Modeling and Analysis of Automotive Systems: Current Approaches and

Future Trends

Paolo Giusto

1

, Ramesh S.

2

and Sudhakaran M.

2

1

General Motors, Palo Alto, U.S.A.

2

General Motors, Warren, U.S.A.

Keywords:

Model-based Development, Software Product Lines, Embedded Control Systems, Virtual Development.

Abstract:

The fierce competition among automotive manufacturers in introducing Advanced Driver Assist Systems

(ADAS) and autonomous features has led to the explosive growth of the Electrical/Electronics (E/E) assets,

including Software, in today’s and future vehicles. The resource demand and quality requirements of these as-

sets has increased consequently. Rigorous methodologies and tools are required for developing the E/E assets

to meet the quality demands of these assets. This paper summarizes the current practices used in the indus-

try for managing the development of these assets and discusses the future trends. The summary includes the

description of three development strategies that are becoming important and critical, which are Model-driven

Feature Development, Product Line Approach and Virtual Development and Integration of E/E architectures.

1 INTRODUCTION

After a modest start in the early 70s, electrification of

automobiles has grown leaps and bounds over the last

few decades; it now appears to take over the industry

as evidenced both by some electronic and software

giants exploring the possibility of building the next

generation autonomous vehicles, and some new play-

ers entering the market. In addition, there has been an

increased focus on Advanced Drive Assist Systems

(ADAS) in recent times. This has resulted in an ex-

plosion of active and passive safety features, realized

by electronics and software, driving the competition

among the manufacturers and tier one suppliers in the

industry.

Today’s vehicle is a complex and heterogeneous

system of systems, containing multiple embedded

systems of different characteristics. For example, the

powertrain sub-system is a deeply embedded mix-

ture of continuous and discrete control system, the

body control system is a state based discrete reactive

system, and the infotainment system is a non-real-

time system requiring an open and flexible platform.

With the emergence of automotive safety standards

such as ISO 26262 (ISO26262, 2011), different lev-

els of safety – the Automotive Safety Integrity Levels

(ASIL) – are applied to different subsystems in the ve-

hicle depending upon the risks associated with them.

In addition, the open platform requirement of info-

tainment systems and the various (intra- and inter-)

communication interfaces, are also raising the secu-

rity risks, causing a major concern to the industry.

The Electrical/Electronic (E/E) architecture in

modern day cars amounts to million lines of soft-

ware, hundreds of sensors, tens of electronic control

units (ECU), a handful of network buses, and miles

of wires distributing power and control signals to the

ECUs. The E/E architecture directly and indirectly

impacts vehicles CO2 emissions and fuel economies

– directly as wires impact the weight of vehicle and

indirectly as the electrical loads of the vehicle (e.g.,

HVAC) may determine higher or lower miles per gal-

lon (mpg). With the ever growing demand for aggres-

sive reduction in these quantities, efficient design and

realization of E/E architectures is a top priority.

GM is one of the largest automakers in the world,

with around 10 million vehicles built annually in 30

countries, with a very high number of brands and

product variants to meet customer demands, and vary-

ing standards of fuel economy and emission, safety

and security around the globe. E/E and Software sub-

systems cannot be designed, implemented, and main-

tained efficiently on a per vehicle basis. They are

managed as a product-line from the customer’s per-

spective, and as a set of vehicle engineering platforms

from GM’s perspective involving extensive reuse of

all life cycle artefacts and components (e.g., Hard-

ware, Software, requirements, designs, test suites),

704

Giusto, P., S., R. and M., S.

Modeling and Analysis of Automotive Systems: Current Approaches and Future Trends.

DOI: 10.5220/0005831007040710

In Proceedings of the 4th International Conference on Model-Driven Engineering and Software Development (MODELSWARD 2016), pages 704-710

ISBN: 978-989-758-168-7

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

and leading to more than 70% reduction of develop-

ment effort and field claims (Clements and Northrop,

2001; Flores et al., 2013). GM’s Software Product-

line is probably one of the most complex product-

lines with tens of concurrent development streams for

approximately 300 hierarchical subsystems with over

3000 engineers contributing to the development.

The main challenge facing automotive OEMs is to

bring new complex vehicle features quickly into mar-

ket, ahead of the competition while meeting the ex-

pected standards of reliability, dependency, security,

and cost. While similar challenges exist in other in-

dustries as well (e.g. Aerospace), what distinguishes

the automotive industry is its (mostly) high volumes,

the huge number of variants, the very stringent cost

constraints, and the cut-throat competition. In or-

der to address this challenge, the industry as a whole

and GM in particular, have been adopting a variety of

strategies. These include a strong focus and rigorous

documentation of system and feature requirements,

model-based development of driver-facing features,

the product-line approach to software development,

a system engineering approach to safety and relia-

bility, the adoption of a standardized Software Ar-

chitecture platform (based upon AUTOSAR - AU-

Tomotive Open System ARchitecture (AUTOSAR,

2003)), traceability across different life-cycle arte-

facts and extensive verification and validation at dif-

ferent stages of development. In addition, GM is also

looking at methodologies, methods, and tools for the

early assessment and optimization of the E/E archi-

tecture platforms that are optimized for cost and other

metrics to support the features being developed.

The management and development of such com-

plex systems must be handled with appropriate

methodologies, methods and tools. A few strategies

that have yielded good amount of success to GM

and other auto companies are model-based design of

features, a product line engineering approach to E/E

design, and virtual development and integration of

E/E architectures. These methodologies and related

modeling and tool technologies are different in focus

and maturity. Model-based design of features is sup-

ported by mature tools like Mathworks’s Simulink/SF

(www.mathworks.com), dSpace’s Hardware-in-Loop

(HIL) simulation (www.dpsace.com) and has be-

come quite main stream in the automotive indus-

try. The product line approach is supported by

tools such as Gears from BigLever for variant man-

agement (www.biglever.com), and the IBM suite

of tools DOORS, RTC and Synergy for require-

ment capture, and configuration management(see

www.ibm.com for more details on these tools). This

approach is largely in the deployment and accep-

tance stage in the majority of the OEMs. The

Virtual Development of Controls and Calibrations

strategy extends the simulation framework to phys-

ical plants, like Engine, Transmission and Chassis

units by making use of various plant modeling tools

like Saber (www.synopsis.com/prototyping/saber),

GT Power (www.gtisoft.com), AmeSim

1

, CarSim

(www.carsim.com), and Software in the loop (SIL)

for control modeling. This strategy targets the vehicle

level and sub-system level modeling and simulation

for the purpose of software development for control

functions and their related calibrations. The objec-

tive is to reduce the usage of expensive mule vehicles

for the development and verification and validation

of software rich controls and calibrations. Because

of the potentially high overhead of vehicle and sub-

system level simulations, large scale multidisciplinary

simulation environments are emerging, e.g., Cosimate

(www.cosimate.com), and Functional Mockup Inter-

faces (FMI) (see www.fmi-standard.org for more de-

tails) enable the deployment of component simula-

tions on several hosts and guaranteeing the physical

(timing) synchronization between the different simu-

lators.

The Virtual Development and Integration of E/E

Architectures is in its early stages. This strategy

aims at supporting the architects in designing and

integrating system, sub-system, and ECU architec-

tures from the perspective of the execution platform

resources. This entails assessing the capacity re-

quirements of ECUs, serial data buses, core proces-

sors and the like, in order to support the require-

ments for controls, safety, security, etc. This strategy

is in the early stages from the perspective of a for-

mal and tool-based approach relying on formal mod-

els for the metrics of interest (e.g., a timing model),

and analysis and simulation tools that can help as-

sessing the best design candidate. Although it is in

its early stages, mature tools for software and mes-

sage timing analysis such as SymTA/S by Symtavi-

sion (www.symtavision.com), for software develop-

ment pre-silicon such as Virtualizer by Synopsys, and

for automated optimization driven design space ex-

ploration such as Model Center by Phoenix Integra-

tion (www.phoenix-int.com) exist. The virtual devel-

opment strategy also supports the current practice of

extensive validation steps starting from unit tests, do-

main bench testing and system level HIL testing be-

fore the final vehicle level testing.

In the rest of this paper, we elaborate on the var-

ious aspects of automotive E/E assets development

1

See www.plm.automation.siemens.com/en us under

their product lifecycle management products for more de-

tails.

Modeling and Analysis of Automotive Systems: Current Approaches and Future Trends

705

outlined above. We review the methods and tools in

production use and discuss how they can be enhanced

to cater to the challenges facing the next generation

automotive E/E development. We propose a prelimi-

nary set of requirements for the enhancement and dis-

cuss the realization of these requirements and the re-

sults of some initial experimentation.

2 MODEL-BASED DESIGN OF

FEATURES

The new customer facing features are developed us-

ing model-based approaches. The focus is on the be-

havior and performance, design and verification &

validation of features. Feature requirements (func-

tional and non-functional) are captured using tools

such as DOORS and semi-formally using English

structured subsets, control algorithms captured in

Matlab/Simulink, and software implementations of

the controls represented as SIL. SIL set-ups, HIL-

benches, and VILS (vehicles in the loop) are used

for the design, verification, and validation of the

features with respect to their functional and non-

functional requirements. Typically, the impact of the

hardware/software platform resources on the perfor-

mance of the feature is assumed and not modeled.

Feature performance verification is done using the

idealistic assumed hardware/software platforms or in

the best-case scenarios, using non-executable perfor-

mance models (e.g., simple excel performance look-

up tables).

The verification of the decomposition of features

in engineering functions, and their allocation to hard-

ware/software platform resources provided by the

underlying E/E architecture is typically performed

using model in the loop (MIL) tools (e.g., Mat-

lab/Simulink models). Here, the performance aspects

are abstracted out or assumed irrelevant for the de-

sign and verification step (e.g., the underlying hard-

ware/software execution platform have no capacity

constraints). Again, due to lack of data or because of

historical reasons, the modeling of the performance

effects of the hardware/software platform is not part

of the design and verification task, or at least the

hardware/software impacts are assumed or estimated.

At the component level, the verification of control

SW implementing one or more SW functions is per-

formed using software-in-the-loop (SIL), which again

is, at best, modeling the scheduling policy of the soft-

ware -implemented functions. Each function is accu-

rately scheduled with zero execution time, no jitter,

instantaneous (taking zero time to execute) and non-

preemptable. This is a strong assumption that rep-

resents only one of the many possible timing behav-

iors of the real implementation. Therefore, the veri-

fication step may not reflect the actual timing behav-

ior of the real implementation and may lead to unex-

pected outcomes (e.g., missed input data due to un-

expected task overruns). During the validation and

testing phase, HILs and Mule vehicles (a.k.a. VIL)

are used. In this case, close-to-real life performance

effects are included as the HIL and/or the VIL are a

more faithful (albeit not final) representation of the

hardware/software platform as well as of the real con-

trolled plant (in this case, the VIL). We consider this

strategy quite mature from the perspective of models

and tools that are used. In fact, the adoption of models

and tools such as Matlab/Simulink is wide-spread in

the auto industry as well as the code generation capa-

bilities used either to generate code for the final target,

for the prototyping box (dSPACE micro Autobox), or

for the host computer where SIL is run. The maturity

here refers to a well-understood design flow and ver-

ification process in which performance effects of the

hardware/software platform are either abstracted out

or assumed.

Although mature and accepted by the automo-

tive community, this stream poses some challenges

when integrating plant models from different tools

and modeling paradigms to be able to validate the

integrated (as a set of engineering functions imple-

mented in hardware/software) feature implementation

against its requirements at the vehicle level. Tools

with different models of computation (e.g., discrete

event, continuous time, etc.) may be difficult to in-

tegrate and synchronize, although the recent efforts

on functional mockup interface (FMI) may come to

help. The other challenge is to make sure that re-

quirements are decomposed and allocated to the hard-

ware/software platform resources, and that traceabil-

ity between implementation and initial requirements

is enabled.

3 PRODUCT-LINE APPROACH

TO DEVELOPMENT

Automotive companies build multiple models of ve-

hicles under many brands which are sold in different

countries. For instance, GM manufactures 60 models

under seven brands and sells them in 150 countries. It

is unmanageable and inefficient to build such a large

number of vehicles on a per variant basis. This ap-

plies to not only the physical assets but also the E/E

components including software. The E/E assets are

conceived as a product-line sharing a common core

components and with a managed set of feature vari-

IndTrackMODELSWARD 2016 - MODELSWARD - Industrial Track

706

ants. In the case of software, all the life cycle arte-

facts, namely requirements, algorithm models, code

and test suite share the same product-line structure

and developed with multiplicities or variants. A spe-

cific instance of the product-line is configured at the

time of deployment in a specific vehicle instance. It is

estimated that as much as 85% reduction is achieved

in the second and subsequent application and around

70% reduction in field claims as a result managing the

E/E assets in a product-line fashion.

GM software product line is one of the most com-

plex product lines and is called a Megascale product

line because of its huge number of features and sub-

systems supported by it (Flores et al., 2013). GM

is an early member of SPL Hall of Fame (GMPT,

2004) and is in the second generation of product line

engineering. Software product lines are managed

through a 4-tier architecture: Functional, Implemen-

tation, Deployment and Application architecture. The

functional architecture defines the requirements of the

product line including the variability information in

the form of bill of features, the implementation their

realization in hardware or software, the deployment

allocates the realized components to appropriate sys-

tem level units, like ECUs, tasks and signals and fi-

nally the application architecture involves laying out

the system level units in the vehicle.

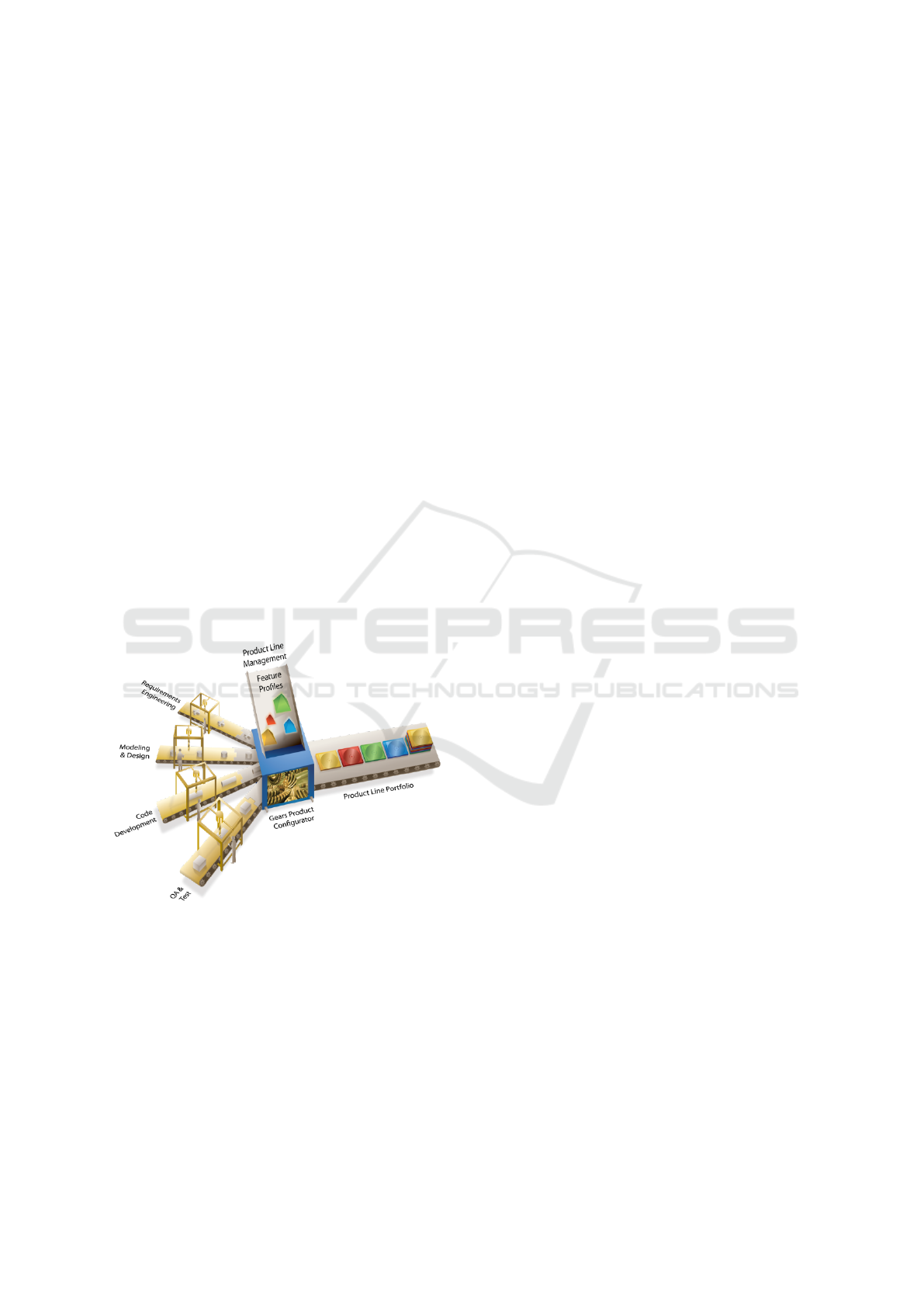

Figure 1: Product Line Approach to Development.

At the level of user facing features, the require-

ments are annotated with variant information which

is then used downstream in all the artefacts like de-

sign model, test objects and code. For instance, GM

uses DOORS for documenting the requirements and

the tool Gears from Big Lever Inc., is used for manag-

ing the product-line aspects. Interestingly, while the

requirements are textual, Gears annotations are ana-

lyzable formal objects. A typed expression language

is defined by Gears to express the annotations. At

the code level, the variant specification is managed by

calibrations which are appropriately set to actuate a

particular instance. An elaborate mechanism and in-

house tool chain is used for managing the calibrations.

GM releases a coordinated software product line ev-

ery 7 weeks and this has been a steady stream since

late 1990s. Figure 1 shows a high level view of the

development of the product line artefacts (BigLever,

2012).

4 VIRTUAL DEVELOPMENT

AND INTEGRATION OF E/E

ARCHITECTURES

At the highest levels, the design and the verification of

the electrical architecture relates to the physical parti-

tioning task. This task includes the determination of

physical resources, e.g. ECUs, fuse boxes and Elec-

trical Centers (ECs) and their potential up integration

into a single resource (e.g., merging two ECs into one)

or decomposition into multiple resources (e.g., adding

a new EC in the rear of the vehicle to the existing un-

der the trunk EC and Instrument EC). Typically merg-

ing is done with product line considerations and vari-

ants, including feature penetrations and manufactur-

ing/part costs. As such, additional information from

marketing (e.g., features penetration rates and product

line data) is required to assess the needs for up and/or

down-integration. In addition, the design and verifi-

cation of non-driver facing features (e.g., ECU wake-

up meta-protocol, ECU programming meta-protocol,

Vehicle Health Strategy) as well as the selection of

enabling architecture bus and middleware protocols

(e.g., AVB vs. Flexray, Autosar, etc.) is part of this

task including the component level selection (e.g., a

specific bus controller implementation).

Within this strategy, there are areas which relate

to the usage of models and tools for wiring harness

routing and optimization with respect to mass re-

duction and timing analysis techniques and tools to

model, design, and verify the timing aspects of the

programming meta-protocol of the ECUs. However,

this strategy is mainly supported by experience-based

semi-manual MS office and ad-hoc based verifica-

tion processes. The main advantage of this approach

is that experienced designers and architects can rule

out obviously unfeasible designs (using their “known

knowns” and the “known unknowns” of the design at

hand). The main drawback is that a semi-manual ap-

proach may be not appropriate to handle a large un-

known design space (e.g., the “unknown unknowns”)

Modeling and Analysis of Automotive Systems: Current Approaches and Future Trends

707

Figure 2: The V-Model of System Development.

and therefore guarantee any hope for (close-to) opti-

mality of the selected design alternative (or set of).

In addition, this approach supports little or no trace-

ability of decisions from requirements to system de-

sign, which is very important to finding root causes

of malfunctioning, and designs not working accord-

ing to the expectations, etc. Moreover, the validation

of the architecture (alternative) is performed via test-

ing on mule-vehicles and hardware benches very late

in the development cycle. Therefore, any assumptions

that were made during the feature development stage

with respect to the performance impact of the hard-

ware/software platform resources of the E/E Archi-

tecture are verified validated very late. Any changes

at this point in the design may be very expensive.

Additional complexities arise, again from considering

product lines and the trade-offs between manufactur-

ing costs (correlated to part numbers) and give-away

costs. The wiring harness optimization is an area that

has seen some progress with the emergence of tools

such as Mentor Graphics Capital.

A new E/E architecture development involves

many steps which address the various business chal-

lenges such as low-cost, weight, time to market, ro-

bustness, reliability, and security. On the other hand,

there are technical challenges to enable the integra-

tion and optimization of new hardware/software tech-

nologies such as AUTOSAR, high bandwidth proto-

cols such as Ethernet, and high processing power on

the controller (multi cores) without suffering from di-

minishing returns. Conventional E/E architecture de-

velopment process is not capable of addressing these

challenges.

Consider the well-known V-model of develop-

ment used in the auto industry, given in Figure 2. The

new methods and tools used for architecture devel-

opment and exploration are on left hand side of the

‘V’ curve. As described earlier, this methodology of

strengthening the design verification early in the de-

sign cycle will increase the robustness of the archi-

tecture and reduce time and cost in the redesign. The

new process relies of virtual integration of models for

functional and performance verification. Functional

verification using models is well-known and we will

focus on performance verification here.

Performance Verification

There are two main approaches to performance veri-

fication which we shall briefly discuss here.

Analytical methods is a well-known approach to

performance verification. They are fast and consist of

identifying the corner cases of a design, like the worst

case or best case scenario and constructing a math-

ematical representation of this case in the form of a

mathematical formula. This formula is then used to

compute the necessary performance metrics. An ex-

ample of analytical methods, illustrated in Figure 3, is

the latency analysis of CAN buses using tindell anal-

ysis (Tindell et al., 1995), used widely in the automo-

tive industry. The graph on the left side of the figure

describes the corner case scenario and the recursive

IndTrackMODELSWARD 2016 - MODELSWARD - Industrial Track

708

Time

(ms)

Sensor A

IO Task B

TxTask

CAN Bus

RxTask

IO Task D

Actuator E

0

Msg C

Legend:

Sample

Instance

End to End Latency, T

AE

Event Driven

Execution!

Value Needs to

Hold !!!

K

khpll

k

l

k

kk

msgC

inTasksInChakk

kkAE

JC

T

r

Cr

RrTT

)(,

,

)(

Assumptions:

All tasks are periodi c and unsynchronized

with each other. CAN messages are sent

synchronously by the CAN controller.

Figure 3: End to End Latency Timing Model for CAN Protocol.

equation shown on the right side is the formula for the

analysis. This equation is solved iteratively to com-

pute the worst case latency of a CAN bus. The models

used in the analytical methods are often abstract and

at the very early stage of the development and helps

in exploring the architecture alternatives efficiently.

An alternative to analytical methods is simulation

based methods. In these methods, the behavior and

the performance of the system are modeled and ex-

ecuted on a virtual platform (as opposed to the real

target vehicle platform). An appropriate set of sce-

narios, representative of the typical use cases of the

systems, are simulated to compute the performance

of the system. A well-known simulation based tool

for the performance evaluation of automotive con-

trol systems is SimEvent toolbox available in Mat-

lab. This toolbox has an associated discrete simu-

lation engine which can be used for simulating the

model over representative input space and calculating

the system performance. Figure 4 illustrates an exam-

ple of a SimEvent model simulating the partial net-

work based power consumption model. In this figure,

the SimEvent model is the network of blcoks shown

on the left hand side and the waveforms shown on

the right hand side are the inputs and outputs to the

model.

The fidelity of simulation methods depends upon

the degree of details included in the models. For in-

stance, one should include the transmission and re-

ceive buffers as they cause a major potential timing

bottleneck, to better assess the performance of the

CAN protocol, The major drawback of simulation

based methods is that simulation scales inversely with

the model complexity; larger the model complexity

and system, higher the simulation times are.

5 CONCLUSION

The design and development of E/E assets is becom-

ing a critical component in the development of mod-

Modeling and Analysis of Automotive Systems: Current Approaches and Future Trends

709

Figure 4: Matlab-SimEvent Simulation Models.

ern day automotive systems. Model-based develop-

ment, product-line engineering and virtual develop-

ment are some of the key-methodologies successully

employed in the industry. Several commercial tools

have been proposed to support these methodologies.

This paper highlights how some of these tools are be-

ing used in GM as well as in other automotive indus-

tries.

ACKNOWLEDGEMENTS

The authors would like to thank Bran Selic for push-

ing us to write this paper, Shoham Ben-David for

her generous support in reading the paper at differ-

ent stages of preparation and providing very useful

comments. We thank also Joseph D’Ambrosio for his

constructive comments.

REFERENCES

AUTOSAR (2003). AUTomotive Open System ARchitec-

ture. www.autosar.org.

BigLever (2012). BigLever’s Gears Product Line En-

gineering Lifecycle Framework. Software Prod-

uct Line Conferences. www.biglever.com/solution/

framework.html.

Clements, P. and Northrop, L. (2001). Software Product

Lines: Practices and Patterns. Addison-Wesley Pro-

fessional, Boston, MA, USA.

Flores, R., Krueger, C. W., and Clements, P. C. (2013).

Second-generation product line engineering: A case

study at general motors. In Systems and Software

Variability Management, Concepts, Tools and Expe-

riences, pages 223–250.

GMPT (2004). General Motors Powertrain: Product Line

Hall of Fame. Software Product Line Conferences.

http://splc.net/fame/gm.html.

ISO26262 (2011). International Standards Or-

ganization (ISO), Road Vehicles – Func-

tional Safety. http://www.iso.org/iso/

catalogue

detail.htm?csnumber=43464.

Tindell, K., Burns, A., and Willings, A. (1995). Calculating

controller area network (can) message response times.

Control Engineering Practice, 3(8).

IndTrackMODELSWARD 2016 - MODELSWARD - Industrial Track

710