Energy Saving and Efficiency Tool

A Sectorial Decision Support Model for Energy Consumption Reduction in

Manufacturing SMEs

Samuele Branchetti, Gessica Ciaccio, Piero De Sabbata, Angelo Frascella, Giuseppe Nigliaccio

and Marco Zambelli

ENEA - Italian National Agency for New Technologies, Energy and Sustainable Economic Development,

Via Martiri di Monte Sole 4, Bologna, Italy

Keywords: Energy Efficiency, Energy Saving Measures, Intelligent Models, Rule Sets, Benchmark, Self-diagnosis,

Sustainable Economy, Energy Consumption Awareness.

Abstract: The problem of Energy Efficiency in industry is a hot topic but companies are not still implementing, on a

mass scale, energy efficiency actions. One of the most important barriers is that companies are scarcely

aware of their consumptions and consider energy as a fixed cost and not as a resource to be managed. In this

paper it is proposed a model, based on self-analysis of consumptions, for facing this barrier. On the base of

this model, a software tool, Energy Saving and Efficiency Tool (ESET), was designed as a starting point of

an energy diagnosis path for SMEs. ESET was developed for textile/clothing sector but the model is general

and, starting from it, similar sectorial tools can be developed. The tool provides different kinds of outputs:

best practices, for helping companies to improve its own energy performances; energy efficiency indices,

compared with reference values; energy use behaviours. Particularly, best practices are selected using a

large set of rules, distilled from the experience of professional energy auditors. The analysis of the accuracy

and completeness of ESET results was performed on six companies selected among all those involved in

ESET testing and application. The results of this evaluation are very encouraging.

1 INTRODUCTION

The manufacturing sector plays an important role in

European economy, since it represents 10% of all

enterprises in the non-financial sector and accounts

for 80% of European exports (European

Commission Factories of the Future, 2013). Its

global turnover in Europe is around 7.080.000

million of € and the total amount of energy costs is

about 140.000 million of € (EUROSTAT, 2013).

Moreover, 99,6% of the 5,1 millions of enterprises

operating in the manufacturing and construction

European sectors are SMEs (3E, 2013).

The problem of Energy Efficiency (EE) in

industry is a hot topic, since the need for reducing

the impact of human activities on the environment

and for saving resources, as raw material and

energy, has become urgent and therefore there is a

strong commitment from policy. Policy instruments

can be split into four main categories: instruments

for planning (like strategies and national

programmes of action), institutional organizations

(like EE implementation management organizations

or cooperation of administrative and municipal

management bodies), financial instruments (like

public investment programme and EE funds) and

communicative instruments (like institutional day of

information) (Ekmanis, 2010).

A certain number of studies has been developed

about energy efficiency methodologies, going from

general energy management methodologies

identifying steps for getting energy efficiency

(Capobianchi, 2011), to models for assessing energy

saving measures (Doukas, 2009; Doukas, 2006).

Moreover, further studies were performed focusing

on (both general and process specific) techniques

and opportunities for energy efficiency, that in the

following sections we refer globally as “best

practices” (Worrell, 2009). The main references, on

these topics, are the Best Available Techniques

(BATs) elaborated from the European IPPC Bureau,

330

Branchetti, S., Ciaccio, G., Sabbata, P., Frascella, A., Nigliaccio, G. and Zambelli, M.

Energy Saving and Efficiency Tool - A Sectorial Decision Support Model for Energy Consumption Reduction in Manufacturing SMEs.

In Proceedings of the 5th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2016), pages 330-339

ISBN: 978-989-758-184-7

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

following the request Article 13(1) of the Industrial

Emissions Directive (The European Parliament and

The Council of the European Union, 2010).

These Best Available Techniques Reference

Documents (BREFs) contain, for each industrial

sector, the more effective techniques for getting a

high level of environment protection and pollution

control, including energy consumption issues.

Considering the previous points (policy

commitment, availability of energy management

standard, methodologies and best practices) why are

companies still not implementing, on a mass scale,

energy efficiency actions? A good answer is

proposed by Dörr (2013), which identifies the

following barriers:

distance between industrial needs and scientific

results;

high costs for the implementation of a company

energy management system, measuring devices

and additional ICT structures;

too general and abstract description of energy

management systems in ISO 50001, that is the

reference standard in this field (ISO, 2011).

The problem of energy efficiency was faced by the

authors of this paper through a series of projects

funded by the European Commission (ARTISAN,

SESEC and SET), focused on Textile and Clothing

sector as pilot (turnover around 150.000 million of €

in 2012 and total amount of energy costs about

2.600 million of €, with peaks of energy intensity

near to 30% for some subsectors like dyeing

(EUROSTAT, 2013)).

Moreover a European informative campaign,

Energy Made to Measure (EM2M), led by the

European industry association (EURATEX), was

launched in 2014 with the aim of improving real

European companies in their energy efficiency

awareness.

From these activities, a further barrier was

identified, which precedes, in time and in logic, the

previous ones: the companies of the sector (and,

more generally, SMEs), have still very scarce

awareness of their consumptions. The main reason is

that they consider energy as a fixed cost that has to

be paid instead than a resource that can be managed

and used in a more efficient way.

In order to overcome this barrier, a path was

defined based on self-analysis of consumptions,

collection of data for improving benchmarks and

suggestion of customised best practice lists

(unfortunately the Textile/Clothing sector BREF is

not so recent, since its date goes back at 2003).

For this purpose, a set of software tools was

developed in the last years, in the context of the

above quoted projects, for supporting companies in

understanding their energy performances, comparing

them with sectorial benchmarks and identifying

which actions could be implemented for improving

their own efficiency.

In this paper the self-analysis standalone tool,

called ESET Tool, developed through the activities

of SET project, will be analysed.

There exist other self-analysis tools, developed

by other initiatives and European projects. Ten tools

were analysed (Table 1), eight for industry and two

for buildings, and compared with ESET Tool.

Among the industry tools, four of them address

specific sectors, two are targeted on specific kinds of

Table 1: Outputs provided by the analysed tools and by ESET Tool.

Audit

results

Energy

savings

Energy

indicators

List of best

practices

Payback

period

Green house

emission / reduction

Cost

savings

Plant Energy Profiler X X X

FanSave X X X X

PumpSave X X X X

AMETHIST X

LiCEA X X

A2A X X X X X X

SEAS 2.0 X X

SENECA X

Green Gain X

Energy Performance

Indicator Tool

X X X

ESET X X X X X X

Energy Saving and Efficiency Tool - A Sectorial Decision Support Model for Energy Consumption Reduction in Manufacturing SMEs

331

subsystems (pumps and fans) and the others are

general.

The inputs required by each of the analysed tools

were compared and two possible approaches were

identified:

very detailed set of inputs (bottom-up approach):

these kinds of tools have a very affordable

output, but filling them is a complex activity and

requires a deep knowledge of company processes

and of related consumptions;

macro-level set of inputs (top-down approach):

in this case there is a loss of details in the final

output, but data analysis is much easier and

quicker.

The second approach is more attractive for the

companies, but the first one gives more effective

results. So, for the ESET Tool a partial and/or

progressive filling approach was chosen.

Furthermore, even with a not complete filling of the

tool, some results are given: the more the input is

complete, the more the output is comprehensive and

faithful. This strategy is thought for making the tool

attractive and for allowing companies to deepen the

self-analysis process, after having observed their

main energy indicators.

Another important point of view for this

comparison is the provided output.

From this point of view, Table 1 shows that the

ESET Tool provides the more complete set of

outputs, among the analysed tools.

A last important point is that, although ESET

Tool is sector specific, it is thought to be easily

portable on different sectors, by developing and

upgrading the model toward other industrial sectors.

2 THE PROPOSED MODEL

ESET

Financial

incentives

Legal

obligations

Guiding

document

ESETWEB

ESETTool

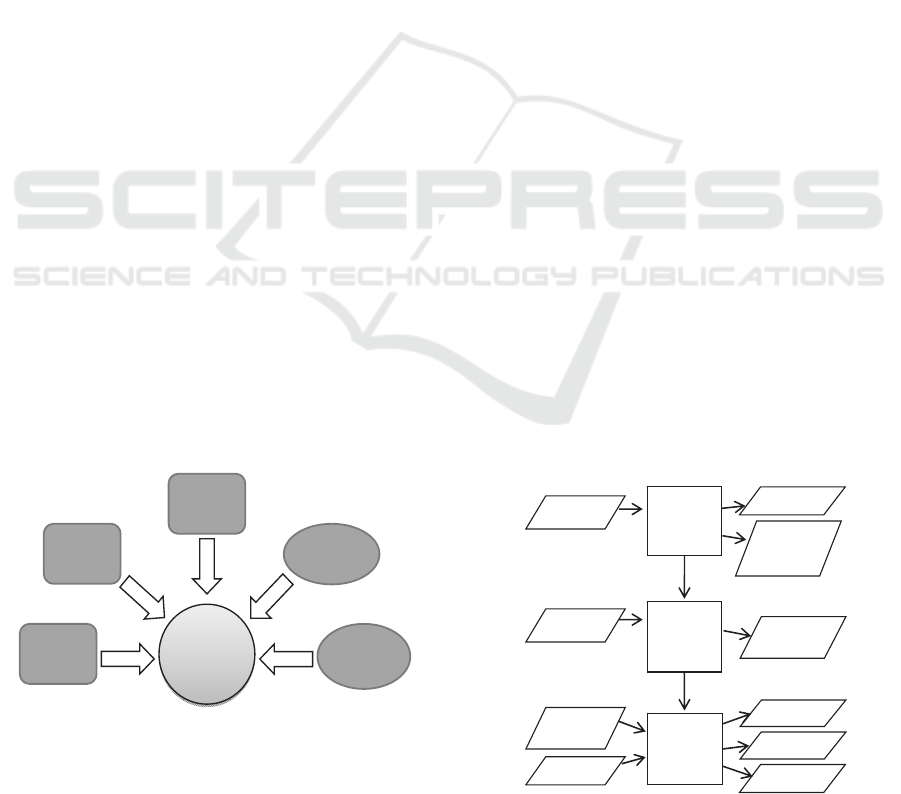

Figure 1: General ESET structure.

The ESET Tool is the starting point of a group of

instruments developed under SET project, including

(in addition to ESET Tool) a web application (ESET

Web), a guiding document and further documents

reporting Financial incentives and Legal obligations

(Figure 1).

The main scope of this article is to present ESET

Tool and the model behind it, with some references

to ESET Web.

2.1 Structure and Approach

Thanks to previous experiences (ARTISAN and

SESEC) we have learnt that companies which deal

with energy efficiency issues, even for the first time,

are interested in receiving indications about

measures they could implement in the factories in

order to reduce energy consumptions and related

costs (possibly with a short payback time); they also

find useful obtaining a series of indices, calculated

on yearly and monthly basis, which give them a

view of their behaviours; particularly they would

like to know which aspects influence their

consumptions or their costs; moreover, they would

like to understand how much their performances

differ from their peers, nationally or on European

scale.

Starting from these learned lessons, the

following outputs were defined:

best practices

indices and comparison with peers

behaviours.

It was immediately clear that a certain amount of

company data is needed, but companies are often not

able to find energy data easily or, if asked for too

many data, they prefer to renounce.

To face this point, ESET was designed with a

step-by-step approach, involving ESET Tool and

ESET Web, asking factories data, organizing them

in self-consistent sections and giving back the

related outputs progressively (Figure 2).

Step1

(ESETTool)

Step2

(ESETTool)

Yearly

data

Monthlyand

Processdata

Step3

(ESETWeb)

Data

uploadedby

ESETtool

Machines

specificdata

Cross‐cutting

BestPractices

Indices

Process

specificBest

Practices

Benchmark

Technology

basedModel

Performances

against

Eurostatdata

elaborations

Figure 2: Flow chart of ESET.

SMARTGREENS 2016 - 5th International Conference on Smart Cities and Green ICT Systems

332

In details, in the first step user is asked to insert

basic yearly information of the factory (data on

business, turnover, production, purchased energy,

cogeneration and energy generation when available,

energy uses). The results are some global energy

indices and a list of recommended best practices,

independent from the production processes (cross-

cutting), which could be applied in the factory and,

consequently, could contribute to reducing energy

consumptions associated to auxiliary systems.

In the second step the ESET Tool requires more

detailed data related to productive phases and

technologies and, on monthly base, production and

energy consumptions. The outputs in this case are

diagrams which analyse monthly data variations and

a list of recommended process specific best

practices. The suggested measures, if applied, could

lead to a reduction in energy consumptions

associated to production processes.

A third step is under test (ESET Web) and aims

to extend and deepen the analysis on factories data

with new indices, performances comparison against

dynamic personalised energy benchmarks;

furthermore a section is dedicated to “Technologies

based models” for the main textile processes, that

allows to calculate the expected theoretical

consumption for single machine or department.

Companies are allowed to access the web

application and its services by anonymously sending

their data through ESET Tool, at the end of the

second step.

The data required by ESET Tool can be retrieved

by companies from the following sources:

purchased energy (amount and costs) usually

available from bills;

production data retrieved from company’s ERP

(Enterprise Resource Planning system);

information on factory organization, processes

and technologies provided by company’s

production technician.

The effort to complete the data set needed by ESET

Tool depends on the capability of the company in

monitoring their production and on their internal

organization.

Anyway, the total time necessary to apply

effectively ESET Tool to a factory ranges from few

hours to a working day.

2.1.1 Best Practices

A list of best practices for improving energy

efficiency in an industrial factory was identified on

the base of several resources: the performed energy

audits, the experience of ENEA experts in the textile

sector, the Berkeley Lab document about Energy-

Efficiency Improvement Opportunities for the

Textile Industry (Hasanbeigi, 2010), the EMS

project outcome (EMS-Textile, 2006), the BAT

document (IPPC, 2003) and the ENEA document

about rational use of energy in textile sector

(Paganelli, 1997).

The review of state of art in energy efficient

measures allowed to split the identified best

practices into the following categories:

Cross-cutting measures

- Reduction of peak power

- Lighting

- Heating/Air conditioning

- Electric motors

- Compressed air

- Pumping systems

- Fan systems

- Steam systems

- Vacuum systems

Sector specific measures (e.g. for textile) for

- yarn production machinery

- fabric production machinery

- finishing systems

The rationalization of the best practices list was

made in two phases.

At first, the best practices list was enriched with

indicative information about:

investment cost

energy saving (fuel and/or electricity)

order of magnitude of payback time.

Then, they were prioritized on the base of the

expected cost, benefit and payback time.

Finally a list of 117 cross-cutting best practices

and 113 process specific best practices was created

(CITEVE, 2014). Each of the identified measures

was linked to a process or kind of machinery,

organized and classified in a hierarchical

classification which covers the most relevant textile

processes and the related phases and technologies.

2.1.2 Comparison of Performances

As reported by a study (Asia Pacific Energy

Research Centre, 2000), moving down along the

pyramid of Figure 3 the faithfulness of energy

indices increases, but the data aggregation level falls

down, the quantity of data required increases and

finding an appropriate benchmark becomes much

more difficult.

Taking into account these dynamics, we have

built a system to support a twofold level of indices,

Energy Saving and Efficiency Tool - A Sectorial Decision Support Model for Energy Consumption Reduction in Manufacturing SMEs

333

Efficienc

y

Anal

y

sis Level

Data A

gg

re

g

ation Level

Q

uantit

y

of data re

q

uired

National Energy Intensity

(Mtoe/$GDP)

International

Statistics

National

Statistics

Sectoral

Statistics

Sub-sectoral

Statistics

Individual

Plant Data

Operational Unit Efficiency

(toe/tonne production)

Individual Plant Efficiency

(toe/tonne)

Sub-sectoral Efficiency

(Mtoe/tonne production or Mtoe/$)

Sectoral Energy Intensity

(Mtoe/$value added)

E

SET Sectoral

references

ESET

Benchmarks

Figure 3: The ESET shifting to Operational Unit Efficiency level on the Energy Efficiency Indicator Pyramid. Elaboration

from Asia Pacific Energy Research Centre (2000) and Phylipsen (1998).

in order to enrich the data analysis moving to the

“Operational Unit Efficiency” level of the pyramid:

Step 1 and Step 2 outputs: sectorial reference

values built on an elaboration of national

Eurostat data based on NACE categories

(finishing, yarn and fabric production);

Step 3 outputs: comparison of internal indices

towards energy benchmarks for textile processes,

dynamically built around the target company

from a centralized database by ESET Web.

The sectorial reference values used in Step 1 and

Step 2 are stored inside the ESET Tool and allow

companies to perform a first comparison. They

consist in four main classes of indices:

Energy cost / turnover (%)

Energy consumption / turnover (toe/Euro)

Energy cost / production (Euro/kg)

Energy consumption / production (toe/kg).

Nevertheless the Eurostat data refers to NACE

categories for the textile industry that are too general

and include kinds of factories very different. This

has led to consider a different approach. In Step 3,

energy benchmarks are built dynamically through a

company profiling approach, based on a centralised

database which collects companies data from the

ESET Tool, and on a web application which

calculates the customised energy benchmarks and

executes further elaborations.

This is a work in progress within the SET

European project, which is involving a number of

textile companies (300) in the application of ESET.

The logic and the methodology of the energy

benchmarks definition deserves an in-depth analysis

and will better explained in an ad hoc paper.

2.1.3 Company Behaviour

To get information about how companies use

energy, it is highly interesting to investigate the

relationship between production and energy

consumptions: in other words how the energy

consumption variation is related to the production.

One of the data analysis performed by ESET

Tool is a regression analysis to check the existence

of a linear relationship between production

(independent variable) and energy consumptions

(dependent variables). Specifically, ESET

implements a linear regression where the model

parameters (slope and interception of the best fit

line) are estimated from monthly data (Figure 4).

The extent of linear relationship is evaluated

through the R-square, that is the square of Pearson

product moment correlation coefficient.

In details, if R-square is close to 1 the model fits

well the data, the consumptions appear strongly

related to the production and the following

indicators can be evaluated:

consumption when production is zero, which

represents those consumptions not directly

related to production and includes avoidable and

unavoidable consumptions;

consumption for each additional unit, the energy

required to produce each additional unit of

product;

SMARTGREENS 2016 - 5th International Conference on Smart Cities and Green ICT Systems

334

Electrical Thermal

R‐square

Consumptionwhenproductionis

zero(kWh)

Consumptionforeachadditional

equivalentunit(kWh/eq.unit)

Baseenergyconsumption(%)

0,91

0,26

42.630,5 526,37

2,76

0,10

8,90 3,12

Figure 4: One of ESET Tool outputs (regression analysis)

from a real case. The electric consumption shows a strong

relationship with the production, while the thermal

consumption appears poorly related (due to winter heating,

production changes, other).

base energy consumption, which is the energy

portion not related to production and represents a

worthy area for further energy saving

investigation to enhance the energy efficiency.

If R-square is close to 0 the model doesn’t fits the

data and the consumptions could be affected by

energy uses not directly linked to the production

(e.g. winter heating, air conditioning, etc.), as shown

in the second graph of Figure 4.

2.2 Implementation

Each ESET step is composed of two main parts: a

data input section and an output section that shows

the outcomes. It has been designed according to a

user-friendly structure, which leads the user in a path

through the different data sections. It allows to run

the analysis also with incomplete information, but in

this case the outcomes could be partial and less

relevant respect to the real case.

ESET Tool is multilingual: presently it is

customized in 12 languages and could easily extend

his interface to new ones, when requested. Moreover

it faces localisation issues like differences in price of

energy, differences in values of conversion factors

for toe calculation (due to different national mix of

electricity generation), comparison against national

Eurostat references.

2.2.1 Rules for Best Practices Selection

A list of suggested best practices for the company is

selected by the ESET Tool through an evaluation

process, which includes two kinds of rules:

cross-rules, which take into account the value of

company energy indices and act on the whole

best practices list;

specific rules, that act on a single best practice

(or on a group of them) taking into account the

companies features related to market positioning,

consumers, technologies, productive phases and

plants features.

It is important to underline that, by default, all best

practices are considered valid and the ESET Tool

discards the ones considered not suitable for the

specific case (Table 2). In details, it discards the

following types of best practices:

the ones linked to those consumptions having a

low incidence within the company energy uses

(based on Pareto’s law, also known as the 80-20

rule) or that having a value lower than the

sectorial references;

the ones without a link to specific consumers,

processes or technologies implemented by the

company or not considered useful on the base of

the company features.

This system of rules is integrated within ESET Tool

and arises from many years of energy audits

performed by experts and from a specific knowledge

of textile sector.

2.2.2 Use of MS Excel (Why?)

The ESET Tool was implemented using MS Excel

VBA (Visual Basic for Application) language.

The choice of using MS Excel as platform for the

tool instead of a Web Application was taken after a

lot of discussions with SET partners more used to

deal with companies and, particularly, with compa-

Energy Saving and Efficiency Tool - A Sectorial Decision Support Model for Energy Consumption Reduction in Manufacturing SMEs

335

Table 2: Simplified scheme of the rules to discard best practices.

Cross rules Specific rules (1) Specific rules (2)

Electrical

consumption

Thermal

consumption

Electrical

index

Thermal

index

Process, phase or

technology linked

to the energy

measure

Answers to the

question (if any)

≤ 20% of

consumptions

Discard

electrical

measures

≤ 20% of

consumptions

Discard

thermal

measures

if absent then

Discard the

linked measure

(or group of them)

if present then

Evaluate the set

of answers linked

to the measure

(or group of them)

between

20-30% of

consumptions

Evaluate

electrical index

between

20-30% of

consumptions

Evaluate

thermal index

≤ sectorial

reference

Discard

electrical

measures

≤ sectorial

reference

Discard

thermal

measures

AND

AND

Other cases: No effects

nies involved in the projects.

The idea is that, if companies are requested to

leave on a server their internal data (like turnover,

consumption and production data) they would

become cautious and could decide to not use the tool

because they do not trust on the confidentiality of

this data. So, it would be easier to convince

companies in using a stand-alone tool. Moreover,

Excel is a software about which non-ICT people

(who should use the tool) is more confident.

3 PILOT APPLICATION

The pilot factories considered in the following

analysis have been selected among about 60

companies already involved in SET project and

EM2M campaign activities.

3.1 Pilots Selection

For a deeper analysis of the quality of the outcomes

provided by ESET Tool, we selected six SMEs

representative of different kinds of companies

involved in the usage of ESET, taking into account

type of production, size of the company (based on

turnover and number of the employees) and

incidence of energy costs on the turnover. In detail:

no. 3 yarn producers

no. 1 fabric producer

no. 1 fabric and finishing producer

no. 1 clothing producer.

The turnover of these companies ranges from

3.000.000 € to 25.000.000 € and the number of

employees ranges from 12 to 204, while the weight

of energy costs on the turnover ranges from 0,8%

(clothing) to 25,37% (yarn production).

These companies were trained by SET experts on

the ESET usage, filled the tool and received the

suggested best practices. In addition, energy

efficiency experts of ENEA visited the factories and

provided a further report with energy analysis and

proposed actions.

A comparison was done, for each of the six

companies, between the ESET outcomes and the

results of the visits performed by ENEA experts.

After, the experts were asked to evaluate the

adequacy of the best practices selected by the tool

for each visited factory.

3.2 Results

The accuracy and completeness of ESET results

were analysed applying the methods used to evaluate

the Information Retrieval (IR) systems (Baeza-

Yates, 2011).

The IR is widely used to achieve and find useful

information from large amount of data.

The notions of “Precision” and “Recall”

(Manning, 2009), which represent respectively a

measure of truthfulness and of completeness of

results, were used to measure the effectiveness of an

IR system.

We applied the notions of “Precision” and

“Recall” to the set of rules used to select and discard

best practices within ESET Tool, which can be

assimilated to an IR system.

In this context, the “Precision” is the fraction of

retrieved best practices that are relevant for the

SMARTGREENS 2016 - 5th International Conference on Smart Cities and Green ICT Systems

336

specific case:

(1)

The “Recall” is the fraction of relevant best practices

that are retrieved:

(2)

3.2.1 ESET Outcomes Analysis

The analysis process of the outcome of ESET Tool

involves ENEA experts which visited the factories

and follows the steps below:

the experts evaluate, for each company, the best

practices (BPs) retrieved by ESET Tool to

indicate the relevant feasible best practices and

the unfeasible ones;

they also identify a “first class” subset, i.e. easily

and quickly applicable, within the relevant

feasible best practices retrieved by ESET Tool;

then, the experts identify the “missing” best

practices that should have been recommended

but were not retrieved by the tool, looking the

whole set of ESET best practices (Figure 5).

BPsretrievedbyESET

Feasible

Unfeasible

First

Class

Missing

Figure 5: Best practices categories.

Table 3: Results from experts evaluations.

BPs

retrieved

by ESET

(A)

Feasible

(B)

First class

(C)

Missing

(D)

Expert evaluation

Case 1 32 23 7 2

Case 2 57 41 25 3

Case 3 40 28 10 2

Case 4 56 48 18 6

Case 5 58 38 5 2

Case 6 73 57 15 1

Total 316 235 80 16

The results of these steps, reported in Table 3,

represent the starting point to analyse the

“Precision” and “Recall” indices calculated both for

feasible best practices and the subset of “first class”

best practices (Table 4).

3.2.2 Results Evaluation

The analysis of “Precision” and “Recall” values for

feasible best practices allowed to assess the

effectiveness of ESET Tool, with the following

considerations:

ESET Tool is able to retrieve best practises with

a high level of precision (74,37%). This result is

coherent with the system of rules integrated into

the tool, that initially considers all the best

practices as valid and then discards only the ones

evaluated as not suitable for the specific case;

the tool is also able to properly select the

relevant best practices (93,63%), losing few

applicable measures (less than 7%).

Some other observations can be done calculating the

values of “Precision” and “Recall” for first class best

practices.

Few of these first class best practices are lost

(recall 83,33%), even if a lot of applicable but not

prior best practices are brought to the attention of the

company (precision 25,32%). But this apparently

low precision value is coherent with the philosophy

of the tool, which does not intend to substitute the

analysis of an expert or an energy audit, but aims to

make companies aware that energy can be saved and

consequently it discards only the really useless best

practices.

Table 4: Values of Precision and Recall indices.

Feasible BPs First class BPs

Precision

B/A

Recall

B/(B+D)

Precision

C/A

Recall

C/(C+D)

Case 1

71,88% 92,00% 21,88% 77,78%

Case 2

71,93% 93,18% 43,86% 89,29%

Case 3

70,00% 93,33% 25,00% 83,33%

Case 4

85,71% 88,89% 32,14% 75,00%

Case 5

65,52% 95,00% 8,62% 71,43%

Case 6

78,08% 98,28% 20,55% 93,75%

Total

74,37% 93,63% 25,32% 83,33%

Energy Saving and Efficiency Tool - A Sectorial Decision Support Model for Energy Consumption Reduction in Manufacturing SMEs

337

4 CONCLUSIONS

A model has been presented in this paper for helping

companies (and in particular SMEs) to become

aware of their energy efficiency and to manage

energy as a resource and not as a cost.

The main instrument for applying this

methodology is a software tool containing

intelligence distilled from the experience of

professional energy auditors. At the moment, this

tool is contextualized for textile and clothing sector,

but the model is general and the tool can be

extended, with little effort, to other industrial

sectors.

The model has been tested comparing its results

with the opinion of energy efficiency experts that

have really visited the pilot companies. The results

were very encouraging. In particular, through these

tests, it was possible to verify that the tool is able to

select the most part of relevant best practices, losing

few of applicable measures.

There are two possible paths for the evolution of

the tool after the end of SET project.

The first one is to make it a ‘largely used tool’

for assessment of company energy efficiency profile

and its evolution year-by-year or after the execution

of energy efficiency improvement actions (so

enabling an objective evaluation of the obtained

benefits). In order to be effective, the application

model has to be pushed in order to foster self-

analysis on large scale. At this aim, the tool is

promoted in EM2M campaign, which is achieving

interesting results (in 2014, more than 20 public

events took place in 8 countries involving around

500 professionals and in 2016 the involvement of

more than 300 companies of textile and clothing

sector is foreseen).

The second one is the improvement of the tool

for supporting the evaluation of the fundability of

the proposed best practices. This extension will

complete the kind of results offered to the

companies, covering the still lacking financial

aspects.

Finally the tool and the related methodology is

meant to be extended to further industrial sectors,

assuring further developments of specific sectorial

benchmark.

ACKNOWLEDGEMENTS

SET is an on-going project funded by the

“Intelligent Energy – Europe” programme (grant no.

IEE/13/557/SI2.675575). It is designed to enable

within 30 months at least 150 European Textile

SMEs to improve their energy efficiency, achieving

tangible and quantifiable benefits.

SESEC was a project co-funded within the

European Programme Intelligent Energy Europe by

EASME (grant no. IEE/11/827/SI2.615931).

ARTISAN was a Research & Development

project co-financed by the European Commission’s

7th Framework Programme (FP7-ICT-2011-7 Grant

agreement 287993).

REFERENCES

3E, 2013. Energy efficiency policy measures for

manufacturing SMEs in Europe: a comparative

analysis [Online]. Available from:

http://www.3e.eu/energy-efficiency-policy-measures-

for-manufacturing-smes-in-europe-a-comparative-

analysis/ [Accessed: 19th June 2015].

Asia Pacific Energy Research Centre, 2000. Energy

Efficiency Indicators – A Study of Energy Efficiency

Indicators for Industry in APEC Economies. Tokyo:

Asia Pacific Energy Research Centre

Baeza-Yates, R., Ribeiro-Neto, B., 2011. Modern

Information Retrieval: The concepts and technology

behind search. New York: ACM Press.

Capobianchi, S., Andreassi, L., Introna, V., Martini, F.,

Ubertini, S., 2011. Methodology Development for a

Comprehensive and Cost-Effective Energy

Management in Industrial Plants. In Kini Dr Giridhar

(ed.) Energy Management Systems. Rijeka: InTech.

CITEVE, 2014. SET - Production Processes and

Efficiency Measures. Internal Deliverable D2.3.

Dörr, M., Wahren, S., Bauernhansl, T., 2013.

Methodology for energy efficiency on process level. In

Procedia of Forty Sixth CIRP Conference on

Manufacturing Systems, Setubal, Portugal, ed.

Elsevier, 2013. 7 (2013). pp. 652 – 657.

Doukas, H., Nychtis, C., Psarras, J., 2009. Assessing

energy-saving measures in building through an

intelligent decision support model. In Building and

Environment 44 (2). pp. 290-298.

Doukas, H., Patlitzianas, K.D., Iatropoulos, K., Psarras, J.,

2006. Intelligent building energy management system

using rule sets. In Bulding and Environment 42 (10).

pp. 3562-3569.

Ekmanis, J., Zebergs, V., Zeltins, N., 2010. Adaption of

the general policy assessment methodology for

managing the energy saving process. In

ENERGETIKA 56 (1). pp. 1-7.

EMS-Textile, 2006. Energy Management Manual. EMS-

Textile Consortium.

European Commission Factories of the Future 2013. Multi

Annual Roadmap for the Contractual PPP.

EUROSTAT, 2013. Annual enterprise statistics for special

aggregates of activities (NACE Rev. 2) [Online]

Available from: http://appsso.eurostat.ec.europa.eu/

SMARTGREENS 2016 - 5th International Conference on Smart Cities and Green ICT Systems

338

nui/show.do?dataset=sbs_na_sca_r2&lang=en

[Accessed: 29 October 2015].

Hasanbeigi, A., 2010. Energy-Efficiency Improvement

Opportunities for the Textile Industry. Berkeley:

Ernest Orlando Lawrence Berkeley National

Laboratory.

IPPC, 2003. Reference Document on Best Available

Techniques for the Textiles Industry. European

Commission.

ISO, 2011. ISO 50001:2011 Energy management systems

– Requirements with guidance for use.

Manning, C.D., Raghavan, P., Schütze, H., 2009.

Evaluation in information retrieval. Cambrigde:

Cambridge University Press.

Phylipsen, G.J.M., Blok, K., Worrell, E., 1998.

benchmarking the Energy Efficiency of the Dutch

Energy-Intensive Industry; A preliminary assessment

of the effects on energy consumption and CO2

emissions. Utrecht: Dept. of Science, Technology and

Society, Utrecht University.

Paganelli, M., Vatrano, F., 1997. Uso razionale

dell'energia nel settore tessile. ENEA.

The European Parliament and the Council of the European

Union, 2010. Directive 2010/75/Eu of the European

Parliament and of the Council on industrial emissions

(integrated pollution prevention and control).

Available from: http://eur-lex.europa.eu/legal -

content/EN/TXT/?uri=celex:32010L0075 [Accessed:

6th October 2015].

Worrell, E., Bernstein L., Roy, J., Price, L., Harnisch, J.,

2009. Industrial energy efficiency and climate change

mitigation. In Energy Efficiency 2 (November). pp.

109-123.

Energy Saving and Efficiency Tool - A Sectorial Decision Support Model for Energy Consumption Reduction in Manufacturing SMEs

339