Aggregating the Flexibility of Heat Pumps and Thermal Storage

Systems in Austria

Tara Esterl

1

, Lukas Leimgruber

1

, Tarik Ferhatbegovic

1

, Andreas Zottl

1

, Mathias Krottenthaler

2

and Bertram Weiss

2

1

Austrian Institute of Technology (AIT), Giefinggasse 2, Vienna, Austria

2

Verbund Solutions, Europaplatz 2, Vienna, Austria

Keywords: Aggregator, Flexibility, Thermal Storage Systems, Heat Pumps, Electricity Market.

Abstract: This study analyses the challenges of aggregating the flexibility of heat pumps in Austria. Flexibility can be

provided by shifting electrical load to other points in time with the use of thermal storage systems. At first

the potential and typical combinations of heat pumps, buildings and thermal storage systems are described.

Afterwards different operation strategies and applications in smart-grid context are discussed. To make

optimal bids to the market a model is necessary that explains the thermal and electrical dynamics of the

system. Therefore a thermal model is combined with an electricity market model. Load shifts can reduce the

operational costs of heat pumps around 8-14 %, but can negatively affect their efficiency. At last a technical

concept is discussed which allows the exchange of signals between aggregator and pool participants.

1 INTRODUCTION

At every time step electric demand and supply must

match each other to guarantee a stable and secure

provision of electricity. If deviations between

demand and supply occur, flexible loads or

generators are necessary, that can alter their

momentary electrical consumption or production

pattern to bring the system back in balance.

Historically this flexibility was usually provided by

large scale generators or loads in the MW-range.

With a higher share of Renewable Energy Systems

(RES) the demand for flexible units is rising. The

residential sector theoretically possesses a huge

potential for flexibilization of the electric demand

side. This study focuses on analyzing the challenges

of using thermostatically controlled loads (TCL),

like heat-pumps in combination with thermal storage

systems, to support smart grids. Water storage tanks

for warm water and space heating purposes as well

as the thermal storage ability of the buildings, where

the heat pump is operated, are further considered.

The operation of TCLs can be modified as long as

devices stay in a defined operational area and user-

defined comfort restrictions are met. The load

shifting potential of a single residential heat pump

and storage unit is rather low, being in the kW-

range. By combining the flexibility of many devices

however, the resulting flexibility pool is capable of

shifting a considerable amount of electrical load.

This is usually realized by an aggregator:

“Aggregator means a legal entity which is

responsible for the operation of a number of demand

facilities by means of demand aggregation” (Entso-

e, Glossary). Demand aggregation refers to “a set of

demand facilities which can be operated as a single

facility for the purpose of offering one or more

demand side response services” (Entso-e, Glossary).

Demand side response (DR) services are the

objective for the aggregation of demand side

facilities. There must be certain incentives (e. g.

monetary) to offer those DR services. Ideally a pool

of heat pumps is capable of switching its electrical

load to other points in time without any drawbacks

for the customers. The flexibility resulting from

those load shifts can be marketed at electricity

markets or used to actively support the electric grid.

To exploit that flexibility however, a pooling

concept must be developed including the analysis of

the existing heat-pump, storage system and building

landscape, potential operation strategies for the pool

and a technical concept to enable signals between an

aggregator and the single heat pump.

372

Esterl, T., Leimgruber, L., Ferhatbegovic, T., Zottl, A., Krottenthaler, M. and Weiss, B.

Aggregating the Flexibility of Heat Pumps and Thermal Storage Systems in Austria.

In Proceedings of the 5th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2016), pages 372-377

ISBN: 978-989-758-184-7

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 AGGREGATION

Around 100.000 – 150.000 heat pumps are used for

space heating (SH) in Austria at the moment.

Another 50.000 heat pumps are installed to provide

domestic hot water (DHW). Heat pumps for SH are

responsible for the major part of newly installed

devices over the last years. In the year 2012 alone,

around 13.600 heat pumps for SH were sold with an

expected minimum growth rate of 5 % (Gaehmi, S.,

2013; Moser et al., 2014; Biermeyer et. al, 2013).

The exact load shifting potential is hard to determine

and depends on several aspects like season, time of

day, ambient temperature and user-specific behavior.

In winter for example the potential for load shifts of

heat pumps used for SH is expected to be

significantly higher than in summer. If also cooling

applications are realized by heat pumps, then the

potential in summer can be increased. Also the time

of day is an important factor. Gaehmi indicates that

the load reduction potential is highest between 6-8

am and 4-6 pm while at other times it is zero if the

heat pumps must run at full load. Additionally

Gaehmi estimates the load shifting potential for

1000 households around 1.3 MW. These values are

still to be closer investigated and strongly depend on

the specific combination of building, heat pump and

thermal storage system. As a consequence also the

different technical characteristics of the devices

forming the flexibility pool are of high interest for

an aggregator. Therefore a market study of typical

building and heating system combinations in Austria

was conducted. To reduce complexity, typical

combinations were summarized to homogenous

groups. An excerpt of these typologies is

exemplarily shown in Table 1 with building types on

the horizontal axis and heating system related

parameters on the vertical axis. Additionally also

passive houses, pure DHW heat pumps and large

scale heat pumps for district heating are considered.

With more pool customers, organizational as well as

technical efforts are higher. Large scale heat pumps

(around 0.25 MW) are expected to be more

favourable in terms of aggregation. Both transaction

costs and costs for the information and

communication technologies (ICT) infrastructure are

declining with fewer pool participants.

The load shifting potential of TCLs can be used

for various applications in smart-grid context

ranging from local voltage control in distribution

grids, increasing the share of RES in the power

system, to participating on electricity markets (Koch

S., Andersson G., 2009a).

Using price spreads on wholesale markets by

Table 1: Excerpt of collected typologies of buildings, heat

pumps and thermal storage systems in Austria.

New

buildin

g

Existing

buildin

g

Renovated

buildin

g

Space heating

[kWh/(m²*a)]

45 [~35 °C] 100 [~55 °C] 70 [~45 °C]

Heated area [ m²] 140 120 120

Therm./el.

capacity [kW]

5 / 1.5 12 / 4 7 / 2.7

Capacity control on/off on/off variable

Heat source air ground air

Heat sink water water water

Heat distribution floor heating radiator radiator

SH storage [l] 300 500 500

DHW storage [l] 300 300 300

shifting electric load to low price periods can

significantly reduce operation costs of heat pumps,

as was shown for the Swiss market (Pfaffen, D.,

Werlen, K., 2013). Furthermore on the EPEX spot

contracts of market participants have to match the

actual schedules. Eventual deviations have to be

compensated by the responsible market participant.

So the flexibility of heat pumps can also be used to

reduce those deviations. Additionally the flexibility

to momentarily adapt the electricity consumption

pattern enables to participate on balancing markets,

where the provision of balancing energy to maintain

frequency stability is compensated by the

Transmission System Operator (TSO) (von Roon et

al., 2014). Positive balancing energy can be

provided by decreasing the electric consumption of

the heat pumps, while negative balancing power is

delivered by increasing their consumption. Different

balancing products exist. In Austria secondary

balancing energy usually features higher revenues

but also poses higher technical requirements than

tertiary balancing energy. The added value of the

pool operation must provide incentives for both,

aggregator and pool participant. Reducing the costs

on energy-bill level can motivate participants to join

the pool. In addition to monetary incentives, also

non-monetary incentives provide interesting

opportunities. While aggregators can eventually

profit from higher customer loyalty and an

innovative image, pooling participants might be

inclined to support smart-grid issues. As a pooling

concept requires an appropriate ICT solution, there

might also be positive effects for participants like a

Aggregating the Flexibility of Heat Pumps and Thermal Storage Systems in Austria

373

monitoring system suggesting eventual cost savings

or higher usability by intelligent control systems via

smart-phone applications.

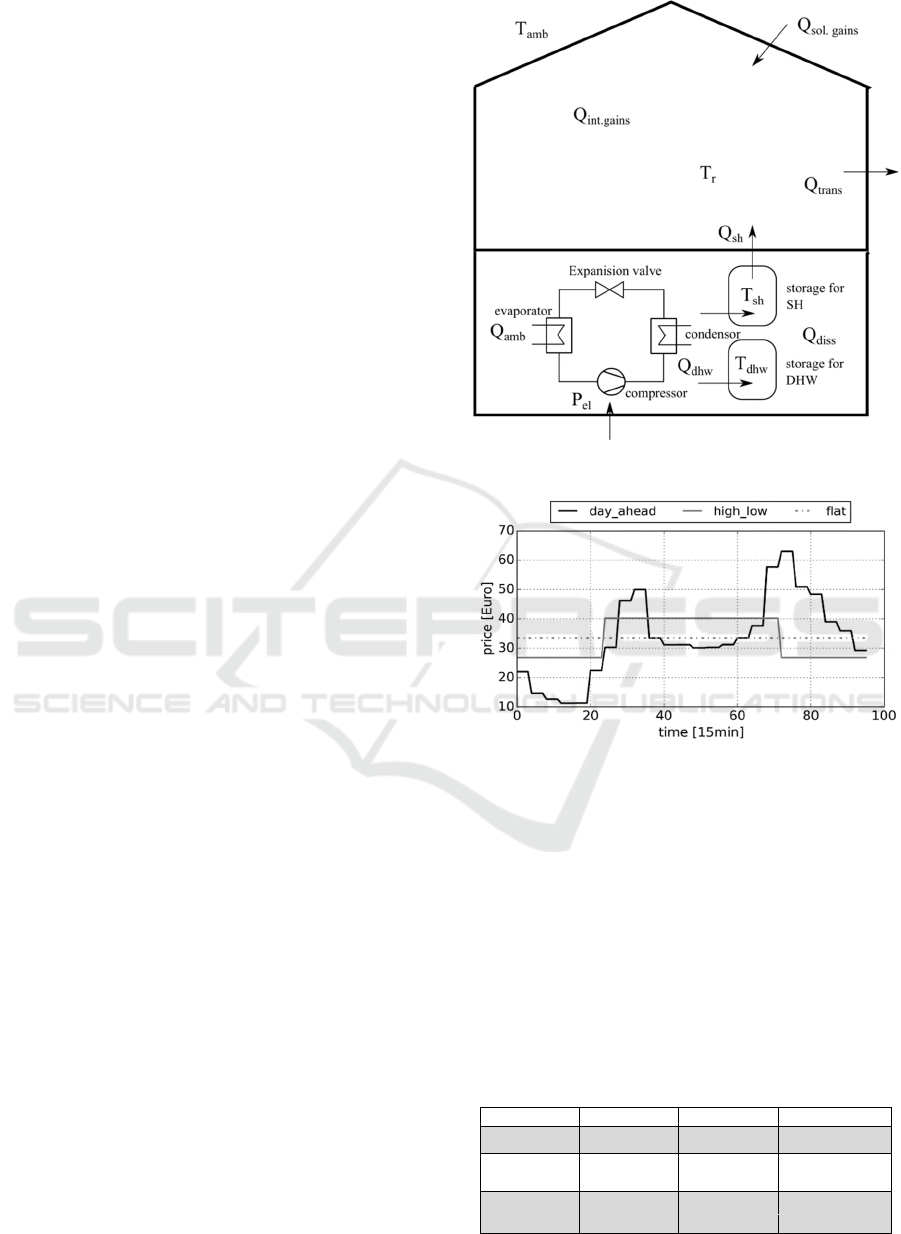

3 MODELLING

Thermal models are necessary to describe the

dynamics of the heating system, make optimal bids

to the market and operate the heat pump pool in real-

time. As the aggregation involves a high number of

different typologies, the models should be

inexpensive and applicable to a large number of

different thermal systems. (Jungwirth, 2014) The

thermal behaviour of TCLs is often expressed by

state-space models (Pfaffen, D., Werlen, K., 2013;

Koch S., Andersson G., 2009a). Alternative

approaches model the thermal storage potential of

TCLs as battery storage systems (Khan S. et al.,

2016; Hao H. et al., 2015). For every typology

evaluated in the market study, a state-space model is

developed describing the thermal dynamics of the

system (Figure 1) and enabling the implementation

into a control system. It describes the changes of the

temperatures in the thermal storage for space heating

T

, domestic hot water T

, and room

temperature T

in response to model inputs. The

model inputs consist of the electrical consumption of

heat pump P

, outdoor temperature T

, heat

losses in the building and the storage systems

Q

, internal gains Q

.

and a DHW profile.

Pool operation aims at gaining synergy effects

compared to separate operation. This can be

achieved by reducing the operation costs of the pool

on wholesale markets and by additionally gaining

revenues with balancing market participation. In

both cases, a schedule has to be sent to the pool

participants, to adhere to contracts made on

electricity markets. Because of the complexity of the

matter, this schedule should be determined by an

optimization model. Here, mixed-integer linear

programming techniques were applied. The focus

lies on minimizing operation costs on wholesale

markets. Load shifting is incentivized by sending

different price signals to the heat pump pool (Figure

2). Flat and high-low price signals serve as reference

cases with none or restricted incentives for load

shifts. A dynamic price signal, coupled to the EPEX

spot day-ahead, highlights the optimized operation

using flexibility via load shifts. The price signals are

scaled to allow for better comparison between each

other (Fischer D. et al. 2014). A simulation is

conducted for 1000 units of every topology (except

large-scale heat pumps).

Figure 1: Basic scheme of thermal model.

Figure 2: Price signals sent to heat pump pool to

incentivize load shifts.

Table 2 shows the operational costs under

different price signals for the year 2014. Under the

here considered assumptions, allowing load shifts,

the operational costs for the heat pump pool can be

reduced around 8-14 % depending on the specific

reference case. The major part of load shifts is

happening during the heating period. The load

shifting potential in summer is lower because only

DHW is required.

Table 2: Operational costs and savings under different

price signals for the year 2014.

Flat High-low Day-ahead

Costs [€]

2.764.870 2.590.735 2.375.584

Savings

[€]

-

-

174.135

-

389.286

215.151

Savings

[%]

- 6,3 14,1

- - 8,3

SMARTGREENS 2016 - 5th International Conference on Smart Cities and Green ICT Systems

374

Load shifts use the possibility to temporarily

overheat the temperature in the thermal storage

systems (Figure 3). In times of low market prices the

heat pumps are switched on and eventual excess heat

is stored in the thermal storage systems. The

maximum allowed temperature is set to 65 °C for

SH and DHW storage systems whereas the

minimum temperature is given by the specific

heating system set points in Table 1. Room

temperatures must stay between the interval 20-23

°C to fulfill user-specific comfort requests.

Overheating the SH and DHW storage is preferred

in contrast to the room temperature due to the higher

storage capacity of water compared to air. The

coefficient of performance (COP) is modelled as a

function of the temperature difference between

source and sink temperature (Fischer et al., 2014).

Figure 4 shows the COP of the corresponding

system with and without load shifts. It can be seen

that due to load shifts the COP of the considered

heat pumps is significantly declining. This effect is

more prominent during the heating period where the

major part of load shifts is happening. For the here

considered case, the costs resulting from efficiency

reduction are in the same scale like the potential

gains of table 2.

Figure 3: Temperatures in thermal storage systems due to

load shifts for a winter day (Case: Renovated Building).

4 TECHNICAL CONCEPT

To control a high number of different demand

facilities a suitable technical concept is necessary

enabling the exchange of signals and data between

the single pooling unit and the aggregator. The

implemented technical concept should be cheap,

secure and in line with certain grid codes to provide

reliable ancillary services. The requirements for the

ICT infrastructure depend on the chosen operation

strategy. While the optimization of the heat pump

schedule is less complex, the participation on

balancing markets must be in line with the

requirements of the TSO.

Figure 4: Coefficient of Performance without (COP_rated)

and with overheating (COP load_shift) of temperature in

thermal storage (Case: Renovated Building).

In case of a balancing energy call, the devices

must be able to track a signal of the Austrian Power

Grid (APG) to provide ancillary service. In case of

tertiary reserve an electronic communication device

is necessary to offer the minimum bid size of 5 MW

in line with IEC 60870-5-101. A point-to-point fixed

line connection like SDH or PDH and a serial

interface V.24 / V.28 not longer than 15 m should be

used. The components must guarantee a time for

data exchange of a maximum of 5 s and an

availability of 95%. Every 2 seconds measured data

has to be sent to the APG. Also during the times no

balancing energy is called, data exchange must be

ensured. The actual electrical consumption as well

as the operating point must be sent to the APG

(Austrian Power Grid, 2014). An analysis of the

different control concepts of heat pumps showed

three types of possible implementations:

External

ripple control signal (ERCS): Via a potential-free

contact demand devices can be externally switched-

off. This is already used by utilities offering special

tariff programmes. Interruptible tariffs e. g., are

usually less expensive than normal ones, allowing an

utility to actively switch heat pumps off for a given

Aggregating the Flexibility of Heat Pumps and Thermal Storage Systems in Austria

375

time, e. g. three times a day for two hours (in Austria

and Germany). ERCS are also used to manage

high/low tariffs where electricity consumed at night

is less expensive than during the day. This concept is

proved, already implemented and often existing

infrastructure can be used. On the other hand, those

external switching orders could result in a higher

wear of the heat pumps, because ERCS are

mandatory switching orders not considering the heat

pump control and operation strategy. EEBus on the

other hand is a protocol connecting IP-based devices

of utilities and distribution service operators (DSOs)

with the not yet IP-based devices of end customers.

For smart control of end user devices the KNX and

ZigBee standards can be used (Koch S. et al.,

2009b). EEBus offers a framework to flexibly

control end-user devices in a household from

external IP-based systems. Typically the devices are

connected to a Home Energy Management System.

Compared to other communication technologies this

is rather expensive and should already be considered

in the construction phase of new buildings. To

subsequently implement this concept for pooling

concepts is rather inappropriate. In Germany exists a

standard called Smart-Grid-ready (SG-ready) label

supported by the German heat pump association. It

is a label specifically designed for heat pumps and is

already implemented in around 370 heat pump

models of 19 different manufacturers. The SG-ready

label defines the operation of heat pumps according

to four operation modes (Bundesverband

Wärmepumpe e. V., 2013, 2015). Mode 1: The heat

pump is switched off for a maximum of two hours.

This includes the already implemented functionality

of interruptible tariffs via ERCS. Mode 2: Here the

heat pump is operated in energy efficient operation

mode according to the local controller taking into

consideration the maximal switching time of two

hours by guaranteeing a certain level of the thermal

storage system. Mode 3: A switching

recommendation is sent to the heat pump to alter its

electrical consumption pattern by modifying the set-

point of the room and/or thermal storage

temperature. It is not an explicit switching order but

a recommendation. Mode 4: The last operation

mode is defined as a compulsory switching order.

Two different mechanisms can be chosen. Either the

compressor of the heat pump (optionally also an

electric heating back-up device) can be directly

switched on or the set-point temperature can be

modified. The main difference to mode 3 is the fact

that the signal is compulsory. Compulsory signals

must be adhered to (mode 1 and 4) and intervene to

some degree into the local heat pump controller.

Switching recommendations leave the control to the

local heat pump controller and only provide

recommendations to alter the consumption pattern of

the heat pump (mode 2 and 3). Regarding mode 4 it

must be considered that directly controlling the

compressor might result in a higher wear of the heat

pump and its components while the control via

temperature set-points is more favourable from

technical view but leaves the exact operation to the

local controller and therefore provides not full

control of the heat pump consumption

(Bundesverband Wärmepumpe e. V., 2013).Of the

above mentioned control mechanisms the SG-ready

label is assumed to be the most favourable because it

is already implemented in many heat pumps and

provides defined operation strategies enabling the

external control of the single heat pump operation.

Moreover it includes the functionality of ERCS and

is considerably cheaper to implement than the

EEBus. The technical concept must guarantee the

conversion of external switching orders in real-time.

This signal S

aggr

is sent by an aggregator resulting

from the participation on the specific electricity

markets. The aggregated consumption of the pool

P

pool

should match the signal S

aggr

. If S

aggr

< P

pool

devices must be switched off until the signal

matches the consumption of the heat pumps. If S

aggr

> P

pool

additional devices must be switched on. In

this context adequate sequencing algorithms are

necessary respecting the actual operational condition

of the single devices. It is favourable to switch those

devices which will be switched in any case in future

due to their normal operation mode. Alternatively a

defined temperature distance to the upper or lower

temperature limit can be used as a sequencing

criterion (Hao et al., 2015; Khan, S., 2016). A smart

box installed at households receives the schedule

and sends adequate orders to the heat pump

corresponding to the SG-ready operation modes 1-4.

The local controller of the heat pump executes the

schedule if possible and sends a feedback of power

P

el

and temperatures T

r

, T

sh

, T

dhw

to the aggregator.

The smart box is basically a communication device

and the link between heat pump and aggregator. The

smart box can be used to subsequently integrate

other residential devices capable of load shifting.

5 CONCLUSIONS

With the use of load shifts the operational costs of a

heat pumps pool can be reduced. In this context it is

important to consider potential efficiency losses

caused by overheating the thermal system. To

SMARTGREENS 2016 - 5th International Conference on Smart Cities and Green ICT Systems

376

approximate the flexibility, models are necessary

that describe the dynamics of the interaction

between electrical and thermal variables. These

models should be inexpensive and applicable to a

high number of different building types. The thermal

model here applied will be further developed by

including four layers to consider the temperature

distribution inside the storage. Additionally also the

efficiency will be considered in more detail. At the

moment a black box building model is developed

and will be validated by a more concise Dymola

model and measured data of residential buildings.

The market model will be extended to also evaluate

the participation on balancing markets considering

the probability a bid is accepted and the probability

of balancing energy calls. At last a technical concept

must be developed that guarantees a secure

exchange of information and signals. The SG-ready

standard is a promising control concept to externally

control residential heat pumps. The concepts

discussed are planned to be verified in a subsequent

demonstration project.

ACKNOWLEDGEMENTS

The work is part of the research project “iWPP-

Flex” of the Austrian Institute of Technology and

the Verbund Solutions, funded by the Austrian

agency “Forschungs-förderungsgesellschaft”.

Furthermore it is integrated in the IEA Annex 42.

REFERENCES

Austrian Power Grid, 2014. Annex,

Informationstechnische.

Anforderungen Tertiärregelreserve.

Bundesverband Wärmepumpe e. V., 2013. Regularien des.

SG Ready-Labels, SG Reagy-Label – für das.

Smartgrid geeignete Wärmepumpen.

Bundesverband Wärmepumpe e. V., 2015. Modell-Liste,

SG Ready‘-Label für Smart-Grid-fähige.

Wärmepumpen.

Biermayr, P. et al., 2013. Innovative Energietechnologien.

in Österreich Marktentwicklung 2012. Wien,

Bundesministerium für Verkehr, Innovation und.

Technologie.

Fischer D., Rivera Toral T., Lindberg K. B., Wille-

Haussmann B., Madani H. , 2014. Investigation of.

Thermal Storage Operation Strategies with Heat.

Pumps in German Multi Family Houses. Energy.

Procedia 58, 137-144.

Gaehmi, S., 2013. Potential analysis of Residential.

Demand Response using GridLAB-D. Wien, IECON.

Hao et al., 2015. Aggregate Flexibility of Thermostaically.

Controlled Loads. IEEE Transactions on Power.

Systems, 30, 10.

Jungwirth, J., 2014. Lastmanagement in Gebäuden,

Entwicklung einer modellprädiktiven Regelung mit.

einem adaptiven Gebäudemodell zur Flexibilisierung.

der Wärme- und Kälteversorgung von Gebäuden. TU.

München.

Khan S., Shahzad M., Habib U., Gawlik W., Palensky P.,

2016. Stochastic battery model for aggregation of.

thermostatically controlled loads. IEEE ICIT 2016.

conference.

Koch S., Andersson G., 2009a. Potentials and.

Applications of Coordinated Groups of Thermal.

Household Appliances for Power System Control.

Purposes. IEEE PES/IAS conference 2009.

Koch S., Meier D., Zima M., Wiederkehr M., Andersson.

G., 2009b. An Active Coordination Approach for.

Thermal Household Appliances – Local.

Communication and Calculation Tasks in the.

Household. IEEE Power Tech conference Bukarest.

2009.

Moser et al., 2014. LoadShift: Lastverschiebung in.

Haushalt, Industrie, Gewerbe und kommunaler.

Infrastruktur Potenzialanalyse für Smart Grids. Wien,

Bundesministerium für Verkehr, Innovation und.

Technologie.

O’Connel N., Pinson P., Madsen H., O’Malley M., 2014.

Benefits and challenges of electrical demand

response:

A critical review. Renewable and Sustainable Energy.

Reviews 39, 686-699.

Pfaffen, D., Werlen, K., 2013. WARMup: Optimale.

Verwertung der Flexibilität von thermischen.

Speichern. Bundesamt für Energie BFE.

Von Roon,, S., 2014. Entwicklung der Erlösmöglichkeiten.

für Flexibilität auf dem Strommarkt. Deutsche.

Energie-Agentur GmbH.

Entso-e, Glossary. https://www.entsoe.eu/data/data-

portal/glossary/Pages/default.aspx.

Aggregating the Flexibility of Heat Pumps and Thermal Storage Systems in Austria

377