The Data-driven Factory

Leveraging Big Industrial Data for Agile, Learning and Human-centric

Manufacturing

Christoph Gröger

1,2

, Laura Kassner

1

, Eva Hoos

1

, Jan Königsberger

1

, Cornelia Kiefer

1

,

Stefan Silcher

1,3

and Bernhard Mitschang

1

1

Graduate School of Excellence advanced Manufacturing Engineering, University of Stuttgart,

Nobelstr.12, 70569 Stuttgart, Germany

2

Robert Bosch GmbH, Robert-Bosch-Platz 1, 70839 Gerlingen-Schillerhöhe, Germany

3

eXXcellent solutions GmbH, Heßbrühlstraße 7, 70565 Stuttgart, Germany

Keywords: IT Architecture, Data Analy

tics, Big Data, Smart Manufacturing, Industrie 4.0.

Abstract: Global competition in the manufacturing industry is characterized by ever shorter product life cycles, increas-

ing complexity and a turbulent environment. High product quality, continuously improved processes as well

as changeable organizational structures constitute central success factors for manufacturing companies. With

the rise of the internet of things and Industrie 4.0, the increasing use of cyber-physical systems as well as the

digitalization of manufacturing operations lead to massive amounts of heterogeneous industrial data across

the product life cycle. In order to leverage these big industrial data for competitive advantages, we present the

concept of the data-driven factory. The data-driven factory enables agile, learning and human-centric manu-

facturing and makes use of a novel IT architecture, the Stuttgart IT Architecture for Manufacturing (SITAM),

overcoming the insufficiencies of the traditional information pyramid of manufacturing. We introduce the

SITAM architecture and discuss its conceptual components with respect to service-oriented integration, ad-

vanced analytics and mobile information provisioning in manufacturing. Moreover, for evaluation purposes,

we present a prototypical implementation of the SITAM architecture as well as a real-world application sce-

nario from the automotive industry to demonstrate the benefits of the data-driven factory.

1 INTRODUCTION

Global competition in the manufacturing industry is

characterized by ever shorter product life cycles, in-

creasing complexity and a turbulent environment.

High product quality, continuously improved pro-

cesses as well as changeable organizational structures

constitute critical success factors for manufacturing

companies (Westkämper, 2014).

With the rise of the internet of things, initiatives

like Industrie 4.0 (MacDougall, 2014), respectively

Smart Manufacturing (Davis et al., 2012), signifi-

cantly foster the use of cyber-physical systems (CPS)

(Shi et al., 2011) as well as the digitalization of man-

ufacturing operations and promote the vision of de-

centralized self-control and self-optimization of prod-

ucts and processes (Brettel et al., 2014). This leads to

enormous amounts of heterogeneous industrial data

across the entire product life cycle, representing big

industrial data (Kemper et al., 2013). These data are

both structured and unstructured, ranging, e.g., from

machine sensor data on the shop floor to data on prod-

uct usage as well as from data on customer complaints

in social networks to data on failure reports of service

technicians. Exploiting these data, that is, extracting

valuable business insights and knowledge from these

data, is one of the central challenges in Industrie 4.0

(Gölzer et al., 2015). For example, these data can be

used for optimization of product design, manufactur-

ing execution and quality management.

However, the prevailing manufacturing IT archi-

tecture in practice, the information pyramid of manu-

facturing (ISA, 2000), prevents comprehensive data

exploitation due to the following limitations:

(1) complex point-to-point integration of heterogene-

ous IT systems limits a flexible integration of new

data sources; (2) strictly hierarchical aggregation of

information prevents a holistic view for knowledge

extraction; (3) isolated information provisioning for

the manufacturing control level and the enterprise

control level impedes employee integration on the

factory shop floor.

40

Gröger, C., Kassner, L., Hoos, E., Königsberger, J., Kiefer, C., Silcher, S. and Mitschang, B.

The Data-driven Factory - Leveraging Big Industrial Data for Agile, Learning and Human-centric Manufacturing.

In Proceedings of the 18th International Conference on Enterprise Information Systems (ICEIS 2016) - Volume 1, pages 40-52

ISBN: 978-989-758-187-8

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

To address these issues, we present the concept of

the data-driven factory which is based on the results

of several research projects we have undertaken at the

Graduate School of Excellence advanced Manufac-

turing Engineering (GSaME) at the University of

Stuttgart in cooperation with various industry part-

ners. The data-driven factory leverages big industrial

data for agile, learning and human-centric manufac-

turing and makes use of a novel IT architecture, the

Stuttgart IT Architecture for Manufacturing (SITAM),

overcoming the insufficiencies of the traditional in-

formation pyramid of manufacturing. The data-driven

factory combines service-oriented integration, ad-

vanced analytics as well as mobile information provi-

sioning in a holistic approach in order to exploit big

industrial data for competitive advantages.

The remainder of this paper is organized as fol-

lows: First, we analyze the limitations of the infor-

mation pyramid of manufacturing with respect to big

industrial data and further discuss related work in

Section 2. Next, we introduce the concept of the data-

driven factory in Section 3 and derive technical re-

quirements. Section 4 focuses on the SITAM archi-

tecture and its components in order to address these

requirements and provide a technical framework for

the data-driven factory. For evaluation purposes, we

present a prototypical implementation of the SITAM

architecture and discuss a real-world application sce-

nario in Section 5 demonstrating the benefits of the

data-driven factory. Finally, we conclude in Section 6

and highlight future work.

2 BIG INDUSTRIAL DATA AND

THE INFORMATION PYRAMID

OF MANUFACTURING

In this section, first, we analyze the limitations of the

traditional information pyramid of manufacturing

with respect to big industrial data in Section 2.1.

Next, we discuss related work, especially recent man-

ufacturing IT architectures addressing these limita-

tions in Section 2.2.

2.1 Limitations of the Information

Pyramid of Manufacturing

The information pyramid of manufacturing, also

called the hierarchy model of manufacturing, repre-

sents the prevailing manufacturing IT architecture in

practice (Vogel-Heuser et al., 2009). It is used to

structure data processing and IT systems in manufac-

turing companies and it is standardized in ISA 95

(ISA, 2000). In a simplified version, the information

pyramid is comprised of three hierarchical levels (see

Figure 1): the enterprise control level refers to all

business-related activities and IT systems, such as en-

terprise resource planning (ERP) systems, the manu-

facturing control level focuses on manufacturing op-

erations management especially with manufacturing

execution systems (MES) and the manufacturing

level refers to the machines and automation systems

on the factory shop floor.

Figure 1: Information pyramid of manufacturing.

Data processing in the information pyramid is based

on three fundamental principles (Vogel-Heuser et al.,

2009):

• Central Automation to control all activities top-

down starting from the enterprise control level

• Information Aggregation to condense all data bot-

tom-up starting from the manufacturing level

• System Separation to allow only IT systems at ad-

jacent levels to directly communicate with each

other

The digitalization of manufacturing operations as

well as the massive use of CPS lead to big industrial

data, i.e., enormous amounts of heterogeneous indus-

trial data at all levels of the information pyramid and

across the entire product life cycle (Kemper et al.,

2013). For instance, besides huge amounts of struc-

tured machine data and sensor data resulting from the

shop floor, there are unstructured data on service re-

ports and customer opinions in social networks. Ex-

ploiting these data, that is, extracting valuable busi-

ness insights and knowledge, enables comprehensive

optimization of products and processes (Gölzer et al.,

2015). For instance, customer satisfaction can be cor-

related with product design parameters using CAD

data and CRM data or root causes of process quality

issues can be analyzed using machine data and ERP

data.

However, data processing according to the infor-

mation pyramid of manufacturing prevents

Manufacturing Control Level

Manufacturing Level

Enterprise

Control Level

MES

ERP

The Data-driven Factory - Leveraging Big Industrial Data for Agile, Learning and Human-centric Manufacturing

41

comprehensive data exploitation due to the following

major technical limitations (L

i

):

• L

1

: Central automation and system separation lead

to a complex and proprietary point-to-point inte-

gration of IT systems, which significantly limits a

flexible integration of new data sources across all

hierarchy levels (Minguez et al., 2010). For exam-

ple, integrating an additional machine typically re-

quires the costly and time-consuming adaptation of

interfaces for a specific MES.

• L

2

: Strictly hierarchical information aggregation

leads to separated data islands preventing a holis-

tic view for knowledge extraction (Kemper et al.,

2013). For instance, historic machine data at the

manufacturing level is separated from ERP data at

the enterprise control level, which prevents a ho-

listic process performance analysis correlating,

e.g., machine parameters and details on product

configurations.

• L

3

: Central control and information aggregation

lead to isolated information provisioning focusing

on the manufacturing control level and the enter-

prise control level and thus impede employee inte-

gration on the manufacturing level (Bracht et al.,

2011). For example, process execution data is typ-

ically aggregated for MES and ERP systems with-

out information provisioning for shop floor work-

ers.

To conclude, the function-oriented and strictly hier-

archical levels of the information pyramid of manu-

facturing support a clear separation of concerns for

the development and management of IT systems.

However, the information pyramid lacks flexibility,

holistic data integration and cross-hierarchical infor-

mation provisioning. These factors significantly limit

the exploitation of big industrial data and necessitate

new manufacturing IT architectures, which are dis-

cussed in the following section.

2.2 Related Work: Manufacturing IT

Architectures

We did a comprehensive literature analysis on recent

architectural approaches for IT-based manufacturing.

As result, we identified the following two major

groups of work:

• Abstract Frameworks for Industrie 4.0 and Smart

Manufacturing, which represent meta models and

roadmaps for standardization issues, especially the

Reference Architectural Model Industrie 4.0

(ZVEI, 2015) as well as the SMLC framework for

Smart Manufacturing (Davis et al., 2012)

• Concrete Manufacturing IT Architectures, which

structure IT components and their relations in and

across manufacturing companies on a conceptual

level, especially (Vogel-Heuser et al., 2009;

Minguez et al., 2010; Holtewert et al., 2013; Pa-

pazoglou et al., 2015)

The above frameworks are defined on a significantly

higher abstraction level than the information pyramid

of manufacturing. Hence, we concentrate on existing

manufacturing IT architectures and analyze them

with respect to the technical limitations of the infor-

mation pyramid identified in Section 2.1. The com-

mon core of all of the above IT architectures is a ser-

vice-oriented architecture (SOA) (Erl, 2008) in order

to enable a flexible integration of IT systems – i.e. IT

services – across all hierarchy levels (Minguez et al.,

2010; Holtewert et al., 2013). In addition, in (Vogel-

Heuser et al., 2009), the need for a common data

model standardizing the interfaces and the data of the

IT services is underlined. In (Holtewert et al., 2013;

Papazoglou et al., 2015), a marketplace with IT ser-

vices is proposed in addition. In (Papazoglou et al.,

2015), a knowledge repository is part of the architec-

ture. However, no concrete concepts for data integra-

tion, data analytics or data quality are presented.

All in all, these existing manufacturing IT archi-

tectures mainly address the limitation of a complex

and proprietary point-to-point integration of IT sys-

tems in the information pyramid of manufactur-

ing (L

1

). Yet, they lack manufacturing-specific ap-

proaches for data analytics and information provi-

sioning to fully address the limitations of separated

data islands (L

2

) as well as of isolated information

provisioning (L

3

). In contrast, our concept of the data-

driven factory and the SITAM architecture address all

three limitations in a holistic approach as detailed in

the following sections.

3 THE DATA-DRIVEN FACTORY

The data-driven factory is a holistic concept to exploit

big industrial data for competitive advantages of man-

ufacturing companies. For this purpose, the data-

driven factory addresses central economic challenges

of today’s manufacturing (Westkämper, 2014), par-

ticularly agility, learning ability as well as employee

orientation, and makes use of a novel IT architecture,

the Stuttgart IT Architecture for Manufacturing

(SITAM), overcoming the insufficiencies of the tra-

ditional information pyramid of manufacturing.

The data-driven factory takes a holistic view on

all data generated across the entire product life cycle,

ICEIS 2016 - 18th International Conference on Enterprise Information Systems

42

from product design over manufacturing execution

until service and support, including both structured

data and unstructured data. Structured data generally

refers to data in a relational form whereas unstruc-

tured data comprises text, audio and video files as

well as images. In contrast to earlier integration ap-

proaches, especially Computer Integrated Manufac-

turing (Groover, 2008), the data-driven factory does

not aim at totally automating all operations and deci-

sion processes but explicitly integrates employees in

order to benefit from their knowledge, creativity and

problem-solving skills.

In the following, we highlight the characteristics

of the data-driven factory in Section 3.1 and derive

corresponding technical requirements in Section 3.2

as a basis for the development of the SITAM archi-

tecture in Section 4.

3.1 Characteristics

From a manufacturing point of view, the data-driven

factory is defined by the following core characteris-

tics (see Figure 2):

• The data-driven factory enables agile manufactur-

ing (Westkämper, 2014) by exploiting big indus-

trial data for proactive optimization and agile

adaption of activities. For instance, machine fail-

ures and turbulences can be predicted near real-

time and manufacturing processes can be proac-

tively adapted.

• The data driven factory enables learning manufac-

turing (Hjelmervik and Wang, 2006) by exploiting

big industrial data for continuous knowledge ex-

traction. For instance, concrete action recommen-

dations can be learned from historic process exe-

cution data to optimize a specific metric, e.g., qual-

ity rate.

• The data driven factory enables human-centric

manufacturing (Zuehlke, 2010) by exploiting big

industrial data for context-aware information pro-

visioning as well as knowledge integration of em-

ployees to keep the human in the loop. For exam-

ple, shop floor workers are immediately informed

about performance issues of the machine they are

currently working at and can digitally create corre-

sponding improvement suggestions, e.g., by re-

cording a video.

To conclude, the data-driven factory leverages big in-

dustrial data for agile, learning and human-centric

manufacturing. In this way, it creates new potentials

for competitive advantages for manufacturing com-

panies, especially with respect to efficient and at the

same time agile processes, continuous and proactive

improvement as well as the integration of knowledge

and creativity of employees across the entire product

life cycle.

Figure 2: Characteristics and technical requirements

of the data-driven factory.

3.2 Technical Requirements

Based on the above characteristics and taking into ac-

count the limitations of the information pyramid of

manufacturing (see Section 2.1), we have derived the

following technical core requirements (R

i

) for the re-

alization of the data-driven factory (see Figure 2):

• R

1

: Flexible Integration of Heterogeneous IT Sys-

tems to rapidly include new data sources for agile

manufacturing, e.g., when setting up a new ma-

chine

• R

2

: Holistic Data Basis and Advanced Analytics

for knowledge extraction in learning manufactur-

ing, e.g., to prescriptively extract action recom-

mendation from both structured and unstructured

data

• R

3

: Mobile Information Provisioning to ubiqui-

tously integrate employees across all hierarchy

levels for human-centric manufacturing, e.g., in-

cluding service technicians in the field as well as

product designers

In order to realize these requirements, a variety of IT

concepts and technologies has to be systematically

combined in an overall IT architecture. As we ana-

lyzed in Sections 2.1 and 2.2, the information pyra-

mid of manufacturing lacks flexibility, holistic data

integration and cross-hierarchical information provi-

sioning (R

1

-R

3

). Thus, a novel manufacturing IT ar-

chitecture is necessary, which is detailed in the next

section.

4 SITAM: STUTTGART

IT ARCHITECTURE

FOR MANUFACTURING

The SITAM architecture is a conceptual IT architec-

ture for manufacturing companies to realize the data-

Data-Driven

Factory

Agile

Learning

Human-

Centric

Technical Requirements

• Flexible Integration of

Heterogeneous IT

Systems

• Holistic Data Basis and

Advanced Analytics

• Mobile Information

Provisioning

The Data-driven Factory - Leveraging Big Industrial Data for Agile, Learning and Human-centric Manufacturing

43

driven factory. The architecture is based on the results

and insights of several research projects we have un-

dertaken in cooperation with various industry part-

ners, particularly from the automotive and the ma-

chine construction industry.

In the following, we present an overview of the

SITAM architecture in Section 4.1 and detail its com-

ponents in Sections 4.2-4.6.

4.1 Overview

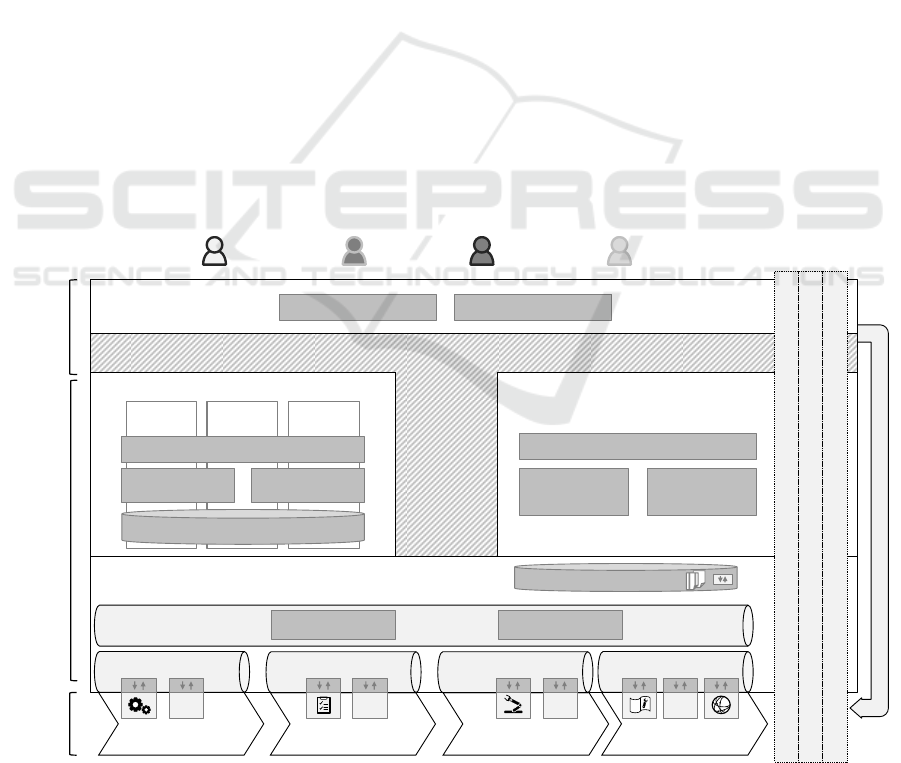

The SITAM architecture (see Figure 3) encompasses

the entire product life cycle: Processes, physical re-

sources, e.g., CPS and machines, IT systems as well

as web data sources provide the foundation for sev-

eral layers of abstracting and value-adding IT.The in-

tegration middleware (see Section 4.2) encapsulates

these foundations into services and provides corre-

sponding data exchange formats as well as mediation

and orchestration functionalities.

The analytics middleware (see Section 4.3) and

the mobile middleware (see Section 4.4) build upon

the integration middleware to provide predictive and

prescriptive analytics for structured and unstructured

data around the product life cycle and mobile inter-

faces for information provisioning.

Together, the three middlewares enable the com-

position of value-added services for both human users

and machines (see Section 4.5). In particular, services

can be composed ad-hoc and offered as mobile or

desktop apps on an app marketplace to integrate hu-

man users, e.g., by a mobile manufacturing dashboard

with prescriptive analytics for workers. The added

value from these services feeds back into the product

life cycle for continuous proactive improvement and

adaptation.

Cross-architectural topics (see Section 4.6) repre-

sent overarching issues relevant for all components

and comprise data quality, governance as well as se-

curity and privacy.

In the following, the components of the SITAM

architecture are described in greater detail.

4.2 Integration Middleware:

Service-oriented Integration

The SITAM’s integration middleware represents a

changeable and adaptable integration approach,

which is based on the SOA paradigm (Erl, 2008). The

integration middleware is specifically tailored to

manufacturing companies, providing the much

needed flexibility and adaptability required in today’s

aforementioned turbulent environment with a perma-

nent need of change.

Figure 3: Overview of the Stuttgart IT Architecture for Manufacturing (SITAM).

Continuous Improvement and Feedback

Integration Middleware

Value-Added Services

PLM Bus

SOA Governance Repository

Mediation Orchestration

Analytics Middleware

Descriptive

Analytics

Predictive

Analytics

Prescriptive

Analytics

Mobile Middleware

Service

Composition & Access

Security & Privacy

Governance

Data Quality

Product Life Cycle:

Processes, Resources,

IT-Systems, Web

Value-adding

Middleware

Role-based

Applications

Manufacturing Knowledge Repository

Mobile

Context-Aware

Data Handling

Mobile

Synchronization

and Caching

Mobile Visualization

Visual Analytics

Information Mining KPI Management

App Composer App Marketplace

After Sales Service Bus

Usage and Support

CRM

Prod. Planning Service

Bus

Production planning

ERP

Engineering Service Bus

Engineering

PDM

Manufacturing Service

Bus

Manufacturing

MES

ICEIS 2016 - 18th International Conference on Enterprise Information Systems

44

To enable those benefits, it builds on a concept of

hierarchically arranged Enterprise Service Busses

(ESBs) following (Silcher et al., 2013). Each one of

these ESBs is responsible for the integration of all ap-

plications and services of a specific phase of the prod-

uct life cycle.

All phase-specific ESBs are connected via a su-

perordinate Product-Lifecycle-Management-Bus

(PLM Bus). The PLM Bus is responsible for commu-

nication and mediation between phase-specific bus-

ses as well as for the orchestration of services.

This concept enables, for example, the easier inte-

gration of external suppliers without opening up too

much of a company’s internal IT systems to them by

just “plugging” their own ESB into the PLM Bus. Be-

sides, it also reduces the complexity by abstraction

over the introduced integration hierarchy.

A dedicated sub-component providing real-time

capabilities is used in the manufacturing phase to con-

nect CPS and other real-time machine interfaces to

the overall ESB compound.

The ESB hierarchy effectively abstracts and de-

couples technical systems and their services into a

more business-oriented view, which we call value-

added services. Value-added services use the basic

services providing access to application data, orches-

trate and combine them.

This decoupling also evens out different speeds in

the development and change of applications or ser-

vices. Companies often face the problem of having to

integrate, e.g., legacy mainframe applications with

modern mobile apps, which inherently have very dif-

ferent development speeds. By decoupling business-

oriented services from the technical systems/services,

each application can be developed separately and at

its own pace, while the integration middleware han-

dles all transformations and mediations that might be

necessary to maintain compatibility.

Each phase-specific ESB also utilizes its own

phase-specific data exchange format to handle the

different requirements of each phase. For example,

engineering has to be able to exchange large amounts

of data, e.g., CAD models, whereas manufacturing re-

quires the quick exchange of a large amount of

smaller data chunks, e.g., MES production data. Af-

tersales on the other hand needs to handle both large

CAD data as well as small, lightweight data struc-

tures, e.g., live car data.

The separation into different phase-specific ESBs

allows each department or business unit to make use

of specialized data exchange formats tailored to

phase-specific needs.

To sum up, the hierarchical composition of phase-

specific ESBs across the entire product life cycle and

the changeable service-oriented abstraction of IT sys-

tems address requirement R

1

(flexible integration of

heterogeneous IT systems) of the data-driven factory.

4.3 Analytics Middleware: Advanced

Analytics

The analytics middleware is service-oriented and

comprises several manufacturing-specific analytics

components which are crucial for a data-driven fac-

tory: The manufacturing knowledge repository for

storing source data and analytics-derived insights, in-

formation mining on structured and unstructured data,

management of key performance indicators (KPIs),

and visual analytics. The analytics middleware in-

cludes functionalities for descriptive, predictive and

prescriptive analytics, with prescriptive analytics be-

ing a novel introduction which provides actionable

problem solutions or preventative measures before

critical conditions lead to losses (Evans and Lindner,

2012). In providing integrative, holistic and near-real

time analytics on big industrial data of all data types,

the SITAM analytics middleware transcends the ana-

lytics capabilities of existing approaches (see Sec-

tion 2). This significantly contributes to the learning

and agile characteristics of the data-driven factory.

Source data are extracted using predefined ETL

functions from the integration middleware. Integrated

data of structured and unstructured type from around

the product life cycle are stored in the manufacturing

knowledge repository along the lines of (Gröger et al.,

2014b) for maximum integration, minimum infor-

mation loss and flexible access. Over the course of the

product life cycle, this repository is enriched with var-

ious knowledge artefacts, e.g., analytics results like

data mining models, business rules and free-form

documents such as improvement suggestions. To

store structured and unstructured source data in a

scalable manner, the repository combines SQL and

NoSQL storage concepts. It also includes the func-

tionality for flexibly creating semantic links between

source data and knowledge artefacts to support rea-

soning and knowledge management (see (Gröger et

al., 2014b)).

The information mining component can be subdi-

vided into classical data mining and machine learning

tools for structured data on the one hand, and tools for

various types of unstructured data – text, audio,

video – on the other hand.

We will discuss text analytics (Aggarwal and

Zhai, 2012) in more detail since its use in a frame-

work for integrative data analytics is novel and since

text data harbor a wealth of hitherto untapped

knowledge. Typically, text analytics applications

The Data-driven Factory - Leveraging Big Industrial Data for Agile, Learning and Human-centric Manufacturing

45

have been focused on one isolated unstructured data

source and one analytical purpose, without integrat-

ing the results with analytics on structured data and

with the disadvantage of information loss along the

processing chain (Kassner et al., 2014).

To secure flexibility of analytics and easy integra-

tion of data from different sources, we propose a set

of basic and custom text analytics toolboxes, includ-

ing domain-specific resources for the manufacturing

and engineering domains and on an individual prod-

uct domain level. This type of toolbox is similar to the

generic and specific text analytics concepts proposed

in (Kassner et al., 2014). Value-added applications of

these text analytics tools fall into two main catego-

ries: (1) information extraction tasks and (2) direct

support of human labor through partial automation.

For example, presenting the top ten errors for a spe-

cific time span based on text in shop floor documen-

tation is an information extraction task which helps

workers gain insights into weaknesses of the produc-

tion setup. Using features of text reports, for example

occurrences of particular domain-specific keywords,

to predict the likelihood of certain error codes which

a human expert must manually assign to these text re-

ports, constitutes an example of a direct support ana-

lytics task (see (Kassner and Mitschang, 2016) for an

implementation and proof of concept of this use case

within the SITAM architecture).

Information mining can then be applied to dis-

cover knowledge, which is currently hidden in a com-

bination of structured data and extracts from unstruc-

tured data. For example, process and machine data

from the shop floor can be matched up with

timestamps and extracted topics or relations from un-

structured error reports to discover root causes for

problems which have occurred. Real-time process

data from the shop floor can be compared to historical

data to discover indicators for problematic situations

and prescribe measures for handling them, for exam-

ple speeding up a machine when a delayed process

has been discovered.

In order to constitute the backbone of a truly data-

driven factory, information mining has to be con-

ducted near real-time, on a variety of data sources as-

needed, and manufacturing processes, sales, delivery,

logistics and marketing campaigns have to adjust to

meet the prescriptions derived from analytics results.

The management of key performance indicators is

another important component and can be greatly im-

proved by readily available and flexible analytics on

a multitude of data sources. Instead of being an off-

line process conducted by the executive layer based

on aggregated reporting data, KPI management can

become a continuous and pervasive process, as data

analytics feedback loops are in place for all processes

around the product life cycle and at any level of the

process hierarchy.

Finally, the analytics middleware also includes

visual analytics for data exploration through human

analysts: This type of analytics mainly combines in-

formation mining and visualization techniques to pre-

sent large data sets to human observers in an intuitive

way, allowing them to make sense of the data beyond

the capabilities of analytics algorithms. Thus, visual

analytics keep the human in the loop according to hu-

man-centric manufacturing.

Thus, the analytics capabilities of our reference

architecture for the data-driven factory transcend

those of related conceptual work in several aspects:

(1) They include prescriptive, not just predictive or

descriptive analytics, (2) they fully integrate struc-

tured and unstructured data beyond the manufactur-

ing process, (3) they stretch across the entire product

life cycle and provide a holistic view as well as holis-

tic data storage, and (4) they are decentralized yet in-

tegrative, since analytics services are combined as-

needed to answer questions or supervise processes

and keep the human in the loop. Advanced analytics

mostly contribute to the fulfillment of requirement

R

2

, but also R

3

and R

1

of the data-driven factory.

4.4 Mobile Middleware: Mobile

Information Provisioning

The mobile middleware enables mobile information

provisioning and mobile data acquisition by facilitat-

ing the development and integration of manufactur-

ing-specific mobile apps. Mobile apps (Clevenger,

2011) are running on smart mobile devices, such as

smartphones, tablets, and wearables, and integrate hu-

mans into the data-driven factory. Due to their high

mobility, workers on the shop floor have to have ac-

cess to the services of the factory anywhere and any-

time, e.g., viewing near real-time information or cre-

ating failure reports on-the-go, supported by the mo-

bile devices’ cameras and sensors. Workers can also

actively participate in the manufacturing process,

e.g., they can control the order in which products are

produced. Furthermore, mobile apps offer an intuitive

task-oriented touch-based design and enable users to

consume only relevant data. Mobile devices also al-

low for the collection of new kinds of data, e.g., posi-

tion data or photos. This enables new kinds of ser-

vices such as context-aware apps and augmented-re-

ality apps (Hoos et al., 2014).

However, the development of mobile apps differs

from the development of stationary applications due

to screen sizes, varying mobile platforms, unstable

ICEIS 2016 - 18th International Conference on Enterprise Information Systems

46

network connections and other factors. In addition,

manufacturing-specific challenges arise (Hoos et al.,

2014), e.g., due to the complex data structures as well

as the high volume of data. In contrast to existing ap-

proaches (see Section 2.2), the mobile middleware

addresses these manufacturing-specific needs.

The mobile middleware comprises three compo-

nents: mobile context-aware data handling, mobile

synchronization and caching as well as mobile visu-

alization.

The mobile context-aware data handling compo-

nent provides manufacturing-specific context models

describing context elements and relations, e.g., on the

shop floor, as well as efficient data transfer mecha-

nism so that only relevant data in the current context

is transmitted to the mobile device. For instance, a

shop floor worker specifically needs information on

the current machine he is working at.

The mobile synchronization and caching compo-

nent supports offline usage of mobile apps. This is

important because a network connection cannot al-

ways be guaranteed, particularly on the factory shop

floor. The components offers mechanisms to deter-

mine which data should be cached using context in-

formation provided by the context models.

The mobile visualization component provides tai-

lored visualization schemas for manufacturing data,

e.g., for CAD product models. For example, it pro-

vides a visualization schema to represent a hierar-

chical product structure and to browse it via touch

gestures. Various screen sizes and touch-based inter-

action styles are considered.

To sum up, the mobile middleware enables the in-

tegration of the human by supporting the develop-

ment and integration of mobile apps. This is done by

offering manufacturing-specific services for data

handling and visualization. Thus, by addressing re-

quirement R

3

(mobile information provisioning), the

mobile middleware contributes to the human-centric

characteristic of the data-driven factory, i.e., keeping

the human in the loop.

4.5 Service Composition and

Value-added Services

The service-based and integrative nature of the

SITAM architecture allows it to provide value-added

services in several ways. We define value-added ser-

vices as services which provide novel uses and thus

create value by transcending the limitations of the in-

formation pyramid of manufacturing (see Section

2.1): By providing flexible interfaces for data and ser-

vice provisioning (addressing limitation L

1

), by inte-

grating, analyzing and presenting data from several

phases around the product life cycle (addressing lim-

itation L

2

) and by providing access to information in

all the contexts in which it is needed and in which the

traditional model may fail to do so (addressing limi-

tation L

3

). The value-added services offered in the

SITAM architecture cut across the architectural lay-

ers, packaging and combining functionalities of the

integration middleware, the analytics middleware and

the mobile middleware.

In the SITAM architecture, services are composed

and adapted on the basis of user roles and the infor-

mation needs and permissions associated with them.

For example, a shop floor worker receives detailed

alerts related to the process step he is responsible for,

whereas his production supervisor is concerned with

the aggregated state of the entire manufacturing pro-

cess across all process steps.

Ad-hoc service composition is enabled by the app

composer. The app composer offers this functionality

for users in all roles, regardless of their educational

background or their ability to code. For example, data

sources and analytics services can be mashed up and

composed via drag-and-drop in a graphic user inter-

face. Atomic or composed services can then be of-

fered and distributed as apps in the app marketplace

for all types of devices, both stationary and mobile.

To sum up, flexible service composition contrib-

utes to the fulfillment of requirement R

1

(flexible in-

tegration of heterogeneous IT systems) and the provi-

sioning of composed services as mobile apps helps to

fulfill requirement R

3

(mobile information provision-

ing) of the data-driven factory.

4.6 Cross-architectural Topics

Security and privacy, governance and data quality are

overarching topics which must be considered at all

layers of the architecture: at the data sources, in ana-

lytics and mobile middleware as well as in the appli-

cations. In the following, we focus on SOA govern-

ance and data quality as they require specific con-

cepts for the data-driven factory. For general security

and privacy issues in data management, we refer the

reader to (Whitman and Mattord, 2007).

The governance of complex service-oriented archi-

tectures is often neglected in existing manufacturing IT

architectures, such as (Papazoglou et al., 2015), even

though a lack of governance is one of the main reasons

for failing SOA initiatives (Meehan, 2014).

SOA governance covers a wide range of aspects (a

list of key aspects can be found in (Königsberger et

al., 2014)). With more and more systems being inte-

grated – especially CPS, but also for example social

media services – it is becoming difficult to keep track

The Data-driven Factory - Leveraging Big Industrial Data for Agile, Learning and Human-centric Manufacturing

47

of planned changes to those systems and services. For

this reason, service change management and service

life cycle management governance processes track

and report those changes to service consumers and

providers, governed for example via consumer and

stakeholder management processes.

When setting up those governance processes, it is

important to keep them as lightweight and unobtru-

sive as possible in order to minimize complexity and

managerial effort. To support this, the SITAM archi-

tecture contains a central SOA governance repository,

which is built on a specific SOA governance meta

model described in (Königsberger et al., 2014). The

repository uses semantic web technologies that allow

for example the use of semantic reasoning to detect

new dependencies or missing information. The SOA

Governance Repository also contains service data as

well as operations data, spanning and providing sup-

port during all phases of the service life cycle, and

therefore also supporting novel software develop-

ment concepts like DevOps.

Apart from SOA governance, the need for high

quality data is a direct consequence of the concept of

the data-driven factory. A data quality framework for

the data-driven factory needs to enable data quality

measurement and improvement (1) in near real-time

(2) at all analysis steps from data source to user (3)

for all types of data accumulating in the product life

cycle, especially structured data as well as unstruc-

tured textual, video, audio and image data.

Existing data quality frameworks, e.g., (Wang and

Strong, 1996; Sebastian-Coleman, 2013), fail to sat-

isfy these requirements. Hence, we translate these re-

quirements into an extended data quality framework,

which allows a flexible composition of data quality

dimensions (e.g., timeliness, accuracy, relevance and

interpretability) at all levels of the SITAM architec-

ture (see (Wang and Strong, 1996) for an example list

of data quality dimensions). Furthermore, we define

sets of concrete indicators considering data consum-

ers at all levels, from data source to user, and we al-

low for near real-time calculation of data quality (e.g.,

the confidence or accuracy of machine learning algo-

rithms, language of text and speech, author of data

sources and the distribution of data points on a time-

line). This makes the quality of data and of resulting

analytics results transparent at all levels and therefore

enables holistic data quality improvement.

To sum up, we have seen that SOA governance

and data quality are crucial factors across all layers of

the SITAM architecture. A flexible composition of IT

systems and services can be offered using service-ori-

ented architectures. But complex service-oriented ar-

chitectures are prone to fail without systematic SOA

governance. Besides, a holistic data quality frame-

work forms the basis to measure and improve data

quality from data source to user, including the gener-

ated analytics results.

5 IMPLEMENTATION AND

EVALUATION

In the following, we present current work on the real-

ization of the SITAM architecture in a prototypical

implementation in Section 5.1. Moreover, we intro-

duce a real-world application scenario from the auto-

motive industry using the SITAM architecture in Sec-

tion 5.2 and finally evaluate the benefits of the

SITAM architecture and the concept of the data-

driven factory in Section 5.3.

5.1 Implementation Strategy

and Prototype

Our current prototype covers core components in

every layer of the SITAM architecture, in particular

with respect to analytics, governance, mobile and re-

pository aspects. In the following, we sketch major

solution details and technologies we utilized. The lat-

ter were chosen from the large available pool of free

and open source software to underline the broad ap-

plicability of the SITAM architecture and make the

implementation easily adaptable to various industrial

real-world settings.

The integration middleware relies on WSO2’s

Application Server and Business Process Server, to

realize the hierarchical ESB structure as well as the

orchestration of basic services and mediation between

phase-specific ESBs as described in (Silcher et al.,

2013). Services within the prototype are implemented

as either conventional SOAP web services or REST

services. Data exchange formats are realized as XSD

documents and stored in the SOA governance repos-

itory. The repository itself relies, as mentioned in

Section 4.6, on semantic web technologies, mainly

the resource description framework (RDF) and pro-

vides a web-accessible as well as a Web Service in-

terface as described in (Königsberger et al., 2014).

In the analytics middleware, the manufacturing

knowledge repository is implemented as a federation

of a relational database and a NoSQL system – we

used the content management system Alfresco

CMS – to store structured and unstructured data.

These systems are integrated by a specific link store

using a graph database such as Neo4j. The infor-

mation mining component includes tools from the

ICEIS 2016 - 18th International Conference on Enterprise Information Systems

48

Apache UIMA framework (Ferrucci and Lally, 2004)

for unstructured data analytics, with the uimaFit ex-

tension (Ogren and Bethard, 2009) for rapidly build-

ing analytics pipelines to allow for on-the-fly analyt-

ics service composition. Structured data mining capa-

bilities are taken for instance from the WEKA data

mining workbench (Hall et al., 2009). On this basis,

manufacturing-specific predictive and prescriptive

analytics are realized using various data mining tech-

niques, especially decision tree induction, as de-

scribed in (Gröger et al., 2014a, 2014b).

Regarding the mobile middleware, we imple-

mented several mobile apps, e.g., a mobile analytics

dashboard for shop floor workers (Gröger et al.,

2014b) and a mobile product structure visualizer for

engineers. We have implemented native apps for An-

droid and for Windows as well as platform independ-

ent web apps using standardized web technology such

as HTML5.

An app marketplace and a graphical interface for

intuitive access to the app composer are currently un-

der development, with inspiration coming from

mashup platforms (Daniel and Matera, 2014) and app

generator tools, such as (Francese et al., 2015).

5.2 Application Scenario: Quality

Management and Process

Optimization in the Automotive

Industry

To demonstrate the concept of the data-driven factory

as well as the SITAM architecture, we have cooper-

ated with an OEM to develop a real-world application

scenario for the automotive industry. The scenario fo-

cuses on quality management and process optimiza-

tion as critical success factors for OEMs especially in

the automotive premium segment.

An automotive manufacturer collects big indus-

trial data, including structured sales and machine

data, sensor and text data around the product life cy-

cle. These data originally reside in isolated databases;

for instance, text reports about product and part qual-

ity from development, production and aftersales are

all gathered via different IT systems. To ensure a re-

alistic representation of source data and processes, on

the one hand, we take advantage of publicly available

data sources, such as the records of automotive com-

plaints covering the US market and maintained by the

NHTSA (NHTSA, 2014). On the other hand, we

make use of anonymized data and internal knowledge

resources of our industry partner.

On this basis, the SITAM architecture is applied

to exploit these data for quality management and pro-

cess optimization. In the following, we give an over-

view of representative value-added services and role-

based apps across the product life cycle which are en-

abled by the SITAM architecture (see Figure 4). We

focus on car paint quality as a recurring example (all

data samples in the following are fictitious for reasons

of confidentiality).

During product development and testing, quality

data are collected through the mobile dev Q app by

engineers and test drivers on the go, including text re-

ports and image material. The aftersales Q app is

used to collect aftersales quality data for the warranty

and recovery process of damaged car parts in the form

of unstructured text reports (e.g., “customer states that

car paint is coming off after washing”, “flaking paint

on fender during extreme summer heat”). It has differ-

ent profiles for quality engineers (whose primary task

is the definition of new error codes), for quality expert

workers (whose task it is to assign error codes to dam-

aged parts) and for executives (who are interested in

comparing aggregated error code data over time). In

addition, quality data come in the form of customer

complaints and via social media crawling services.

Figure 4: Value-added services and role-based apps

in the application scenario.

After aggregating these data into the manufactur-

ing knowledge repository via the integration middle-

ware, topic recognition on the text data is performed

as an information mining step. The topics (e.g., “paint

flaking – heat”, “paint damage – washing”) are pre-

sented to a human analyst via visual clustering to pick

the most pressing ones or perform minor reclassifica-

tion. This constitutes a value-added service of recur-

ring issue identification and is performed via the topic

visualizer app, which makes use of the mobile graph

Manufacturing

Knowledge Repository

Analytics & Mobile Middleware

Quality Engineer

Value-Added Services

Dev Q

App

Aftersales Q

App

Topic Recognition

Recurring

Issue

Identification

Mashup

Dashboard

Root Cause

Identification

Shop Floor

Notifier

Automatic

Machine

Reconfiguration

To pic

Visualizer

Proactive

process

optimization

Visual Clustering

Mobile Graph

Visualizer

Error

Reports

Production

Plans

Machine

Data

Customer

Complaints

Social

Media

Shop Floor WorkerDeveloperAnalyst

Error

Reports

Role-based Apps

Integration Middleware

…

The Data-driven Factory - Leveraging Big Industrial Data for Agile, Learning and Human-centric Manufacturing

49

visualizer from the mobile middleware.

Next, the problem topics are combined with his-

torical data from the production phase, especially ma-

chine data, shop floor environment data, and struc-

tured error counts for root cause identification (e.g.,

elevated humidity in the paint shop leading to a lower

quality of paint and a higher risk of flaking when ex-

posed to harsh environmental conditions). This ana-

lytics step is executed in an analytics and data mashup

dashboard app, where data sources and analytics al-

gorithms are combined ad-hoc, but can also be stored

for recurring use.

Identified root causes and condition patterns serve

as input for proactive process optimization. It makes

use of prescriptive analytics to automatically identify

potentially problematic situations (e.g., critical hu-

midity in paint shops) during process execution and

recommend actions to on-duty workers through a

shop floor notifier app (e.g., to air the paint shops to

decrease humidity) or trigger automatic machine re-

configuration (e.g., increasing air conditioning and

heating to decrease humidity).

5.3 Evaluation and Benefits

Taking the above application scenario, we conceptu-

ally evaluate the SITAM architecture by analyzing

the fulfillment of the technical requirements of the

data-driven factory and contrasting it with the tradi-

tional information pyramid of manufacturing. More-

over, we summarize the resulting benefits of the data-

driven factory.

In the application scenario, diverse systems across

the product life cycle, such as machines, social media

sources as well as sensors, are encapsulated as ser-

vices and are uniformly represented in the SOA gov-

ernance repository to ease integration and access in

the integration middleware. By this service-oriented

abstraction, the SITAM architecture enables a flexible

integration of heterogeneous data sources as well as a

flexible service composition fulfilling requirement R

1

.

This enables agile manufacturing, the first characteris-

tic of the data-driven factory. Accessible service-based

and role-based information provisioning also works to-

wards keeping the human in the loop (human-centric

manufacturing). In contrast, a proprietary point-to-

point integration according to the information pyramid

of manufacturing would not scale up to the entire prod-

uct life cycle in terms of complexity and costs.

To merge structured and unstructured data from

different life cycle phases, e.g., aftersales quality data

and machine data in the application scenario, all data

are integrated in the manufacturing knowledge repos-

itory of the analytics middleware. Moreover, predict-

tive and prescriptive analytics are provided, for in-

stance, to derive action recommendations for process

optimization according to the application scenario.

Thus, the SITAM architecture provides a holistic data

basis encompassing the product life cycle as well as

advanced analytics for knowledge extraction ful-

filling requirement R

2

. This analytics capability pro-

vides functionalities for learning manufacturing,

such as learned improvements for the quality-optimal

design of both processes and products. It also is a pre-

requisite for agile process adaptations (agile manu-

facturing), such as the near real-time adaptation of

production conditions to prevent known product qual-

ity issues. In contrast, the information pyramid of

manufacturing is limited by separated data islands

due to strictly hierarchical information aggregation.

In the application scenario, various mobile apps

support seamless integration of employees, e.g., for

data acquisition by test drivers using the dev Q app or

for notifications of shop floor workers using the shop

floor notifier. The mobile middleware facilitates the

development of such manufacturing-specific apps us-

ing predefined manufacturing context models as well

as specific visualization components, especially for

product models. These apps can be easily deployed

on various devices using the app marketplace. In this

way, the SITAM architecture enables mobile infor-

mation provisioning and fulfills requirement R

3

of the

data-driven factory to ubiquitously integrate employ-

ees across all hierarchy levels. Thus, it provides the

framework for human-centric manufacturing in keep-

ing the human expert in the loop through data provi-

sioning and data gathering. In contrast, central control

and information aggregation lead to isolated infor-

mation provisioning in the information pyramid of

manufacturing.

To sum up, the SITAM architecture enables flex-

ible system and data integration, advanced analytics

and mobile information provisioning and thus fulfills

all technical requirements (R

1

-R

3

) of the data-driven

factory. In doing so, it exhibits the three characteris-

tics of the data-driven factory, agile manufacturing,

learning manufacturing and human-centric manufac-

turing.

6 CONCLUSION AND

FUTURE WORK

In this article, we have presented the data-driven fac-

tory, an important contribution on the way to the re-

alization of Industrie 4.0 and Smart Manufacturing.

This concept completely alters the ways in which IT

ICEIS 2016 - 18th International Conference on Enterprise Information Systems

50

systems are used and data are processed in manufac-

turing companies, thereby enabling agile, learning

and human-centric manufacturing by leveraging big

industrial data. The data-driven factory provides a

stark contrast to the traditional information pyramid

of manufacturing, which is fraught with the central

weaknesses of proprietary point-to-point integration

of IT systems, separated data islands and isolated in-

formation provisioning. Instead, the data-driven fac-

tory collects, analyzes and uses data holistically

around the product life cycle and across all hierarchy

levels of manufacturing. Thus, continuous data-

driven optimization of processes and resources with

the active participation of the ‘human in the loop’ is

facilitated.

To realize the data-driven factory, we have devel-

oped the SITAM architecture which (1) flexibly inte-

grates heterogeneous IT systems, (2) provides holis-

tic data storage and advanced analytics covering the

entire product life cycle, and (3) enables mobile in-

formation provisioning to empower human workers

as active participants in manufacturing. We have pro-

totypically implemented core components of the

SITAM architecture in the context of a real-world ap-

plication scenario concerned with quality and process

management in the automotive industry. Our concep-

tual evaluation shows that the SITAM architecture

enables the realization of the data-driven factory and

the exploitation of big industrial data across the entire

product life cycle.

In the future, we will extend our current prototype

and further investigate the benefits of the data-driven

factory on the example of additional industrial case

studies, e.g., to concretize resulting competitive ad-

vantages in specific industries.

ACKNOWLEDGEMENTS

The authors would like to thank the German Research

Foundation (DFG) as well as Daimler AG for finan-

cial support of this project as part of the Graduate

School of Excellence advanced Manufacturing En-

gineering (GSaME) at the University of Stuttgart.

REFERENCES

Aggarwal, C.C. and Zhai, C.X. (2012), “An Introduction to

Text Mining”, in Aggarwal, C.C. and Zhai, C.X. (Eds.),

Mining Text Data, Springer, Boston, pp. 1–10.

Bracht, U., Hackenberg, W. and Bierwirth, T. (2011), “A

monitoring approach for the operative CKD logistics”,

Werkstattstechnik, Vol. 101 No. 3, pp. 122–127.

Brettel, M., Friederichsen, N., Keller, M. and Rosenberg, M.

(2014), “How Virtualization, Decentralization and Net-

work Building Change the Manufacturing Landscape:

An Industry 4.0 Perspective”, International Journal of

Science, Engineering and Technology, Vol. 8 No. 1,

pp. 37–44.

Clevenger, N.C. (2011), iPad in the enterprise. Developing

and deploying business applications, Wiley, Indianap-

olis.

Daniel, F. and Matera, M. (2014), Mashups - Concepts,

Models and Architectures. Data-Centric Systems and

Applications, Springer, Heidelberg.

Davis, J., Edgar, T., Porter, J., Bernaden, J. and Sarli, M.S.

(2012), “Smart Manufacturing, Manufacturing Intelli-

gence and Demand- Dynamic Performance”, Comput-

ers & Chemical Engineering, Vol. 47, pp. 145–156.

Erl, T. (2008), SOA. Principles of service design, The Pren-

tice Hall service-oriented computing series from

Thomas Erl, Prentice Hall, Upper Saddle River.

Evans, J.R. and Lindner, C.H. (2012), “Business Analytics:

The Next Frontier for Decision Sciences”, Decision

Line, Vol. 43 No. 2, pp. 4–6.

Ferrucci, D. and Lally, D. (2004), “UIMA. An architectural

approach to unstructured information processing in the

corporate research environment”, Natural Language

Engineering, Vol. 10 No. 3-4, pp. 327–348.

Francese, R., Risi, M., Tortora, G. and Tucci, M. (2015),

“Visual Mobile Computing for Mobile End-Users”,

IEEE Transactions on Mobile Computing, to appear.

Gölzer, P., Cato, P. and Amberg, M. (2015), “Data Pro-

cessing Requirements of Industry 4.0 - Use Cases for

Big Data Applications”, in Proceedings of the Euro-

pean Conference on Information Systems (ECIS) 2015,

Paper 61.

Gröger, C., Schwarz, H. and Mitschang, B. (2014a), “Pre-

scriptive Analytics for Recommendation-Based Busi-

ness Process Optimization”, in Proceedings of the In-

ternational Conference on Business Information Sys-

tems (BIS) 2014, Springer, Cham, pp. 25–37.

Gröger, C., Schwarz, H. and Mitschang, B. (2014b), “The

Manufacturing Knowledge Repository. Consolidating

Knowledge to Enable Holistic Process Knowledge

Management in Manufacturing”, in Proceedings of the

International Conference on Enterprise Information

Systems (ICEIS) 2014, SciTePress, pp. 39–51.

Groover, M.P. (2008), Automation, production systems,

and computer-integrated manufacturing, 3

rd

ed., Pren-

tice Hall, Upper Saddle River.

Hall, M., Frank, E., Holmes, G., Pfahringer, B., Reutemann,

P. and Witten, I.H. (2009), “The WEKA Data Mining

Software: an Update”, SIGKDD Explorations, Vol. 11

No. 1, pp. 10–18.

Hjelmervik, O.R. and Wang, K. (2006), “Knowledge Man-

agement in Manufacturing: The Soft Side of

Knowledge Systems”, in Wang, K., Kovacs, G.L.,

Wozny, M. and Fang, M. (Eds.), Knowledge Enter-

prise: Intelligent Strategies in Product Design, Manu-

facturing, and Management, Vol. 207, Springer, pp.

89–94.

The Data-driven Factory - Leveraging Big Industrial Data for Agile, Learning and Human-centric Manufacturing

51

Holtewert, P., Wutzke, R., Seidelmann, J. and Bauernhansl,

T. (2013), “Virtual Fort Knox - Federative, secure and

cloud-based platform for manufacturing”, in Proceed-

ings of the CIRP Conference on Manufacturing Systems

(CMS) 2013, Elsevier, pp. 527–532.

Hoos, E., Gröger, C. and Mitschang, B. (2014), “Mobile

Apps in Engineering: A Process-Driven Analysis of

Business Potentials and Technical Challenges”, in Pro-

ceedings of the CIRP Conference on Intelligent Com-

putation in Manufacturing Engineering (CIRP ICME)

2014, Procedia CIRP Vol. 33, Elsevier, pp. 17–22.

ISA (2000), Enterprise-Control System Integration No.

ISA-95.

Kassner, L., Gröger, C., Mitschang, B. and Westkämper, E.

(2014), “Product Life Cycle Analytics - Next Genera-

tion Data Analytics on Structured and Unstructured

Data”, in Proceedings of the CIRP Conference on Intel-

ligent Computation in Manufacturing Engineering

(CIRP ICME) 2014, Procedia CIRP Vol. 33, Elsevier,

p. 35–40.

Kassner, L. and Mitschang, B. (2016), “Exploring Text

Classification for Messy Data: An Industry Use Case

for Domain-Specific Analytics”, in Proceedings of the

International Conference on Extending Database Tech-

nology (EDBT) 2016, OpenProceedings.org, to appear.

Kemper, H.-G., Baars, H. and Lasi, H. (2013), “An Inte-

grated Business Intelligence Framework. Closing the

Gap Between IT Support for Management and for Pro-

duction”, in Rausch, P., Sheta, A.F. and Ayesh, A.

(Eds.), Business Intelligence and Performance Man-

agement. Theory, Systems and Industrial Applications,

Advanced Information and Knowledge Processing,

Springer, London, pp. 13–26.

Königsberger, J., Silcher, S. and Mitschang, B. (2014),

“SOA-GovMM: A meta model for a comprehensive

SOA governance repository”, in Proceedings of the

IEEE International Conference on Information Reuse

and Integration (IRI) 2014, IEEE, pp. 187–194.

MacDougall, W. (2014), “Industrie 4.0 – Smart Manufac-

turing for the Future”, available at: http://www.gtai.de/

GTAI/Content/EN/Invest/_SharedDocs/Downloads/G

TAI/Brochures/Industries/industrie4.0-smart-manufact

uring-for-the-future-en.pdf (accessed 29.10.15).

Meehan, M. (2014), “SOA adoption marked by broad fail-

ure and wild success”, available at: http://searchsoa.tec

htarget.com/news/1319609/SOA-adoption-marked-by-

broad-failure-and-wild-success (accessed 28.10.15).

Minguez, J., Lucke, D., Jakob, M., Constantinescu, C. and

Mitschang, B. (2010), “Introducing SOA into Produc-

tion Environments - The Manufacturing Service Bus”,

in Proceedings of the 43

rd

CIRP International Confer-

ence on Manufacturing Systems (CMS), Neuer Wissen-

schaftlicher Verlag, Wien, pp. 1117–1124.

NHTSA (2014), “NHTSA Data”, available at: http://www-

odi.nhtsa.dot.gov/downloads/ (accessed 28.10.15).

Ogren, P.V. and Bethard, S.J. (2009), “Building test suites

for UIMA components”, in Proceedings of the Work-

shop on Software Engineering, Testing, and Quality As-

surance for Natural Language Processing (SETQA-

NLP), ACM, pp. 1–4.

Papazoglou, M.P., Heuvel, W.-J.v. and Mascolo, J.E.

(2015), “A Reference Architecture and Knowledge-

Based Structures for Smart Manufacturing Networks”,

IEEE Software, Vol. 32 No. 3, pp. 61–69.

Sebastian-Coleman, L. (2013), Measuring data quality for

ongoing improvement, Elsevier, Burlington.

Shi, J., Wan, J., Yan, H. and Suo, H. (2011), “A survey of

Cyber-Physical Systems”, in Proceedings of the Inter-

national Conference on Wireless Communications and

Signal Processing (WCSP), IEEE, Piscataway, pp. 1–6.

Silcher, S., Dinkelmann, M., Minguez, J. and Mitschang, B.

(2013), “Advanced Product Lifecycle Management by

Introducing Domain-Specific Service Buses”, in Cor-

deiro, J., Maciaszek, L.A. and Filipe, J. (Eds.), Enter-

prise Information Systems (ICEIS) 2013. Revised Se-

lected Papers, Lecture Notes in Business Information

Processing, Vol. 141, Springer Berlin, pp. 92–107.

Vogel-Heuser, B., Kegel, G., Bender, K. and Wucherer, K.

(2009), “Global information architecture for industrial

automation”, Automatisierungstechnische Praxis,

Vol. 51 No. 01-02, pp. 108–115.

Wang, R.Y. and Strong, D.M. (1996), “Beyond accuracy:

what data quality means to data consumers”, Journal of

Management Information Systems, Vol. 12 No. 4, pp.

5–33.

Westkämper, E. (2014), Towards the Re-Industrialization

of Europe. A concept for manufacturing for 2030,

Springer, Berlin.

Whitman, M.E. and Mattord, H.J. (2007), Principles of in-

formation security, 3

rd

ed., Thomson Course Technol-

ogy, Boston.

Zuehlke, D. (2010), “SmartFactory - Towards a factory-of-

things”, Annual Reviews in Control, Vol. 34 No. 1, pp.

129–138.

ZVEI (2015), “The Reference Architectural Model Indus-

trie 4.0 (RAMI 4.0)”, available at:

http://www.zvei.org/Downloads/Automation/ZVEI-In

dustrie-40-RAMI-40-English.pdf (accessed 28.09.15).

ICEIS 2016 - 18th International Conference on Enterprise Information Systems

52