Sensor Array based on Metal Oxide Semiconductors for Detecting

Gas Mixtures and Its Sensing Properties

Byung-Min Kim and Jung-Sik Kim

Department of Materials Science and Engineering, The University of Seoul, Seoul, 130-743, Korea

Keywords: Gas Sensor Array, Gas Mixture, Metal Oxide Semiconducting Materials, MEMS Micro Sensor.

Abstract: Metal oxide semiconductor (MOS) gas sensors are very attractive owing to their low cost simplicity of use,

large number of detectable gases and various potential application fields. However, the MOS gas sensor has

a serious shortcoming of low selectivity in a mixture of gases, In this study MOS micro gas sensors were

fabricated for detecting carbon monoxide (CO), nitrogen oxide (NO

2

), ammonia (NH

3

) and formaldehyde

(HCHO) gases, as well as their binary mixed gas systems. Four sensing materials, Pd-SnO

2

for CO, In

2

O

3

for NO

X

, Ru-WO

3

for NH

3

, and SnO

2

-ZnO for HCHO were synthesized using a sol-gel method and

deposited in the middle of sensor platform. The micro gas sensor platform was fabricated by using a MEMS

technology. The sensing electrode and micro heater were designed to be a co-planar type structure with the

Pt thin film layer. The gas sensitivity and sensing behaviour for gas mixtures suggested that the selective

adsorption of one gas with respect to others occurred for gas mixture and resulted in good selectivity for a

particular gas species. Furthermore, the careful pattern recognition of sensing data obtained with sensor

array makes it possible to distinguish a gas species from gas mixture and to measure its concentration.

1 INTRODUCTION

Metal oxide semiconductor (MOS) gas sensors are

some of the most studied groups of gas sensors

owing to their low cost, simplicity of use, and large

number of detectable gases and various potential

application fields. On the other hand, MOS gas

sensors have serious shortcomings of their low

selectivity, response drifts and environmental

influences such as temperature, vibrations and the

gas flow (Korotcenkov, 2005). For practical

applications, MOS gas sensors have four major

issues of concern: selectivity, long-term stability,

reproducibility of the devices, and sensitivity.

Regarding the selectivity issue, the electronic nose

(e-nose) concept has been developed to achieve the

ability of classifying complex gas mixtures, such as

aromas and odors, using cross-sensitive sensors

(Weimar, 1998). In general, an e-nose system

utilizes gas sensing signals within the sensor array,

and the characteristics of individual sensors should

be as diverse as possible to ensure that the partial

sensor gas responses are not correlated for the

reliable discrimination of a certain gas from gas

mixture. As other issues related to the long-term

stability and reproducibility, such e-nose systems

require good reproducibility of the sensor array and

high training cost for sensor maintenance. This

appears to be one of key challenges requiring the

breakthrough (Eranna, 2004).

Gas identification techniques have attracted

considerable attention over the past twenty years.

The ability to monitor the leakage of combustible

and explosive gases is essential for preventing

accidental explosions and problems with the

pollution and the toxicity. Accordingly, there is

urgent demand for sensors combined with pattern

recognition systems that can detect and determine

the various kinds of combustible gases selectively

(Zhang, 2008).

In previous studies, we developed

four different MEMS-type gas sensors for the

detection of carbon monoxide (CO) (Kim, 2007),

nitrogen oxides (NO

x

) (Yoon, 2009), ammonia

(NH

3

) (Lee, 2010), and formaldehyde (HCHO) (Kim,

2012). Four sensing materials with nano-sized

particles for these target gases (Pd-SnO

2

nano-

powder for CO, In

2

O

3

nano-particle for NO

X

, Ru-

WO

3

nano-composite for NH

3

, and hybridized SnO

2

-

ZnO material for HCHO) were synthesized using a

sol-gel method. Each MEMS gas sensor showed

good sensing performance for its target gas, and the

optimal operating temperature was determined.

Kim, B-M. and Kim, J-S.

Sensor Array based on Metal Oxide Semiconductors for Detecting Gas Mixtures and Its Sensing Properties.

DOI: 10.5220/0005738201690174

In Proceedings of the 5th International Confererence on Sensor Networks (SENSORNETS 2016), pages 169-174

ISBN: 978-989-758-169-4

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

169

In this study, micro-hotplate-based MOS gas

sensors, which have a number of interesting features

and are particularly attractive for their practical

approach, were utilized for the detection of gas

mixtures. The sensing responses of four sensors

were investigated for the gas mixture, particularly

binary mixed gases along CO, NO

x

, NH

3

, and

HCHO. Then, selectivity and response pattern for

these sensors to a particular gas along mixed gases

were examined.

2 EXPERIMENTAL

2.1 Preparation of Sensing Materials

The appropriate sensing materials for four different

gases; SnO

2

for CO (designated as SN sensor), In

2

O

3

for NO

X

(IN sensor), WO

3

for NH

3

(WO sensor),

and SnO

2

-ZnO for HCHO (SZ sensor), were

synthesized using the sol-gel based method. Figure 1

shows field emission scanning electron microscopy

(FESEM) images of the four sensing materials. The

average particle sizes were 40 nm for SN, 70 nm for

IN, 1,000 nm for WO, and 20 nm for SZ sensors,

respectively.

(a) (b)

(c) (d)

Figure 1: Micro-structures of the four gas sensing

materials: (a) Pd-SnO

2

, (b) In

2

O

3

, (c) Ru-WO

3

, and (d) Pd

doped SnO

2

-ZnO.

Each sol-precusor containing its sensing element

was dripped with a micro-pipet on the electrode of

sensor platform, and then heat-treated at its

appropriate sintering temperature. Table 1 represents

main features of sensing materials and the optimum

temperature for their gas sensing.

Table 1: Main features of four different sensing materials.

Composition Average

Particle Size

Optimum

Temp. (°C)

SN 1% Pd-SnO

2

40 nm 225

IN In

2

O

3

70 nm 225

WO 1% Ru-WO

3

1.0 μm 367

SZ 1% Pd + SnO

2

-ZnO 20 nm 367

2.2 Fabrication of MEMS-based

Sensors

Micro gas sensor platforms were designed with co-

planar type in which sensor electrode and micro-

heater were existed on the identical film (Pt thin

film) layer, and fabricated using the MEMS process,

previously (Choi, 2012). The sensor chip size of the

MEMS platform was 1.8 mm × 1.8 mm, and the

membrane located in the central part of the sensor

chip was 0.9 mm × 0.9 mm. Figure 2(a) shows the

photograph of the IN sensor device with TO-39

package in which the sensor chip was placed and

connected to the electric terminals by Au wires. The

fabricated sensor had low power dissipation, and its

power consumption increased linearly with

increasing operation temperature as shown in Figure

2 (b). For example, power consumptions operated at

225°C for the SN sensor and 367°C for the WO

sensor were 35.26 and 64.37 mW, respectively.

(a)

(b)

Figure 2: (a) Photograph of fabricated sensor on the TO-

39 package and (b) electro-thermal characteristic as the

heating power vs. operating temperature.

SENSORNETS 2016 - 5th International Conference on Sensor Networks

170

2.3 Measurement of Sensing Response

The sensing properties were tested for gas mixture in

a gas chamber in which four gas sensors were placed.

The gas chamber was connected to a computer-

supervised continuous gas flow system that

produced the desired concentration for each gas and

gas mixtures with a good reproducibility. The test

gases (CO, NO

X

, NH

3

, and HCHO) were diluted

with a nitrogen gas and carried by dry air at a

constant flow rate. The total gas flow rate was about

500 ml/min. The concentration of each test gas was

0 ~ 60 ppm for CO, 0~0.6 ppm for NO

2

, 0 ~ 10.0 ppm

for NH

3

, and 0 ~ 5.0 ppm for HCHO, respectively.

To quantify the sensor response for both oxidizing

and reducing gases as well as their mixtures, the gas

sensitivity (S) was defined as S = log (R

g

/R

a

), where

R

a

is the sensor resistance in air and R

g

is the sensor

resistance after injecting the test gas. The gas

sensitivity showed negative values (S < 0) for

reducing gases, and positive values (S > 0) for

oxidizing gases because all sensors were

simultaneously sensitive to both reducing (CO, NH

3

and HCHO) and oxidizing (NO

2

) gases. The gas

sensing properties and selective reactions to several

gases were analyzed by quantifying the sensitivity.

3 RESULTS AND DISCUSSION

3.1 Sensing Response for CO-NO

2

Gas

Mixture

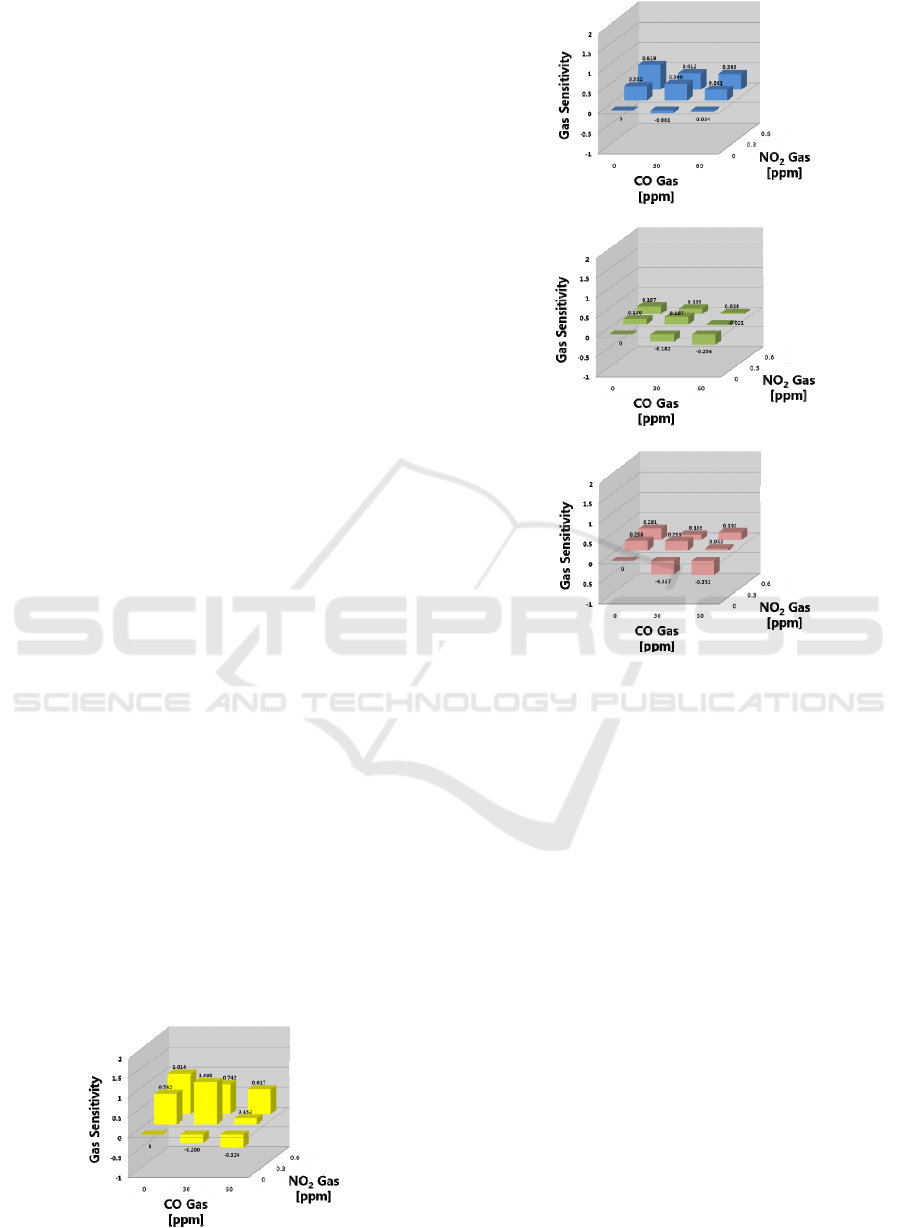

Figure 3 shows the variations of the gas sensitivity

of all sensors to CO and NO

2

gases and their mixture.

The SN and IN sensors showed stronger responses

to NO

2

gas than CO, and their sensitivities showed

positive values in the presence of NO

2

gas. The SN

sensor exhibited a strong response to both gases and

their mixtures, whereas the IN sensor responded

only to NO

2

. The WO and SZ sensors exhibited

similar behaviors to the SN sensor, but their

sensitivities to NO

2

gas were slightly lower.

(a)

(b)

(c)

(d)

Figure 3: Gas sensing properties in the CO-NO

2

system;

(a) SN, (b) IN, (c) WO, and (d) SZ sensors.

3.2 Sensing Response for CO-NH

3

Gas

Mixture

In the CO-NH

3

gas mixture, the CO gas responses

were much higher than NH

3

gas in a mixture of

reducing agents, but the sensitivities in the gas

mixture were higher than that to each gas separately

under most experimental conditions (Figure 4). The

SN and SZ sensors were more sensitive to their

target gas (CO) than NH

3

within the test ranges: S =

-0.179 and -0.420 for SN, and S = -0.100 and -0.176

for SZ sensors (at CO 30 ppm and 60 ppm). On the

other hand, the changes in resistance were slightly

lower in the case of a gas mixture. The IN sensor

responses were quite poor to both CO and NH

3

gases.

The WO and SZ sensors were sensitive to both the

single gases and their mixtures, with higher

sensitivities observed with the gas mixtures. For the

tests in a mixture of reducing agents, the sensor

responses targeting these gases did not show any

synergic effects. The sensitivity of the SN sensor

was -0.420 for 60 ppm CO gas, but the sensitivity

Sensor Array based on Metal Oxide Semiconductors for Detecting Gas Mixtures and Its Sensing Properties

171

(a)

(b)

(c)

(d)

Figure 4: Gas sensing properties in the CO-NH

3

system;

(a) SN, (b) IN, (c) WO, and (d) SZ sensors.

was slightly lower (S = -0.327) for CO 60 ppm –

NH

3

2.5 ppm. This phenomenon was not observed in

the other sensors, which had gas selectivity for the

specific gas species. In three mixtures (CO 60 ppm –

NH

3

0 ppm, CO 60 ppm – NH

3

5.0 ppm, and CO 60

ppm – NH

3

10.0 ppm), the CO concentration was

identical. As the NH

3

concentration increased,

however, the sensitivity of the SN sensor was

slightly lower for the gas mixtures than for the single

CO gas. This suggests that the specific adsorption

and selective activation of adsorption sites might

occur in gas mixtures and offer a priority for the

adsorption of a specific gas, which will be discussed

in the following section.

3.3 Sensing Response for NO

2

-NH

3

Gas Mixture

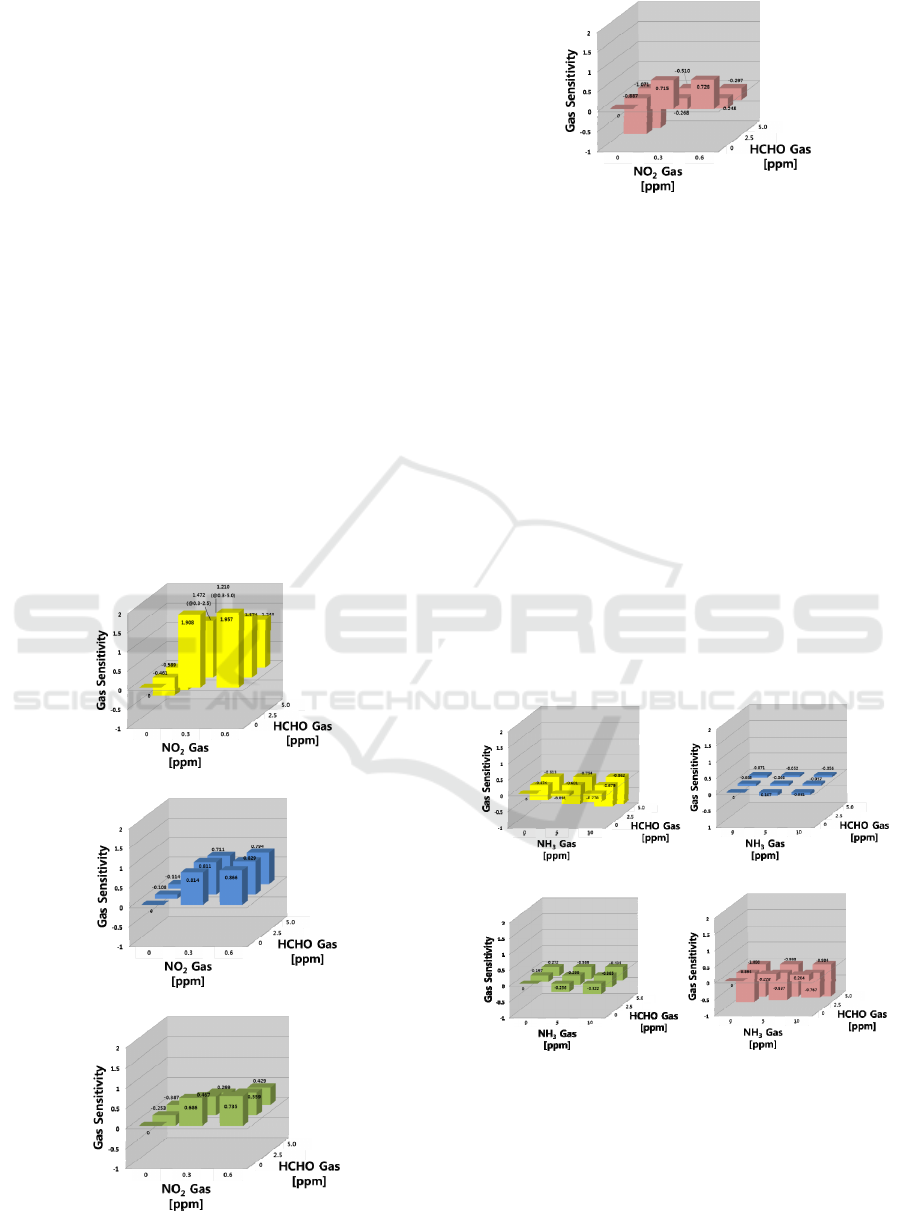

In the NO

2

-NH

3

gas mixture, as shown in Figure 5,

the responses to NO

2

gas were stronger than those of

NH

3

. In the SN sensor, the sensitivities exhibited

increasing behavior to NO

2

and decreasing behavior

to NH

3

at higher concentrations, showing that the

sensor responds to both gases (S = 0.934 at 0.3 ppm).

(a)

(b)

(c)

(d)

Figure 5: Gas sensing properties in the NO

2

-NH

3

system;

(a) SN, (b) IN, (c) WO, and (d) SZ sensors.

SENSORNETS 2016 - 5th International Conference on Sensor Networks

172

In the gas mixtures, the changes in resistance were

higher than the baseline (Ra) and decreased with

increasing NH

3

concentration. On the other hand, the

sensitivities to both gases had positive values (S > 0)

within the test ranges. The IN sensor had a selective

response to NO

2

gas but was barely sensitive to NH

3

gas. As the NH

3

gas concentration increased, the IN

sensor exhibited a slight decrease in sensitivity to

NO

2

gas in the NO

2

-NH

3

mixed gas system. The

WO sensor showed similar behaviour to the IN

sensor, but it was a little more sensitive to NO

2

gas.

3.4 Sensing Response for NO

2

-HCHO

Gas Mixture

In the NO

2

-HCHO system, the responses to NO

2

gas

were stronger than those of HCHO (in Figure 6). In

the SN and WO sensors, the sensitivities showed

increasing behavior to NO

2

and decreasing behavior

to HCHO at higher concentrations. On the other

hand, the IN sensor is selective to NO

2

gas, since it

shows no response to HCHO gas. As the HCHO gas

concentration increased, the IN sensor showed a

slight decrease in sensitivity to NO

2

gas in the NO

2

-

(a)

(b)

(c)

(d)

Figure 6: Gas sensing properties in the NO

2

-HCHO

system; (a) SN, (b) IN, (c) WO, and (d) SZ sensors.

HCHO mixed gas system. The WO sensor showed

similar behavior to the IN sensor, as it is selective to

NO

2

gas. The SZ sensor responses toward HCHO

were stronger than NO

2

gas for the NO

2

and HCHO

gas mixture.

3.5 Sensing Response for NH

3

-HCHO

Gas Mixture

For the NH

3

-HCHO system as shown in Figure 7,

the IN sensor did not respond to any of gases; NH

3

and HCHO, three other sensors (SN, WO and SZ)

were sensitive to either single gas or its mixture. The

SZ sensor is selective to HCHO. In this mixture of

two reducing gases, there was no synergic effect in

the SN sensor responding to both NH

3

and HCHO

gases.

(a) (b)

(c) (d)

Figure 7: Gas sensing properties in the NH

3

-HCHO

system; (a) SN, (b) IN, (c) WO, and (d) SZ sensors.

3.6 Discussion

The present study analyzed the sensing properties of

micro gas sensor arrays by examining the raw data

Sensor Array based on Metal Oxide Semiconductors for Detecting Gas Mixtures and Its Sensing Properties

173

in the gas mixtures. Overall, the IN sensor could

detect NO

2

selectively, whereas the SN sensors

detected all four gases (CO, NO

2

, NH

3

and HCHO).

If coupled with an IN sensor, SN is capable of

detecting NO

2

sensitively. On the other hand, the gas

sensitivity signals of the two sensors were not

sufficient for the detection of all four gases. The WO

and SZ sensors detected all four gases but had low

gas selectivity. Therefore, the four-sensor-array

would be sufficient to discriminate mixtures of these

gases. To gain clear insight into the applicability of

the sensor array in this application, the responses

with sensitivity can be arranged in a 4 × 4 matrix, in

which each element represents the response of each

sensor to each target gas. This matrix suggests how

the different gas contributions can be extrapolated

from the sensor array data using the signal process.

4 CONCLUSIONS

The sensing properties for the MEMS-based MOS

gas sensors were investigated with gas mixtures

along CO, NO

X

, NH

3

, and HCHO gases. Four

different gas sensors were fabricated for the

detection of CO, NO

X

, NH

3

, and HCHO gases,

respectively. Each sensor exhibited good sensitivity

to its target gas, and the optimum operating

temperature of micro-heater was examined. The

sensing response behaviors for gas mixture were

analyzed using the experimental data in the MEMS

gas sensor arrays with respect to selectivity and

response pattern. The gas sensing behaviors in

mixed gas systems suggest that specific adsorption

and selective activation of adsorption sites might

occur in gas mixtures and offer priority for the

adsorption of a specific gas. An analysis of the

sensing performance of the sensor arrays will make

it possible to discriminate the components in

harmful gas mixtures as well as their concentrations

using pattern recognition techniques.

ACKNOWLEDGEMENTS

This research was supported by the National

Research Foundation of Korea (NRF) funded by the

Korea government (MSIP) (No. 2015-

R1A2A2A01005790).

REFERENCES

Korotcenkov, G., 2005. Gas Response Control Through

Structural and Chemical Modification of Metal Oxide

Films: State of the Art and Approaches. Sens.

Actuators B, Vol. 107, pp.209-232.

Weimar, U., Gopel, W., 1998. Chemical Imaging. Part II:

Trends in Practical Multiparameter Sensors Systems.

Sens. Actuators B, Vol. 52, pp.143-161.

Eranna, G, Joshi, B. C., Runthala, D. P., Gupta, R. P.,

2004. Oxide Materials for Development of Integrated

Gas Sensors-A Comprehensive Review. Critical

Reviews in Solid State Materials Sciences, Vol. 29,

pp.111-188.

Zhang, S., Xie, C., Zeng, D., Li, H., Bai, Z., Cai, S., 2008.

A Method of Feature Extraction from the Desorption

Part of MOX’s Response Curves to Gases. IEEE Sens.

J., Vol. 8, pp.1816-1823.

Kim, S. D., Kim, B. J., Yoon. J. H., Kim, J. S., 2007.

Design, Fabrication and Characterization of a Low-

Power Gas Sensor with High Sensitivity to CO Gas. J.

Kor. Phys. Soc., Vol. 51, pp.2069-2076.

Yoon, J. H., Kim, J. S., 2009. Design and Fabrication of a

MEMS-Based Gas Sensor. Adv. Mater. Res., Vol. 74,

pp.255-258.

Lee, H. J., Yoon, J. H., Kim, B. J., Jang, H. D., Kim, J. S.

2010. Gas Sensing Characteristics of Ru Doped-WO

3

Micro Gas Sensors. Kor. J. Met. Mater., Vol. 49,

pp.395-399.

Kim, B. J., Lee, H. J., Yoon, J. H., Kim, J. S., 2012. Highly

Sensitive Formaldehyde Gas Sensors Based on SnO

2

-

ZnO Nanocomposites. Sens. Lett., Vol. 10, pp.1-7.

Choi, W. S., Kim, B. J., Lee, H. J., Choi, J. W., Kim, S. D.,

Min, N. K., 2012. Study on the Micro-Heater

Geometry in MEMS Gas Sensor Platforms and Effects

on Gas Detecting Performances. J. Nanosci. Nanotech.,

Vol. 12, pp.1-4.

SENSORNETS 2016 - 5th International Conference on Sensor Networks

174