IT-enabled Management of Sharing Logistic Trucks

Ichiro Satoh

National Institute of Informatics, 2-1-2 Hitotsubashi, Chiyoda-ku, Tokyo 101-8430, Japan

Keywords:

Carbon Emission, Earth-friendly Logistics, Process Calculus.

Abstract:

This paper proposes a management system for sharing trucks as cooperative logistics. To reduce fossil fuel

consumption and carbon dioxide emissions resulting from transport, we should improve transport efficiency

of trucks, which play an essential role as carriers in modern logistics services. We propose a language for

specifying the routes of trucks and an order relation between the requirements of routes and the possible

routes of trucks. The former is formulated as process calculus and the latter selects suitable trucks whose

itineraries can satisfy the requirements of users and are more friendly the environment.

1 INTRODUCTION

Green logistics is important to minimize the ecolog-

ical impact of logistics activities. Transportation ac-

counts for about 23-percent of energy-related carbon

dioxide (CO

2

) emissions(Agency, 2009). IEA has ex-

pected, given current trends, energy demand and CO

2

emissions in transport nearly 80-percent higher by

2050 without any efficiency improvements. Trucks,

which play an essential role as carriers in modern lo-

gistics services, emit a huge quantity of carbon diox-

ide (CO

2

) into the atmosphere. There have been sev-

eral approaches to reducing fossil-fuel consumption

and CO

2

emissions from tracks.

• Low-emission tracks: the amount of CO

2

emis-

sion from tracks is reduce by using environmen-

tally friendly trucks, which produces less harm-

ful impacts to the environment than comparable

conventional internal combustion engine vehicles

running on gasoline or diesel, or one that uses cer-

tain alternative and sustainable fuels.

• Low-emission operation for individual tracks:

since the amount of CO

2

emission from each track

is basically in proportion to the distance traveled

by the track. Shortening such a distance can re-

duce CO

2

emission. Environmentally friendly

driving is important because driving of trucks,

e.g., slowing down and up, depends on the amount

of CO

2

emission.

• Low-emission management for trucks: the num-

ber of tracks seriously affect the amount of CO

2

emission. It is reduced by efficiently managing

trucks in addition to reducing freights.

This paper addresses cooperative logistics as a solu-

tion to the third approach. Cooperative logistics has

been expected as one of the most efficient and pop-

ular ways of improving truck-load ratios and reduc-

ing trucks. However, it tends to be complicated in

comparison with existing (non-earth-friendly) logis-

tics. In fact, several industries, e.g., food and automo-

bile manufacturers, in addition to the dairy industry,

have attempted to use cooperative logistics.

Nevertheless, most attempts to support coopera-

tive logistics have been failed because of their man-

agement problems for several reasons. There are

often conflicts between the requirements of suppli-

ers/customers and the operations of shared trucks.

Even if there are many shared trucks, it is difficult

to find trucks that can satisfy the requirements of sup-

pliers/customers, because the requirements are more

complicated than those of moving people. Most coop-

erative logistics management tends to depend on hu-

mans, e.g., logistics managers in suppliers and truck

drivers. This may be rational in a small scale cooper-

ative logistics consisting of two or three suppliers, but

seriously affect scalability. We need a systematic and

scalable approach for managing cooperative logistics.

To solve these problems, we propose an e-logistics

for sharing trucks between operators or customers

to support cooperative logistics. This paper de-

fines our e-logistics management system for sharing

trucks. The system is constructed based on a theoreti-

cal framework consisting of a process-calculus-based

language that describes truck routes and a mechanism

for selecting suitable trucks according to the require-

ments of customers. This is because the selection

17

Satoh I..

IT-enabled Management of Sharing Logistic Trucks.

DOI: 10.5220/0005571300170024

In Proceedings of the 12th International Conference on e-Business (ICE-B-2015), pages 17-24

ISBN: 978-989-758-113-7

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

of trucks need to be exact in the sense that selected

trucks must satisfy the requirements. The mechanism

is defined based on an algebraic relation that deter-

mine whether a truck can visit various points, e.g.,

farmers and manufacturers, along its route to collect

or deliver items. It enables collection/delivery points

to select trucks according to the truck route because

the route a truck takes is critical in determining its ef-

ficiency.

2 EXAMPLE SCENARIO

Milk-run operation is one of most typical cooperative

logistics ones for improving truck-load ratios, refers

to a means of transportation in which a single truck

cycles around multiple suppliers to collect or deliver

freight. The name is derived from the milk-runs car-

ried out by farmers collecting milk from dairy cows

spread out over pastures (Fig. 1). Using the milk-run

approach, one truck calls at each of the suppliers on a

daily basis before delivering the collected milk to the

customer’s plant. On the other hand, in a traditional

approach, e.g., the Just-In-Time approach, all suppli-

ers have their own trucks and send one truckload per

day to the customer (Fig. 1). The milk-run approach

is effective in reducing the amount of CO

2

emitted by

trucks.

Conventional approach

(three trucks)

Milk-run approach

(one truck)

Dairy factory

Dairy farmar

Dairy farmar

Dairy

farmar's

truck

Dairy

factory's

truck

Dairy

farmar's

truck

Dairy

farmar's

truck

Figure 1: Legacy approach and milk-run approach.

As mentioned previously, existing cooperative lo-

gistics has serious problems in their management.

The cooperative logistics approach needs for logis-

tics operators to provide multiple trucks using varied

routes to satisfy the needs of customers and cater for

the requirements of the products. Therefore, the cus-

tomers are confronted by another problem: they need

to design truck routes and select suitable trucks with

routes that satisfy their requirements. For example,

suppose five suppliers, e.g., dairy farmers, send their

products to the processing plant every weekday. Fig-

ure 2 shows five factories, A, B, C, D, and E, that have

the following dependencies:

• Factory A manufactures products and ships the

products to factories B and C.

• Factory B manufactures products and ships the

products to factory D.

• Factory C manufactures products and ships the

products to factory D.

• Factory D manufactures products and ships the

products to factory E.

E

D

C

Factory A

B

Product

Figure 2: Five factories with dependencies.

We assume that a truck has sufficient carrying ca-

pacity. It starts at factory A and may visit factory

A again. Figure 3 shows four trucks carrying out

milk-runs on different routes. The first, second, and

third trucks can satisfy the above requirements but the

fourth cannot. The third is less efficient than the first

and second on their rounds. The system proposed in

this paper was inspired by our real experiences. Al-

though the milk-run approach is effective in reducing

the amount of CO

2

emitted by trucks, its management

tends to be complicated, which is one of the most sig-

nificant barriers preventing wider adoption of the ap-

proach in real logistics.

Truck 1

A

E

D

C

B

Truck 2

A

E

D

C

B

Truck 3

A

E

D

C

B

Truck 4

A

E

D

C

B

Figure 3: Four trucks for milk-run operation.

ICE-B2015-InternationalConferenceone-Business

18

This paper assumes that one or more trucks in-

volved in milk-run logistics operations call at multi-

ple points along their routes. Customers and suppliers

have to decide which truck and which route will best

satisfy their requirements, and this decision is not an

easy one.

3 REQUIREMENTS

The proposed e-logistics system was inspired from

our discussions on real logistics companies. The

system must therefore satisfy the following require-

ments:

• In cooperative logistics trucks may be shared by

multiple customers, so that they collect products

at one or more source points and deliver the prod-

ucts at one or more destination points on their

way. The trucks need to visit the source points

before they visit the destination points. Our sys-

tem therefore needs to specify the order in which

trucks call at various points.

• Some products may be collected/delivered at

points by trucks without any need for a specific

order of arrival at collection/delivery points. That

is, the order of the movement of trucks between

points does not affect the efficiency of the trucks’

operations. Suppliers or customers should select a

truck according to the number of movements be-

tween the points that the trucks visit.

• One or more trucks are available in cooperative

logistics, but their routes may be different. Most

logistic trucks runs their driving plans, which

were submitted to or assigned by truck opera-

tors’ offices, although they may be changed daily,

weekly, or monthly. That is, trucks do not change

their routes after starting their operations.

• Our e-logistics management system should re-

ceives the routes submitted by truck operators and

maintains the routes in its database. When it re-

ceives queries about the trucks that can satisfy the

requirements of customers, it returns such trucks

to them. The system should provide truck opera-

tors and customers with web-based interfaces.

• Pallets or boxes that contain multiple products are

considered as transport units in many current lo-

gistics systems, rather than as individual products.

These types of containers may have multiple des-

tinations required by their inner products and the

receivers may take only some of the products in

the container when it arrives at their point.

4 APPROACH

The selection of the routes of trucks for cooperative

logistics, including milk-run operations, is critical for

industrial efficiency and for minimizing carbon diox-

ide emissions. Careful consideration must be given

to selecting suitable trucks with routes that satisfy the

requirements of customers and suppliers. To select

suitable trucks exactly, our e-logistics management

system should be constructed based on a theoretical

framework.

• It provides a specification language for describ-

ing and analyzing truck routes. The language

is aimed at specifying only the routes of trucks

formulated as an extended process calculus with

the expressiveness of truck routes between collec-

tion/delivery points.

• It defines an algebraic order relation over the

terms of the language. The relation is defined

based on the notion of bisimulation and compares

possible truck routes and the routes required by its

specifications. This allows us to accurately deter-

mine whether the former satisfies the latter.

Note that the order relation is not intended to gener-

ate the most efficient route, because truck routes tend

to be designed according to external factors. Thus,

the computational complexity for this relation is not

large. Some readers may think that simple executable

languages, such as Lisp and Prolog, should be used

to specify routes, but it is difficult to verify whether

or not routes written in such languages will satisfy

the requirements of customers and suppliers because

these languages have many primitives that are not

used in describing routes. We explain the reason why

our e-logistics management system is constructed as

a process calculus-based approach, because itinerary

plans, which transporters are obligated to make for

their trucks, can be treated as the sequences of desti-

nations that the truck visit like expressions of process

calculi. Therefore, we can easily transform itinerary

plans for trucks into process calculus-based specifica-

tion in comparison with other approaches, i.e., logic-

based and graph-based specifications.

5 TRUCK SHARING MODEL

This section defines our model for sharing logistic

trucks. The model provides a language for speci-

fying about truck routes and a system for selecting

the routes that can satisfy the requirements of suppli-

ers/customers. The language consists of two classes.

The first is designed to specify truck routes and the

IT-enabledManagementofSharingLogisticTrucks

19

second is designed to specify the routes required by

products or customers.

Definition 1. The set E of expressions of the lan-

guage, ranged over by E,E

1

,E

2

,... is defined recur-

sively by the following abstract syntax:

E ::=

0

| ℓ | E

1

;

E

2

| E

1

+

E

2

| E

1

#

E

2

| E

1

%

E

2

| E

1

&

E

2

| E

*

where L is the set of location names ranged over by

ℓ, ℓ

1

,ℓ

2

,..., and where points correspond to the loca-

tions of suppliers and customers. We often omit

0

.

We describe a subset language of E as S , when elim-

inating E

1

#

E

2

, E

1

%

E

2

, E

1

&

E

2

, and E

*

from E . Let

S, S

1

,S

2

,... be elements of S.

⊓

⊔

Our e-logistics system assumes that each truck has its

own route written in S and that its driver visits points

along the route. Although its semantics is defined in

the Appendix, we describe intuitive meaning of the

terms is as follows:

•

0

represents a terminated route.

• ℓ represents that a truck moves to a point called ℓ.

• E

1

;

E

2

denotes the sequential composition of two

routes E

1

and E

2

. If the route of E

1

terminates,

then the route of E

2

follows that of E

1

.

• E

1

+

E

2

represents the route of a truck according to

either E

1

or E

2

, where the selection is done by the

truck.

• E

1

#

E

2

means that a truck itself can go through ei-

ther E

1

or E

2

.

• E

1

%

E

2

means that a truck can follow either E

1

be-

fore E

2

or E

2

before E

1

on its route.

• E

1

&

E

2

means that two routes, E

1

and E

2

, may be

executed asynchronously.

• E

*

is a transitive closure of E and means that a

truck may move along E an arbitrary number of

times.

where in E

1

+

E

2

the truck can select the E

1

(or E

2

)

route when the E

1

route is available. For example, if

the E

1

route is available and the E

2

route is congested,

the truck goes through the E

1

route. E

1

#

E

2

means

that a truck can go through either E

1

or E

2

. E

1

%

E

2

,

E

1

&

E

2

, and E

*

are used to specify possible routes.

1

For example, E

1

#

E

2

permits the truck to go through

one of the E

1

or E

2

routes.

We show several basic examples of the language

as shown in Fig. 4. The first diagram in Fig. 4

1

E

*

specifies that the truck follows the E route more than

zero times like the notion of Kleene closure. The operator

is used to specify that the requirement of a truck’s route

permits the truck to visit specified destinations if the truck

wants to do this.

a

e

d

c

b

a

e

d

c

b

a;(b#c);d;e

a;(b%c);d;e

a;((b;c)&d);e

a

e

d

c

b

a

e

d

c

b

a;b;c;d;e

Figure 4: Examples of specification.

shows the transitions of a

;

b

;

c

;

d, the second shows

a

;

(b

#

c)

;

d

;

e the third shows a

;

(b

%

c)

;

d

;

e, and

the fourth shows a

;

((b

;

c)

&

d)

;

e.

We formally defines a system for selecting the

routes of trucks that can satisfy the requirements in

the Appendix. The system selects trucks according

to their routes based on the concept of bisimulation

(Milner, 1989). The relation is suitable for selecting

a truck for a milk-run operation with a route that sat-

isfies the requirements of suppliers and customers, as

specified an inequality E ⊒

n

S. The informal meaning

of E ⊒

n

S is that S is included in one of the permissible

routes specified in E and n corresponds to the number

of movements of a truck that can satisfy E. Since

the language supports an external selection operator,

i.e., +, like other process calculi, our truck selection

cannot be defined as simple algebraic relations, e.g.,

trace-based semantics. We show several basic proper-

ties of the order relation below. Let us look at some

basic examples.

• (a

%

b)

;

c ⊒

3

a

;

b

;

c

where the left-hand-side requires a truck to carry

products to a, and b in an indefinite order and then

return to point c; the right-hand-side requires a

truck to carry products to three points, a, b, and c,

sequentially. When the right-hand-sideis changed

to b

;

a

;

c, the relation is still preserved, but when

the right-hand-side becomes c

;

a

;

b or a

;

c

;

b,

the relation is not preserved.

• (a

;

b

;

c)

#

(a

;

c

;

b

;

c) ⊒

3

a

;

b

;

c

where the left-hand-side means that a truck fol-

lows one of either a

;

b

;

c or b

;

c

;

a. When the

right-hand-side becomes a

;

c

;

b

;

c, the relation

ICE-B2015-InternationalConferenceone-Business

20

is not preserved, because ⊒

3

means that the truck

can visit its destinations at most three times. Nev-

ertheless, ⊒

4

is preserved with a

;

c

;

b

;

c at its

right-hand-side.

• ((a

;

b

;

c)

&

d

*

)

;

d ⊒

6

a

;

d

;

b

;

d

;

c

;

d

where the left-hand-side allows a truck to drop

in at point d an arbitrary number of times on

route a

;

b

;

c and then finish its movementat point

d. The right-hand-side is a star-shaped route

between three destinations, a, b, c, and point

d satisfies the left-hand-side. When the right-

hand-side becomes a

;

b

;

d

;

c

;

d, a

;

d

;

b

;

c

;

d,

or a

;

b

;

c

;

d, the relation is preserved, but

a

;

b

;

c

;

d is the most efficient route.

6 E-LOGISTICS MANAGEMENT

SYSTEM FOR SHARING

TRUCKS

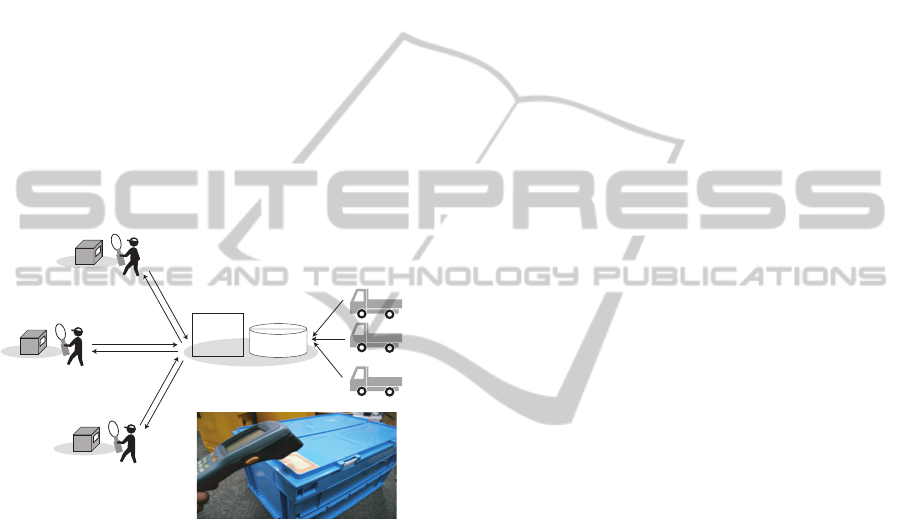

This section describes a prototype implementation

of our e-logistics system. The experiment was con-

structed as a distributed logistics management system

consisting of six supplier points in addition to a cus-

tomer point with a route-selection server. Figure 5

shows the basic structure of the system. The server

was responsible for receivingroute requirements from

suppliers and customers through a network and se-

lecting suitable trucks with routes that satisfied these

requirements.

a

b

c

d

e

Truck 1

a

b

c

d

e

Truck 2

a

b

c

d

e

Truck 3

a;b;e;c;d;e

a;c;b;d;e a;b;d;e

Database

Verification

engine

a;b;e;c;d;e

1

2

3

a;c;b;d;e

a;b;d;e

1

2

3

Bisimulation

e-Logistics system for managing shared trucks

Step 2:

Submitting routes

Step 1:Specifying routes

a

b

c

d

e

(a;(b%c))&(a;d;e) Truck 2

Step 3: Querying about the trucks

that can satisfy the requirement.

Step 4: Selecting trucks

Customer

When more than one truck

can satisfy the requirement,

the truck that has the shortest

route is selected

Requirement

Figure 5: Basic structure of logistics management system.

6.1 Route Selection Algorithm

Here, let us explain the selection algorithm used for

the current implementation, which we tried to make

as faithful to Definition 3 as possible. The server

maintains its own repository database containing the

routes of trucks. To reduce the cost of the selection

algorithm, the possible routes written in E are trans-

formed into tree structures before they are stored in

the database. These are called

transition trees

or

derivation trees

in the literature on process cal-

culus (Milner, 1989). Each tree is derived from a

route in E according to Definition 2 and consists of

arcs corresponding to ℓ-transitions or τ-transitions in

the route. When a route selection server receives a

required route from suppliers or customers, it extracts

the required route written in S and then transforms the

route into a transition tree. It next determines whether

or not the trees derived from the routes stored in the

database system can satisfy the tree derived from the

required route by matching the two trees according to

the definition of the order relation (⊒

n

⊆ E × S) as in

the following.

(1) If each node in one of the two trees has arcs corre-

sponding to ℓ-transitions, then the corresponding

node in the other tree can have the same arcs, and

the sub-nodes derived through the matching arcs

of the two trees can still satisfy either (1) or (2).

(2) If each node in the tree derived from the required

route has one or more arcs corresponding to τ-

transitions, then at least one of the nodes derived

through the arcs and the corresponding node in the

tree derived from the truck’s route can still satisfy

(1) or (2).

(3) If neither (1) nor (2) is satisfied, the route selec-

tion server backtracks from the current nodes in

the two trees and tries to apply (1) or (2) to their

two backtracked nodes.

a;b;(c+d)a;((b;(c+d))#d)

(b;(c+d))#d

τ

τ

b;(c+d)

d

b;(c+d)

c+d

dc

dc

a

a

b

b

d

3

Figure 6: Matching transition trees in route-order relation

algorithm.

Figure 6 illustrates the matching of two transition

trees in the above algorithm. If one or more truck

IT-enabledManagementofSharingLogisticTrucks

21

routes in the database satisfy the required route, it se-

lects the truck with the least number of truck move-

ment between points, which is n of ⊒

n

in Definition

3. Although the cost of selecting a route is dependent

on the number of trucks and the length of their routes,

the system can handle each of the routes presented in

this paper within a few milliseconds.

Non-deterministic operators, e.g.,

#

and

%

, tend

to cause the exposition of a number of sub-trees in

transition trees. Nevertheless, our algorithm can eas-

ily restrain the number of sub-trees resulting from

non-deterministic operators because the expansion

rules of expressions, i.e., the operational semantics

of the language, distinguish between derivations re-

sulting from deterministic operators and those result-

ing from non-deterministic operators. Readers may

wonder why E

*

operator creates an infinite number

of sub-trees, but the current implementation interprets

the operator in a lazy evaluation manner.

Route

Database

Client (Supplier A)

Client (Supplier C)

Client (Supplier B)

Recommended

truck identifier

Route

RFID tag reader

RFID tag reader

RFID tag

reader

Box with

RFID tag

Box with

RFID tag

Box with RFID tag

Recommended truck

Recommended truck

Required route

in RFID tag

Required route

in RFID tag

Required route

in RFID tag

Route

Selection

Engine

Route selection server

Route

Route

Figure 7: Experiment.

We have implemented the e-logistics system on a

PaaS cloud computing infrastructure, called Google’

App Engine. Trucks’ routes are maintained in a key-

value store, called Bigtable, provided by the infras-

tructure. When our system receives a truck route

from a truck operator, it transforms the required route

into a tree structure and stores the structure into the

Bigtable database. When it receives a request with a

required route, our route selector engine transforms

the required route into a tree structure and matches

between the structure and the structures correspond-

ing to trucks’ routes. This means truck operators and

suppliers do not need any special equipment to use

the logistics management system. This is important

because in cooperative logistics, most suppliers are

small to medium enterprises that do not want to have

to invest in additional equipment for cooperative lo-

gistics.

The current implementation assumes that the

routes required for products or pallets are stored in

RFID tags attached to the products or pallets because

they may have their own delivery requirements. It

assumes that each client-side system at a supplier or

customer point has more than one RFID tag reader,

which periodically or explicitly tries to detect the

presence of tags within its coverage area. It supported

Phillips i-Code system (13.56 MHz), which provides

each tag with 112 bytes. We were able to maintain

each of the example routes presented in these papers

in the first and second tag systems, where the length of

the identifier for each point was 4 bytes. The current

implementation of the algorithm was not optimized

for performance. Nevertheless, we describe the ba-

sic performance of the implementation. By using an

RFID reader embedded with a WiFi network inter-

face, the cost of reading the route specification in a

tag depends on the length of the specification, e.g. the

cost of reading a specification with a length of less

than 40 bytes is within 0.2 sec. When the routes of

five trucks were registered in the server running on a

computer (Intel Core 2 Duo 2 GHz and WindowsXP),

the cost of selecting a truck after the reader had de-

tected a tag, including the cost of communication be-

tween the server and client via a TCP/IP session, was

less than 1.2 sec. Client-side systems for suppliers

and customers can be operated using only RFID read-

ers, which connect to a server through either wired

or wireless networks. This means they do not need

any special equipment to use the logistics manage-

ment system. This is important because in milk-run

logistics, most suppliers are small to medium enter-

prises that do not want to have to invest in additional

equipment for milk-run logistics.

7 RELATED WORK

There have been many attempts to use process calculi,

e.g., as formal methods for various businessenterprise

processes. Several researchers have used process cal-

culi, e.g., π-calculus, as business-process modeling

languages, such as BPEL, (K. Xu, 2006; M. Mazzara,

2006; F. Puhlmann, 2005; Smith, 2003). π-calculus

has been used as a formal composition language for

software composition and Web service composition,

e.g., Orc (J. Misra, 2004) and SCC (M. Boreale and

Zavattaro, 2006). Process calculi are theoretically

sound and support bisimulation analysis and model

checking. They are also gaining increasing accep-

tance as a support tool in industry. However, there

have been no process-calculus-based formal methods

for logistics, in particular for improving the transport

efficiency of trucks.

ICE-B2015-InternationalConferenceone-Business

22

8 CONCLUSIONS

This paper presented an e-logistics system for man-

aging for shared trucks to reduce the environmental

impacts of transport operations. The system was for-

mulated based on a process calculus-based language

and an order relation over two terms corresponding

to truck routes and the required routes in the lan-

guage. The language could specify truck routes for

milk-run operations and the required routes for ship-

ping. The relation could be used to accurately deter-

mine whether a truck route satisfies the requirements

of customers and suppliers. A prototype implementa-

tion system based on the framework was constructed

using Java language and RFID tag systems and ap-

plied to our experimental distributed logistics man-

agement system.

REFERENCES

Agency, I. E. (2009). Transport energy and co2 (moving

toward sustainability). Technical report, International

Energy Agency.

L. Cardelli and A. D. Gordon. Mobile Ambients, Proceed-

ings of Foundations of Software Science and Compu-

tational Structures. in Springer, 1998.

F. Puhlmann, M. W. (2005). Using the pi-calculus for for-

malizing workflow patterns. In Proceedings of In-

ternational Conference on Business Process Manage-

ment.

J. Misra, W. R. C. Computation orchestration: A basis for

wide-area computing. In Journal of Software and Sys-

tems Modeling.

K. Xu, Y. Liu, J. Z. C. W. (2006). Pi-calculus based bi-

transformation of state-driven model and flow-driven

model. International Journal of Business Process In-

tegration and Management, 1(4).

M. Boreale, R. Bruni, L. Caires, R. De Nicola, I. Lanese,

M. Loreti, F. Martins, U. Montanari, A. Ravara, D.

Sangiorgi, V. T. Vasconcelos, and G. Zavattaro Scc:

a service centered calculus. ”Proceedings of Web Ser-

vices and Formal Methods”, in Springer 2006.

M. Mazzara, R. L. (2006). A pi-calculus based semantics

for ws-bpel. Journal of Logic and Algebraic Program-

ming, 70(1).

Milner, R. (1989). Communication and Concurrency. Pren-

tice Hall.

Smith, H. (2003). Business process management-the third

wave: Business process modeling language (bpml)

and its pi-calculus foundations. Information and Soft-

ware Technology, 45(15).

APPENDIX

To accurately express such routes, we need to define

a specification language based on a process calculus

approach such as CCS (Milner, 1989). The semantics

of the language are defined by the following labeled

transition rules:

Definition 2. The language is a labeled transition

system h E, L ∪ {τ} {

α

−→⊆ E × E |α ∈ E ∪ {τ} } i.

The transition relation −→ is defined by two kinds of

axioms or induction rules as given below:

−

ℓ

ℓ

−→

0

E

1

ℓ

−→ E

′

1

E

1

;

E

2

ℓ

−→ E

′

1

;

E

2

E

1

ℓ

−→ E

′

1

E

1

+

E

2

ℓ

−→ E

′

1

E

2

ℓ

−→ E

′

2

E

1

+

E

2

ℓ

−→ E

′

2

E

1

ℓ

−→ E

′

1

E

1

&

E

2

ℓ

−→ E

′

1

&

E

2

E

2

ℓ

−→ E

′

2

E

1

&

E

2

ℓ

−→ E

1

&

E

′

2

−

E

1

#

E

2

τ

−→ E

1

−

E

1

#

E

2

τ

−→ E

2

−

E

1

%

E

2

τ

−→ E

1

;

E

2

−

E

1

%

E

2

τ

−→ E

2

;

E

1

E

1

τ

−→ E

′

1

E

1

;

E

2

τ

−→ E

′

1

;

E

2

E

1

τ

−→ E

′

1

E

1

+

E

2

τ

−→ E

′

1

E

2

τ

−→ E

′

2

E

1

+

E

2

τ

−→ E

′

2

E

1

τ

−→ E

′

1

E

1

&

E

2

τ

−→ E

′

1

&

E

2

E

2

τ

−→ E

′

2

E

1

&

E

2

τ

−→ E

1

&

E

′

2

where

0;

E, E

&0

, and

0&

E are treated to be syn-

tactically equal to E and E

*

is recursively defined

as

0#

(E

;

E

*

). We often abbreviate E

0

τ

−→ E

1

τ

−→

···

τ

−→ E

n−1

τ

−→ E

n

to E

0

(

τ

−→)

n

E

n

.

⊓

⊔

In Definition 2, the ℓ-transition defines the semantics

of a trucks movement. For example E

ℓ

−→ E

′

means

that the truck moves to a point named ℓ and then be-

haves as E

′

. Also, if there are two possible transi-

tions E

ℓ

1

−→ E

1

and E

ℓ

2

−→ E

2

for a truck, the process-

ing by the truck chooses one of the destinations, ℓ

1

or ℓ

2

. In contrast, the τ-transition corresponds to a

non-deterministic choice of a truck’s routes .

Readers may think that the above operational se-

mantics could be more compact. However, the aim

is to design a system that can be easily implemented

because the purpose of our e-logistics system is not

to provide just a theoretical foundation for determin-

ing truck-route logistics, but a practical mechanism

for selecting suitable trucks for milk-run operations.

The language does not needs recursive or loop nota-

IT-enabledManagementofSharingLogisticTrucks

23

tions, because each truck does not continue to run for

24 hours everyday.

• Route specification, a

;

b

;

c

;

d, in S is interpreted

as follows:

a

;

b

;

c

;

d

a

−→ b

;

c

;

d

b

−→ c

;

d

c

−→ d

d

−→

The first diagram in Fig. 4 illustrates the above

derivation.

• Next, we show an example of a specification in E.

This is a route requirement.

a

;

(b

#

c)

;

d

;

e

a

−→ (b

#

c)

;

d

;

e

τ

−→ b

;

d

;

e or c

;

d

;

e

where

#

corresponds to a combination of two re-

quired routes so that trucks are required to follow

both routes as shown in the third diagram in Fig.

4. That is, a truck needs to call at point a and then

at either b or c. Next, it calls at d and then e.

• We show another route requirement specification,

a

;

(b

%

c)

;

d

;

e, in E. It has two derivations as

follows:

a

;

(b

%

c)

;

d

;

e

a

−→ (b

%

c)

;

d

;

e

τ

−→ b

;

c

;

d

;

e or c

;

b

;

d

;

e

where

%

means that trucks can take either one of

the two routes before they take the other. The sec-

ond diagram in Fig. 4 shows possible routes that

could satisfy this requirement specification.

• a

;

((b

;

c)

&

d)

;

e in E is an example of

&

.

a

;

((b

;

c)

&

d)

;

e

a

−→ ((b

;

c)

&

d)

;

e

b

−→ (c

&

d)

;

e

c

−→ d

;

e

d

−→ e

where

&

corresponds to asynchronous reduction.

Thus, this permits a truck to move to d while mov-

ing along c

;

b. As shown in the fourth diagram in

Fig. 4, the following two derivations are possible

in addition to the above derivation.

a

;

((b

;

c)

&

d)

;

e

a

−→ ((b

;

c)

&

d)

;

e

b

−→ (c

&

d)

;

e

d

−→ c

;

e

c

−→ e

or

a

;

((b

;

c)

&

d)

;

e

a

−→ ((b

;

c)

&

d)

;

e

d

−→ (b

;

c)

;

e

b

−→ c

;

e

c

−→ e

• The first requirement presented in the pre-

vious section is described as specification

(a

;

(b

%

c))

&

d

*

&

e

*

. We show one of the possi-

ble derivations from the specification as follows:

(a

;

(b

%

c))

&

d

*

&

e

*

a

−→ (b

%

c))

&

d

*

&

e

*

b

−→ c

&

d

*

&

e

*

We can also have another derivation from the

specification as follows:

(a

;

(b

%

c))

&

d

*

&

e

*

a

−→ (b

%

c))

&

d

*

&

e

*

c

−→ b

&

d

*

&

e

*

where E

&

d

*

means that the truck can visit d

more than zero times while it moves along E.

(a

;

(b

%

c))

&

d

*

&

e

*

def

= (a

;

(b

%

c))

&

(

0#

d

;

d

*

)

&

e

*

τ

−→ (a

;

(b

%

c))

&

(d

;

d

*

)

&

e

*

d

−→ (a

;

(b

%

c))

&

d

*

&

e

*

Next we show an algebraic order relation as a theoret-

ical foundation of our selection of trucks.

Definition 3. A binary relation R

n

(R ⊆ (E × S) ×

N ) is an n-route prebisimulation, where N is the set

of natural numbers, if whenever (E,S) ∈ R

k

where

k ≥ 0, then, the following holds for all ℓ ∈ L or τ.

i) if E

ℓ

−→ E

′

then there is an S

′

such that S

ℓ

−→ S

′

and (E

′

,S

′

) ∈ R

k−1

ii) There is an E

′

such that E (

τ

−→)

∗

E

′

and (E

′

,S) ∈

R

k

iii) if S

ℓ

−→ S

′

then there exist E

′

, E

′′

such that

E (

τ

−→)

∗

E

′

ℓ

−→ E

′′

and (E

′′

,S

′

) ∈ R

k−1

where E ⊒

n

S if there exist some n-route prebisimula-

tions such that (E, S) ∈ R

n

. We call the ⊒

n

n-route

order. We often abbreviate ⊒

n

to ⊒ where n is infi-

nite.

⊓

⊔

ICE-B2015-InternationalConferenceone-Business

24