Application of 3D Navier-Stokes Equations and Mathematical

Optimization Techniques to Improve the Efficiency of Seven-Stage

Axial Compressor

Oleg V. Baturin, Grigorii M. Popov, Evgeny S. Goryachkin and Yilia D. Novikova

Department of Aircraft Engine Theory, Samara State Aerospace University, Samara, Russian Federation

Keywords: High Pressure Compressor, Efficiency, Optimization, Numerical Model, Performance Map.

Abstract: The paper presents the results of an optimization of the high-pressure compressor of the engine NK-36ST

using the mathematical optimization techniques. The article describes in detail the search algorithm of the

optimal form of the compressor blades using the software package Numeca and software package IOSO.

The description of the used numerical model is given, its verification was carried out. It is shown that only

by correcting the stagger angles of the blade rows the efficiency of the considered compressor can be

increased by 1.5% at the current position of the working point on the characteristic of the compressor. Also

the search possibility of compromise solution that provides a simultaneous increase in the efficiency of the

compressor in two modes is shown.

1 INTRODUCTION

The gas turbine plants (GTP) must always be

improved to retain a share in the market and to

successfully compete with the newly appearing

products. The designers and manufacturers of the

engines must constantly work to reduce the costs.

They should identify and remedy the defects, find

actions to increase durability of details, that will

increase the engine resource and time of its life. The

cost of fuel makes up a large part of the life cycle

cost of the engine and the reduction of consumption

can provide the significant economic benefits

(Kulagin, 2002).

All engine-enterprises are faced with problem

described above. Such as JSC "Kuznetsov". This

company is located in Samara (Russia) and it is the

manufacturer of the GTP for the drive of the gas

compressor units and the electric generating station

with the capacity from 4 to 32 MW. Over the past

five years the company carries out active work to

modernize the engine NK-36ST with the capacity 25

MW. This engine is used to drive the gas

compressor units. It is made according to the scheme

with the free turbine (FT) and it has the three-shaft

gas generator based on the aircraft turbofan engine

(turbojet). The company is conducted the search

operations that is aimed at the overall efficiency

increasing of the engine for 2...3%. Samara State

Aerospace University (SSAU) also is involved in

this work. The work on the modernization of the

engine NK-36ST is supported by Government of

Russian Federation.

The series of the thermodynamic calculations

was carried out in SSAU and it was shown that the

components of the high-pressure stage and the FT

have the greatest influence on the working process

and efficiency of the GTP. The values of the

coefficients of impact on the overall efficiency

(Kulagin, 2002) of the high pressure compressor

(HPC), the high pressure turbine (HPT) and the FT

are equal to 0.167, 0.202 and 0.284 (Kuzmichev,

Rybakov, Tkacheno, Krupenich, 2014).

To the authors team of the this article it was

tasked to find the ways of the HPC efficiency

increase of the engine NK-36ST for the operation

mode which is corresponding to 100% capacity of

the power plant (25 MW). This compressor is axial,

seven stage, subsonic. The value of the pressure

ratio at n=100% is

к

*

=4,2. In order to reduce the

manufacturing costs of the modernized version the

JSC "Kuznetsov" has set severe restrictions. It was

forbidden to change any elements of the rotor and

stator except blades, but also the shape of blade

airfoil should remain unchanged as much as

possible. In fact, to obtain the compressor efficiency

increase it is planned to correct only the stagger

227

V. Baturin O., M. Popov G., S. Goryachkin E. and D. Novikova Y..

Application of 3D Navier-Stokes Equations and Mathematical Optimization Techniques to Improve the Efficiency of Seven-Stage Axial Compressor.

DOI: 10.5220/0005570302270232

In Proceedings of the 5th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2015),

pages 227-232

ISBN: 978-989-758-120-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

angle of compressor blades. In addition, the quite

tight deadline were set for obtention of the first

results.

2 THE USED COMPUTATIONAL

MODEL

Comercial CFD software package NUMECA and

software of the mathematical optimization IOSO is

used for solving the problem.

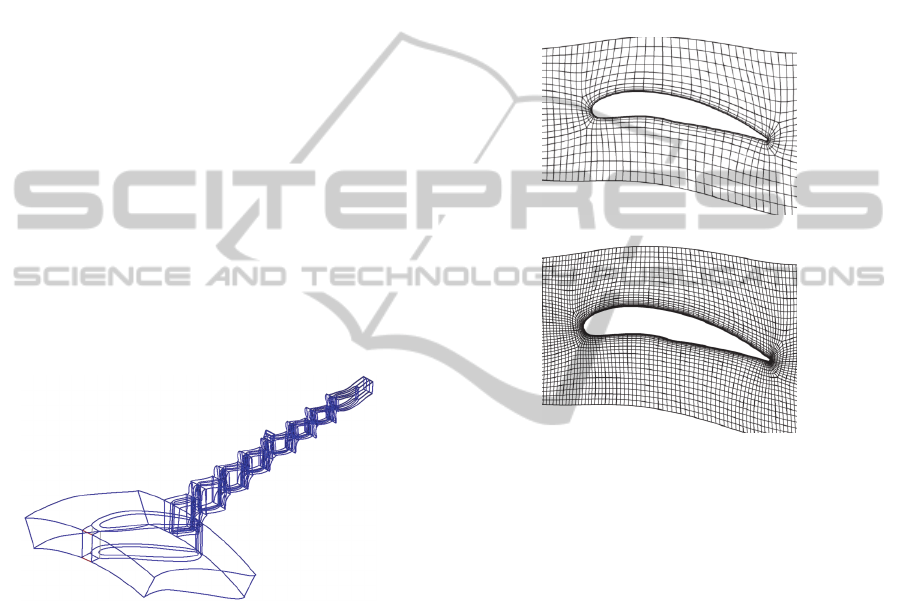

The initial geometric model of the computational

domain was based on the design documentation

provided by JSC "Kuznetsov" and it contained

domains of the middle bearing, inlet guide vanes,

and blade wheel (BW), guide vanes (GV) and output

area (Figure 1). The geometry of the blades airfoils

transmitted to NUMECA as text files in the format

.geomTurbo, which previously had been formed in

the software Profiler developed in SSAU (Shablii,

Dmitrieva, 2014). The geometry of the

computational domain took into account the changes

in the diameter of the compressor under the

influence of the heat and centrifugal loads (Matveev,

Popov, Goryachkin, Smirnova, 2014).

Figure 1: HPC computational model of NK-36ST.

The calculation model of the HPC took into

account the presence of a radial clearance over the

rotor blades, the values of which in the operation

have been taken on the recommendations JSC

"Kuznetsov". Also in the model, the presence of the

working fluid bleed after the BW of fourth turbine

cooling stage in an amount of 2.75% of the total air

flow rate at the compressor inlet was taken into

account.

The created model was divided into the finite

volumes by block-structured grid using internal tools

of the software NUMECA. Two grid models were

created. Model №1 contained two million of the

finite volumes. On average the one BR had 120

thousand of the finite volumes. The maximum value

of the parameter y + for this grid was 12. Model №2

contained 8.2 million of the finite volumes. On

average, the one BW had 500 thousand of the finite

volumes. The maximum value of the parameter y +

for this grid was 1. To improve the description

quality of the processes in the boundary layers in

both models, in the description of turbulence the

option Extended Wall Function was used.

Comparison of the finite volumes mesh of the

models №1 and №2 is shown in Figure 2. In the

considered computational domain the space around

the rotor blade and guide vanes was allocated.

а)

b)

Figure 2: Comparative picture of the finite volumes grid of

the models №1 (a) and №2 (b).

As the boundary conditions at the inlet of the

HPC the value of the total pressure was set equal to

р

*

=101,325kPa and the total temperature was equal

to T * = 288,15K. The flow direction at the inlet of

the computational domain 30

is relative to the

axis of rotation. k-ε turbulence model was used.

Parameters of the turbulence at the inlet boundary

are k=5m

2

/с

2

,

=30000 m

2

/с

3.

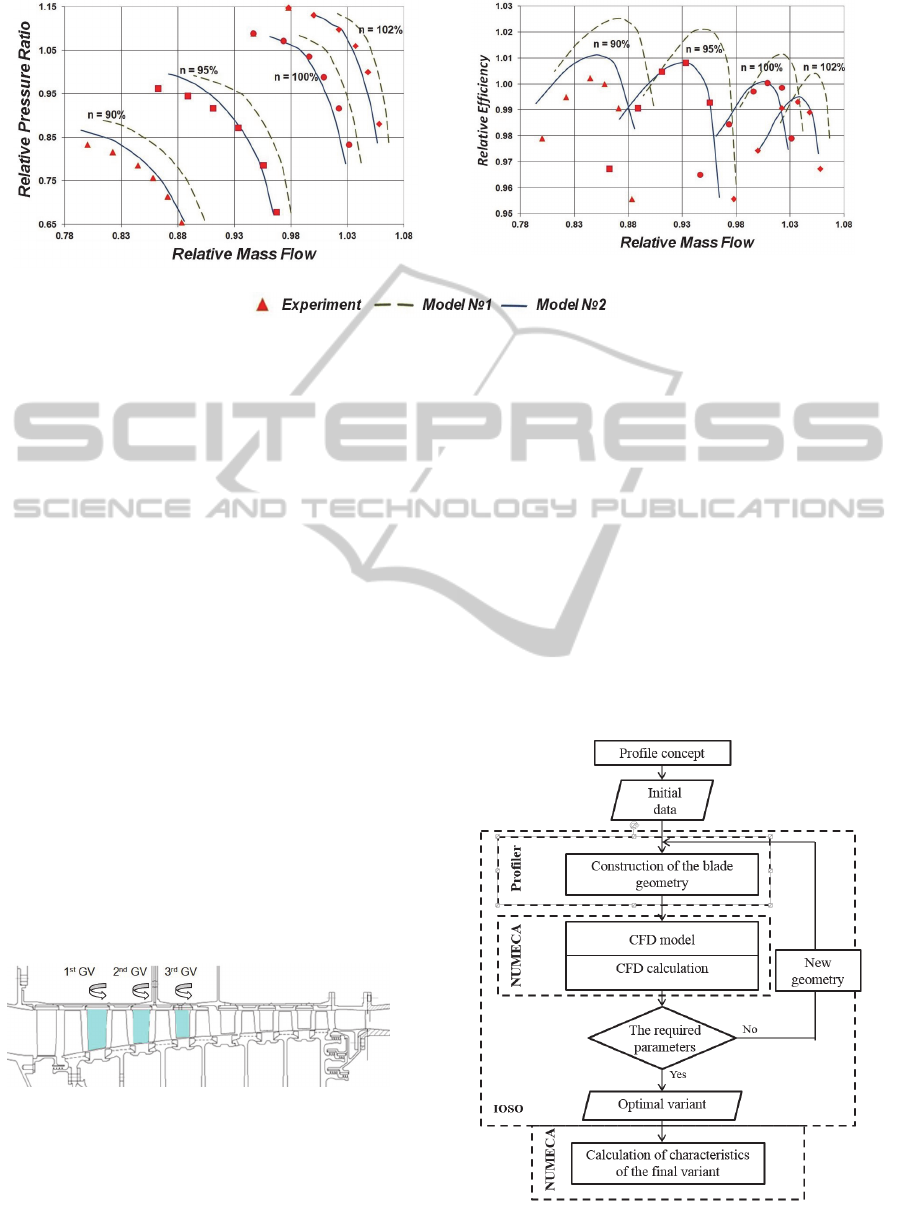

To evaluate the quality of the grid models

created by program Numeca Fine Turbo the

characteristics head branches of the engine NK-

36ST were calculated at rotor speeds n=90, 95, 100

и 102% (the rotational speed n=100% corresponds

to the GTP work at power in the output shaft is equal

to 25 MW). The obtained results were compared

with the experimental studies data of the considered

compressor which was provided by JSC

"Kuznetsov".

Characteristics are presented as the parameters

that correspond to the operating mode with the rotor

speed of 100 rev / min.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

228

Head characteristic

Efficiency characteristic

Figure 3: Comparison of the characteristics, obtained by the different grid models, of the investigated HPC with the

experimental data.

The results of the comparison are shown in Figure 3.

It shows the dimensionless characteristics of the

NK-36ST HPC as two dependences: the relative

compression ratio and the relative efficiency of the

relative air flow rate through the compressor.

As it can be seen from Figure 3, the both created

numerical models show the good qualitative

coincidence with the experimental results. However,

the model №2 shows significantly better quantitative

coincidence with the experimental results. The

difference of values for the efficiency and the

compression ratio is not more than 2%. For this

reason, the model №2 was used for further studies.

Streamline workflow of the HPC BY THE GUIDE

VANES stagger angle of the first stages/

In the first phase, by agreement with JSC

"Kuznetsov", it was decided to find out how the

HPC efficiency can be improved at operation mode

is n = 100% by changing the stagger angles of the

guide vanes of the first three stages (Figure 4). The

range of variation of the stagger angles was limited

by company to 5 of the initial values for the

maximum preservation of the parts of the existing

engine.

Figure 4: Guide vanes, the stagger angles of which have

changed.

It was decided for finding the maximum

efficiency to use the methods of the mathematical

optimization. In particular, the program IOSO was

used. It is based on the optimization method which

based on the creating of the response surface, which

is refined and evolved for each access to calculation

model. A detailed description of the algorithm IOSO

can be found in the work (Egorov, Kretinin,

Leshchenko, Kuptzov, 2002).

The search algorithm of the optimal geometry of

the compressor on the basis the three-dimensional

numerical simulation under the control of program

optimizer IOSO (Figure 5) was developed to solve

this problem. It is as follows. The program IOSO

generates the input data block based on which the

software Profiler changes the geometry of the blades

(changes the stagger angle) and transmits it as the

text file in NUMECA.

Figure 5: Search algorithm of the optimal form of the

compressor blades using the software package IOSO.

Applicationof3DNavier-StokesEquationsandMathematicalOptimizationTechniquestoImprovetheEfficiencyof

Seven-StageAxialCompressor

229

Figure 6: Comparison of the characteristics of the initial HPC with characteristics of the compressor with optimized stagger

angles of the first three stages.

There, on the basis of the obtained information,

the computational model was created and the flow

was calculated in it as a result of which the

compressor efficiency and other parameters is

determined, the results were written to the output

file. IOSO wrote this file and on the basis of

calculation, as well as calls to previous numerical

model, created the new combination of the input

data and the process is repeated to the required

extremum.

The software package IOSO had 102 calls to

computational model to solve the problem of

optimization. The total computation time was more

than 150 hours of computer time on cluster of 10

PCs.

Figure 6 shows comparison of the characteristics

of the initial and optimized version of the HPC. An

analysis of the obtained results shows that by

decreasing the stagger angles of the GV in 1, 2 and 3

stages at 1.9480, 1.9470 and 1.7290 degrees

respectively it succeeded to increase the efficiency

of the compressor at the HPC rotor speed n = 100%

to 0,3% (abs.). The efficiency increase caused by

matching of the contact angles of the first stages.

The decrease in the GV stagger angles has led to the

fact that the сщккусеув specific air flow rate in the

considered mode is decreased by 1.3%, that may

cause the decrease in the engine power.

Thus, it was demonstrated that by correcting of

the stagger angles of the GV it's possible to achieve

the increase of the HPC efficiency, but this increase

is not a significantly. In addition by the results of the

study it had concluded to save the joint work of

nodes while optimizing it should the impose

restrictions on the position of key operating point on

the characteristic of the compressor. Streamline

workflow HPC by stagger angles of all blade rows.

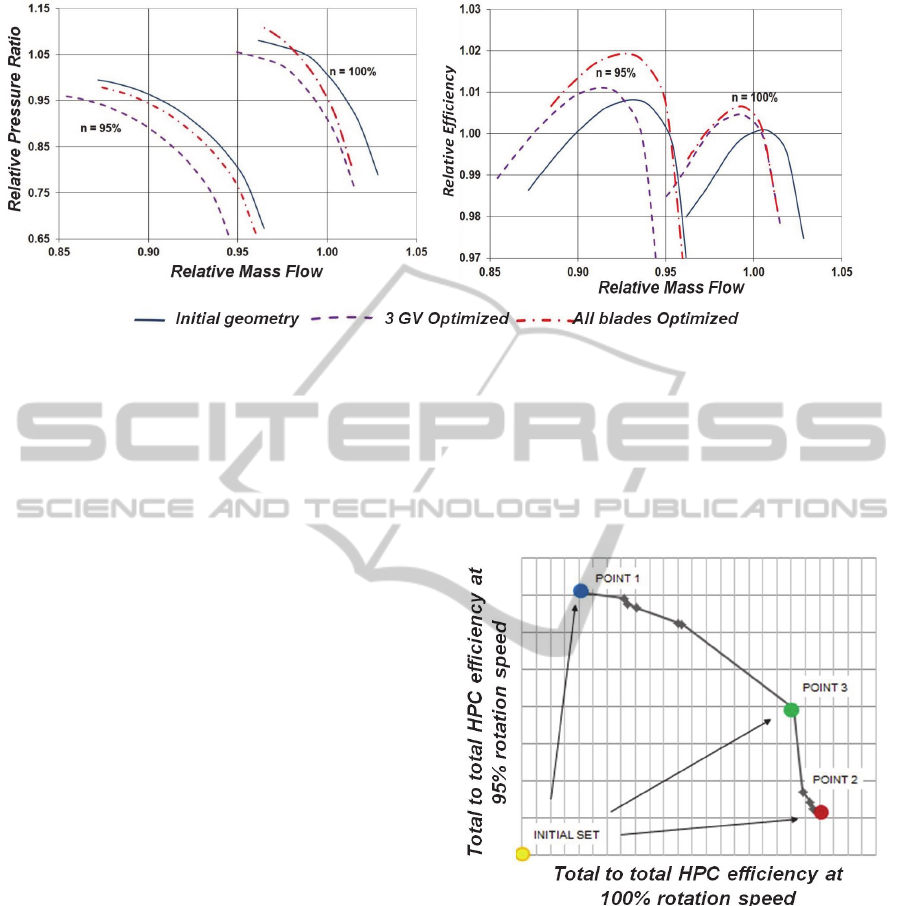

According to the studies results which described

above the JSC "Kuznetsov" was convinced that the

significant increase of the efficiency of HPC is not

possible by changing the number of the blade rows .

For this reason, the task has been adjusted. It was

instructed to determine how the efficiency of the

considered HPC can be increased by changing of the

blade rows stagger angles, which are placed there.

Together with this it was tasked to achieve the

efficiency increase of the HPC not only at rotational

speed of 100%, but at rotational speed of 95%, while

maintaining the flow rate and the compression ratio

at these operation modes.

To reach the given task the problem of

optimization has been changed. Maximum

efficiencies of the compressor at the relative

rotational speeds of 95% and 100% were selected as

optimization criteria.

In order to prevent the shift of characteristics of

the compressor, in agreement with the JSC

"Kuznetsov", the following restrictions were set in

the optimization:

the flow rate of the working fluid through the

HPC at the relative frequency of rotation of

95% was not supposed to be different from the

respective flow rate of the base compressor

more than ±1,3%;

the flow rate of the working fluid through the

HPC at relative frequency of rotation of 100%

was not supposed to be different from the

respective flow rate of the base compressor

more than ±0,6%;

the value change of the HPC pressure ratio in

comparison with the base compressor at points

of the maximum efficiency at relative

rotational speeds of 95% and 100% was

allowed within ±1,5%.

The stagger angles of all rotor blades, the GV and

IGV of the HPC were selected as varied variables.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

230

Figure 7: Comparison of the characteristics of optimized versions of the compressor and basic HPC.

The range of the stagger angles change of the vanes

of each blade row has been selected so that during

the blades rotation their profiles fits into the existing

blade stoppers. The blades number in the row wasn't

changed. This solution allowed to find the variant to

increase the efficiency of the HPC, that would not

require the modification of the disk and the body

parts of the compressor. The total number of the

changed variables was 15.

To solve the formulated problem of the

optimization the software package IOSO had 446

calls to the numerical model of the HPC. Each call

to the numerical model is calculation of two points

on the characteristic of the HPC (points of the

maximum efficiency on the branches corresponding

to the relative frequency of the rotation of 95% and

100%) in the software package NUMECA

FineTurbo.

As a result, a lot of unimprovable solutions

(Pareto set) were obtained, which are a compromise

between the increase of efficiency at the relative

rotational speed of 95% and the increase of

efficiency at the relative rotational speed of 100%

(Figure 8). Each point of Pareto set corresponds to

the unique geometry of the HPC which is

represented as an array of the stagger angles of all

blade rows of the HPC.

Analysis of the extreme points of Pareto set

shown that at relative rotation frequency of 95% the

highest increase of the maximum efficiency is 1.8%

(abs.) at the substantially constant maximum

efficiency at the relative rotational speed of 100%

(point 1 of Pareto set in Figure 8). When the relative

rotational speed is 100% the highest increase of

maximum efficiency is 0.6% (abs.) at the increase of

the maximum efficiency at relative rotational speed

of 80% to 1% (point 2 Pareto set in Figure 8).

However, for further research the one of midpoints

of the set Pareto have been selected (point 3 in

Figure 8), which is provide the increase of the

efficiency as at relative rotation frequency of 100%

(0.5% (abs.)) and at the relative frequency rotation

of 95 % (1.2% (abs.)).

Figure 8: Pareto set.

The numerical model of the HPC corresponding to

the selected point #3 of the Pareto set was created to

analyze the results of the optimization. The

characteristics of optimized version of the HPC at

the relative rotational speeds of 95% and 100% were

obtained by this numerical model and their

comparison with the characteristics of the HPC base

version (Figure 7) and with the searching results of

the optimal combination of the stagger angles at the

first three stages was performed.

As the result of the comparison the following

characteristics was revealed:

Applicationof3DNavier-StokesEquationsandMathematicalOptimizationTechniquestoImprovetheEfficiencyof

Seven-StageAxialCompressor

231

the operation stall margin of the optimized

HPC was changed slightly in comparison

with the base case at the investigated rotation

frequencies;

the values change of the air flow rate and the

compressor pressure ratio of the optimized

HPC at points of the maximum efficiency at

the investigated rotation frequencies is within

the accepted limits;

the HPC efficiency at the relative rotation

frequency of 95% has increased by 1.2%

(abs.) and at relative rotation frequency of

100% the increase of efficiency was 0.5%

(abs.).

Analysis of the flow structure in the optimized

version of the HPC at the point of the maximum

efficiency at the relative rotation frequency of 100%

shown that the optimization of the HPC blades

stagger angles has removed the stall in the hub

section of the fourth and fifth HPC BW (Figure 9).

Figure 9: Comparison of the fields of the relative Mach

number near the hub section of the base and optimized

HPC.

3 CONCLUSIONS

As a result of the work described above the

searching algorithm the optimal form of compressor

blades by numerical models of workflow in program

NUMECA and optimizer

program IOSO has been

developed and implemented.

The adequacy of the developed method has been

proved by the example of solving the problem of

optimization of the high pressure compressor of real

gas turbine plant.

It was found the configuration of the compressor

allowing to obtain improved efficiency by 1.2% at

the rotating frequency of 95% and efficiency by

0.5% at the rotation frequency of the rotor of 100%.

Changing the shape of blades,the guide vanes

and the flow part during optimization has allowed to

obtain the higher values of efficiency of the

compressor.

ACKNOWLEDGEMENTS

This work was supported by the Ministry of

Education and Science of the Russian Federation in

execution of the order №218 from 09.04.2010

(theme code 2013-218-04-4777).

The work was financially supported by the

Ministry of education and science of Russia in the

framework of basic part of government assignment.

REFERENCES

Kulagin, V., 2002. The theory, calculation and design of

aircraft engines and power plants Fundamentals of the

theory of the CCD. Workflow and thermodynamic

analysis, Mashinostroenie, Moskow.

Kuzmichev, V., Rybakov, V., Tkacheno, A., Krupenich,

I., 2014. Optimization of working process parameters

of gas turbine engines line on the basis of unified

engine core. In ARPN Journal of Engineering and

Applied Sciences, vol. 9, pp 1873-1878.

Shablii, L., Dmitrieva, I., 2014. Blade geometry

transformation in optimization problems from the

point cloud to the parametric form. In Russian

Aeronautics, vol. no 3, pp. 276–282.

Matveev, V., Popov, G., Goryachkin, E., Smirnova, Y.,

2014. Effect of Accounting of Air Bleed from the

Flow Passage of the Multi-Stage Axial Low Pressure

Compressor on its Design Performances. In Research

Journal of Applied Sciences, vol. 9, no. 11, pp. 784-

788.

Egorov, I., Kretinin, G, Leshchenko, I., Kuptzov, S., 2002.

Optimisation Toolkit - Novel Software to Create

Better Design. In Proc. of 9th AIAA/ISSMO

Symposium on Multidisciplinary Analysis and

Optimisation.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

232