Welding Groove Mapping

Implementation and Evaluation of Image Processing Algorithms on Shiny Surfaces

Cristiano Rafael Steffens, Bruno Quaresma Leonardo, Sidnei Carlos da Silva Filho, Valquiria Huttner,

Vagner Santos da Rosa and Silvia Silva da Costa Botelho

Federal University of Rio Grande – FURG, Av. It

´

alia – Carreiros – Km 8, 96203–900, Rio Grande, RS, Brazil

Keywords:

Robotics, Image Processing, Automation, Welding Robot, Multi-exposure Composition.

Abstract:

Electric arc welding is a key process in the heavy steel industries. It is a very complex task that demands a high

degree of control in order to meet the international standards for fusion welding. We propose a Vision-Based

Measurement (VBM) system and evaluate how different algorithms impact the results. The proposed system

joins hardware and software to image the welding plates using a single CMOS camera, run computer vision

algorithms and control the welding equipment. A complete prototype, using a commercial linear welding

robot is presented. The evaluation of the system as a groove mapping equipment, considering different pro-

cessing algorithms combined with noise removal and line segment detection techniques, allows us to define

the appropriated approach for shop floor operation, combining low asymptotic cost and measurement quality.

1 INTRODUCTION

Welding is a fundamental task in the heavy steel in-

dustry. Its automation is required in order to keep

pace with the demanding and competitive market.

The manual welding process affects directly the qual-

ity of the weld - it is very common to have rework

due to bad quality welds (Ang Jr et al., 1999). To exe-

cute GMAW (Gas Metal Arc Welding) tasks, involv-

ing linear steel plates, the welding gun has to perform

a longitudinal movement while following the groove

between the plates that are being welded. Human

operated robots are often used to carry the welding

gun. The control parameters of the welding equip-

ment have to be continuously adjusted during the op-

eration. The parametrization demands constant atten-

tion and skill of the welding professionals exposing

them a harsh and unhealthy conditions.

The overall quality of electric arc welds is highly

dependent on the equipment configuration: voltage,

current, tractor speed, torch positioning, wire feeding

speed and torch weaving, among other parameters.

When not properly adjusted, this may result in plate

warping, weld spatter, weld slags and fume. Provid-

ing a higher level of control for the process is a way

to improve the weld quality and avoid rework. It is

necessary to implement a system capable of finding

the best parameters settings for each welding opera-

tion and automate the most critical parts of the pro-

cess. This can be achieved using algorithmic tech-

niques making the welding process less dependent of

the human interaction. In order to achieve this, dif-

ferent techniques can be used depending on the avail-

able hardware - sensor and data acquisition system -

and cost. We can highlight three main approaches. A

combination of structured illumination laser and cam-

era, as used in (Kawahara, 1983), (Drews et al., 1986),

(Liu, 2010), (Zhang et al., 2014) and (De Xu, 2004);

a touch sensor based approach as in (Kim and Na,

2000) or, a last case, where the arc current feedback

is explored, as in (Dilthey and Gollnick, 1998) and

(Halmøy, 1999).

The technology has led to a scenario where it is

possible to use automated robotic systems to optimize

tasks and achieve higher efficiency, productivity and

quality, as well as reduce operational costs and re-

work. Furthermore, the use of robots is recommended

for tasks that are taken in hazardous environment or

characterize as laborious and repetitive.

Moreover, the advances in both hardware and soft-

ware technologies enable the development of cheaper,

faster, higher quality and smaller cameras and elec-

tronic devices. Therefore, vision based methods have

become a viable option, combining image acquisition

with an operations unit, where algorithms are used to

extract useful information. (Shirmohammadi and Fer-

326

Steffens, C., Leonardo, B., Filho, S., Huttner, V., Rosa, V. and Botelho, S.

Welding Groove Mapping - Implementation and Evaluation of Image Processing Algorithms on Shiny Surfaces.

DOI: 10.5220/0005709103240332

In Proceedings of the 11th Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2016) - Volume 3: VISAPP, pages 326-334

ISBN: 978-989-758-175-5

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

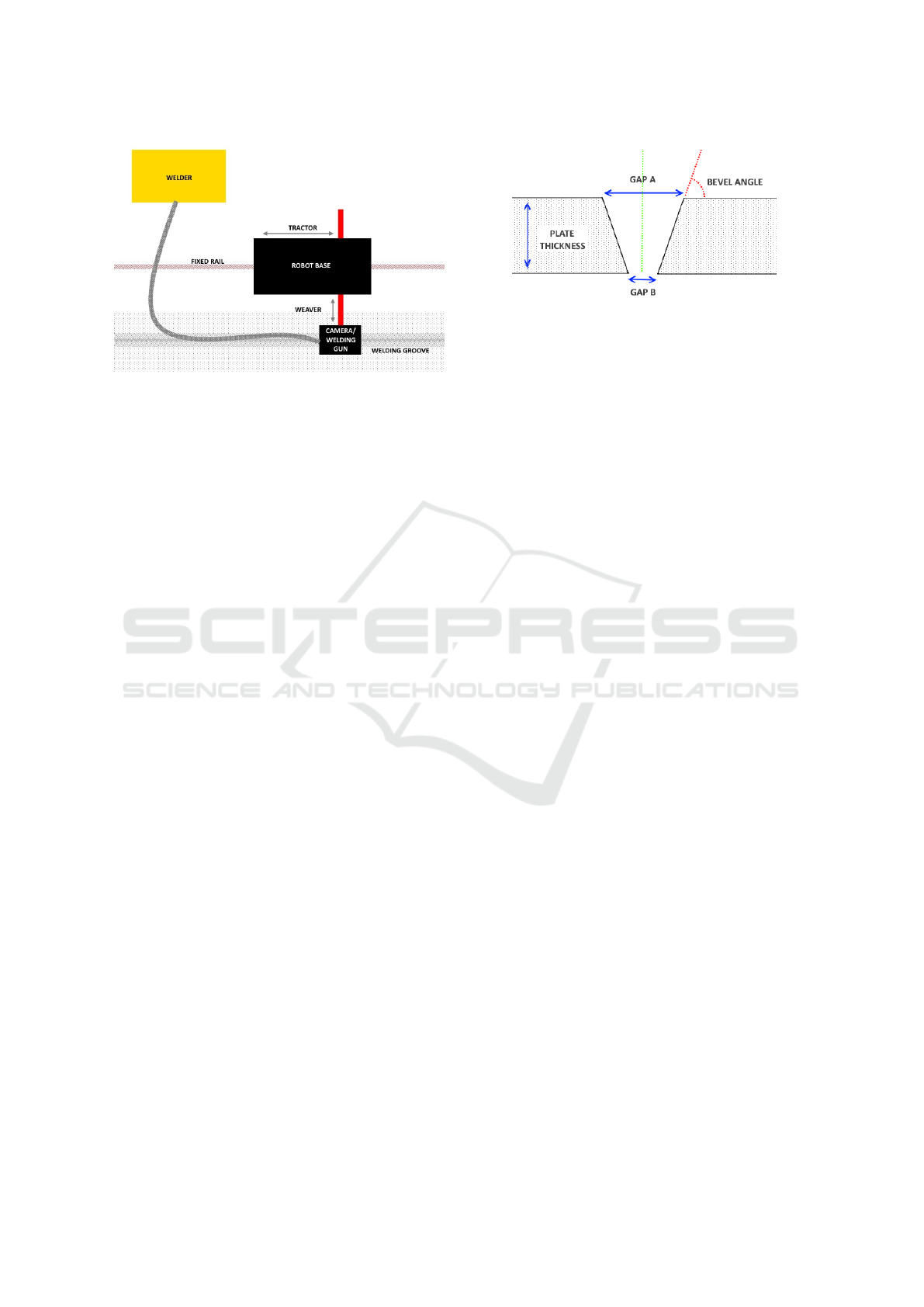

Figure 1: Typical linear welding robot installation.

rero, 2014) argues that, besides the level of automa-

tion, Vision-Based Measurement (VBM) is typically

faster and more accurate than manual or human based

techniques, once it uses electronic devices and com-

putational intelligence.

Imaging a metallic surface, however, is a chal-

lenge. This paper proposes a VBM system to recog-

nize the groove geometry for a robotic welding pro-

cess. Hardware and software are combined to map

the welding groove geometry providing the neces-

sary data to adjust the control settings of the weld-

ing equipment. A number of alternatives is tested

to evaluate the capabilities and impacts of each algo-

rithm choice. Multi-exposure composition is consid-

ered as an alternative to obtain non-saturated images

of the shiny and reflective surface. The system is im-

plemented on top of a Bug-O Matic Weaver welding

robot, manufactured by Bug-O Systems International,

using an Altera DE0-Nano FPGA board and a Terasic

D5M 5 megapixel camera.

2 LINEAR WELDING

ARCHITECTURE

Figure 1 presents a typical setup used on linear weld-

ing of thick steel plates employing a welding robot to

carry the welding gun. The robot runs on a rail that is

fixed to the floor or any other plane surface. The rail

is usually parallel to the welding groove that is be-

ing welded. The welding equipment is neither a part

nor is it dragged by the robot. In a typical scenario,

the robot is solely used to drag the welding gun with

controlled speed an weaving.

Depending on the groove properties (see Figure

2), the weaver and tractor are combined to produce

different weld patterns (a.k.a Oscillation Regime):

• Continuous: the robot travels continuously over

the rail both during weave and dwell;

Figure 2: Welding groove properties.

• Step: the robot travels only during dwell, and

stops during the Weaver cross stroke;

• Tractor Stop on Dwell: robot travels on the rail

during weave stroke. Tractor and Weaver stop

during dwell;

• Line or Stringer Bead: weaver is turned off;

In our approach, a lighting system and camera

equipment are attached to the welding gun mounting

point. The robot control is mapped and modified to

enable an automated control of the tractor and weaver,

allowing us to adjust the camera position while the

robot travels over the entire rail, and thus map the

welding groove properties.

3 A VISION BASED APPROACH

FOR WELDING GROOVE

MEASUREMENT

A VBM system usually consists of a visual sensor

plus operations unit (Figure 3 gives an overview of

the VBM system). The visual sensor can be a cam-

era, laser scanner, x-ray scanner, or any other sensor

which an image of the physical scene containing the

measurand can be obtained, and the operations unit

can be implemented in software or hardware (Shir-

mohammadi and Ferrero, 2014).

3.1 Image Aquisition

Figure 4 gives an overview on the proposed image

acquisition setup. Proper choice of lighting, camera

and lens are keys to any successful VBM system de-

sign. For our application, they become even more im-

portant once the steel or iron plates can present both

specular and diffuse reflection and the amount of light

that is reflected is also highly affected by the plate

oxidation or dust. Therefore, a lighting system has

been designed to enhance the groove properties. It

uses an arrangement of LEDs (Light-Emitting Diode)

positioned beside the camera.

Welding Groove Mapping - Implementation and Evaluation of Image Processing Algorithms on Shiny Surfaces

327

Figure 3: High-level architecture of a Vision-Based Measurement system.

Figure 4: Image Acquisition setup.

On a pinhole camera, assuming that a fixed work-

ing distance will be ensured on the setup steps, the

Horizontal Field of View is given by Eq. 1, where

W D is the distance from the lens front principal plane

to the object plane and AFOV is the Angular Field of

View of the lens.

HFOV [mm] = 2 ·WD ·tan

AFOV [

◦

]

2

(1)

The lens experiences greater magnification as the

object distance from the lens changes. Since the top

and bottom faces of the welding plate have a different

W D the pixel to metric unit conversion has to consider

that difference when computing the groove width and

bevel angle. The scale factor S is given by Eq. 2,

where d

ob ject

is the physical dimension of a given ob-

ject in millimeters and d

image

is the size of the corre-

spondent object on the image in pixels.

S[mm/pixel] =

d

ob ject

d

image

(2)

Raw data is obtained from the Bayer-filter CMOS

sensor and converted to a grayscale image. Metallic

surfaces introduce some difficulties that are not yet

resolved in the literature. They differ from standard

rigid structured, non-reflective surfaces that computer

vision usually deals with. Slight changes on the illu-

mination, camera movement, parent material oxida-

tion or dust often produce extreme differences in radi-

ance values that are impossible to capture without ei-

ther under-exposing or saturating the sensor. Standard

image processing operations expect pixel values to be

proportional to the scene radiance. Due to nonlinear

image response these operations often produce incor-

rect results for conventional images. Therefore, from

this point, taking advantage of the low level control

provided by the customised hardware, we have tested

two different alternatives for the image acquisition.

1. Single frame capture using fixed exposure time:

a exposure time that is at the center of the range

the camera supports is used. It provides reason-

able visibility of the details in the scene for most

cases. The image is normalized and the histogram

is equalized.

2. Multi-exposure image composition: The exposure

time is controlled to obtain k images of the exact

same place. Multi-exposure composition, as pro-

posed in (Debevec and Malik, 2008), is used to

obtain a High Dynamic Range (HDR) image. The

HDR image is latter normalized to a 2

8

range, so it

can be used as input on standard image processing

techniques as they are implemented in OpenCV

3.0. On the same hand, normalizing the pixel val-

ues to a lower range also works as a low pass filter,

removing noisy pixels.

3.2 Operations Unit

The proposed system uses image processing and ma-

chine vision to detect the welding groove’s proper-

ties. The groove is modeled as a set of almost parallel

lines on the image. As the system is implemented in

hardware, the algorithms must be carefully selected to

maximize the accuracy and performance levels.

3.2.1 Noise Removal

We apply a gaussian unsharp mask to enhance the

high frequency regions present at the groove edges.

VISAPP 2016 - International Conference on Computer Vision Theory and Applications

328

(a) HDR Input images

(b) Single Exposure (c) HDR composition

(d) Line Segment detection (e) Final groove modeling

Figure 5: Processing in the VBM system.

While it improves the overall contrast, it also accen-

tuates the small failures and aberrations that are al-

ready on the captured image. Therefore, a noise re-

moval step is necessary. For the noise removal step

test three filters: a mean box filter, a median filter and

a gaussian filter. Gaussian and mean filters have a lin-

ear computational complexity, but both of them work

as low-pass filters, which might be a drawback given

that edges perform an important rule on the groove

detection. The classic median filter has a O(nlog(n))

complexity, once, by definition it requires the pixels

in the neighbourhood to be ordered by their value.

Optimized approaches, as presented in (Perreault and

H

´

ebert, 2007), can bring it down to O(n).

3.2.2 Straight Line Detection

The camera position is orthogonal to the observed sur-

face. Once the image is preprocessed we can now

work on the line detection to determine the groove

properties. Among previous approaches that focus

on standardized computer vision algorithms, such as

(Ma et al., 2010), (Hou and Liu, 2012) and (Xu et al.,

2012), the combination of a Canny edge detector and

a Hough transform is the most recurrent alternative.

In order to identify the straight lines the Hough trans-

form associates to each pixel on a input image, in a

polar geometry space, to the bundle of lines passing

through it.

However, as we intend to implement the ma-

chine vision step on a low cost equipment with real-

time performance, we have to consider the algorithms

complexity and use a solution that maximizes the

asymptotic cost/ output quality ratio. Although it is

non-deterministic, it has been evidenced in (Risse,

1989) and latter in (Hollitt, 2009) that the computa-

tional cost of the Canny edge detection plus the cost of

the classical Hough line transform can be over O(n

4

),

where n is the number of pixels in the analysed im-

age. Using some simplification steps, authors were

able to reduce the complexity down to O(n

3

log n)

(Hollitt, 2009), which we believe is still not appro-

priated for the system restrictions. Besides its com-

plexity, the Canny edge detector also depends on pre-

defined threshold values. Therefore, four alternative

algorithms were evaluated:

• PPHT – Progressive Probabilistic Hough Trans-

form for Line Detection (Galamhos et al., 1999):

It is non-deterministic like the standard Hough

transform itself. Considering its enhanced voting

scheme we tested it expecting it to be less suscep-

tible to random noise.

• Fast LSD (Von Gioi et al., 2012): LSD works

with gray scale images detecting lines formed by

edges. The LSD was designed with the intention

of not requiring parameters adjustment. It has a

O(nlog(n)) asymptotic complexity.

• EDLines (Akinlar and Topal, 2011): It is parame-

terless and has a O(nlog(n)) asymptotic complex-

ity. It works upon the Edge Drawing algorithm

(Topal et al., 2010) that uses Sobel gradient filters

to replace the classic Canny filters.

• LSWMS – Line Segment Detection Using

Weighted Mean Shift (Nieto et al., 2011): De-

signed to detect line segments in real-time appli-

cations, the algorithm has a O(n) complexity. Au-

thors agree it generates noisy results, but recom-

mend it for application like vanishing point de-

tection because it provided enough accuracy and

great speed.

3.2.3 Heuristics

Once we know the possible groove edges, a greedy

Non-Maximum Suppression algorithm is used to sep-

arate false positives and negatives that still remain

after the image processing. To determine the point

that better represents the groove edges on the image,

Welding Groove Mapping - Implementation and Evaluation of Image Processing Algorithms on Shiny Surfaces

329

the endpoints of the line segments are interpolated

and combined to form a histogram of the aggregated

values in the image row axis. Using the application

domain information we can establish some threshold

values to filter the outputs of the vision algorithms.

For instance, it is known the steel plates thickness

can vary from 13mm up to 20mm and groove an-

gle can vary within 45-55

◦

. Also a restriction of the

application domain, the Gap B, on the plate bottom,

has to be something between 3mm and 9mm. Pixel

to millimeter conversion and world position associa-

tion achieved via encoder based dead-reckoning com-

plete the mapping, supporting the decision making

and welding equipment actuation.

4 IMPLEMENTATION

The VBM system has been implemented as a mod-

ule to replace the original Control Unit of the BUG-O

modular system. The digital system features a FPGA

based hardware/software architecture. The main goal

of using a FPGA system instead of a standard com-

puter is the customization level and integration of the

hardware/software solution that can be obtained. The

DE0-Nano board, manufactured by Altera Corpora-

tion, was chosen due to their low cost, high number of

logic cells and digital I/O pin count, integrated flash

memory, RAM, and 12-bit A/D conversion. Further-

more the DE0-Nano is pinout compatible with the

D5M camera module, simplifying the electronic de-

sign. The electronic interfaces were developed using

low cost off-the-shelf integrated and discrete compo-

nents for signal conditioning.

Both the image acquisition system and the weld-

ing torch are mounted on the end-effector of the robot.

A Terasic D5M camera is used for image acquisi-

tion. It features a single package containing sensor

and lens. Table 1 shows its specification considering

a full resolution image capture according to the manu-

facturer. Once we crop the image for our application,

the angular field of view is reduced in the same ratio.

A LED illumination circuit has been created to

provide an adequate homogeneous illumination and

minimize the influence caused by changes of ambient

light. For the image acquisition a CMOS camera has

been used. The operations unit, as well as the light

control and image acquisition, is implemented on the

FPGA development board , which is responsible for

receiving the image acquired by the visual sensor, per-

forming the image processing and the adjustment of

the robot’s and welder’s parameters in real time.

The raw data acquisition and basic image process-

ing are performed on the FPGA board taking advan-

Table 1: Terasic D5M Sensor and Optics Specification.

Specification Value

Sensor Active Array Size 2592 x 1994

Image Size 5.7mm(H) x 4.28mm(V)

Pixel Size 2.2µm x 2.2µm

Focal Lenght 7.12mm

Fixed Aperture F/3.25 (± 5%)

Angular Field Of View 55

◦

Relative Illumination ≥ 65.0%

Barrel Distortion ≤ 1.0%

tage of the embedded Altera’s Nios

r

II processor.

A SDRAM memory is used to create a frame buffer.

The image is sent, without compression, to a standard

PC via Universal Asynchronous Receiver/Transmitter

(UART) and a USB FTDI breakout port. Camera

and robot control instructions are sent via Modbus

RTU serial communication protocol with 921600 of

baudrate. Noise suppression and straight line detec-

tion steps are executed on a C++ OpenCv version

3.0 based software. We use the code made avail-

able by the authors for the LSWMS algorithm and

Fast LSD. The EDLines algorithms is implemented

“in house” since the authors do not make it publicly

available. Non-maximum suppression and heuristics

are used to identify the welding groove parameters.

The processed data is then used to control the robot

and welder.

The system is integrated with a reliable and widely

accepted industrial robot. Encoders are used as

odometer sensors (dead reckoning) of the tractor and

weaver arm. The data is decoded using an 8-bit

quadrature decoder module designed in VHDL. Both

tractor and weaver speed setpoints are calculated us-

ing a ∆Σ module with 12 bit resolution.

A Lincoln Electric Flextec

TM

450 Multi-Process

Welder is used. It is able to perform stick, DC TIG,

MIG, Flux-Cored, Arc Gouging welds. For our appli-

cation, the original user interface is replaced to use

the digital input provided by the VBM system. A

sample of the relationship between the grove geom-

etry and the equipment controls is shown in Table 2.

These settings have been carefully defined by weld-

ing specialists at Mitsubishi Heavy Industries. The

oscillation regime defines the behaviour of the pendu-

lum extension and the weaving amplitude. Depending

on the groove properties it can require up to 4 layers

of weld. Electrode diameter, electrode extension and

gun position are predefined by the welder. The os-

cillation regime (OR) is a preset that combines the

robot’s tractor and weaver, with a specific speed and

distance, to result in different weld patterns.

An overview of the digital control system is shown

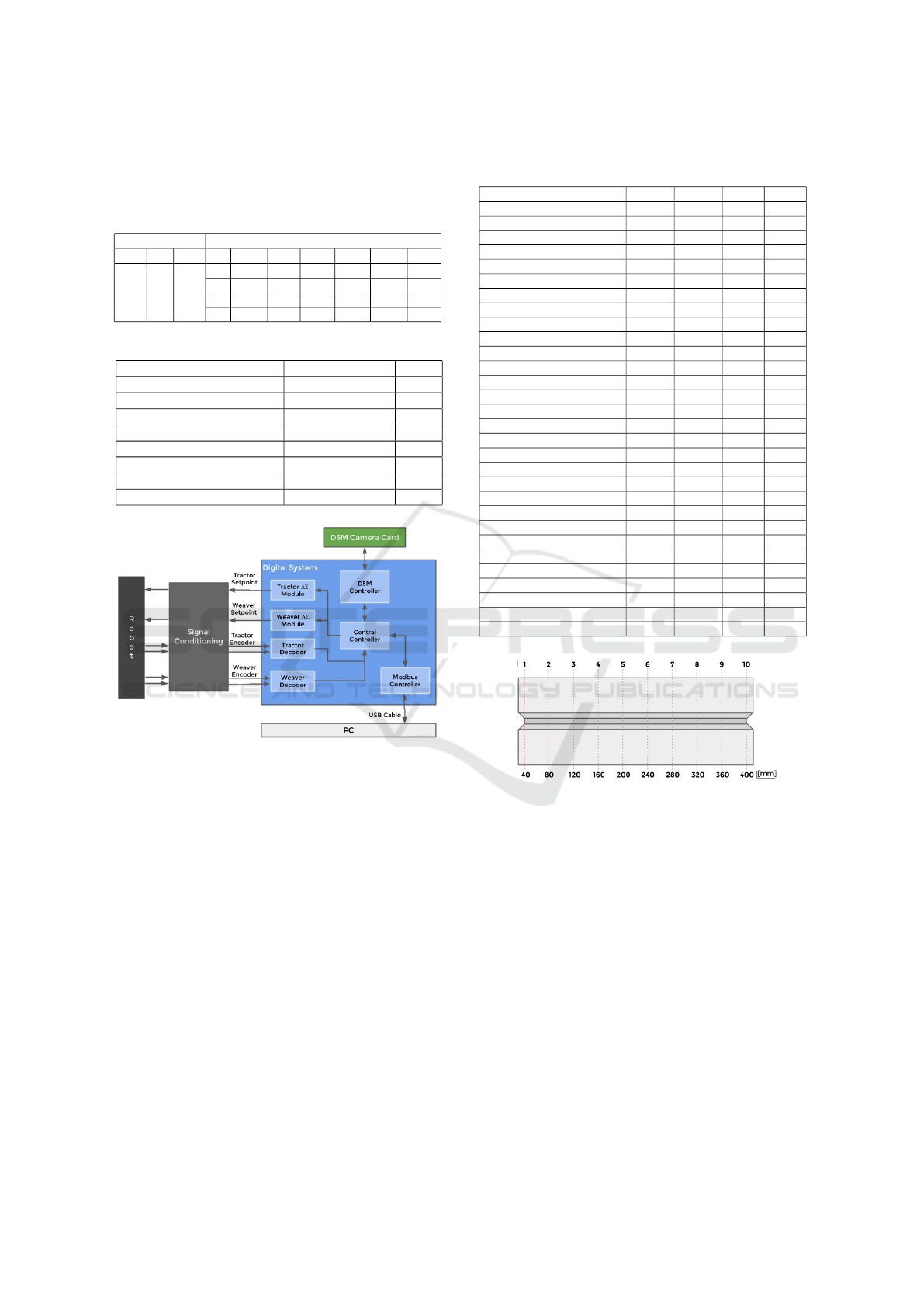

in Figure 6. The central controller is the main unit in

the system. All the tasks involving the control and

VISAPP 2016 - International Conference on Computer Vision Theory and Applications

330

Table 2: Sample of the geometry to welder control mapping.

Legend: PT – Plate Thickness [mm]; G – Gap B; B

o

– Bevel

Angle [

o

]; WS – Weld Speed [mm/min]; TS – Tractor Speed

[%]; LH – Layer Height [mm]; OR – Oscillation regime;

WF – Wire Feed Speed [m/min]; A – Current [A].

Groove Prop. Equipment Settings

PT G B

o

L WS TS LH OR WF A

13 3 45

1 450 64 3 a 14 6.2

2 340 49 5 a 14 6.2

3 330 75 3 b 14 6.2

4 320 75 3 b 14 6.2

Table 3: Compilation report.

Specification Description Used

FPGA Device EP4CE22F17C6 –

Total Logic Elements 5.916 27%

Combinational Functions 5.380 24%

Dedicated logic registers 3.152 14%

FPGA PLLs 1/4 24%

I/O pins (external) 96 62%

Embedded Multiplier 9-bit 0 0%

Total memory bits 42.992 7%

Figure 6: Overview of Digital Control System.

parametrization of the camera, sending or receiving

data via modbus and ∆Σ module are controlled in this

component. The execution order is to read all the

data signals from the decoders and read any message

driven from the modbus component, based on that

take actions such as start or stop the camera acquisi-

tion or move the robot using the tractor or weaver ∆Σ

module. The project is designed in Altera’s develop-

ment platform tool Quartus II. The compilation report

presented in Table 3, showing the relative occupation

of its resources.

5 EXPERIMENT RESULTS

The proposed VBM system is evaluated as a mea-

suring equipment considering both measurement er-

ror and measurement uncertainty. According to the

GUM (BIPM et al., 2008), the purpose of a measure-

Table 4: Measurement Evaluation. Values in millimeters.

Lower error and standard deviation is better.

¯

E A σ A

¯

E B σ B

Gauss + EDLines 0.407 0.370 1.071 0.407

Mean + EDLines 0.340 0.383 0.961 0.739

Median + EDLines 0.344 0.290 1.002 0.505

Gauss + LSWMS 1.204 2.197 0.933 0.797

Mean + LSWMS 0.367 0.389 0.842 1.134

Median + LSWMS 1.548 2.640 1.066 1.123

Gauss + PPHT 12.053 10.312 4.506 2.657

Mean + PPHT 0.424 0.392 1.225 0.417

Median + PPHT 3.267 6.380 1.559 1.304

Gauss + Hough 19.916 0.000 6.558 0.000

Mean + Hough 17.963 6.176 5.976 1.838

Median + Hough 16.001 8.470 5.429 2.391

Gauss + LSD 0.143 0.084 0.780 0.157

Mean + LSD 0.306 0.298 0.902 0.380

Median + LSD 0.241 0.257 1.056 0.442

HDR + Gauss + EDLines 1.110 2.249 1.327 0.670

HDR + Mean + EDLines 0.359 0.399 0.731 0.505

HDR + Median + EDLines 0.254 0.190 0.912 1.188

HDR + Gauss + LSWMS 1.586 2.406 0.678 0.680

HDR + Mean + LSWMS 1.119 1.945 0.970 0.772

HDR + Median + LSWMS 1.511 2.299 0.912 0.800

HDR + Gauss + PPHT 19.916 0.000 6.558 0.000

HDR + Mean + PPHT 0.242 0.112 0.763 0.296

HDR + Median + PPHT 0.294 0.228 1.054 0.780

HDR + Gauss + Hough 19.916 0.000 6.558 0.000

HDR + Mean + Hough 17.920 6.327 5.908 2.054

HDR + Median + Hough 10.107 10.346 3.618 3.105

HDR + Gauss + LSD 0.358 0.388 0.985 0.420

HDR + Mean + LSD 0.364 0.355 0.697 0.477

HDR + Median + LSD 0.345 0.302 0.782 0.485

Figure 7: Groove unit separation in 40mm each.

ment is to determine the value of the measurand, i.e.,

the value of the particular quantity to be measured.

A complete measurement is taken by an appropriate

specification of the measurand, the method of mea-

surement, and the measurement procedure. Gener-

ally, the result of a measurement is only an approx-

imation or estimate of the value of the measurand and

thus is complete only when accompanied by a state-

ment of the uncertainty of that estimate.

The groove is measured using a caliper rule with

three digits decimal precision, at a temperature of 20

◦

Celsius. A 400mm specimen is used to obtain 10

sample points, separated 40mm from each other as

shown in Fig. 7. The robot is programmed to fol-

lows the groove stopping at each sample point. At

each position a image is acquired and processed us-

ing 30 combinations of noise removal filters and line

Welding Groove Mapping - Implementation and Evaluation of Image Processing Algorithms on Shiny Surfaces

331

Figure 8: Average error and standard deviation of the mea-

sured values on the top of the plate (Gap A). Values in mil-

limeters.

segment detection algorithms. The task is completed

after the entire plate is mapped. It is important to note

that the samples 6, 7, 8, and 9 where obtained on a

recently polished part, which consequently presents

more specular reflection.

We used a 5 pixels kernel for all the noise sup-

pression filters. The gaussian filter uses a 0.7 standard

deviation. The Canny minimal an maximal threshold

values are set to 100 and 200 respectively. The Hough

transform uses a L

1

norm. On images were one of the

lines failed to be detected, Gap A and Gap B were

considered as 0. Fig. 8 shows the Gap A (plate top)

values measured by the VBM system for the 10 sam-

ples of the welding plate. Fig. 9 shows the Gap B

(plate bottom) values measured for the same samples.

Table 4 allows us to compare the ground truth with

the VBM system measurements, showing the average

value and distribution. The combination of median

blur and EDLines line segment detection shows the

smallest standard deviation. On the other hand, Gaus-

sian combined with EDLines presents the smallest er-

ror.

Based on the data we can state that, for these sam-

ple points, Fast LSD algorithm provides the best re-

sults. Using any of the noise suppression kernels

its standard deviation is still lower than the other

Figure 9: Average error and standard deviation of the mea-

sured values on the bottom of the plate (Gap B). Values in

millimeters.

tested combinations on both Gap A and Gap B mea-

surements. The next best solutions, which minimize

error and standard deviation are obtained using the

EDLines algorithm. As third position in the rank,

LSWMS also presents a low error, but depending on

the noise suppression choice, its standart deviation

can go over two millimeters.

It is important to note that both classic Hough

Transform and its variant PPHT perform worse than

the others. The combination of Gaussian kernel with

the classic Hough transform fails in all sample points.

Other classic Hough combinations also fail in many

of the processed images. In this sense, PPHT shows

a significant improvement. When combined with the

mean filter, it presents a very low standard deviation,

becoming a suitable option given that systemic error

can be easily compensated. It is important to note that

the Canny thresholds are a user input. Varying them

to get proper edge detection for each test point im-

age would improve the results, but that is not a viable

option when developing an automated solution.

Furthermore, the results also show the HDR com-

position does not significantly increase the output

quality. Although it reduces the standard deviation

in most cases, it increases the average error. That is

a unexpected behaviour, once we could expect the vi-

VISAPP 2016 - International Conference on Computer Vision Theory and Applications

332

sually improved images to perform better due to the

absence of saturated and underexposed regions.

Evaluating the combinations we can also make

some assumptions about the relation within filters and

line detectors. Fast LSD and EDLines are little af-

fected by the kernel choices. In both single exposure

images and multi-exposure composed images, the re-

sults change less than 100 nanometers. LSWMS is af-

fected by the filter type when applied to HDR images.

Hough and PPHT, in the other hand, are highly af-

fected by the filter choice. Using a Gaussian low pass

filter reduces the detection rate, making the detector

fail in all cases. The median filter, also increases error

and variation, making the mean filter the best option.

Finally, the experiment results show that, even

though it is widely used in academic research, the

Hough transform can be replaced by modern, state-

of-the-art algorithms, improving both detection qual-

ity and computational complexity bounds.

6 CONCLUSIONS AND FUTURE

WORK

We present a system that integrates different tech-

niques to perform dimensional measurement of thick

steel plate bevels. We show how, using domain

knowledge, the extracted dimensions can be mapped

in control settings for the robotic welding equipment.

Unlike the previous approaches, it does not rely on

a single moving spot like laser trackers, nor a pat-

tern of spots like optical contact systems, neither a

line like laser scanners. No structured light or polar-

ized lenses are used. The approach is based on image

acquisition and processing making use of computer

vision algorithms. The groove modeling is achieved

through the use of line detection algorithms that look

for straight lines and segments. State-of-the-art al-

gorithms, such as Debevec’s HDR composition, Fast

LSD, PPHT, LSWMS and EDLines were tested on

real data to evaluate their capabilities.

Experimental results demonstrated that, using

carefully selected algorithm combinations, the system

can successfully extract the measurand dimensions.

The proposed approach has evident advantages over

the manual process that is used in shop floor nowa-

days, given that it can yield a large number of fea-

tures in a very short time using state of the art algo-

rithms, is not susceptible to the most frequent mea-

surement error sources and automatically controls the

welding equipment settings. In the same hand, we

also demonstrated obsolete and non-deterministic al-

gorithms could be replaced by state-of-the art alterna-

tives achieving better results at lower computational

cost.

We will be further exploring lighting options,

noise suppression algorithms and image composition

techniques to test how the achieved results can be im-

proved to surpass the precision requirements of the

welding industry. Previous studies have shown the

impact of illumination wavelength on enhancing or

suppressing desired properties on the image surface.

We believe it might also impact the image acquisition

on reflective surfaces. On the same hand, bilateral

filtering and image smoothing via L0 gradient mini-

mization (Xu et al., 2011), which have not been tested

yet due to their computational complexity bounds and

inability to perform in real-time on the proposed hard-

ware architecture, will be included in the compari-

son. Furthermore, Debevec’s multi-exposure image

composition will be compared to other recent ap-

proaches that minimize the computational cost and

are hardware-friendly.

In the long term, machine learning and deep learn-

ing will be used to extract information of the pro-

cess and produce a general purpose welding work-

cell. Therefore it must be able to identify the ma-

terial and it’s conditions; the environment variables

such as wind and humidity and incorporate the knowl-

edge that only experienced weldors today have. Stud-

ies have already been realized to map the main differ-

ences among senior and novice weldors and we intend

to use them to elevate the overall quality of the weld-

ing process.

ACKNOWLEDGEMENTS

This work was supported by National Counsel of

Technological and Scientific Development (CNPq),

Coordination for the Improvement of Higher Educa-

tion Personnel (CAPES) and Funding Authority for

Studies and Projects (FINEP).

REFERENCES

Akinlar, C. and Topal, C. (2011). Edlines: A real-time line

segment detector with a false detection control. Pat-

tern Recognition Letters, 32(13):1633–1642.

Ang Jr, M. H., Lin, W., and Lim, S.-Y. (1999). A

walk-through programmed robot for welding in ship-

yards. Industrial Robot: An International Journal,

26(5):377–388.

BIPM, I., IFCC, I., ISO, I., and IUPAP, O. (2008). Evalua-

tion of measurement data – guide to the expression of

uncertainty in measurement.

De Xu, Min Tan, X. Z. Z. T. (2004). Seam tracking and

visual control for robotic arc welding based on struc-

Welding Groove Mapping - Implementation and Evaluation of Image Processing Algorithms on Shiny Surfaces

333

tured light stereovision. International Journal of Au-

tomation and Computing, 1(1):63.

Debevec, P. E. and Malik, J. (2008). Recovering high dy-

namic range radiance maps from photographs. In

ACM SIGGRAPH 2008 classes, page 31. ACM.

Dilthey, U. and Gollnick, J. (1998). Through the arc sens-

ing in gma-welding with high speed rotating torch. In

Industrial Electronics Society, 1998. IECON’98. Pro-

ceedings of the 24th Annual Conference of the IEEE,

volume 4, pages 2374–2377. IEEE.

Drews, P., Frassek, B., and Willms, K. (1986). Optical

sensor systems for automated arc welding. Robotics,

2(1):31–43.

Galamhos, C., Matas, J., and Kittler, J. (1999). Progres-

sive probabilistic hough transform for line detection.

In Computer Vision and Pattern Recognition, 1999.

IEEE Computer Society Conference on., volume 1,

pages –560 Vol. 1.

Halmøy, E. (1999). Simulation of rotational arc sensing

in gas metal arc welding. Science and Technology of

Welding & Joining, 4(6):347–351.

Hollitt, C. (2009). Reduction of computational com-

plexity of hough transforms using a convolution

approach. In Image and Vision Computing New

Zealand, 2009. IVCNZ’09. 24th International Confer-

ence, pages 373–378. IEEE.

Hou, X. and Liu, H. (2012). Welding image edge detection

and identification research based on canny operator.

In Computer Science & Service System (CSSS), 2012

International Conference on, pages 250–253. IEEE.

Kawahara, M. (1983). Tracking control system using image

sensor for arc welding. Automatica, 19(4):357–363.

Kim, C. H. and Na, S. J. (2000). A study on rotating arc

using hollow shaft motor. Journal of Korean Welding

Society, 18:589–594.

Liu, X. (2010). Image processing in weld seam tracking

with laser vision based on radon transform and fcm

clustering segmentation. ICICTA, pages 470–473.

Ma, H., Wei, S., Sheng, Z., Lin, T., and Chen, S. (2010).

Robot welding seam tracking method based on pas-

sive vision for thin plate closed-gap butt welding.

The International Journal of Advanced Manufactur-

ing Technology, 48(9-12):945–953.

Nieto, M., Cuevas, C., Salgado, L., and Garc

´

ıa, N. (2011).

Line segment detection using weighted mean shift

procedures on a 2d slice sampling strategy. Pattern

Analysis and Applications, 14(2):149–163.

Perreault, S. and H

´

ebert, P. (2007). Median filtering in con-

stant time. Image Processing, IEEE Transactions on,

16(9):2389–2394.

Risse, T. (1989). Hough transform for line recognition:

complexity of evidence accumulation and cluster de-

tection. Computer Vision, Graphics, and Image Pro-

cessing, 46(3):327–345.

Shirmohammadi, S. and Ferrero, A. (2014). Camera as

the instrument: the rising trend of vision based mea-

surement. Instrumentation & Measurement Magazine,

IEEE, 17(3):41–47.

Topal, C., Akınlar, C., and Genc¸, Y. (2010). Edge drawing:

a heuristic approach to robust real-time edge detec-

tion. In Pattern Recognition (ICPR), 2010 20th Inter-

national Conference on, pages 2424–2427. IEEE.

Von Gioi, R. G., Jakubowicz, J., Morel, J.-M., and Randall,

G. (2012). Lsd: a line segment detector. Image Pro-

cessing On Line, 2(3):5.

Xu, L., Lu, C., Xu, Y., and Jia, J. (2011). Image smoothing

via l 0 gradient minimization. In ACM Transactions

on Graphics (TOG), volume 30, page 174. ACM.

Xu, Y., Yu, H., Zhong, J., Lin, T., and Chen, S. (2012).

Real-time seam tracking control technology during

welding robot gtaw process based on passive vision

sensor. Journal of Materials Processing Technology,

212(8):1654–1662.

Zhang, L., Ke, W., Ye, Q., and Jiao, J. (2014). A novel laser

vision sensor for weld line detection on wall-climbing

robot. Optics & Laser Technology, 60:69–79.

VISAPP 2016 - International Conference on Computer Vision Theory and Applications

334