Low Cost 3D-Printed Biosensor Arrays for Protein-based Cancer

Diagnostics based on Electrochemiluminescence

James F. Rusling

1,2,3,4

, Karteek Kadimisetty

1

, Spundana Malla

1

,

Gregory W. Bishop

1

and Jennifer E. Satterwhite-Warden

1

1

Department of Chemistry, University of Connecticut, Storrs, Connecticut 06269-3060, U.S.A.

2

Institute of Materials Science, University of Connecticut, Storrs, Connecticut 06269-3136, U.S.A.

3

Department of Surgery and Neag Cancer Center, University of Connecticut Health Center,

Farmington, Connecticut 06030, U.S.A.

4

School of Chemistry, National University of Ireland at Galway, Galway, Ireland

Keywords: 3D-Printing, Cancer, Multiplexed Protein Detection, Microfluidics, Immunoarray.

Abstract: Development and fabrication of bioanalytical devices by 3D printing offers revolutionary new routes to low

cost clinical diagnostic devices for molecular measurements. Relevant to future protein-based cancer

diagnostics, we describe and review here our recent development of prototype protein immunoarray devices

using desktop Fused Deposition Modeling (FDM) and stereolithographic 3D printers. All these system

feature sensitive electro-optical detection by a method called electrochemiluminescence (ECL). Our first

3D-printed immunoarray features screen-printed sensors in which manual manipulations enable gravity flow

reagent delivery for measurement of 3 proteins at detection limits of 0.3 to 0.5 pg/mL. ECL detection is

achieved in an open channel on integrated disposable screen-printed sensor elements. We then address the

issue of printing and processing optically clear plastic using a stereolithographic printer to build a closed

ECL detection chamber. Finally, we describe a prototype 3D-printed microprocessor-controlled enclosed

microfluidic ECL immunoarray featuring reagent reservoirs, micropumps and clear plastic detection

chamber with printed nanowells for ECL emission.

1 INTRODUCTION

Desktop 3D printers offer unprecedented new

options to design and fabricate low cost, high

performance biosensors (Gross, B.C., et al., 2014).

Development of microfluidic sensing devices by 3D-

printing can provide rapid computer-based design

prototyping and testing, avoiding the necessity for

masks or templates used in more traditional

approaches such as lithography. Design-to-device

fabrication can be rapidly achieved with 3D-printers,

and devices can be produced cheaply without the

need for economies of scale. Recent examples

include 3D printed systems for monitoring metal

ions (Su et al., 2014) and add-ons for turning

smartphones into food allergen sensors (Coskun &

Wang, et al., 2013; Wei , Nagi, et al., 2014; Coskun

& Nagi, et. al, 2013; Roda et al., 2014; Wei, Luo, et

al., 2014). Electrochemical sensing was integrated

into 3D-printed fluidic devices for dopamine, nitric

oxide (Erkal et al., 2014) and hydrogen peroxide

(Bishop et al., 2015). Biological and diagnostic

applications have recently been reviewed (O’Neill,

et al. 2014; Meng, et al. 2015).

There is a high level of interest in the medical

community for measuring levels of multiple

biomarker proteins for cancer diagnostics (Hanash,

et al., 2011). Measuring biomarker proteins in

conjunction with genomic analysis of patients and

their cancers are expected to help usher in a new era

of Precision Medicine (Kohane, 2015). Serum levels

of proteins are biomarkers that can serve to indicate

the onset, existence or progression of cancer

(Hanash, et al., 2011, Rusling, et. al., 2011).

Measurement of panels of protein biomarkers holds

enormous potential for early cancer detection as well

as personalized cancer therapy and treatment

monitoring.

.

However, these applications have yet to

be broadly realized in a form that can be readily

adapted to point-of-care. For such diagnostic

strategies to reach widespread clinical or point-of-

care (POC) use, low cost, sensitive, easy to use

devices are needed to measure multiple biomarker

proteins in patient serum (Rusling, et al. 2010).

Rusling, J., Kadimisetty, K., Malla, S., Bishop, G. and Satterwhite-Warden, J.

Low Cost 3D-Printed Biosensor Arrays for Protein-based Cancer Diagnostics based on Electrochemiluminescence.

DOI: 10.5220/0005649000170022

In Proceedings of the 9th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2016) - Volume 1: BIODEVICES, pages 17-22

ISBN: 978-989-758-170-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

17

Enzyme-linked immunosorbent assay (ELISA) is the

gold standard for clinical protein assays with DLs as

low as 1-3 pg/mL, but with limitations in sensitivity,

analysis time, multiplexing, and sample size. Newer

commercial multiprotein detection systems are very

useful for research, and rely on expensive,

technically demanding instrumentation difficult to

implement in the clinic (Hanash, et al., 2011,

Rusling, et. al., 2011). These approaches rarely

achieve detection below pg mL

-1

levels, while some

biomarker proteins have serum levels well below 1

pg mL

-1

.

In this paper, we describe new approaches to

develop 3D-printed multiplexed protein

immunoassay devices using a sensitive electro-

optical detection method called

electrochemiluminescence (ECL) (Forster, et al.,

2009). Detection employs an ECL-active dye that

can be loaded into nanoparticle labels, and

electrochemically active co-reactant, and applied

voltage to produce visible ECL light detected by a

charge-coupled device (CCD) camera. Below we

describe a prototype 3D-printed immunoassay

system with screen-printed sensors in which manual

manipulations are used to enable gravity flow

reagent delivery for the detection of 3 proteins. This

system uses ECL detection in an open channel

without a window in front of the sensor elements.

We then address the issue of printing and processing

optically clear plastic to build a closed chamber that

will emit ECL light. Finally, we present a prototype

3D-printed microprocessor-controlled microfluidic

ECL immunoarray featuring reagent reservoirs and

clear plastic detection chamber with printed

nanowells for ECL emission.

2 RESULTS

2.1 Gravity-flow Immunoarray

A prototype protein immunoarray was fabricated

using the desktop Fused Deposition Modeling

(FDM) 3D printer MakerBot Replicator 2X and

polylactic acid (PLA). This device (Figure 1)

features an open channel housing a screen-printed

electrode array insert powered by a supercapacitor

for ECL generation detected by a CCD camera

(Kadimisetty, et al, 2016). The main array unit has

three 170 µL reagent reservoirs with sealing caps

connected to a common downstream microfluidic

channel (Figure 1). Solutions in the reservoirs flow

into and fill the 160 µL detection channel under

hydrostatic pressure. Initially, the insert caps seal the

reservoirs. Flow of sample and reagents commences

by removing the cap to drain the prefilled reservoir

into the detection channel. To run the assay the

operator releases the reagents in sequence by

removing the inserts.

A larger wash reservoir works with a lever-

activated platform that holds the sensor array, wash

reservoirs and waste tank at the bottom (Figure 1B).

Wash reservoirs also employ custom fit inserts to

turn flow on and off. Changing the lever to wash

position tilts the sensor array 25º to wash unused

immunoreagents to waste.

The sensors in the array have antibodies

attached to them to capture the protein analytes from

the sample. Assays proceed by allowing sample to

fill the detection chamber for an incubation period in

which antibodies capture the analytes, then

sequential washing, adding 100 nm RuBPY-silica-

antibody detection nanoparticles, washing, and

incubating. At this point the RuBPY-silica-antibody

particles have bound onto the sensors sites that have

previously bound analyte proteins in a sandwich

immunoassay. Finally TPrA co-reactant is added to

fill the detection channel and 1.2 V is applied by the

supercapacitor for 30 s. ECL light is initiated from

RuBPY in the silica nanoparticles by

electrochemical oxidation with TPrA co-reactant,

and light is detected by a CCD camera. The

supercapacitor is recharged using a small solar panel

and a cell phone light.

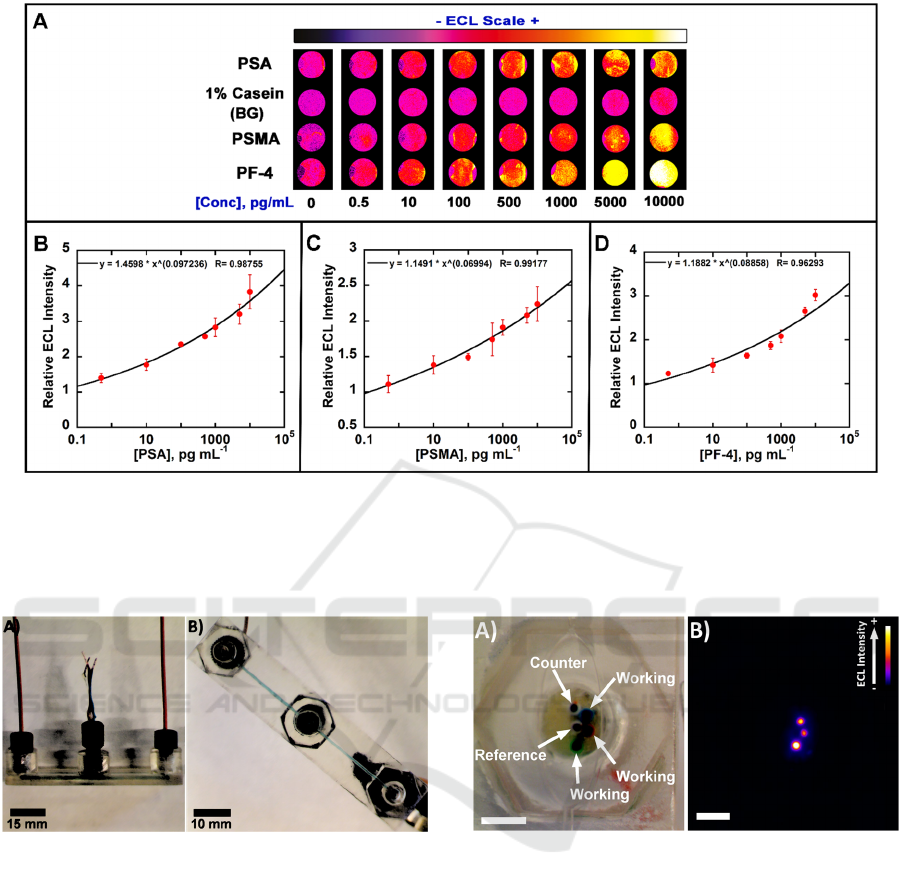

This immunoarray was tested by detecting three

prostate cancer biomarker proteins in serum. The

proteins were prostate specific antigen (PSA),

prostate specific membrane antigen (PSMA) and

platelet factor-4 (PF-4), and assays were completed

in 35 min. Detection limits of 0.3-0.5 pg mL

-1

for the

3 proteins in undiluted calf serum were found, and

the dynamic range is consistent with the levels of

these proteins in blood of cancer patients and

cancer-free individuals. Assays of 6 prostate cancer

patient serum samples gave good correlation with

conventional single protein immunoassays

(Kadimisetty, et al., 2016). Results suggest

successful 3D-printing of major components of a

very low cost portable immunoarray device (€0.90

in materials) with replaceable single-use electrode

array (€0.20 in materials) for sensitive, accurate

detection of proteins in biological samples. Assays

cost ~€0.50 each in expendable reagents. Power is

supplied by a portable Cellergy, 2.1 V, 80 mF

supercapacitor (€10) with a Sparkfun, 0.45 W, 94

mA solar panel (€12) for recharging. The entire

immunoarray with power supply costs ~€25, not

including the CCD camera. A drawback for point-

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

18

Figure 1: 3D-printed main array and wash reservoir module. (A) Basic array showing three reagent reservoirs equipped with

inserts along with flow path for reagents to reach microfluidic channel. (B) Wash reservoir module (1B Left) 3D model

showing freely moving lever to change between wash and load position along with wash reservoirs aligned with main array,

(1B Right) assembled immunoarray setup with both main array and wash module.

of-care (POC) applications is the lack of automation.

Nevertheless, this prototype suggests that 3D-

printing will be amenable to more sophisticated

immunoarray devices that can be automated

(Kadimisetty, et al., 2015).

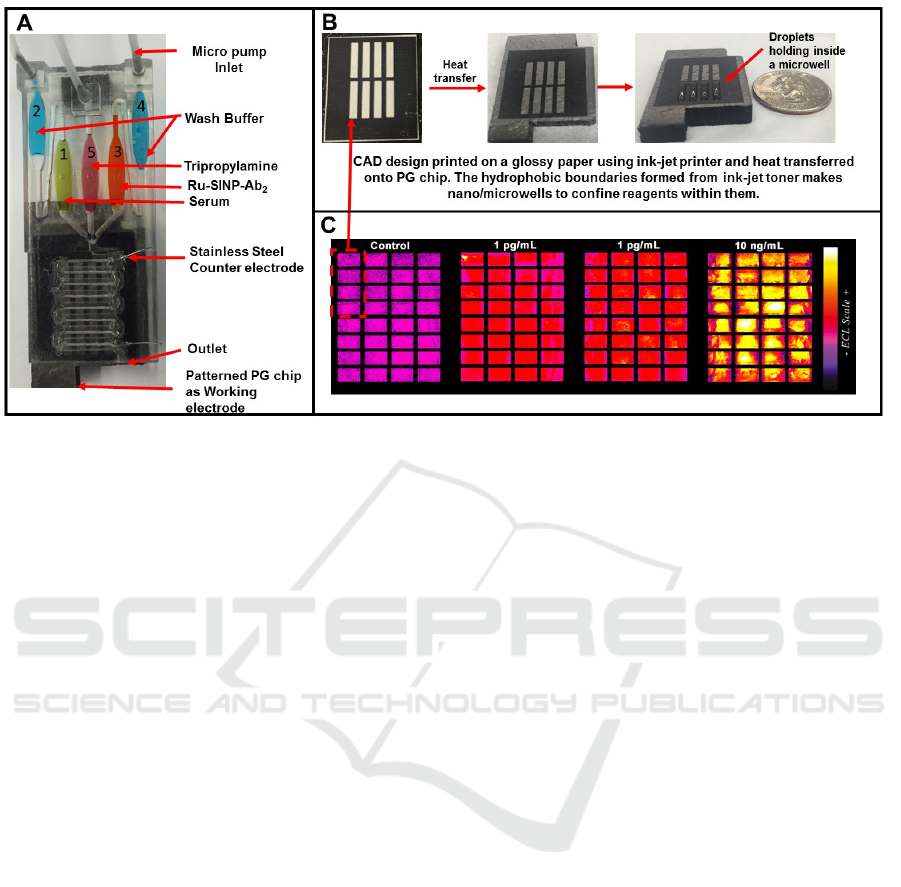

2.2 Transparent 3D-Printed Devices

for ECL Detection

FDM printers produce opaque finishes unsuitable for

a closed optical detection chamber. Thus, we

designed and printed a prototype ECL sensor device

using a Form1+ 3D printer (Formlabs) and clear

methacrylate-based resin (Bishop, et al., 2015).

Uncured resin was removed by forcing isopropanol

through the device channels and then submerging in

isopropanol for 10 s. The device was polished using

abrasive papers, rinsed with water and dried, then

spray-coated with clear acrylic (Krylon, Cleveland,

OH) to achieve high clarity. Flow devices were

designed with 800 µm diam. channels featuring an

oval opening and screw-in inlet and outlet lines to

introduce solutions (Figure 3).

We first ascertained that the electrochemical cell

in this device gave theoretical voltammetry for

standard redox couples that was not influenced by

location in the flow channel. We then did simple

experiments to demonstrate ECL detection on

working electrodes through the clear plastic cell

windows. Oxidation of TPA leads to the formation

of cation radicals (TPA

●+

) and free radicals (TPA

●

)

that react with soluble [Ru(bpy)

3

]

2+

(as well as the

RuBPY-silica in the earlier example) to generate

electronically excited [Ru(bpy)

3

]

2+

* that emits ECL

light at 610 nm. The 3D-printed channel with

integrated electrodes was placed under a CCD

camera housed in a lightproof box to measure ECL

(Figure 4). At potential +0.95 V vs. Ag/AgCl,

images for 10 min exposure time were clearly

visible. Increasing concentrations of the

[Ru(bpy)

3

]

2+

in the reaction mixture gave increased

ECL. This simple device and experiments

established the technology to design and 3D print

ECL based biosensor arrays.

2.3 Prototype Automated 3D-Printed

ECL Immunoarray

We then developed a 3D printed array with

automated microprocessor controlled sample and

reagent delivery. Using the Form 1+ 3D printer we

printed a unibody optically clear ECL microfluidic

array (Figure 5A) with 5 reagent reservoirs leading

into a common microfluidic serpentine channel. The

channel addresses an underlying 32-microwell array

filled with upright single-wall carbon nanotubes

with attached antibodies for simultaneous detection

of multiple proteins (Figure 5B). The device is 6.5 x

3.0 x 0.5 mm (L x W x H) and takes 1.5 hours to

print at €1.2 per array. The maximum volume of

reagent chambers is ~150 µL and total volume of the

serpentine channel ~140 µL. Three micropumps are

connected to the 3 inlets of the array to pump sample

and reagents sequentially from the 5 chambers

(Figure 5A) to the detection channel to complete a

sandwich immunoassay. Complete automation is

achieved by programing micropumps with an

Arduino microcontroller to run the assay protocol.

The serpentine channel is 3D printed to be open on

one side with dimensions 1.2 x 0.15 cm L x W, and

350 µm thick. A tiny groove inside the channel

houses a stainless steel wire to serve as a counter

Low Cost 3D-Printed Biosensor Arrays for Protein-based Cancer Diagnostics based on Electrochemiluminescence

19

Figure 2: Calibration data from the 3D printed gravity fed immunoarray for 3 proteins in undiluted calf serum showing

influence of biomarker protein concentration on ECL response: (A) Recolorized ECL images of 8 arrays with showing

increase in ECL intensity with increased concentration. ECL signals digitized for (B) PSA, (C) PSMA and (D) PF-4 in calf

serum. Error bars show standard deviation for n = 4. Reprinted with permission from Kadimisetty, K., et al., 2016,

Copyright Elsevier 2016.

Figure 3: Clear 3D-printed fluidic device with

incorporated electrodes for ECL detection. A) Side view

equipped with threaded nuts and tubing for inlet/outlet

access to the 730 µm fluidic channel and a threaded nut in

the center through which Ag/AgCl reference and graphite

working and counter electrodes are integrated. B) Bottom

view of device, with electrodes on right. Reprinted with

permission from Bishop, G.W. et al., 2016, Copyright

Amer. Chem. Soc. 2016.

electrode. A pyrolytic graphite wafer was patterned

with microwells using an inkjet printer (Figure 1B)

as the working electrode to produce ECL. This wafer

was attached to the open side of the serpentine

channel using high tact silicone spray adhesive. The

resulting chip defines 32 microwells with 4 spots per

turn of the serpentine channel.

Prior to attaching the processed PG chip to the

array, upright single wall carbon nanotube forests

Figure 4: Photographs of 3-working electrode array

incorporated into the 3D-printed channel in figure 3. A)

Bottom view of 0.5 mm Ag/AgCl reference, 0.5 mm

graphite counter and three graphite working electrodes; B)

ECL response from electrode array in 180 µM

[Ru(bpy)

3

]

2+

in 0.2 M phosphate buffer with 100 mM

TPrA. Scale bars represent 3 mm. Reprinted with

permission from Bishop, G.W. et al., 2016, Copyright

Amer. Chem. Soc. 2016.

were grown in each microwell, followed by

chemically linking capture antibodies (Ab

1

) to the

carboxylated nanotube ends (Kadimisetty, et al.,

2015). This Ab

1

coated surface is then exposed to

incoming proteins in serum pumped by micropump

1 from chamber 1 during the assay (Figure 5A).

Then pumping stops for a 15 min incubation

followed by pumping wash buffer from chamber 2.

Later micropump 2 is initiated by the program to

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

20

Figure 5: Prototype 3D printed automated immunoarray and proof-of-concept data: (A) Full array with reagent, sample and

buffer reservoirs, and serpentine channel covering a series of microwells for ECL generation; (B) the process of forming

microwells on the pyrolytic graphite wafer; (C) recolorized 4-array illustration of detection of prostate specific antigen in

serum at 0, 1 and 10 pg/mL PSA concentrations.

pump the 100 nm RuBPY-SiNP-Ab

2

detection beads

from chamber 3 to the array with captured proteins.

RuBPY-SiNP-Ab

2

are then incubated for 15 min,

followed by washing unused label particles using

wash buffer from chamber 4 to complete the Ab

1

-

protein-Ab

2

sandwich on the sensors. Then, the ECL

generating reagent (350 mM tripropylamine (TrPA)

with 0.05% Tween-20 (T20) and 0.05% Triton-X in

0.2 M phosphate buffer) is pumped into the

detection chamber from chamber 5. ECL is then

generated using a tiny Cellergy supercapacitor

applying 1.5 V for 120 s with light captured by a

CCD camera in a dark box.

Proof-of-concept experiments on this array

showed moderate reproducibility with RSD’s ≤ 17

% from spot-to-spot (n=32) and array-to-array ≤13

% (Figure 1C). Protocol and printing optimizations

are currently underway to improve these RSDs, and

to enable reliable multiplexing. Nevertheless, these

experiments establish that the automated 3D-printed

device can be used for relatively sensitive protein

detection. The entire immunoarray was built for

~€250 with three micropumps (€200), an Arduino

microcontroller (€30), a supercapacitor (€10) and a

3D printed array including the PG chip (€7). The

3D-printed component cost less that €1 and can be

disisable. The 3D-printed array can be disposable, or

regenerated and reused. The CCD camera is of

course reusable, but we are also exploring cheaper

alternatives.

3 CONCLUSIONS

Our exploratory work described above suggests that

low cost 3D printers provide excellent tools to build

the molecular diagnostic devices of the future. First,

we have fabricated a viable 3D-printed gravity fed

immunoarray to detect 3 proteins with better

detection limits that most commercially available

protein assays. Second, we have developed a

approach capable of fabricating closed microfluidic

devices that can measure ECL, and realized a

prototype automated 3D-printed immunoarray

capable of low concentration protein detection.

Future applications of the latter device are planned

for sensitive detection of 10 proteins in serum.

Universal protein-centered cancer diagnostics

promises to decrease overall cancer mortality by

earlier detection and molecular therapy monitoring

leading to better patient prognoses (Hanash, et al.,

2011, Rusling, et. al. 2010). However, widespread

translation of these technologies into the clinic will

require cheap, reliable, sensitive, automated

multiplexed protein detection devices. As we can

expect further advances in feature resolution and

speed (Tumbleston, J. R., 2015), 3D printing may

grow to become a major approach for fabrication of

bioanalytical measurement devices.

Low Cost 3D-Printed Biosensor Arrays for Protein-based Cancer Diagnostics based on Electrochemiluminescence

21

ACKNOWLEDGEMENTS

This work was supported financially by grants No.

EB016707 and EB014586 from the US National

Institute of Biomedical Imaging and Bioengineering

(NIBIB), NIH.

REFERENCES

Bishop, G. W., et al., 2015. 3D-Printed Fluidic Devices for

Nanoparticle Preparation and Flow-Injection

Amperometry Using Integrated Prussian Blue

Nanoparticle-Modified Electrodes, Anal. Chem. 87,

5437-5443.

Bishop, G. W., et al., 2016, Electrochemiluminescence at

Bare and DNA-Coated Graphite Electrodes in 3D-

Printed Fluidic Devices, ACS Sensors, in press.

Coskun, A. F., Wong, J., et al., 2013. A personalized food

allergen testing platform on a cellphone, Lab Chip. 13,

636-640.

Coskun, A. F., Nagi, R., et al. 2013. Albumin testing in

urine using a smart-phone, Lab Chip. 13, 4231-4238.

Erkal, J. L., et al. 2014. 3D printed microfluidic devices

with integrated versatile and reusable electrodes, Lab

Chip. 14, 2023-2032.

Forster, R. J., et al., 2009. Electrogenerated

chemiluminescence, Annu. Rev. Anal. Chem. 2, 359-

385.

Gross, B. C., et al., 2014. Evaluation of 3D printing and its

potential impact on biotechnology and the chemical

sciences, Anal. Chem. 86, 3240-3253.

Hanash, S. M., et al. 2011. Emerging molecular

biomarkers—blood-based strategies to detect and

monitor cancer, Nature Rev. Clin. Oncol. 8, 142–150.

Kadimisetty, K., et al., 2015. Automated Multiplexed ECL

Immunoarrays for Cancer Biomarker Proteins, Anal.

Chem. 87, 4472-4478.

Kadimisetty, K., et al. 2016, 3D-Printed Supercapacitor-

Powered Electrochemiluminescent Protein

Immunoarray, Biosens. Bioelectron., 77, 188–193.

Kohane, I. S. 2015. Ten Things We Have To Do To

Achieve Precision Medicine, Science. 349, 37-38.

Meng, C., et al., 2015. 3D printed microfluidics for

biological applications, Lab on Chip, 15, 3627-3637.

O'Neill, P. F., et al. 2014. Advances in three-dimensional

rapid prototyping of microfluidic devices for

biological applications. Biomicrofluidics 8, 052112.

Roda, A., et al., 2014. Integrating Biochemiluminescence

Detection on Smartphones: Mobile Chemistry

Platform for Point-of-Need Analysis, Anal. Chem. 86,

7299-7304.

Rusling, J. F., et al., 2010. Measurement of Biomarker

Proteins for Point-of-Care Early Detection and

Monitoring of Cancer, Analyst. 135, 2496-2511.

Su, C., Hsia, S., Sun, Y., 2014. Three-dimensional printed

sample load/inject valves enabling online monitoring

of extracellular calcium and zinc ions in living rat

brains, Anal. Chim. Acta. 838, 58-63.

Tumbleston, J. R., et al., 2015. Continuous liquid interface

production of 3D objects, Science, 347, 1349-1352.

Wei, Q., Nagi, R., et al., 2014. Detection and Spatial

Mapping of Mercury Contamination in Water Samples

Using a Smart-Phone, ACS Nano. 8, 1121-1129.

Wei, Q., Luo, W., et al., 2014. Imaging and Sizing of

Single DNA Molecules on a Mobile Phone, ACS

Nano. 8, 12725-12733.

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

22