was

4.55. Subsequently, regression analysis on the 104

on-site record data was performed to determine the

construction time for secondary bored piles, as

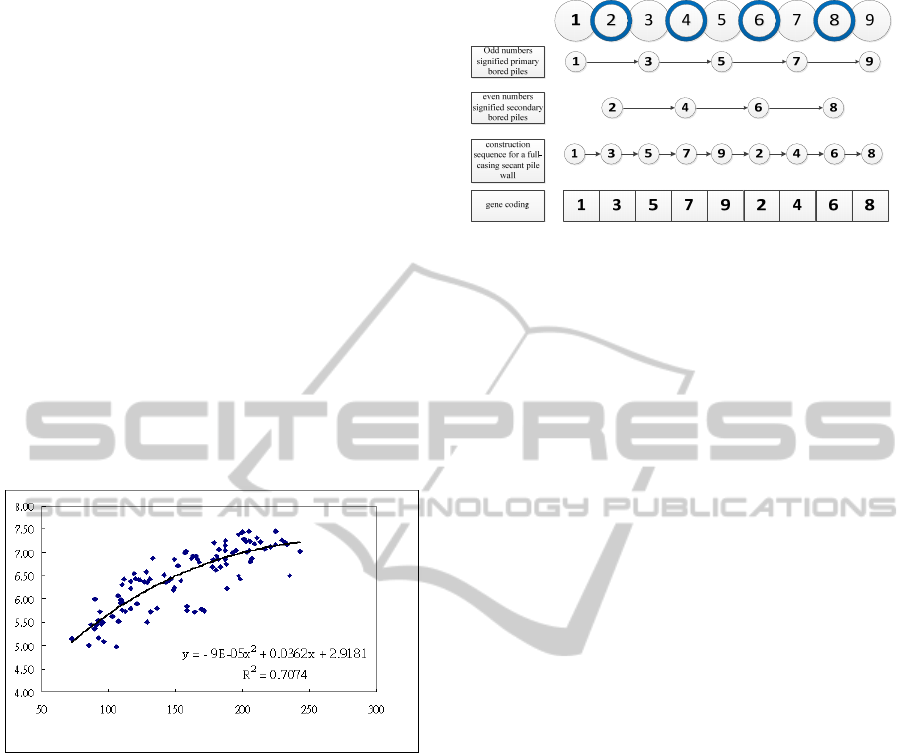

shown in Equation (1) and Fig. 1.

T

s

=-0.00009 T

p

2

+0.0362T

p

+2.9181 (1)

where T

s

denotes the construction time for the

secondary bored piles, and T

p

denotes the

construction time for the primary bored piles (the

longest construction time was selected).

Figure 1: The estimation of the time spent on constructing

secondary bored piles.

2.3 Development of the GA Model

In the GA model developed in this study, piles were

numbered. Odd numbers signified primary bored

piles, and even numbers signified secondary bored

piles. Fig. 2 displays 5 primary bored piles and 4

secondary bored piles, or 9 units of full-casing

secant piles in total. Therefore, the chromosome

displayed in Fig. 2 indicates that the construction

sequence for a full-casing secant pile wall is

1→3→5→7→9→2→4→6→8.

Construction sequence for primary bored piles

Construction sequence for secondary bored

piles

Construction sequence for a full-casing secant

pile wall

Genetic codes

Figure 2: Construction sequence for secant piles and its

genetic representations.

(a) Production of parents: After the number of

primary bored piles (P) was input into the

model, random numbers were used to produce a

sequence (P-1) for the construction of secondary

bored piles.

(b) Crossover: One-point crossover was adopted.

(c) Mutation: Single-point mutation was conducted

in the model.

(d) Penalty function: The penalty function adopted

in this study was different from that commonly

used. Typically, a relatively extreme value is

used as a penalty function. For example, the

target value in this study was the total working

time consumption, which was a small value. A

total of 999 hours were allocated to a selected

pile that is not yet ready for pile construction.

Thus, the gene representative of that pile

becomes an undesired choice and has a low

possibility of being selected in the crossover

pool. However, this study adopted a deferred

penalty function. The produced parent

construction sequence was 2, 4, 6, 8, and 10,

and in other words, the second pile was the first

to be constructed. If the curing time for the

preceding first pile was shorter than the

minimum curing time, the second pile can only

be processed when the curing time (for the

preceding first pile) equaled the minimum

curing time. This waiting time was the deferred

penalty. Compared with the fixed penalty, the

deferred penalty allows the generation of

reasonable parent solutions.

(e) Selection: After the operation of the stated four

steps, the produced offspring T (the total time

consumption) was obtained by calculation. This

study adopted the roulette wheel selection,

where the roulette area was determined as 1/T,

which was used to select and retain the

offspring. Additionally, an elitist selection was

employed to retain superior combinations

among various generations and increase the

convergence speed.

OptimizingConstructionSequencesforSecantPileWalls

147

3 CASE STUDY

The case study involved the Siphon well

construction for circulating water in the Datan power

generation project, which is located in Datan

Village, Guanyin Township, Taoyuan County,

Taiwan. The parameters were set as follows:

(a) The number of primary bored piles: The number

of primary bored piles was denoted as N

p

, which

conformed to the principle of N

p

≧ 2 to enable

the construction of secondary bored piles. The

adopted numbers of primary bored piles in this

study were 5, 6, 7, 8, 9, 10, 15, 20, 25, and 30,

enabling the observation of variations in

construction times spent on various numbers of

primary bored piles.

(b) The construction time for the primary bored

piles: The construction time for the primary

bored piles was calculated based on the 104 on-

site construction data, from which the maximum

(4.55) and minimum (2.55) hours were

extracted. The system-produced time for

constructing primary bored piles (i.e.,T

p

) was

generated using random numbers; T

p

ranged

from 2.55 to 4.55.

(c) Number of working hours per day: The

construction crew’s working hours each day

were denoted as T

p

. Through interviews, this

study categorized the working times as 8 hours

(one-day work), 12 hours (one-day of work and

4 hours of overtime), 16 hours (shifts taken by

two construction crews), and 24 hours (shifts

taken by three construction crews, that is, the

full-day construction crews).

(d) The upper limit of the function: The upper limit

of the function was the condition for

terminating system operation. When the waiting

time exceeded the upper limit of the function,

the resulting sequence was regarded as

inadequate and would not be adopted

subsequently. In this study, the upper limit was

assumed to be 200 hours.

(e) The minimum curing time: At a construction

site, the time when the construction of the

secondary bored piles can be initiated (denoted

as T

a

) is generally based on a standard of seven

days. However, construction may also be

initiated after only three days of curing of

primary bored piles. In other words, the

standard curing time is not fixed. In this study,

various lengths of curing time were employed in

the analysis: 3 days (72 hours), 4 days (96

hours), 5 days (120 hours), and 7 days (168

hours).

The number of primary bored piles in a single

cycle: In one cycle, the number of constructed

primary bored piles may influence the time

consumption in that cycle and further influence the

total construction time. Accordingly, the quantities

of primary bored piles in one cycle were set as 6, 7,

8, 9, 10, 15, 20, 25, and 30 for the analysis, to

understand the required construction time when the

amounts of curing time were 72 hours, 96 hours, 120

hours, 144 hours, and 168 hours.

3.1 Analysis of Working Hours

per Day

The construction crew’s working hours each day

may influence the construction time of one cycle,

thereby influencing the total time consumed to

complete the entire construction project. Thus, the

quantity of primary bored piles in one cycle was set

as 5, 6, 7, 8, 9, 10, 15, 20, 25, and 30, and the curing

times were set as 72 hours, 96 hours, 120 hours, 144

hours, and 168 hours, for the subsequent analysis of

the working hours per day, which were 8 hours, 12

hours, 16 hours, and 24 hours.

The total amount of construction time was

influenced when the daily working hours were 12

and 16 hours. However, when the number of

working hours was 8 and 24 per day, the working

hours did not positively influence the total

construction time, because the required curing times

remained the same.

3.2 Sensitivity Analysis

The analysis in the previous section focused on a

single cycle. This study analysed three influencing

factors (the quantity of constructed primary and

secondary bored piles, the working hours per day,

and the curing time for the primary bored piles) and

employed the GA to optimize the construction

sequence for the secondary bored piles, yielding

satisfactory research outcomes. However, in

practice, a given project may need to construct a

fixed number of secant piles. In addition, the

working hours for each day and the possible curing

time are determined using cycle-number calculations

employed by previous studies. For example, in a

given project, 300 primary bored piles and 299

secondary bored piles must be completed. Assuming

that the curing time is 72 hours, working hours are 8

hours per day, and the number of primary bored

piles constructed in each cycle is 20, then the total

time consumption is calculated as follows:

ICSOFT-EA2015-10thInternationalConferenceonSoftwareEngineeringandApplications

148

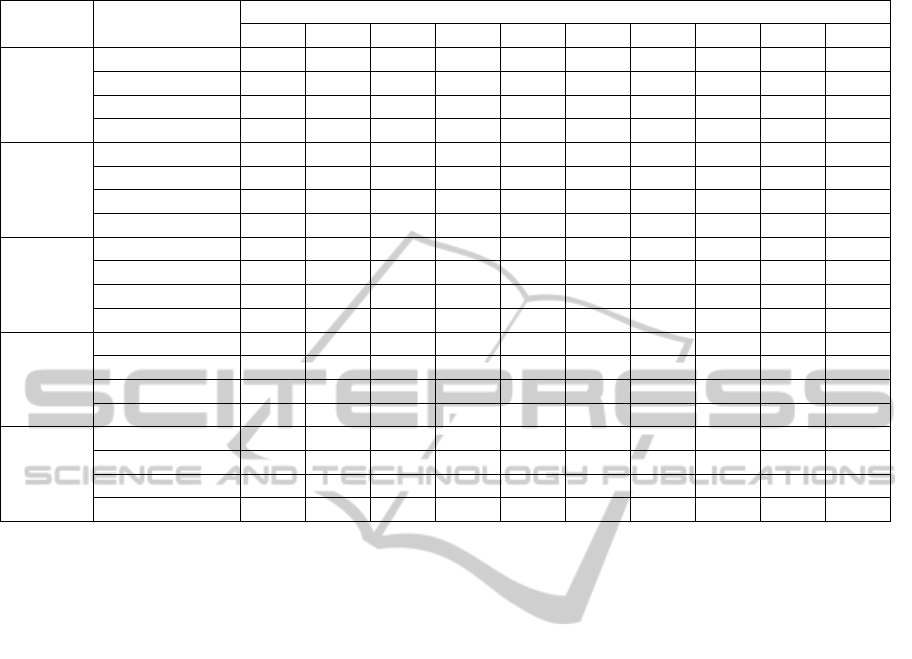

Table 1: Curing time, quantities of primary bored piles, working hours per day, and the total amount of construction time.

Curing time Working hours/day

Number of piles

5 6 7 8 9 10 15 20 25 30

72 hr

8hr

10450.8

9911.0 9531.9 10144.9 9818.3 9556.5 10691.0 11258.3 10734.6 10625.5

12 hr 7871.4 7492.5 6665.6 6519.8 5988.3 5943.9 7331.0 7298.3 8142.6 8705.5

16 hr 7545.0 6555.0 6422.1 5628.4 5188.7 5217.0 4443.0 5138.3 5341.3 5171.1

24 hr 7014.6 6283.0 5621.1 5114.6 4715.7 4494.9 3593.4 3142.2

2958.4

3075.2

96 hr

8 hr

11904.6

11121.5 10565.6 10144.9 9818.3 9556.5 10691.0 11258.3 10734.6 10625.5

12 hr 9358.2 8709.0 8501.6 7432.1 7413.3 7395.6 7331.0 7658.3 8142.6 8945.5

16 hr 9370.8 8711.0 7728.9 7439.3 6822.3 6672.9 5540.6 5498.3 5341.3 5345.5

24 hr 8565.6 7502.0 6683.6 6061.5 5573.3 5225.1 4086.6 3521.7 3400.4

3316.6

120 hr

8hr 13351.8 12327.0 11595.0 11045.6 10618.3 10276.5 10691.0 11258.3 10734.6 10625.5

12 hr

13352.4

12327.5 11595.0 11045.6 10618.3 10276.5 9251.0 9098.3 9294.6 9425.5

16 hr 10842.0 9921.5 8777.1 8344.5 7633.0 7396.2 6022.2 5498.3 5341.3 5345.5

24 hr 10461.6 9030.0 7743.0 7002.4 6613.3 6143.4 5061.0 4418.3 3980.0

3731.1

144 hr

8 hr

14793.0

13527.5 12623.6 11945.6 11418.3 10996.5 10691.0 11258.3 10734.6 10625.5

12 hr 14793.0 13527.5 12623.6 11945.6 11418.3 10996.5 9731.0 9098.3 9294.6 9425.5

16 hr 12300.0 11127.0 9816.4 9245.6 8437.0 8116.5 6502.2 5858.3 5341.3 5345.5

24 hr 11910.6 10247.5 9057.4 8345.3 7635.0 7066.2 5542.2 4778.3 4268.0

3971.1

168 hr

8 hr

16233.0

14727.5 13652.1 12845.6 12218.3 11716.5 10691.0 11258.3 10734.6 10625.5

12 hr 16233.0 14727.5 13652.1 12845.6 12218.3 11716.5 10211.0 9458.3 9294.6 9425.5

16 hr 13746.6 12327.5 10847.6 10145.6 9237.0 8836.5 6982.2 6218.3 5629.3 5345.5

24 hr 13353.0 11782.0 10098.0 9245.6 8655.7 7790.1 6022.2 5138.3 4556.0

4211.1

Total time consumption = 300 (number of piles) / 20

(number of piles/cycle) * 750.55 (hours/cycle) =

11258.3 (hours)

Accordingly, this study investigated the total

time consumption under various standards of curing

time.

Assuming that the curing of concrete requires 72

hours, the total construction time is 10450.8 hours at

most and 2958.4 hours at least.

Assuming that the curing of concrete requires 96

hours, the total time consumption is 11904.6 hours

at most and 3316.6 hours at least.

Assuming that the curing of concrete requires

120 hours,the total construction time is 13352.4

hours at most and 3731.1 hours at least.

Assuming that the curing of concrete requires

144 hours, if the number of working hours is

between 8 hours and 24 hours per day, the total

construction time is 14793.0 hours at most and

3971.1 hours at least.

Assuming that the curing of concrete requires

168 hours, if the number of working hours is

between 8 hours and 24 hours per day, the total

construction time is 16233.0 hours at most and

4211.1 hours at least.

In sum, full-day construction requires the shortest

work duration. But the full-day crews may cost over

the budget of the project.

4 CONCLUSIONS

1. This study established an optimal construction

sequence model for secant pile walls. Regression

equations corresponding to various geological

conditions can be used for optimization

computations. Construction teams can reference

this method when determining the sequence of

secant pile wall construction.

2. A case study was conducted based on on-site

observations. Regression analysis was applied

according to the curing times for primary bored

piles and the drilling times for secondary bored

piles. The regression results indicated that the

two variables exhibited a strong correlation.

3. A close relationship was observed among the

working hours per day, the minimum curing

time, and the number of constructed piles. This

study conducted simulations on these three

variables in various combinations. Future studies

are recommended to focus on using these three

variables in simulations to determine the optimal

combinations of these variables, thereby

providing a reference for on-site construction

teams.

OptimizingConstructionSequencesforSecantPileWalls

149

ACKNOWLEDGEMENTS

This research is partially supported by the

“Developing a Simulation-Based Carbon Footprint

Assessment Model for Construction Operations” of

Ministry of Science and Technology, Taiwan,

R.O.C. under Grant no. MOST103-2221-E008-071-

MY2.

REFERENCES

Adeli, Hojjat, and Karim, Asim (1997), “Scheduling/cost

optimization and neural dynamics model for

construction”, J. of Constr. Engrg. and Mgmt., ASCE,

123(4), 450-458.

Al-Harbi, Kamal Al-Subhi, Selim, Shokri Z., and Al-

Sinan, Maazen (1996), “A multiobjective linear

program for scheduling repetitive projects”, Cost

Engrg., 38(12), 41-45.

Ammar, Mohammad A., and Elbeltagi, Emad (2001),

“Algorithm for determining controlling path

considering resource continuity”, J. Comp. in Civ.

Engrg., ASCE, 15(4), 292-298.

Chan, W. T., and Hu, Hao (2002), “Production Scheduling

for Precast Plants using a Flow Shop Sequencing

Model”, J. Comp. in Civ. Engrg.,ASCE, 16(3), 165-

174.

Dzeng, R. J., Tserng, H. P.,and Wang, W. C. (2005),

“Automating Schedule Review for Expressway

Construction”, J.of Constr. Engrg. and Mgmt.,ASCE,

131(1), 127-136.

Dzeng, R. J., Wang, W. C., and Tserng, H. P. (2004),

“Module-Based Construction Schedule Administration

for Public Infrastructure Agencies.” J.of

Constr.Engrg.and Mgmt., ASCE, 130(1), 5-14.

Feng, Chung-Wei, Cheng, Tao-Ming, and Wu, Hsien-

Tang (2004), “Optimizing the schedule of dispatching

RMC trucks through genetic algorithms”, Automation

in Construction, 13(3), 327–340.

Thomas, Randolph H., Oloufa Amr A, 「 Labor

Productivity, Disruption and Ripple Effect 」 , Cost

Engineering, Vol. 37, No.12, 1995.

Harris, Robert B. and Ioannou, Photios G. (1998),

“Scheduling projects with repeating activities”, J. of

Constr. Engrg .and Mgmt., ASCE, 124(4), 269-278.

Huang, Rong-Yau (2002), “Demand-supply model for

resource planning of repetitive construction projects”,

J.of Chinese institute of civil and hydraulic

engineering, 14(3), 551-559.

Leu, Sou-Sen, and Hwang, Shao-Ting (2002), “GA-based

resource-constrained flow-shop scheduling model for

mixed precast production”, Automation in

Construction, 11(4), 439-452.

Leu, Sou-Sen, and Hung, Tzung-Heng (2002), “A genetic

algorithm-based optimal resource-constrained

scheduling simulation model”, Construction

Management and Economics, 20(2), 131-141.

Leu, Sou-Sen, and Yang, Chung-Huei (1999), “GA-Based

Multicriteria Optimal Model for Construction

Scheduling”, J. of Constr. Engrg. and Mgmt., ASCE,

125(6), 420-427.

Mattila, Kris G, and Abraham, M. (1998), “Resource

leveling of linear schedules using integer linear

programming”, J. of Constr. Engrg. and Mgmt.,

ASCE, 124(3), 232-244.

Moselhi, Osama, and El-Rayes, Khaled (1993),

“Scheduling of repetitive projects with cost

optimization,” J. of constr. Engrg. and Mgmt. ASCE,

Vol. 119, No. 4, pp. 681-697.

Reeves, C. R. (1995), “A genetic algorithm for flowshop

sequencing”, Comp. and Operations Res., Oxford,

U.K., 22(1), 5–13.

ICSOFT-EA2015-10thInternationalConferenceonSoftwareEngineeringandApplications

150