Increased Charge Storage Capacity of Titanium Nitride Electrodes

by Deposition of Boron-doped Nanocrystalline Diamond Films

Suzan Meijs

1

, Matthew McDonald

2

, Søren Sørensen

3

, Kristian Rechendorff

3

, Václav Petrák

4

,

Miloš Nesládek

2

, Nico Rijkhoff

1

and Cristian P Pennisi

5

1

Center for Sensory-Motor Interaction, Aalborg University, Fredrik Bajers vej 7D, Aalborg, Denmark

2

Institute for Materials Research, University of Hasselt, Agoralaan, Diepenbeek, Belgium

3

Danish Technological Institute, Kongvangs Alle 29, Århus, Denmark

4

Nano6 s.r.o., Kleinerova 1469, Kladno, Czech Republic

5

Laboratory for Stem Cell Research, Aalborg University, Fredrik Bajers vej 3B, Aalborg, Denmark

Keywords: Diamond, Titanium Nitride, Cyclic Voltammetry, Electrical Stimulation, Neural Prostheses.

Abstract: The aim of this study was to investigate the feasibility of depositing a thin layer of boron-doped nanocrys-

talline diamond (B-NCD) on titanium nitride (TiN) coated electrodes and the effect this has on charge injec-

tion properties. The charge storage capacity increased by applying the B-NCD film, due to the wide poten-

tial window typical for B-NCD. The impedance magnitude was higher and the pulsing capacitance lower for

B-NCD compared to TiN. Due to the wide potential window, however, a higher amount of charge can be in-

jected without reaching unsafe potentials with the B-NCD coating. The production parameters for TiN and

B-NCD are critical, as they influence the pore resistance and thereby the surface area available for pulsing.

1 INTRODUCTION

Neural stimulation with implantable electrodes is

used for many applications (Zhou, 2009). The sur-

face to area ratio of these electrodes can be increased

by applying a porous coating (Cunha, 2009; Specht,

2007). This gives the electrodes the following ad-

vantages: fast stabilization of the open circuit poten-

tial (OCP), making stimulation and sensing with the

same electrode possible (Specht, 2007), high charge

injection capacity, which allows for electrode minia-

turization (Cogan, 2008; Zhou, 2009).

Titanium nitride coatings can be made smooth or

porous by controlling deposition parameters, such as

nitrogen (N

2

) flow. At a low N

2

flow a smooth Ti-

rich metallic film can be obtained. Increasing the

flow results in a smooth (stoichiometric) TiN film

and further increasing the N

2

flow results in a porous

(over-stoichiometric) N-rich film (Cunha, 2009).

The pores extend deep into the coating, resulting in a

high surface to area ratio and a high charge storage

capacity (CSC) (Cunha, 2009; Norlin, 2005).

An increased amount of nitrogen in the coating,

however, also results in increased dissolution rates

and oxide thickness when high anodic potentials are

reached (Cunha, 2009). In addition, higher potentials

were observed when applying stimulation pulses

using implanted TiN electrodes (Meijs, 2015), which

may compromise safety during electrical stimula-

tion. It is thus advantageous to apply an additional

coating to improve the corrosion resistance and in

vivo electrochemical properties.

Boron-doped nanocrystalline diamond (B-NCD)

was selected, to combine its be mechanical stability,

biocompatibility (Tang, 1995; Garrett, 2015) and

corrosion resistance (Hupert, 2003) with the large

sufe to area ratio of TiN (Cunha, 2009). B-NCD

further has metal-like electrical properties and a

wide safe potential window (Garret, 2012; Meijs,

2013). In addition, B-NCD is fouling resistant (Hu-

pert, 2003), which may decrease the electrode poten-

tial during pulsing with implanted electrodes.

2 METHODS

2.1 Electrode Fabrication

The TiN coatings were deposited on the tip of 16

Ti6Al4V electrode pins (6 mm

2

) by reactive DC

106

Meijs, S., McDonald, M., Sørensen, S., Rechendorff, K., Petrak, V., Nesladek, M., Rijkhoff, N. and Pennisi, C..

Increased Charge Storage Capacity of Titanium Nitride Electrodes by Deposition of Boron-doped Nanocrystalline Diamond Films.

In Proceedings of the 3rd International Congress on Neurotechnology, Electronics and Informatics (NEUROTECHNIX 2015), pages 106-109

ISBN: 978-989-758-161-8

Copyright

c

2015 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

magnetron sputtering using an industrial CC800

coating unit (CemeCon AG, Germany). Sputtering

was done from four Ti targets (88 x 500 mm

2

) with

99.5% purity in an Ar/N

2

mixture atmosphere. The

N

2

flow was varied from 120 to 300 sccm, while the

Ar flow was constant. The deposition time was var-

ied in order to obtain different coating thicknesses.

Titanium-nitride electrodes were then coated

with B-NCD using an Astex AX6500 microwave

plasma enhanced chemical vapor deposition system.

The electrodes were first immersed in a 0.33 g/L

solution of diamond nanoparticles (3.8 ± 0.7 nm)

from Shinshu University to seed the surface for

diamond growth. Hydrogen gas with an addition of

1% CH4 was added to the chamber at a total flow

rate of 500 sccm. Tri-methyl boron (TMB) was

added to the gas as the dopant source, at boron to

carbon concentrations of 10,000ppm. The plasma

was maintained at a temperature of ~750 °C by us-

ing a pressure of 25 torr and a microwave power of

2500 W for the plasma.

2.2 Electrochemical Measurements

All electrochemical measurements were carried out

in a 3-electrode set-up, using the TiN/B-NCD pins

as working electrodes (0.06 cm

2

), a platinum foil

counter electrode (50 cm

2

) and a Ag|AgCl reference

electrode (1.6 cm

2

). Measurements were performed

in Ringer solution at room temperature.

The impedance spectrum was measured from 0.1

Hz-100 kHz, 5 points/decade using a sinusoidal

measurement current of 5.0 µA. Impedance spec-

troscopy was performed using Solartron, Model

1294 in conjunction with 1260 Impedance/gain-

phase Analyzer (Solartron Analytical, UK).

Cyclic voltammetry was performed by cycling the

electrode potential between the water window limits.

These limits were determined by increasing and

decreasing the electrode potential until an exponen-

tially increasing current was observed using a sweep

rate of 0.05 V/s. Measurements were made at 0.05,

0.1, 0.5 and 1.0 V/s; 10 cycles were recorded at each

sweep rate. The cathodic charge storage capacity

(CSC) of the electrodes was found by calculating the

surface area under the 0 A axis.

Voltage transient measurements were made us-

ing a cathodic-first bipolar symmetric current pulse

with an inter-phase, during which no current was

applied. Each phase had a phase width of 200 µs and

the duration of the inter-phase was 40 µs. For analy-

sis of the voltage transients, the OCP was set to 0 V

and the IR drop was subtracted. The IR-drop was

calculated for each phase by subtracting the potential

at 20 µs after pulse cessation from the last data point

of the respective phase. The pulsing capacitance

(C

pulse

) was calculated for each pulse using the fol-

lowing equation:

I

stim

= C

pulse

ௗ

ௗ௧

(1)

where I

stim

is the stimulation current and

ௗ

ௗ௧

is the

slope of the last 90% of the cathodic phase of the

voltage transient.

Cyclic voltammetry and voltage transient meas-

urements were performed with VersaSTAT 3 poten-

tio- galvanostat (Princeton applied research, USA).

3 RESULTS

Two of the pins were coated with a smooth (stoichi-

ometric) TiN coating, while all others were over-

stoichiometric and displayed an open pyramidal

columnar structure. The surface to area ratios of the

porous electrodes ranged from 89 to 295, calculated

by dividing the CSC of the porous coatings by the

CSC of the smooth coating. The coating thicknesses

varied with N

2

flow and deposition time (table 1).

Diamond films were deposited on the TiN coatings.

These films had uniform coverage on the TiN with

grain size of ~50nm (Fig. 1). The film thickness was

measured using silicon substrates coated under the

same conditions, which gave a film thickness on the

order of the grain size, around 50-70nm.

Table 1: Deposition parameters and coating thicknesses

for porous TiN coatings.

N

2

flow

(sccm)

Deposition

time (10

3

s)

Coating thick-

ness (µm)

Ref.

nr.

120 27.5 5.2 45

180 10 2.1 46

180 27.5 6.3 52

180 60 13.1 54

240 10 2.0 47

240 27.5 4.6 53

300 27.5 1.6 55

Figure 1: SEM of B-NCD coated TiN electrode (ref. 52).

Increased Charge Storage Capacity of Titanium Nitride Electrodes by Deposition of Boron-doped Nanocrystalline Diamond Films

107

Figure 2: The CV of the B-NCD coated TiN electrodes

had wider safe potential limits, which increased the CSC.

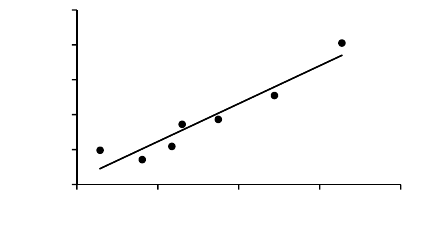

Figure 3: CSC increased linearly with coating thickness.

The blue markers correspond to TiN (r

2

=0.71) and red

markers to B-NCD (r

2

=0.74).

Figure 4: C

pulse

did not increase with coating thickness.

The blue markers correspond to TiN (r

2

=0.32) and red

markers to B-NCD (r

2

=0.01).

Figure 5: C

pulse

of B-NCD coated TiN electrodes was

decreased compared to uncoated TiN. This caused a steep-

er voltage rise and greater electrode potentials.

The water window was -0.6 V – 0.9 V (Ag|AgCl)

for TiN and -1.3 V – 1.2 V for B-NCD. Due to the

wide potential window typical for B-NCD, the CSC

of the B-NCD coated electrodes was 2-3 times larger

than the CSC of TiN electrodes (Fig. 2). Further-

more, the CSC of both B-NCD and TiN electrodes

increased with increasing coating thickness (Fig. 3).

The CSC of B-NCD coated electrodes was consist-

ently higher than the CSC of TiN electrodes

The impedance magnitude for the B-NCD and

the TiN electrodes decreased with increasing thick-

ness. All B-NCD coated electrodes had a higher

impedance than without the B-NCD coating.

Contrary to the CSC, C

pulse

did not increase with

coating thickness. The trend lines even have a slight-

ly negative slope for both TiN and B-NCD elec-

trodes. Also, C

pulse

of the B-NCD coated electrodes

was lower than C

pulse

of the corresponding TiN elec-

trodes (Fig. 4). Fig. 5 shows that a lower C

pulse

re-

sulted in in higher electrode potentials. The potential

limit for B-NCD, however, is higher than for TiN.

The highest CSC and lowest impedance magni-

tude for TiN with and without B-NCD coating were

obtained using the thickest coating (ref. nr. 54). The

main parameter that influenced the coating thickness

was the coating time. The highest C

pulse

, however,

was obtained with thinner coatings.

4 DISCUSSION

We have coated 16 TiN electrodes with various high

surface to area ratios with a thin layer of B-NCD.

Depositing a B-NCD thin film on a porous TiN

substrate improved the previously reported electro-

chemical performance of the B-NCD electrodes

(Garrett, 2012; Meijs, 2013) to a level that is compa-

rable to porous TiN electrodes.

The TiN electrodes had a high surface to area ra-

tio (89-295), which resulted in a high CSC and low

impedance magnitudes. A thicker coating resulted in

a higher CSC due to the increased surface to area

ratio. This suggests that pores extend into the entire

depth of the coating (Cunha, 2009; Norlin, 2005).

Depositing B-NCD on top of the TiN further in-

creased the CSC. There was a linear relation be-

tween the TiN CSC and the B-NCD CSC (fig. 6).

This indicates that the B-NCD coating did not block

the pores, but covered the inner surface of the TiN

columns without obstructing the pores.

The highest C

pulse

for TiN electrodes was found

for a 6.3 µm thick coating, while the lowest C

pulse

for

B-NCD coated electrodes was found for a 2.1 µm

thick coating. Both TiN coatings were produced un-

-0,8

-0,6

-0,4

-0,2

0,0

0,2

0,4

0,6

-1,4-1,2 -1 -0,8-0,6-0,4-0,2 0 0,2 0,4 0,6 0,8 1 1,2

Current (mA)

Potential (V)

TiN 46

TiN 54

B-NCD 46

B-NCD 54

0

50

100

150

200

250

300

0 5 10 15

CSC (mC/cm

2

)

Thickness (µm)

120 ml/min

180 ml/min

240 ml/min

300 ml/min

0

0,5

1

1,5

2

2,5

0 5 10 15

C

pulse

(mF/cm

2

)

Thickness (µm)

120 ml/min

180 ml/min

240 ml/min

300 ml/min

-0,07

-0,05

-0,03

-0,01

0,01

0,03

0,05

-0,1 0,0 0,1 0,2 0,3 0,4 0,5 0,6 0,7

Potential (V)

Time (ms)

TiN 46

TiN 54

B-NCD 46

B-NCD 54

NEUROTECHNIX 2015 - International Congress on Neurotechnology, Electronics and Informatics

108

Figure 6: There is a linear relationship between the CSC of

TiN and B-NCD coated TiN electrodes (r

2

=0.91).

der similar conditions and the increased thickness

was achieved by increasing the coating time. As the

B-NCD coating is added, however, the pores of the

electrodes become narrower. This increases the pore

resistance and decreases the pore depth that can be

used under pulsing conditions (Cogan, 2008). This

makes it less advantageous for electrical stimulation

purposes to increase the coating thickness beyond a

certain level. For TiN electrodes, the optimal thick-

ness is between 6.3 and 13.1 µm, while for B-NCD

coated TiN electrodes it is between 2.1 and 5.2 µm

with the settings used in this study. A thicker coating

may be more advantageous, if the pores are wider

without comprising mechanical stability.

The electrochemical properties of the B-NCD

coated TiN electrodes are far better than those of

conventional B-NCD electrodes (Garret, 2012;

Meijs, 2013). This is due to the large surface to area

ratio gained by the TiN on which B-NCD was

grown. B-NCD with a high surface to area ratio was

also made by growing diamond on carbon nano-

tubes, resulting in great improvements in impedance

and CSC (Piret, 2015). The CSC of the current elec-

trodes is, however, 3-10 times higher than the CSC

of B-NCD coated carbon nanotube electrodes.

Although C

pulse

is decreased for B-NCD coated

electrodes compared to TiN, it is important to view

this result in the light of wide safe potential window

of B-NCD (Garrett, 2012, Piret, 2015). The decrease

in C

pulse

after depositing B-NCD ranged from 67% to

less than 1%, while the cathodic potential limit was

more than doubled (-0.6 V vs Ag|AgCl for TiN and -

1.3 V vs Ag|AgCl for B-NCD). This means that the

amount of charge that can be injected without reach-

ing unsafe potentials is doubled by applying a B-

NCD coating on top of a porous TiN coating.

In order to achieve increased charge injection

(Q

inj

), the production parameters are of critical im-

portance, as the extra coating increases the pore

resistance, which may deteriorate Q

imj

. This study

suggests that specific deposition parameters are

optimal for stimulation electrodes, as increased

thickness and N

2

flow only result to a certain extent

in larger C

pulse

and Q

inj

. These settings, however, also

depend on the thickness of the diamond film.

5 CONCLUSIONS

The charge storage and charge injection capacity of

porous TiN electrodes can be improved by adding a

B-NCD coating. We further expect that the B-NCD

coating will improve the corrosion and fouling re-

sistance of porous TiN electrodes.

REFERENCES

Cunha L T, et al. 2009 The role of composition, morphol-

ogy and crystalline structure in the electrochemical

behaviour of TiNx thin films for dry electrode sensor

materials Electrochem. Acta vol. 55 pp. 59-67

Cogan, S F 2008 Neural stimulation and recording elec-

trodes Annu. Rev. Biomed. Eng. vol. 10 pp. 275-309

Garrett D J et al. 2012 Ultra-nanocrystallline diamond

electrodes: optimization towards neural stimulation

applications J. Neural. Eng. vol. 9, 10 pp

Garrett D J et al.2015 In vivo biocompatibility of boron

doped and nitrogen included conductive diamond for

use in medical implants J. Biomed. Mater. Res., Part B

Hupert M et al. 2003 Conductive diamond thin-films in

electrochemistry Diam. Relat. Mater. vol. 12 pp.

1940-1949

Meijs S et al. 2015 “Electrochemical properties of titani-

um nitride nerve stimulation electrodes: an in vitro and

in vivo study” Front. Neurosci. vol. 9 art. 268

Meijs S et al.2013 Electrochemical characterization of

boron-doped nanocrystalline diamond electrodes for

neural stimulation IEEE EMBS Conference on Neural

Engineering

Norlin A, Pan J and Leygraf C 2005 Investigation of

electrochemical behavior of stimulation/sensing mate-

rials for pacemaker electrode applications I. Pt, Ti, and

TiN coated electrodes J. Electrochem. Soc. 152 J7-J15

Piret G at al. 2015 3D-nanostructured boron-doped dia-

mond for microelectrode array neural interfacing Bio-

materials vol. 53 pp. 173-183

Specht H, Krueger F, Keitel O and Frericks M 2007 Elec-

trochemical properties and application stability of

coatings for cardiac pacing and neuromodulation de-

vices Medical Device Materials IV ed J Gilbert (ASM

International)

Tang L et al. 1995 Biocompatibility of chemical-vapour-

deposited diamond Biomaterials vol. 16 pp. 483-488

Zhou D and Greenbaum E 2009 Implantable Neural Pros-

theses I Devices and Applications (New York: Spring-

er-Verlag)

50

100

150

200

250

300

25 50 75 100 125

B-NCD CSC

TiN CSC

Increased Charge Storage Capacity of Titanium Nitride Electrodes by Deposition of Boron-doped Nanocrystalline Diamond Films

109