Cause Analysis and Treatment of Abnormal Shear in Head Cutting

Flying Shear of Hot Rolling

Xiaoyan Chen

Department of Telecommunication Engineering, Hubei Radio & TV University, WuHan,, China

147897514@qq.com

Keywords: The Flying Shear Control, Abnormal Cut, Optimal Signal Switching.

Abstract: Precise shearing of flying shear plays a very important role in cost control of a hot-roll line. The

malfunction of sensors which help to locate where to cut accurately makes it difficult to achieve this goal.

This paper discussed in detail three key control processes in completing precise shearing. Possible causes of

abnormal shear in production practice were analyzed, based on which the optimal signal switching control

measures was put forwards. A monitoring system watchdoged the signals from sensor. If sampling showed

that malfunction happened, a backup signal was used. Also the possible backup signals were discussed how

to replace the breakdown devices. In practice, these measures obtain a good application effect in precise

shearing. Mistakes in cutting are reduced to minimum.

1 INTRODUCTION

Flying shear is one of key equipments in hot rolling

line, used to cut the lower temperature and irregular

parts in strip ends after rough rolling. This procedure

can prevent band steel from jamming in finish

rolling process and reduce the impact on the mill

rolls from the irregular part. Precise shearing can

also help achieve effective improvement in the

production.

Abnormal cut happens frequently in the head/tail

cutting and cutting waste loss accounts for more

than 1.5% loss of the whole process. When the head

/ tail enters the finishing mill, it is very easy to cause

the serious accident of roll breakage. If abnormal

shear frequency can reduce by 50%, loss will be

lowered by 3%, and direct economic benefits of

more than 6000000 RMB Yuan can be achieved.

2 THREE CRITICAL CONTROLS

OF FLYING SHEAR PROCESS

A complete precise shear process can be gained by

controlling flying shear to complete the following

three key functions (OUYANG Xiang-xin, 2003):

strip end tracking and calculation, strip speed

tracking and control and shear blade position

tracking and control (Masahiro Kayama etc, 1998).

2.1 Strip End Tracking / Calculation

As the basis of flying shear accurate cutting control,

motion control unit must accurately track and

compute the strip end position, in order to determine

when the shear performing certain actions. It makes

possible that the blade cuts into the strip at set length

(distance to the strip ends) and moves with the bar

until the strip is cut off (Jiro Jumayama etc,1996).

2.2 Tracking / Control Strip Speed

In order to ensure cutting blade touching the strip at

right time, the component of velocity along the

rolling direction must be kept consistent with that of

the strip until the strip is cut, which requires the

exact tracking and control of strip speed based on

the strip end tracking and calculation. Drum flying

shear with a crank is employed in this plant. The

structure is shown in Figure 1. Space trajectory of

shear blade in the cutting process is round, as shown

in figure 2.

393

Chen X.

Cause Analysis and Treatment of Abnormal Shear in Head Cutting Flying Shear of Hot Rolling.

DOI: 10.5220/0006027103930396

In Proceedings of the Information Science and Management Engineering III (ISME 2015), pages 393-396

ISBN: 978-989-758-163-2

Copyright

c

2015 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

393

Figure 1: Sketch map of flying shear.

.

Figure 2: Trajectory of shear blade.

Velocity tracking is shown in equation:

Vc = K(2Lc - LR2+ r*sinα)/ 2Lc *

VL/cosα

(1)

Vc - set velocity of shear, m/s,

K - leading or lag coefficient,

r - trajectory radius of shear blade, mm,

α - cutting angle calculated from the thickness of

steel, °

Lc -circumference distance of blade in this stage,

mm,

LR2 - distance between cutting point and flying

shear, mm.

According to the position relationship between the

cutting blade and strip, blade track is divided into

four stages.

POS1: from Start position to AX in figure 3. The

primary control target is to control cutting

blade location based on the strip end position,

which determines the accuracy of cutting

length. At the same time, the control system

requirements horizontal velocity of cutting

blade at the end of the stage (AX) and the

value is equal to that of strip , so the velocity

control target has to be achieved - setting

target speed according to the end position of

band.

POS2: from AX to the 00 position in the figure 3.

Because the blade has touched the strip, the

actual cutting length is fixed, therefore in this

stage the only control objective is to cut at the

same speed with the strip.

POS3: from figure 00 positions to AY. In the same

stage although blade has cut the strip, the

blade is still with the strip. Therefore, the

control goal is to follow the speed of the

band.

POS4: from AY to Start position. The stage is a

slow-down process, so position control is the

only goal, which makes the blade stop in the

starting position.

2.3 Tracking / Control Strip Speed

The following is formula of the position control:

P = 270°- (2Lc - LR2 + r* sinα) *( 270°–α)/ 2Lc (2)

P-set position of blade

In POS1, position control can compensate for the

shearing speed changes in following the actual speed

of strip when the final position is unpredictable. So

both speed control and position control is important

in this stage. So blade cuts into bar steel at

synchronous speed (horizontal) of strip in set cutting

position, ensuring the flying shear can coherently

finish cutting process even in velocity fluctuations.

In POS2 and POS3, position controller

implements cutting, and there is only speed control

to the blade.

In POS4, as mentioned before, there is only

position control to the blade. So the output of the

speed controller is always zero. Setting value is 270.

The system diagram is as shown in Fig.3.

Figure 3: System diagram of shear control.

ISME 2015 - Information Science and Management Engineering III

394

ISME 2015 - International Conference on Information System and Management Engineering

394

3 ANALYSIS ON THE CAUSES

OF TYPICAL ABNORMAL

SHEAR

In practice, because of the influence of the cooling

water, rolling vibration and electromagnetic

interference, abnormal shear occurs mostly when the

bar end calculation is not accurate caused by the

abnormal signal gotten from the line.

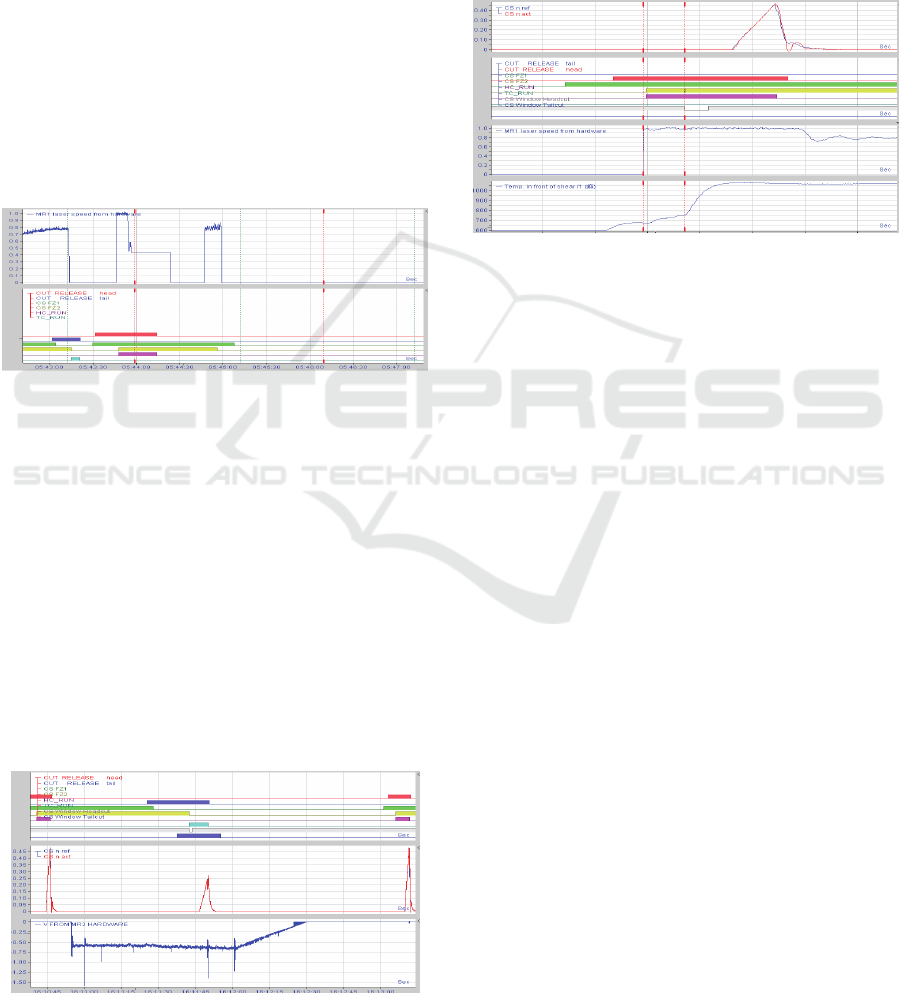

3.1 Laser Velometer Measurement

Abnormal

Due to poor field conditions and effect of water fog,

or the velocimeter's own fault, signal is abnormal, as

shown in Fig. 4.This situation mostly leads to

missing cutting the head of the band.

Figure 4: Abnormal signal from Laser velocimeter.

Signal from laser velocimeter for the strip speed

in the shear region is a constant value. But

sometimes the value suddenly drops to zero.

3.2 Measure Roll Tacho Measurement

Abnormal

The feedback value waveform coming from feed

roller encoder after clamping roller, which is used to

strip tail length calculation and velocity tracking

concusses, indicates the fluctuation of velocity.

Waveform deterioration leads to inaccurate tail

length calculation and tail cutting normal. The

abnormal situation is shown in figure 5.

Figure 5: Abnormal signal from Measure roll tacho.

3.3 HMD FZ2 Measurement Abnormal

As is shown in Figure 6, the FZ2 and laser

velocimeter is turned on at almost the same time,

then turned off immediately. This is a early missing

connection, leading to the subsequent flying shear

early cutting. In the end, the blade misses cutting the

head of band, because of the arrival of thermal field

ahead of the actual situation.

Figure 6: Abnormal signal from FZ2.

4 MEASURES

Abnormal shear is caused by the abnormalities of

measurement in the field. In order to improve the

cutting precision, a more reliable substitute signals

must be found as a standby signal. When the main

signals are abnormal, fast switching will use standby

signal. According to this idea, the following

measures are taken.

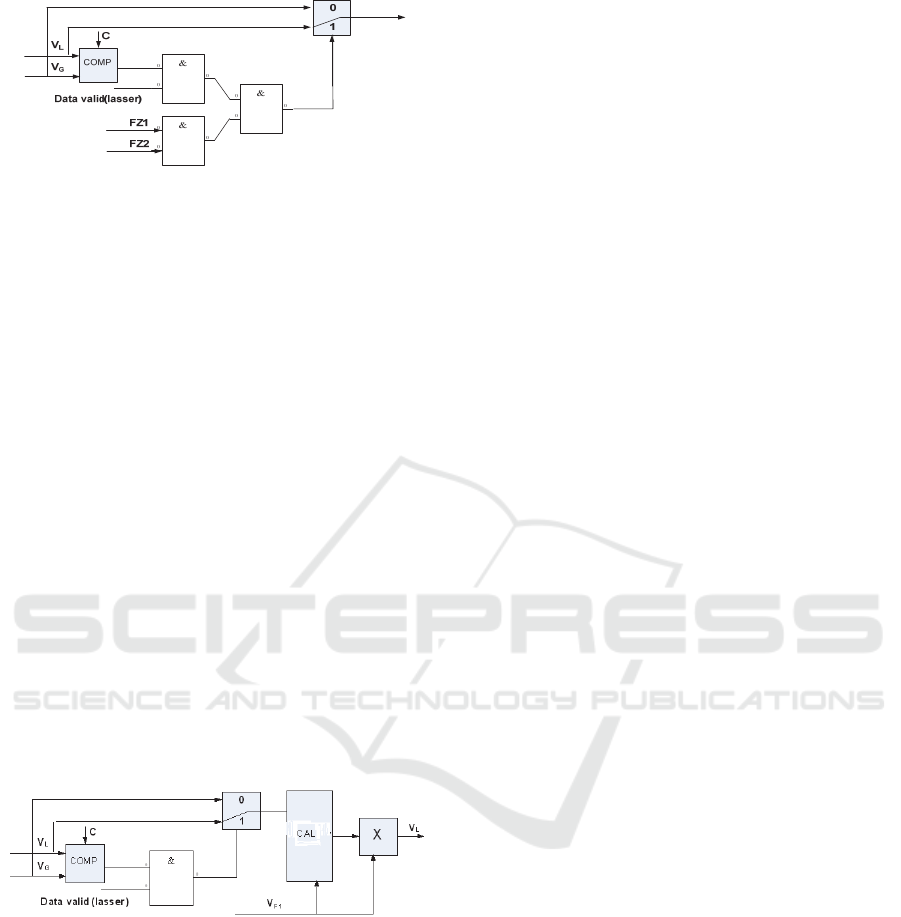

4.1 Measures 1: Switch the Abnormal

Signal to Roller Speed from the

Laser Velocimeter, When Cutting

Head

A laser velocimeter is used to measure the actual

speed of the strip in cutting head. Practice has

proved, without considering the slip, speed signal

from roller can be used to substitute the signal from

velocimeter. By using logic judgment between laser

velocimetry and roller speed, the abnormal signal

from laser velocimeter can automatically switch to

that of the roller speed. The following figure 7

shows the logic diagram:

Cause Analysis and Treatment of Abnormal Shear in Head Cutting Flying Shear of Hot Rolling

395

Cause Analysis and Treatment of Abnormal Shear in Head Cutting Flying Shear of Hot Rolling

395

Figure 7: auto-switch between laser velocimeter and roller

speed when cutting head

VL -real-time velocity of the strip, m/s;

VG-speed of the roller, m/s;

The measure is mainly programming in the TDC

controller of flying shear and the signal from laser

velocimeter is compared with threshold C, then logic

judgment makes roller speed switch happen.

4.2 Measures 2: In Considering the

Backward Slip Situation, using the

F1 Velocity Instead of the Feedback

Value from the Roller Encoder,

When Cutting Tail

As shown in Figure 9, speed signal from F1 in

finishing roll is most stable and not subject to

environmental influence. But in the application the

backward slip factor of steel in F1 rolling must be

considered. Use the signals from velocimeter and F1

to get the real-time backward sliding coefficient and.

Multiply the real-time F1 speed with the backward

slip coefficient, then relatively stable strip speed is

gained.

Figure 9: Real-time backward sliding coefficient calculate

when cutting tail.

The calculation formula of simplified sliding

coefficient:

K

L = VL/ VF1,

VF1- speed of F1, m/s;

5 CONCLUSIONS

Based on the analysis of the causes of abnormal

shear, the idea of using the signals of more stable to

replace the existing signal in the cutting head and

tail cutting process is put forward. In this way,

abnormal signals are switched to reserved ones, and

abnormal shear due to abnormal signal inputs was

reduced to 0.32%. Meanwhile, down time of the

equipments is decreased by 72% and production

coefficient and production efficiency are improved

as well.

REFERENCES

OUYANG Xiang-xin, Principle And Operation Of The

Auto-Control System For Flying Shears, SOUTHERN

METALS,(134), pp. 30-33, 2003.

Masahiro Kayama etc, Advanced plant maintenance and

control system.7th

.

Conf

.

On steel roiling, Cln'ba,

Japan, pp.20-23, 1998.

Jiro Jumayama etc: Information and control system

technology for iron and steel plants . Hitachi

Review,Japan, pp.18-23, 1996.

ISME 2015 - Information Science and Management Engineering III

396

ISME 2015 - International Conference on Information System and Management Engineering

396