Computer-aided Design of Transmission Shaft and Rolling Contact

Bearing Selection based on Expert System

Huang Pinghua and Guo Xiaoxi

92941 Unit, huludao,Liaoning,China

14692423@sohu,lasti@qq.com

Keywords: Transmission Shaft Design, Computer-aided Analysis, Expert System, Optimal Selection.

Abstract: In order to solve the inefficiency problem in traditional method of transmission shaft design, this paper

analyzes the strength and deformation of rotation step shaft through computer program. These bearings have

a large number of transmission elements, such as: gear, pulley, etc. Three dimensional modeling is applied

to all of them. Moreover, a motion analysis can be made by detecting the force implemented on the

transmission shaft. The finite element method is applied to calculate V shaped groove of stress

concentration which is presented in a diagram, and finally, the optimal rolling contact bearing is selected

based on the knowledge of expert system.

1 INTRODUCTION

To adopt the traditional method to design and

analyze machine parts is a quite troublesome job.

Recently, computer-aided design and analysis is

introduced into this field. Therein, the transmission

shaft is used to transmit force and motion, the

corresponding design requires a large number of

calculation and diagrams. The method of

computer-aided modeling can be used to effectively

design the transmission shaft and reduce plentiful of

work amount. The software adopted in

computer-aided design can be independently

developed or resorted to the existing commercial

software.

The force-transmit element on the transmission

shaft must be accurately positioned. It is advised to

use the shaft shoulder of step shaft to make sure that

these elements are aligned to the coordinate of the

shaft and assembled. Besides, the stress analysis for

special points on the shaft must also be taken into

consideration.

This paper studies the computer-aided analysis

of transmission shaft under two dimension

conditions and supposes that the force-transmit

element be able to bear imaginable force. The more

the elements on the shaft are, the more complicated

the analysis will be. If the influence of stress

concentration is taken into consideration, plus

application of the traditional solution, the calculation

will be very time-consuming and complicated.

Furthermore, stress concentration data presented in

diagrams is inconvenient for reading. The purpose

of this paper is to analyze and select the optimal

diameter of shaft, so as to make it strong and rigid

enough to satisfy the stipulated conditions. The

computer program is applied to obtain the optimal

parameters for critical section and the stress

concentration data is formulized and adjusted to

adapt to the needs for being entered into computer.

Based on the aforesaid calculation, under provided

assembling condition of the shaft, the optimal

rolling contact bearing can be selected. The

realization of the aforesaid function cannot occur

without the assistance of expert system. It can serve

3

Pinghua H. and Xiaoxi G.

Computer-aided Design of Transmission Shaft and Rolling Contact Bearing Selection based on Expert System.

DOI: 10.5220/0006018000030006

In Proceedings of the Information Science and Management Engineering III (ISME 2015), pages 3-6

ISBN: 978-989-758-163-2

Copyright

c

2015 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

3

the specific application of selecting materials for the

cutter and designing the cutter. Please consult the

relevant literature for specific details.

2 STEP SHAFT DESIGN

This paper studies the two aspects of shaft design,

i.e., deflection and rigidity, pressure and strength.

Deflection and rigidity covers the two kinds of

motions of bending and twisting, deflection and the

inclination of force bearing point. Pressure and

strength involves fatigue strength and stability. The

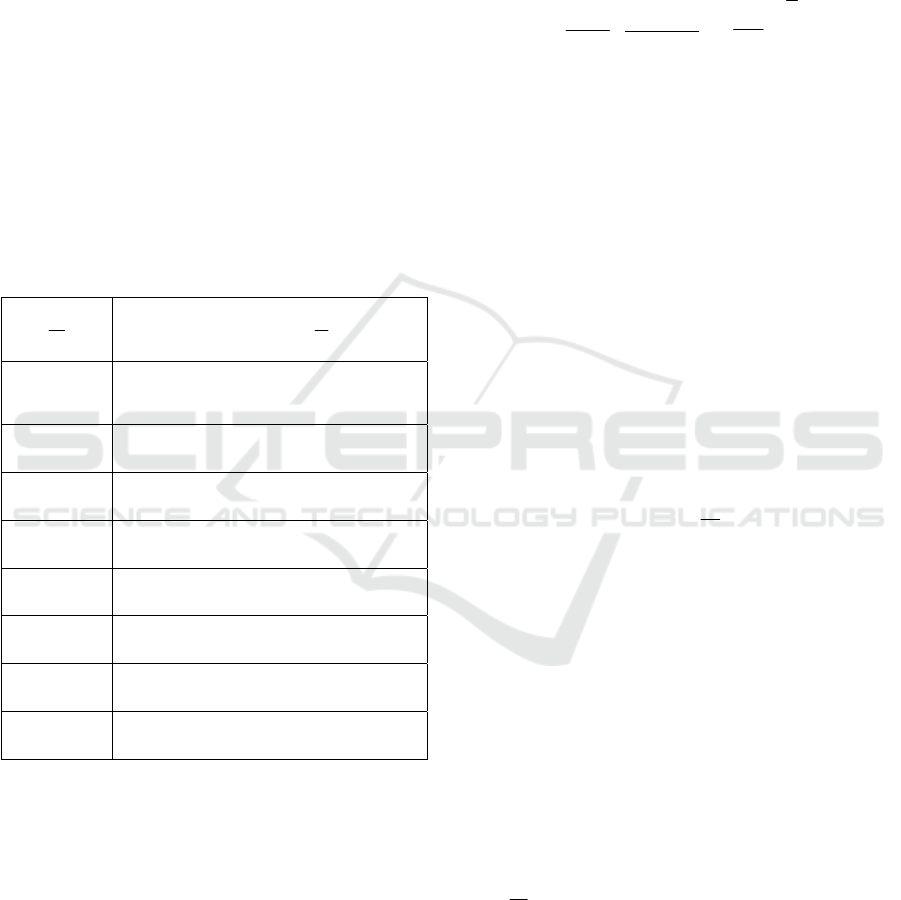

theoretic data is shown in Table I:

Table 1:Theoretic data of bending shaft

K

T

.

d

D

K

T

【Note: A=(

d

r

)】

1.01

0.9034×

A

18.0−

1.02

0.938×

A

19.0−

1.03

0.95

A

2.0−

1.05

0.956×

A

21.0−

1.1

0.9496×

A

23.0−

1.2

0.926×

A

25.0−

1.5

0.916×

A

27.0−

2

0.896×

A

3.0−

2.1 Influencing Factors and Linear

Regression

When the shaft bears completely reverse bending

force and stable torque, the critical bending stress

generally lies in the stress concentration point.

Stress concentration generally occurs within limited

range where geometric shapes are not continuous,

for example, the v-shaped groove. At the time of

designing the equation, the influence from stress

concentration must be taken into account. With

various factors having been taken into consideration,

the calculation formula for shaft diameter is as

follows:

()

[

]

{

}

S

ut

T

m

S

e

M

a

K

f

n

d

2

2

32

3

1

+

∗

∗

=

π

(1)

Where,

M

a

is bending moment,

T

m

is torque, n

is safety coefficient,

S

ut

is the ultimate strength

of material. .

′

∗∗=

S

K

K

K

S

e

dcb

e

,

(

)

11 −+=

KK

Tf

q is

fatigue stress concentration factor.

K

K

K

dcb

,,

respectively represent dimension, groove and

surface factor.

q

is the V-shaped groove sensitive

factor. The calculation formula for

K

T

is as

follows:

1

6

1

i

TTi

r

KK

d

−

=

⎛⎞

∑

⎜⎟

⎝⎠

(2)

where,

d

D

B

B

B

B

B

B

B

BK

BK

BK

BK

BK

BK

T

T

T

T

T

T

=

−−−=

++=

+−=

−+−=

+−=

−+−=

.7.8575.5154161

,86167.44.29197.1946

,15.462249566.416

,8.21715.8674.399

,022.418.145932.86

,43687.3681.1172706.6

2

6

2

5

2

4

2

3

2

2

2

1

2.2 Deflection Analysis

Deflection analysis cannot be started unless the

geometric shape of the shaft is completely

ISME 2015 - Information Science and Management Engineering III

4

ISME 2015 - International Conference on Information System and Management Engineering

4

determined. It is one function for complete

geometric shape of the shaft. Meanwhile, the

pressure of the point we are studying is the function

for the deformation and motion of this point.

Therefore, in case of designing and analyzing step

shaft, pressure and strength calculation must be

taken into consideration. In the meanwhile of

determining the deflection, the dimension of the

shaft must be given. The mixed torque borne by step

shaft comes from the axial force of spiral and helical

gears. Therefore, deflection calculation adopts

elastic limit rather than curvature radius

ρ

. The

calculation formula for curvature radius

ρ

:

[]

dx

dy

x

d

y

d

2

1

2

3

2

2

1

+

±=

ρ

(4)

The calculation formula for shaft camber y can be

obtained by using finite element method.

()

M

i

M

i

M

i

EI

h

y

i

y

i

y

i

y

i

1

2

1

2

2

1

5

4

23

+

+−

−

=+

+

−

+

+

+

−

(5)

h is pitch, E is elastic limit, M is bending moment

and I is moment of inertia.

3 COMPUTER PROGRAM

DEVELOPMENT

This program is developed based on Q-Basic

language. It is simple and easy to operate. It is

applicable for personal computer. Moreover, this

program is provided with such functions as digital

analysis, vector calculation and graphic description.

It enables the users to solve their unique problems.

Besides, it is provided with interactive function and

a basic database with detailed instructions on

different materials attached thereto.

The calculation content includes the base

reaction force from two directions of vertical and

horizontal, bending moment diagram, deflection and

shaft inclination. Then, based on the aforesaid

calculation, the optimal rolling contact bearing is

selected. To conduct shaft analysis, firstly, it is

required to choose the appropriate material and

design parameters, for instance: the position of

rolling contact bearing and machine parts, rotating

direction and the designed length of shaft. Similarly,

to conduct strength calculation, it is required to

choose safety coefficient, input force and rounds per

minute. The calculation of force and torque of gears

on the shaft is decided by the corresponding

parameters entered in, for instance, pitch, etc. The

bending moment is calculated in digital mode,

including the two directions of horizontal and

vertical. Then, it goes through smoothing processing

and is presented in diagrams. The calculation of the

parameter of critical point and force and torque

under the condition of composite loads can be

processed simultaneously. At the time of calculating

bending deflection, the two directions of vertical and

horizontal should be taken into account. With the

aforesaid calculation result, the optimal diameter of

step shaft can be obtained by using the two methods

of one-dimension search and interval halving. See

computer program for specific realization.

4 ROLLING CONTACT SHAFT

SELECTION and DATABASE

DEVELOPMENT

Due to the needs of function, the rolling contact

bearing is required to have reasonable service life,

high stability and rather low cost. To reach the

aforesaid requirements, the dynamic bearing

capacity, working conditions, equal bearing capacity

and constant load and so on must be taken into

account. The calculation formula for equal bearing

capacity.

Computer-aided Design of Transmission Shaft and Rolling Contact Bearing Selection based on Expert System

5

Computer-aided Design of Transmission Shaft and Rolling Contact Bearing Selection based on Expert System

5

(

F

eqv

):

F

eqv

F

F

ar

YX +∗=

(6)

where,

F

r

is axial force,

F

a

is radial force. The

calculation formula for dynamic bearing capacity:

(

)

10

6

L

K

F

eqv

C =

(7)

the specific selection process is seen in the flow

chart below.

Flow Chart 1

Expert system is a computer simulation program

based on knowledge. It adopts knowledge-decision

unit and IF_THEN rule to conduct reasoning. The

expert system mainly comprises several parts like

database, decision unit, and storage unit, etc. To

apply this expert system, one must use LEONARDO

software.

5 CONCLUSION

a. The computer program developed is considerably

flexible. It allows the users to solve their own

specific problems. The fatigue analysis for optimal

shaft design and stress sensitive factor are

formulized and entered into computer program.

b. A better protocol is found between calculation of

the optimal diameter of the critical section of step

shaft by using computer simulation method and

analytic method. Moreover, a balance is also

reached between value calculation method and

analytic method in terms of bending-torsion and

torque.

c. The expert system adopting the optimal rolling

contact bearing is developed. It can be used for the

teaching of computer-aided design.

REFERENCES

PU Liang-gui, JI Ming-gang, 2001. Machine Design

HIGER EDUCATION PRESS. Beijing.

YING Hui, 2001. Discussion on the design of recycled

water supply systems for rare metals metallurgical

Plant. Rare Metals and Cemented

Carbides,03:50-52,55.

ZHANG Yu-dong, WU Le-nan, WANG Shui-hua, 2010.

Survey the development rule of Expert system.

Computer Engineering and Applications,19:43-47.

XU Tong-le, CHEN Wu-qin, 2010. Research of rolling

bearing fault diagnosis based on expert system. Coal

Mine Machinery, 11:234-236.

CAI-fan, LI Chu-ye, MA Yan, 2010. Contact pressure and

pull-out force reffect on the interference fit.Machinery

Design&Manufacture, 11:7-9.

LI Wei, LI Wen-bin,2014. Analysis and Design of Shaft

System Structure of Separated High-speed

Rolling

Structure. Machine Building& Automation

,2014,

43( 2) : 19- 23

TANG Lin, ZOU Hui-jun, 2000. Accomplishing CAD of

mechanical kinematic scheme by the design unit

approach, Journal of Computer-Aided Design &

Computer Graphics, 8:614-617.

d

RRRR

BZBYAZAY

,,,,

F

r

F

a

e

C

F

a

,,

C

F

eqv

,

Compare C and the preset value

and choose the optimal one

ISME 2015 - Information Science and Management Engineering III

6

ISME 2015 - International Conference on Information System and Management Engineering

6