Development of Computerized Severe Accident Management

Guidelines of AP1000 Nuclear Power Plant

Gang Chen

1,2

, Shuang Xiao

1

, Haidan Wang

1

, Yiqiang Xiong

1

and Yixue Chen

1

1

State Nuclear Power Software Development Centre, South Side of Future Science & Technology Park,

Changping District, Beijing, China

2

National Energy Key Laboratory of Nuclear Power Software, Beijing, China

Keywords: Nuclear Power Plant, Computerized Severe Accident Management Guidelines, AP1000.

Abstract: Nuclear Power is considered to be one of the solutions to fulfil the increasing need of clean energy in China.

Making use of this clean energy can help reduce the consumption of fossil energy, which could enhance the

surrounding areas by preventing the environment from harmful air pollution. However, the consequence of

severe accident of nuclear power is unbearable, such as Chernobyl and Fukushima Accidents. So as to

improve the safety of nuclear power, the severe accident shall be managed in case to reduce the negative

impacts to the environment and people health. This paper introduces the Severe Accident Management and

Emergency Response System (SAMERS), which aims to help the operators and technicians deal with the

severe accidents. Especially, the development of Computerized Severe Accident Management Guidelines

(CSAMG) is described in detail, which is a module of SAMERS. CSAMG is based on the AP1000 severe

accident management guidelines, which could enhance the operator performance during severe accident.

1 INTRODUCTION

Due to the rapid development of Chinese economics

and the demand for more environmentally friendly

energy, China has issued an ambitious program of

nuclear power development. By 2020, the nuclear

installation will reach 40 GW (CNDRC, 2007), which

means many nuclear power plants will be built in the

next few years. A big part of the new-built nuclear

power plants (NPPs) will be of AP1000 type,

including Sanmen and Haiyang NPPs. Fukushima

accident has drown people’s attention to the severe

accident consequence. After Fukushima accident, all

NPPs in China planned to enhance their capability of

severe accident management and emergency

response, as required by the regulation organization.

One way to improve the severe accident management

capability is to investigate the scenario and

phenomena of accident to improve the calculation of

severe accidents. The other efficient way is to employ

the computer-based procedure system rather than the

paper-based procedures in the implement of severe

accident management guidelines (Robert et al., 2009).

To enhance the safety of nuclear power plant,

especially for the AP1000 type NPPs during severe

accidents, Severe Accident Management and

Emergency Response System (SAMERS) is designed

to support the operators and technicians during the

severe accident and emergency conditions. It is

supposed to be able to monitor the plant status and to

simulate the accident process in advance. Then it

could show the plant response to the mitigation

intervention, and evaluate the accident consequence.

Computerized Severe Accident Management

Guidelines (CSAMG) is a relatively independent

module of SAMERS. The main function of CSAMG

is to monitor the plant status and to provide the proper

advice to mitigate the accident effectively. The

ultimate objective of SAMERS and CSAMG is to

apply to NPPs for accident mitigation and emergency

response. But in the near term, the application of

SAMERS and CSAMG would be used to train the

new operators and technicians to enhance their

understanding of severe accident progress.

2 SAMERS

SAMERS consists of 3 subsystems:

(1) Accident Analysis and Prediction Subsystem

(AAPS)

199

Chen G., Xiao S., Wang H., Xiong Y. and Chen Y..

Development of Computerized Severe Accident Management Guidelines of AP1000 Nuclear Power Plant.

DOI: 10.5220/0005560901990204

In Proceedings of the 5th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2015),

pages 199-204

ISBN: 978-989-758-120-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

(2) Plant Status Evaluation Subsystem (PSES)

(3) Plant Information and Interface Display

Subsystem(PIDS)

The Client/Server architecture is employed for its

futures of high stability, intensive interaction, mass

data processing and communication. The 4-tier

architecture of SAMERS is shown in figure 1.

Plant Data

Display

Severe Accident

Phenomenon Display

Human Machine

Interface

Software Interface

SA Simulator

Operation

Platform

PIDS

AAPS

Safety Status

Evaluation

CSAMG

PSES

Data Access Interface

Plant Data

Database

Meteorological

Data

Material Data

Base

Presentation

Layer

Business

Layer

Data

Access

Layer

Database

Layer

Figure 1: The 4-tier architecture of SAMERS.

2.1 AAPS

The main function of AAPS is to simulate the severe

accident scenario by using the severe accident

simulator. The severe accident simulator adopts the

Severe Accident Source Term (SAST) code as the

calculation engine. It could simulate in real-time

scenario or faster-than-real-time scenario. When the

SAMERS is connected to the NPP network, which is

called on-line mode, the plant data that is transferred

from the detectors on site could provide the initial

conditions and boundary conditions for simulating.

The AAPS could predict the scenario in advance, so

the operators and technicians could figure out

mitigation actions; also they could apply these actions

to the simulator to make sure the impact is positive.

Besides the on-line mode, the off-line mode of

SAMERS is used only as a training system which

means AAPS could provide a virtual reactor for the

trainees to operate.

2.2 PSES

PSES consists of 2 major modules, one is safety status

evaluation module; the other one is CSAMG. The

safety status evaluation module is capable of

evaluating several critical safety status such as the

reactor core damage, containment hydrogen

flammability and spent fuel pool status. These safety

statuses are the uppermost issues in the plant

operation. This module could offer the clear results of

these safety evaluations, help the operators to decide

the mitigation actions.

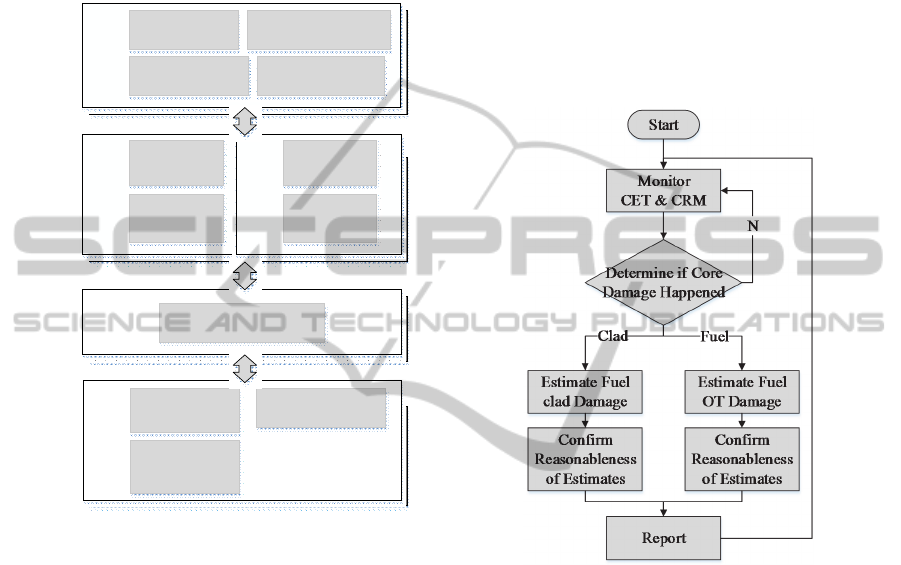

Figure 2: Flowchart of reactor core damage evaluation.

CSAMG is a support tool for the operators and

technicians under the condition of severe accident.

When linked to the plant database, it could monitor

the parameters and automatically remind the

operators of dangerous situations that need to be

concerned. It also provides many mitigation advices.

The function of CSAMG will be described in detail

in the next chapter.

2.3 PIDS

PIDS is the user interface of SAMERS. It not only

displays the real-time plant data, but also shows a

severe accident phenomenon simulation, which helps

users to understand the process taking place in a

severe accident. The visual image of accident

phenomenon is important for the trainees to learn the

accident scenario. Furthermore, PIDS provide human

machine interface which is used to manipulate the

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

200

severe accident simulator, and all the software

interfaces including CSAMG.

3 COMPUTERIZED SEVERE

ACCIDENT MANAGEMENT

GUIDELINES

Severe accident management guideline is a paper-

based handbook for the NPP operators and

technicians to consult when the accident happened. It

requires the operators and technicians to be very

familiar with its content so as to locate the

information they need quickly. It would cost lots of

time and energy to learn the guidelines during the

training courses. And under the condition of severe

accident, due to the tension and pressure of operators,

they might be inefficient to look up through the

handbook. Compared to the paper based procedures,

Computerized Procedure System could improve the

performance of operators in the procedure application

(Lee et al., 2010). It also could reduce workload and

save time during the accidents (Yuji et al., 1996).

To develop the CSAMG, firstly, the AP1000

SAMG is investigated to learn the work mode of

operators and technicians during the accident; then

the requirements are analysed to provide the design

basis of CSAMG; next is the function design of

CSAMG. At the same time the prototype of CSAMG

is developed. At last is the test and validation. We are

in the stage of function design and prototype

development.

3.1 AP1000 SAMG

AP1000 SAMG consists of three major parts: (Zheng,

2012)

(1) Control Room Severe Accident Management

Guidelines (CR SAMG);

(2) Technical Support Centre Severe Accident

Management Guidelines (TSC SAMG);

(3) TSC Severe Challenge Response Guidelines

(TSC SCRG).

The CR SAMG is guided by the control room, while

the TSC SAMG and TSC SCRG are both guided by

the TSC. The CR SAMG consists of two separate

guidelines SACRG-1 and SACRG-2, which are

defined by the status of the Technical Support Centre

(TSC). SACRG-1 is the entry guideline from the

AP1000 EOP to the SAMG. SACRG-1 includes

many steps that are same as in the EOP. SACRG-2 is

intended to enhance the cooperation of the control

room and TSC. The primary responsibility of TSC is

evaluating the plant status and recommending

possible actions to mitigate the core damage. But if

the core damage occurs before TSC is functional, the

control room operators must response to the situation.

SACRG-1 is the guideline for this condition. When

the TSC becomes functional, the responsibility of

severe accident management would pass to the TSC.

The operators move to execute the SACRG-2.The

control room operators will remain in SACRG-2 until

the TSC decide to exit SAMG to other procedures.

The TSC SAMG and SCRG both can be divided

into two sections: diagnostics and relative

management strategies. These guidelines are used by

the TSC to evaluate the plant status and to

recommend the management strategies. The

diagnostics consist of two parts: a Diagnostic Flow

Chart (DFC) and a Severe Challenge Status Tree

(SCST).

The DFC specifies several key parameters to

monitor for diagnosis of plant status. The key

parameters are monitored in a continual periodic way

until all the parameters are in the safe region, so the

plant could be declared to be safe. If one of the

parameters is outside the range, the TSC should

evaluate the need to implement strategies to make the

parameter back into the safe range. The strategies are

specified in a set of seven corresponding procedures

called Severe Accident Guidelines (SAGs). It is

worthwhile to notice that the mitigation strategies can

have negative impacts. It is reasonable for the TSC to

decide not implement any actions.

The SCST is the other tool for diagnosis of

ongoing fission product releases and challenges to

fission product boundaries. In the SCST, some key

parameters are identified to be monitored too. The

main difference between the DFC and SCST is the

urgency of implementing the mitigation strategy. In

the DFC, the impacts of the strategy should be

evaluated by the TSC to determine whether to

implement the strategy or not. But in the SCST, due

to serious conditions, the strategy should be

implemented immediately without the evaluation of

the impact, because without the mitigation strategy,

the fission product is about to release.

The seven SAGs corresponding to the DFC

specify a systematic, logical evaluation of possible

mitigation strategies to a given parameter. The SAGs

helps the TSC staff identify the possibility of

implement, balance of positive and negative impacts,

symbol of the successful strategy, and long term

concern of the strategy.

The four SCGs corresponding to the SCST are

similar to the SAGs. The SCGs don’t need the

DevelopmentofComputerizedSevereAccidentManagementGuidelinesofAP1000NuclearPowerPlant

201

evaluation process of the positive and negative

impacts. Through the SCGs, the TSC staff only needs

to determine the most appropriate strategy, and to

identify the successful symbol and long term concern

of the strategy.

3.2 Requirement Analysis

Computerized procedure system based on computer

information processing aims to assist operators and

TSC members to monitor and control the implement

of procedures. The ultimate goal of CSAMG is to

assist the TSC members and operators execute the

SAMG.

Basic functional requirements of CSAMG are

similar to the CPS used on the AOPs and EOPs (Gang,

2013). But due to the difference between the AP1000

SAMG and other procedures, some requirements are

special to the CPS of the AP1000 SAMG. The

analysis could help the design to be more appropriate.

(1) CSAMG shall be capable of identifying the data

availability and justify the data quality. The key

parameter specified in DFC and SCST are very

important for the TSC staff to evaluate the status

of the plant. If the data is not available, the user

should be warned by CPS, and the user should

justify the procedure.

(2) CSAMG shall be capable of parallel monitoring

plant status, especially the availability of systems

and equipment (Park and Ahn, 2010). Any

information of availability changed shall be

displayed as warning to the operators and TSC

technicians. The situation of severe accident is

very complex, and the status of plant systems and

equipment may change all the time. Since the

availability of the systems and equipment affect

the mitigation strategies directly, TSC technicians

shall be aware of it timely. They need to re-

evaluate the strategies already in use.

(3) CSAMG shall provide a convenient operation

mode for the control room operators and TSC

technicians to cooperate better. The information

transferring and interaction process in the severe

accident operation requires a convenient tool in

CSAMG to make the communication and

cooperation more effective. The communication

function shall be combined with the parameter

monitoring and strategies evaluating.

(4) CSAMG shall be capable of networking operation

of multi-user from different locations to cooperate

together. As mentioned above, the AP1000

SAMG is implemented by the main control room

and TSC technicians. The TSC staff could be a

group of experts from different places and they

work on-line together with the control room to

make the executing order. Furthermore, the CPS

should guide the users to work together. Different

users may have different tasks, and some of them

could just evaluate the plant, and the others could

take actions. Or the status of the plant is evaluated

by different users, the final decision of implement

the procedures are made by the joint discussion of

these users.

(5) After one strategy is implemented, the long term

impact of this strategy should be monitored. Due

to the change of availability of systems and

equipment, the old strategy may not be the most

appropriate way to mitigate the accident. But to

monitor every strategy that has been executed is

difficult for operators or TSC technicians.

CSAMG shall be capable of automatically

monitoring the necessary information of

implemented strategies. This function shall

collaborate with the function of parallel

monitoring.

(6) CSAMG shall provide easy access to the

execution of mitigation strategies, such as provide

the link to the operation interface of related

systems and equipment. This function could

accelerate the process of accident mitigation;

especially benefit the management of fast-acting

core damage sequence.

(7) CSAMG shall be capable of connecting to the

severe accident simulator. The severe accident

simulator could simulate different scenario to help

the trainees manage severe accident and help

validate the CSAMG. In the practical application

rather than training application, severe accident

simulator could also help the TSC technicians to

evaluate the potential strategies by simulating

them in advance and providing the impact to the

plant.

3.3 Design Proposal

According to the requirement analysis of CSAMG,

the CSAMG is designed to have two modes. One is

on-line mode, connecting to the plant database or

severe accident simulator for the use of accident

mitigation and training; the other mode is off-line

mode, which means it is independent from the data

source, and it could be used by the students to learn

the content of SAMG.

3.3.1 Architecture

The architecture of CSAMG is shown in figure 3. It

is similar with the architecture of SAMERS, both of

whom are client/server.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

202

Figure 3: The architecture of CSAMG.

3.3.2 Module Function

The CSAMG could be divided into 7 modules. Each

module has relative independent function.

(1) Account Management. This module is used for

assigning user roles, and user authorities. There

are 5 basic user roles: administrator, operators,

TSC technicians, trainer and trainee. Different

roles are assigned with different user authorities.

The proper role assignment would benefit the user

cooperation in the accident. Furthermore, user

authority could be assigned separately to qualified

users. This is because important operations may

have great influence on reactor safety. Only the

qualified users could have the right to execute this

kind of functions.

(2) User Collaboration. User collaboration is a special

feature of AP1000 CSAMG. The cooperation of

the 2 major users of AP1000 SAMG, operators

and TSC technicians, is the foundation of SAMG

implement. So the communication between them

would be very important. When they use the

paper-based SAMG, the communication is

inefficient through talking and writing. In

CSAMG, different users could send message to

each other in the chat window and also send the

link to the present guideline that they are reading.

This efficient way of sharing information and

opinions is time-saving and helps the users to

focus on the issues of accident.

(3) Guidelines Management. CSAMG could automa-

tically evaluate the plant status. If the parameters

fulfil the conditions of some guidelines, CSAMG

will remind the user to initiate the guideline and

follow the instructions. Of course the ultimate

power of decision is controlled by the users, they

could decide whether to follow the guidelines or

not. The content of SAMG needs to be built in

CSAMG before usage. The Guidelines

management module implement the functions of

add guideline, edit guideline, delete guideline and

logic builder. Logic builder is used to build the

logic that CSAMG need to calculate when it

evaluate whether the conditions of guidelines are

fulfilled.

(4) Guidelines Operation. Guidelines Operation is the

core function of CSAMG. CSAMG display the

content of SAMG in flowchart, so the users could

clearly know the previous and next steps. The

detailed content of present step will be displayed

too. Users could mark the present step as an

implementing step, and go on to read information

of any steps in any guidelines. When the users

want to go back to the implementing step,

CSAMG provide the return function to go back to

the implementing step display interface by

clicking one button. It will be very helpful when

users need to read a lot of content in many

different guidelines. CSAMG also provide the

link to the relative operators HMI, where

operators need to complete the actions as

guidelines instruct.

(5) Parallel Monitoring. CSAMG is connected to the

database of plant parameters or severe accident

simulator. All the parameters related to the

guidelines are monitored in the CSAMG. Any of

these that reach the set point or exceed the safe

region will cause alarm to users. Users could read

the real time value of these parameters, and

directly go into the relative display interface of

guidelines. For some parameters of particular

concern, users could choose them to display on

the specific window.

(6) Search. Search function is prepared for the user to

find out the specific text information or parameter

information, such as which guidelines need to

monitor core damage or specific parameters they

want to monitor. It contains the fuzzy search

function to help user retrieval the information they

need. It is useful not only for accident mitigation,

but also for the training.

(7) Quick Deployment. Quick deployment means the

CSAMG could export the setting of SAMG, so

another client could import it to finish deployment.

DevelopmentofComputerizedSevereAccidentManagementGuidelinesofAP1000NuclearPowerPlant

203

3.4 Verification and Validation Plan

Since the CSAMG is designed to assist the users to

deal with the severe accidents of NPPs, it needs a lot

of verification and validation (V&V). The V&V

process could be divided into several parts:

(1) V&V of SA simulator;

(2) Verification of CSAMG contents;

(3) Verification of CSAMG logic;

(4) Validation of CSAMG by operating it with the SA

simulator.

Firstly the V&V of SA simulator is very important to

the whole process of V&V of CSAMG. Because of

the uncertainty of severe accidents, V&V of SA

simulator itself is a challenge (Jeong, et al., 2002).

Our SA simulator will run all the accident scenarios

that are analysed in the PSA report of AP1000 NPP.

The results will be analysed to make sure it is

reasonable.

Secondly the contents of CSAMG must be the

same as the handbook of AP1000 SAMG. The

CSAMG could export all the contents into a pdf file

in the format of AP1000 SAMG. Comparing these

two files will verify the contents of CSAMG.

Thirdly the logic of CSAMG needs to be test

carefully to make sure that all monitoring parameters

and their evaluation mechanism are set correctly.

Last but not least, CSAMG will be operated by

connecting to the SA simulator to mitigate the

simulated accidents. By the practice, CSAMG could

be validated whether it would help the users in the

accident mitigation.

4 CONCLUSIONS

In this paper SAMERS is described in brief as an

emergency supporting system to deal with the severe

accidents. CSAMG, as one of its modules, is an

assistant tool for severe accident mitigation. The

CSAMG could help the SAMG users to get a better

performance.

CSAMG could improve the cooperation between

the operators and TSC technicians. It could monitor

the plant status automatically and recommend the

mitigation strategies. It is efficient to provide useful

information of SAMG related to the current accident

status. It will save time, reduce human errors, and

improve plant safety.

There are some problems in the development of

CSAMG. One is the survival of detectors and

equipment during the severe accident. The lack of

data source could lead to the paralysis of monitoring

function of CSAMG. And without the monitoring

parameters CSAMG could not evaluate status and

provide advices. Another problem is the evaluation of

mitigation strategies is based on the current condition

and depend on the experience of operators. There are

no rules for all the strategies evaluation. CSAMG

may provide some improper strategies to confuse the

operators. The validation of CSAMG is also a

question need further discussion.

ACKNOWLEDGEMENTS

The research is funded by the Chinese National

Science and Technology Major Project under contract

No. 2013ZX06004-008.

REFERENCES

CNDRC, 2007. Nuclear Power Medium and Long Term

Development Plan (2005~2020), Beijing: Chinese

National Development and Reform Commission.

Gang, C., 2013. Functional Requirements of Computerized

Severe Accident Management Guidelines, Beijing:

SNPSDC.

Jeong, K.-S., Kim, K.-R., Jung, W.-D. & Ha, J.-J., 2002.

Development of Severe Accident Management

Advisory and Training Simulator (SAMAT). Annals of

Nuclear Energy , pp. 2055-2069.

Lee, J.-W., Kim, J.-T. & Park, J.-C., 2010. Computer-based

Alarm Processing and Presentation Methords in

Nuclear Power Plants. World Academy of Science,

Engineering and Technology, pp. 594-598.

Park, S.-Y. & Ahn, K.-I., 2010. SAMEX: a Severe Accident

management Support Expert. Annals of Nuclear

Energy, pp. 1067-1075.

Robert, F. T., Charles, K. D., Lewis, H. F. & Joseph, N. A.,

2009. Guidelines for Design and Implementation of

Computerized Procedures. Nuclear News, pp. 85-90.

Yuji, N., Hollnagel, E. & Green, M., 1996. Guidelines for

Computerized Presentation of Emergency Operating

Procedures. Nuclear Engineering and Design, 7, pp.

113-127.

Zheng, Y., 2012. The Foundation of Severe Accident

Management Guidelines of AP1000 Nuclear Power

Plant. Technology Innovation and Application, pp. 6-7.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

204