Wireless Sensor Network Microcantilever Data Processing using

Principal Component and Correlation Analysis

Viktor Zaharov

1

, Angel Lambertt

2

and Ali Passian

3

1

Polytechnic University of Puerto Rico, San Juan, PR 00918, U.S.A.

2

Universidad Anahuac Norte, Huixquilucan, Edo. de Mexico, Mexico

3

Oak Ridge National Laboratory, Oak Ridge, TN 37831, U.S.A.

Keywords:

Wireless Sensor Network, Microcantilever, Karhunen-Lo

`

eve Transform, Correlation Analysis, Data Denois-

ing.

Abstract:

One of the main purpose of the wireless sensor network is an identification of unknown physical, chemical

and biological agents in monitoring area. It requires the measurement of the microcantilever sensor resonance

frequencies with high precision. However, resolving the weak spectral variations in dynamic response of

materials that are either dominated or excited by stochastic processes remains a challenge. In this paper we

present the analysis and experimental results of the resonant excitation of a microcantilever sensor system

(MSS) by the ambient random fluctuations. In our analysis, the dynamic process is decomposed into the bases

of orthogonal functions with random coefficients using principal component analysis (PCA) and Karhunen-

Lo

`

eve theorem to obtain pertinent frequency shifts and spectral peaks. We show that using the truncated

Karhunen-Lo

`

eve Transform helps significantly increase the resolution of resonance frequency peaks compared

to those obtained with conventional Fourier Transform processing.

1 INTRODUCTION

The fast grow of wireless sensor networks perma-

nently demands to apply some sophisticated tech-

niques to increase the reliability of acquired data for

various applications, like physical and environmental

conditions monitoring. A wide range of applications

for the study of physical, chemical and biological pro-

cesses require sensitive standoff detection of chemi-

cal and biological agents (Parmeter, 2004; Bengtsson

et al., 2006; Farahi et al., 2012; Dada and Bialkowski,

2011).

The more advanced sensing device whenever has

been implemented, which can be used for detec-

tion of unknown agents, is the microcantilever sen-

sor system (MSS) (Buchapudi et al., 2011; Wig et al.,

2006). MSS acquires the data by reading a reflected

laser spot from the microcantilever sharp nanoscale

tip. The reflected beam undergos intensity and shape

modifications before reaching the sensitive photodi-

ode, which reads out the microcantilever motion. Fur-

ther processing of the microcantilever output data

allows to find the resonance frequencies helping to

identify unknown physical, chemical, or biological

agent (Van Neste et al., 2009; Measures, 1984).

Many remote sensor applications operate in at-

mospheric conditions, dense gases and fluids causing

sensitivity difficulties due to gas kinetic and hydro-

dynamic dissipation and coupling. Depending upon

the concentration of the sought analyte and random

characteristics of both the environment and the mea-

suring systems, the acquired data can contain a va-

riety of stochastic components that in many applica-

tions dominate over the useful signal despite employ-

ment of phase sensitive detection. As a result, the

measured data are complemented by the high level of

random fluctuations that obstruct the systematic pat-

tern (Labuda et al., 2012; Kawakatsu et al., 2002).

As for any laser remote sensing measurement the na-

ture of these fluctuations are uncorrelated or weakly

correlated random noise, and weakly or strongly cor-

related instrumental errors (Measures, 1984). Clean-

ing up the systematic pattern is a big challenge and

the solution can be found using quite sophisticated

data denoising techniques. In the literature denoising

techniques, as a rule, refer to manipulation of some

orthogonal decompositions coefficients. The coeffi-

cients split out into two orthogonal subsets – the de-

terministic data pattern and the stochastic data; the

first one includes the values which exceed a speci-

Zaharov, V., Lambertt, A. and Passian, A.

Wireless Sensor Network Microcantilever Data Processing using Principal Component and Correlation Analysis.

DOI: 10.5220/0005933200970105

In Proceedings of the 13th International Joint Conference on e-Business and Telecommunications (ICETE 2016) - Volume 6: WINSYS, pages 97-105

ISBN: 978-989-758-196-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

97

fied threshold level, and the second one the values

which do not exceed a threshold level. Afterward,

the denoised data can be reconstructed using an in-

verse transform over the deterministic data pattern co-

efficients. To process the data from standoff exper-

iments toward better recognition many well-known

denoising techniques are presented in the literature,

e.g, Fourier transform (FT), wavelet transform, Haar

transform, and so on (Ahmed and Rao, 1975; Wang,

2012).

In this paper we employ more promising type of

decomposition that are based on the principal compo-

nent analysis (PCA) (Wang, 2012) and can be suc-

cessfully used for the purpose of data denoising –

Karhunen-Lo

`

eve Transform (KLT). We analyze pros

and cons of KLT, and discuss its discrete implemen-

tation. We show that denoising of data with KLT al-

lows to increase the precision of resonance frequen-

cies measurement because of the highest resolution

ability of KLT over any known existing transforms.

The simulation result confirms the high performance

of KLT.

The paper is organized as follows. Section 2 dis-

cusses the microcantilever sensor system analysis and

experimental setup, Section 3 introduces the KLT and

its discrete implementation. Section 4 presents the ap-

plication of KLT to sensitive cantilever experimental

data processing and the result discussion. In Section 5

we discuss the threshold value determination between

deterministic pattern and random fluctuations by in-

volving the correlation analysis. We summarize our

work in Section 6.

2 MICROCANTILEVER SENSOR

SYSTEM ANALYSIS AND

SETUP

Resonant microcantilever is a device that absorbs the

particles and actuates them into vibration of ampli-

tudes. The resonance cantilever frequencies are iden-

tified as peaks of maximal oscillation amplitudes in

the frequency domain, and the resonance frequencies

strongly depend on the nature of the particles. By

measuring a shift in the resonance frequencies the un-

known material can be detected and classified. The

sensitivity of a cantilever is defined by the quality fac-

tor (Q-factor) that determines the resolution, and, as a

result, the precision of resonance frequency shift mea-

surement. The Q-factor of a cantilever is a specified

value that depends on the cantilever geometry, ma-

terial elasticity and mass. A change in mass due to

interaction with the surrounding gases causes a shift

in the resonance frequency of vibrating cantilever.

The higher the Q-factor, the higher the sensitiv-

ity of sensor and, as a result, the narrower the res-

onance peak bandwidth; hence, a shift in resonance

frequency can be detected and estimated with high

precision. However, despite the high Q-factor pro-

vides high sensitivity, the response of the sensor is

rather slow. As shown in (Albrecht et al., 1991) for

a cantilever with Q = 50, 000 and a resonance fre-

quency f

r

= 50 kHz, the maximum available band-

width is only 0.5 Hz, corresponding to the respond

time τ = 2Q/2π f

r

= 0.32 s, which is too long for

many applications. The dynamic range of high sen-

sitivity sensor is also restricted due to high ampli-

tude response on the resonance frequency. Because of

mentioned constraints, using the cantilever with very

high Q-factor in majority applications is undesirable.

Low Q-factor cantilevers operate with faster re-

sponse, but because of their low peaks resolution the

shifting in the resonance frequency can not be esti-

mated precisely, especially when the shift is rather

small. Hence, we have contradictory cantilever im-

plementation requirements: it should operate with a

fast response (requires low Q-factor), and in the same

time it should be highly sensitive providing high res-

olution (requires high Q-factor) . Satisfaction to both

conditions is a big challenge and an acceptable solu-

tion sometimes does not exist. Therefore, the goal of

this paper is to achieve the high peak resolution spec-

tra of low Q-factor cantilevers by using KLT.

In our test the microcantilever dynamics is moni-

tored via optical beam deflection in atomic force mi-

croscopy (AFM) head. The signal of AFM, S(t),

is split and sent to four channels of a digitizing os-

cilloscope, where the four channels are captured in

rapid succession, each channel measurement contain-

ing 10,000 points sampled at 200 ns intervals. Farther,

we analyze the 4th channel data.

Let us consider S(t) as the signal representing the

relevant observable in the cantilever dynamics, that is,

the deformation u(x,t) at a given x. The vibrations of

AFM cantilever, u(x,t), can be described by a partial

differential equation using the Euler Bernoulli beam

theory

EI

∂

4

u(x,t)

∂x

4

+ ρA

∂

2

u(x,t)

∂

2

= 0. (1)

where E is the Youngs modulus, I is the second mo-

ment of inertia of the cross section, ρ is the mass

density, and A is the cross sectional area (Measures,

1984).

In the absence of any external driving forces, S(t)

represents the equilibrium state of u(x,t) and the ac-

cumulative random fluctuations in the entire system,

WINSYS 2016 - International Conference on Wireless Networks and Mobile Systems

98

that is, the electronics noise, the Brownian oscilla-

tions of the cantilever, thermal, acoustic, mechanical

noises, etc.

The solution of (1) has been found in (Passian

et al., 2007; Lozano and Garcia, 2009) by the method

of separation of variables, resulting

u(x,t) =

∞

∑

k=1

φ

k

(x)e

jkω

k

t

, (2)

where φ

k

(x) is a set of normalized orthogonal eigen-

functions.

Each term in (2) represents a kth vibration mode,

whose dynamic equation is described by a second or-

der differential equation with an effective spring con-

stant µ

k

, an effective mass m

k

, a frequency ω

k

, and a

quality factor Q

k

(Mokrane and et al, 2012)

m

k

∂

2

u

k

(t)

∂t

+

m

k

ω

k

Q

k

∂u

k

(t)

∂t

+ µ

k

u

k

(t) = F

noise

. (3)

where F

noise

the variable that represents all external

and internal noises.

The fluctuation-dissipation theorem states that the

power spectral density (PSD) of the thermal noise at

the free end of the cantilever is expressed at a kth vi-

bration mode as

S(ω) =

2K

b

T

µ

k

πω/2

Q

k

(1 −(ω/ω

k

)

2

)

2

Q

2

k

+ (ω/ω

k

)

2

. (4)

where K

b

is the Boltzman constant and T is the tem-

perature in degrees of Kelvin.

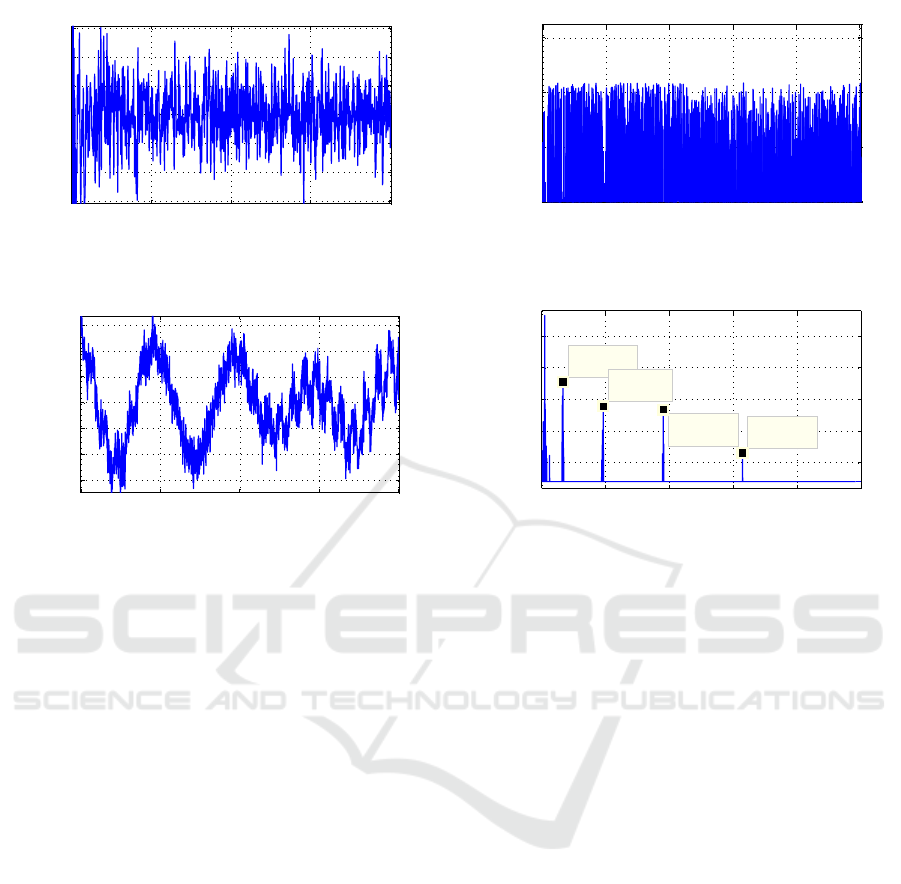

The resonant oscillations of the cantilever, S(t), by

stochastic excitation are shown in Fig. 1. The corre-

sponding PSD obtained as S(ω) = S(ω)S(ω)

∗

is de-

picted in Fig. 2, where S(ω) is FT of S(t). S(t) rep-

resents a signal of a free cantilever, that is, when the

tip of the micro cantilever probe is outside the range

of interfacial force fields, typically a few nanometers

away from the surface.

Practically only few resonances can be directly

observed during the random fluctuations; therefore,

we consider in details only the first and the second

resonance frequencies of the cantilever, i.e., f

(1)

r

=

10 kHz, f

(2)

r

= 66.7 kHz. Nevertheless, the data de-

picted on Fig. 1 allow to analyze much higher res-

onance frequencies because of the total observation

time is t

tot

= 2 ms and a sampling rate is 5 MHz (∆t =

0.2 µs). Obviously, the sampling time ∆t = 0.2 µs

yields an oversampling for the first and for the second

resonances, but it is more suitable for the higher order

resonances.

0 2000 4000 6000 8000 10000

0.07

0.08

0.09

0.1

0.11

0.12

Cantilever output signal, Ts=2.0e-7

Time (Samples)

Amplitude of cantilever,V

0 500 1000 1500 2000

0.07

0.08

0.09

0.1

0.11

0.12

Cantilever output signal, Ts=2.0e-7

Time (Samples)

Amplitude of cantilever,V

Figure 1: Equilibrium state microcantilever output data,

sample time 2 ×10

−7

s a) 10,000 samples, b) 2,000 sam-

ples.

0 2 4 6 8 10

x 10

4

-85

-80

-75

-70

-65

-60

-55

-50

X: 1e+04

Y: -47.73

Fourier Spectrum

Frequency, (Hz)

Spectral density, dBW/Hz

X: 6.7e+04

Y: -55.45

Figure 2: Fourier spectrum of the microcantilever dynamic

response. The peak f

(1)

r

= 10 KHz represents the first res-

onance frequency and at f

(2)

r

= 66.7 KHz represents the

second one.

3 KLT AND ITS DISCRETE

IMPLEMENTATION

3.1 Karhunen-Lo

`

eve Decomposition of

Stochastic Process

One of the simplest and non-expensive orthogonal de-

composition of the stochastic processes from the point

Wireless Sensor Network Microcantilever Data Processing using Principal Component and Correlation Analysis

99

of view of computational complexity is the Fourier

transform (FT) with the complex exponents orthogo-

nal bases functions. Unfortunately, some series draw-

backs of FT, like low resolution of the spectral com-

ponents, slow convergence of the truncated decom-

position to the origin data (especially when the data

vector is short) encourage looking for some other or-

thogonal decompositions techniques with the lack of

mentioned serious weaknesses.

One promising technique that helps to over-

come many drawbacks of Fourier transform is the

Karhunen-Lo

`

eve transform (KLT). KLT is an orthog-

onal transform and it is optimum under the mean

squared error (MSE) between truncated and the ac-

tual data providing the highest convergence of the

data vector into smaller dimension subspace (Lo

`

eve,

1978; Wang, 2012; Marple, 1987). In the opposite

of Fourier transform, where the basis vectors are the

complex exponent functions, the orthogonal basis of

KLT are the eigenvectors of the data covariance ma-

trix. It succeeds very attractive properties, because of

complete decorrelation of the measured data helps to

squeeze the data information into minimum number

of parameters, and, ultimately, among other orthogo-

nal transforms to reach the highest resolution of the

data spectral components (Lo

`

eve, 1978; Wang, 2012;

Marple, 1987).

We propose exploiting the highest resolution

property of KLT applying it for denoising of low Q-

factor cantilever data, thereby significantly increasing

the precision of the resonance frequency estimation.

To introduce KLT we consider a decomposition of

the stochastic data S(t),t ∈ [t

1

,t

2

] as an infinite linear

combination of orthogonal functions in L

2

[t

1

,t

2

]

S(t) =

∞

∑

k=1

Z

k

e

k

(t), (5)

where

Z

k

=

Z

t

2

t

1

S(t)e

k

(t) (6)

are uncorrelated random variables and e

k

(t) is the set

of continuous real-valued functions on [t

1

,t

2

], which

are pairwise orthogonal in L

2

[t

1

,t

2

].

Varying the set of orthogonal functions (6) bearing

the transformations like Fourier transform, wavelet

transform, Haar transform, and so on (Ahmed and

Rao, 1975; Wang, 2012). Kari Karhunen and Michel

Lo

`

eve (Karhunen, 1947; Lo

`

eve, 1978) had found the

set of orthogonal functions that provide the optimum

approximation of the original stochastic process in

the sense of the minimum total mean-square error

[S(t) −

˜

S(t)]

2

, where

˜

S(t) =

∑

L

k=1

Z

k

e

k

(t) is a trun-

cated to L terms decomposition of S(t). The solution

has been found by solving the homogeneous Fred-

holm integral equation of the second kind

Z

t

2

t

1

K

S

(τ,t)e

k

(τ)dτ = λ

k

e

k

(t). (7)

where K

S

(τ,t) the covariance function (kernel) that

satisfies the definition of a Mercer theorem (Wang,

2012) postulating that such a set of eigenvalues λ

k

and

eigenfunctions e

k

(t) exists, which forms an orthonor-

mal basis in L

2

[t

1

,t

2

], and K

S

(τ,t) can be expressed

as

K

S

(τ,t) =

∞

∑

k=1

λ

k

e

k

(τ)e

k

(t). (8)

As a result, (6) becomes the Karhunen Lo

`

eve Trans-

form (KLT), and its basis provide the fastest conver-

gence of

˜

S(t) toward S(t). However, the serious draw-

back of the KLT is the high numerical cost of deter-

mining the eigenvalues and eigenfunctions of its co-

variance operator, because it requires the solution of

the integral equation (7). However, the implementa-

tion of KLT can be significantly simplified when input

data is a discrete random process, because the linear

algebra tools like the eigenvalues decomposition of

discrete covariance matrix can be used. Furthermore,

the fast KLT algorithms can help in some particular

cases (Wang, 2012; Reed and Lan, 1994). Below we

discuss the discrete KLT implementation in details.

3.2 KLT Discrete Implementation

Implementation of discrete KLT is interconnected

with several inconveniences. Firstly, before KLT can

be used for data processing, some preliminary data

preprocessing should be done. It includes, a) storing

in a memory the ”training” set of representative data

samples, b) forming the data covariance matrix, and

c) finding the proper basis functions by computing

the data covariance matrix eigenvalue decomposition.

This preprocessing makes KLT a data dependent lin-

ear transform, and the proper basis functions are never

known a priori excepting when the model of the data

is known. Secondly, KLT has much higher computa-

tional cost and memory requirements that any other

known orthogonal transform restricting both its soft-

ware and hardware implementations. Nevertheless,

KLT is a very attractive tool for data denoising be-

cause of data can be split into two orthogonal sub-

spaces, the useful data and the noisy data, and after-

ward the noisy data can be just ignored. The data de-

noising algorithm that involves KLT includes the fol-

lowing sequence of operations (Wang, 2012).

1. Find the data covariance matrix R =

1

M

∑

M

i=1

S

i

S

T

i

, M ≥ N, where S

i

is a data N ×1

vector, and M is a number of data vector running.

WINSYS 2016 - International Conference on Wireless Networks and Mobile Systems

100

2. Find the eigenvalue decomposition R = ΦΛΦ

T

,

where Λ = [λ

1

,λ

2

,...,λ

N

] is a N × N diagonal

matrix with elements sorted in descending order,

and matrix Φ = [φ

1

,φ

2

,...,φ

N

] is an eigenvectors

matrix, where φ

i

, i = 1, ... ,N, is a N ×1 vectors.

3. Determine the threshold that split the data space

into two subspaces, the subspace of the useful

eigenvalues, and subspace of the unwanted eigen-

values, and determine m significant eigenvalues

which succeed the threshold (m ≤ N).

4. Form N × m truncated KLT transform matrix

Φ

m

= [φ

1

,φ

2

,...,φ

m

] that includes only eigenvec-

tors belonging to larger m eigenvalues of R.

5. Compute direct KLT as y = Φ

T

m

x.

6. Compute inverse KLT as x = Φ

m

y for reconstruc-

tion and data denoising .

Unfortunately, we are not able to practically imple-

ment step 1 because of lack of sufficient statistics –

only one realization of the data vector is available.

To form the full rank matrix R the number of avail-

able realizations must be at least equal to the number

of data points, otherwise the matrix R is a deficient

one. Furthermore, forming the full rank matrix R re-

quires enormous numbers of measurements (at least

10,000 in our case), and posterior tough computa-

tions. However, the computational work can be short-

ened if the true covariance matrix R (it is asymptotical

covariance matrix when M → ∞) can be successfully

replaced by the analytical matrix. Various types of

random processes and their analytical covariance ma-

trices have been derived and presented in (Maccone,

2009). It is well known that in the absence of any ex-

ternal driving forces, the microcantilever accumula-

tive random fluctuations is the Brownian oscillations

process (Mokrane and et al, 2012; Measures, 1984).

Therefore, the analytical Brownian covariance matrix

is formed according to (Maccone, 2009).

4 MICROCANTILEVER DATA

PROCESSING WITH KLT

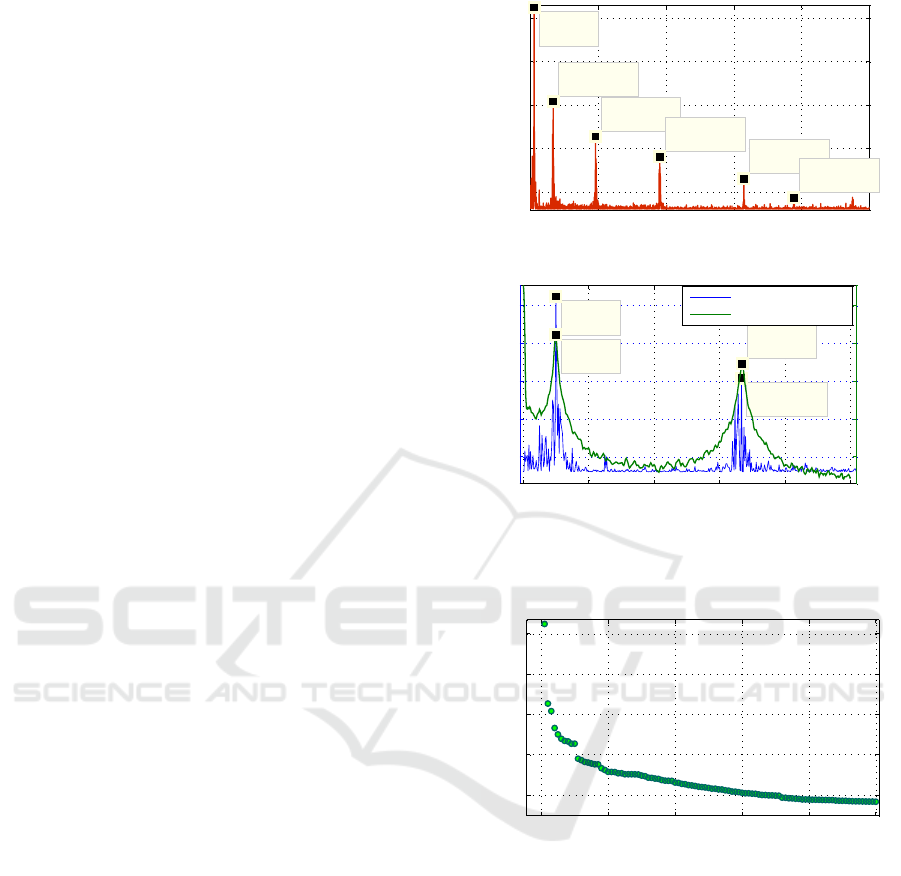

We find the KLT of the data depicted in Fig. 1 using

the algorithm described in Section 3, where all 10,000

eigenvalues are involved. Fig. 3a shows resulting KLT

spectrum for the frequency range 0 - 1 MHz (despite

the whole available range of frequencies for the sam-

ple rate T

s

= 2 ×10

−7

s is 0 - 2.5 MHz), and Fig. 3b

shows KTL spectrum in details in the frequency range

0 - 100 KHz just helping to compare the KLT spec-

trum with the reference FT spectrum.

0 2 4 6 8 10

x 10

5

-25

-20

-15

-10

-5

X: 1e+004

Y: -3.783

KLT Spectrum, (dBW/Hz)

Frequency, (Hz)

X: 6.675e+004

Y: -14.59

X: 1.915e+005

Y: -18.63

X: 3.813e+005

Y: -20.97

X: 6.295e+005

Y: -23.5

X: 7.765e+005

Y: -25.7

0 2 4 6 8 10

x 10

4

-25

-20

-15

-10

-5

X: 1e+004

Y: -3.783

KLT Spectrum, (dBW/Hz)

Frequency, (Hz)

X: 6.675e+004

Y: -14.59

0 2 4 6 8 10

x 10

4

-80

-70

-60

-50

-40

X: 1e+004

Y: -47.73

FT Spectrum, (dBW/Hz)

X: 6.7e+004

Y: -55.45

KLT Spectrum

FFT Spectrum

Figure 3: Cantilever output data Fourier spectrum vs. KLT

spectrum a) f

max

= 1 MHz, b) f

max

= 100 kHz.

0 20 40 60 80 100

-25

-20

-15

-10

-5

Eigenvalues distribution

Eigenvalue #

Eigenvalues intensity (V)

Figure 4: Distribution of the first 100 eigenvalues of data.

As follows from Fig. 3 the KLT spectrum has

much higher resolution than the reference FT spec-

trum, even in the presence of complementary noise

that can both distort and displace the result of reso-

nance peak frequencies measurements. However, de-

noising of the original data helps to identify the res-

onance frequencies with more higher precision. We

start the data denoising with finding of the data co-

variance matrix eigenvalues distribution, and the re-

sult is presented in Fig. 4. Applying the KLT to the

output data and afterward reconstructing the data in-

volving the very first largest eigenvalue resulting the

perfect emerging of high resolved peak on the first

resonance frequency 10 kHz. Then involving three

largest eigenvalues results the second peak at the fre-

Wireless Sensor Network Microcantilever Data Processing using Principal Component and Correlation Analysis

101

0 2 4 6 8 10

x 10

4

-100

-80

-60

-40

-20

0

X: 1e+04

Y: -6.779

Frequency, (Hz)

Spectral density, dBW/Hz

X: 6.675e+04

Y: -17.41

FT Spectrum

KLT Spectrum

Figure 5: Estimation of the first and the second resonance

frequency peaks involving three largest eigenvalues.

0 500 1000 1500 2000

-0.01

-0.005

0

0.005

0.01

Output data, descarding three largest eigenvalues out of 10,000

Time (Samples)

Amplitude of cantilever,V

Figure 6: Data reconstructed using three largest eigenval-

ues.

quency 66.7 kHz as Fig. 5 shows. Emerging strong

and narrow peaks helps to estimate resonance fre-

quencies with much higher precision than those that

can be provided by the reference spectrum obtained

by FT. Fig. 6 depicts the time domain data when the

first three eigenvalues are used in computing of the in-

verse KLT , where the first and the second resonance

frequencies can be recognized as the lower and the

higher frequencies oscillated waves, respectively.

5 THRESHOLD

DETERMINATION BETWEEN

USEFUL PATTERN AND NOISE

USING CORRELATION

ANALYSIS

In previous section to detect and identify the res-

onance frequencies we involve the fist three larger

eigenvalues that correspond to the first and to the sec-

ond resonances, e.i., 10.0 kHz and 66.7 kHz, and

the rest of the eigenvalues were discarded as un-

wanted. However, as Fig. 3a shows, KLT spectrum

allows to estimate the higher order resonance frequen-

cies as well. Particularly, 191.5 kHz, 381.3 kHz,

629.5 kHz and 776.5 kHz, which can provide ad-

ditional meaningful information about the measured

data. It means that all eigenvalues that represent the

higher order resonance frequencies belong to the set

of eigenvalues that bearing additional useful informa-

tion. Hence, discrimination of the desire eigenvalues,

which represent the useful data and unwanted eigen-

values which represent the purely stochastic com-

ponents, refers to the threshold determination prob-

lem. Finding appropriate threshold helps to solve

the data denoising problem, i.e., to suppress the in-

terfering random fluctuations that distort the reso-

nance frequencies measurement result. The thresh-

old determination problem is formulated as following

(Marple, 1987). In the whole set of N eigenvalues

Λ = {λ

1

,λ

2

,...,λ

m

,λ

m+1

,...,λ

N

}obtained by eigen-

values decomposition of the data covariance matrix

determine the value m, 1 < m < N, that splits the set Λ

into two orthogonal subspaces, one of them is a signal

subspace, Λ

S

, that contains the useful deterministic

components (excited the resonances) and other one,

Λ

n

, is a subspace of the random noise that contains

uncorrelated residual components (interferer), i.e.

R =

m

∑

k=1

λ

k

φ

k

φ

H

k

+

N

∑

k=m+1

λ

k

φ

k

φ

H

k

, (9)

where unknown value m must be determined. In the

literature numerous attempts are done to determine

the value m. For example, Konstantinides (Konstan-

tinides and Yao, 1988) propose firstly to find the ratio

(

∑

m

k=1

λ

k

/

∑

N

k=1

λ

k

)

1/2

, and then compare it with some

predetermined value ε, which depends on the vari-

ance of the random noise; however it require a priory

information about the variance of the noise, hence,

some additional measurements or analysis of data is

needed. Marple (Marple, 1987) propose to use the

rule based on the Akaike information criterion (AIC)

(Sakamoto et al., 1986), that is

AIC{m}= (N −m)ln(

1

N−m

∑

m

k=m+1

λ

k

∏

m

k=m+1

λ

N−m

k

)+m(2N −m).

(10)

Afterward, the minimum AIC over all m should be

chosen. Despite the Akaike criteria estimates a rela-

tive information lost for a given data model, it does

not provide the testing of a null hypothesis, meaning

that some weak amplitude components of a useful sig-

nal can be lost.

Below we propose the solution of the threshold es-

timation problem by using the correlation analysis of

the stochastic data subspace in order to find the subset

that contains only the random uncorrelated compo-

nents. Other words, we find the value m using the trial

and errors approach ensuring that

∑

N

k=m+1

λ

k

φ

k

φ

H

k

is a

random uncorrelated data. For this, we successively

WINSYS 2016 - International Conference on Wireless Networks and Mobile Systems

102

-1 -0.5 0 0.5 1

x 10

4

0

0.2

0.4

0.6

0.8

1

Autocovariance after descarding three largest eigenvalues

Lag

Coefficients

-1 -0.5 0 0.5 1

x 10

4

0

0.2

0.4

0.6

0.8

1

Autocovariance after descarding three largest eigenvalues

Lag

Coefficients

-1 -0.5 0 0.5 1

x 10

4

-0.2

0

0.2

0.4

0.6

0.8

1

Autocovariance after descarding 50 largest eigenvalues

Lag

Coefficients

-1 -0.5 0 0.5 1

x 10

4

0

0.2

0.4

0.6

0.8

1

Autocovariance after descarding 110 largest eigenvalues

Lag

Coefficients

Figure 7: Data autocovariance after a) discarding three larger eigenvalues, b) discarding 20 larger eigenvalues, c) discarding

50 larger eigenvalues, d) discarding 110 larger eigenvalues.

discard m = 1,2,..., N larger eigenvalues from the

data and for each m we are testing the null hypoth-

esis of the rest of the data. The resulting autoco-

variance function when m is 3, 20, 50 and 110 are

presented in Fig. 7. As follows from Fig. 7, when

only 3 or even 20 largest eigenvalues are discarded,

the correlation is still high (lagged correlation coeffi-

cients oscillat with the high amplitudes), but when the

number of largest eigenvalues to be discarded are in-

creasing, then lagged correlation coefficients are get-

ting lower approaching the level −N ±2/

√

N, and

for m = 110 the null hypothesis (the sequence rep-

resents the random process with zero correlation) can

be accepted inside the 95% confidence interval lim-

its (Kendall et al., 1977). Resulting plots of splitting

random noise and deterministic pattern when m = 110

in both time and frequency domains are depicted in

Fig. 8, and Fig. 9, respectively. Visually Fig. 8 repre-

sents the poorly random data showing stochastic fluc-

tuation in the time domain and almost equal ampli-

tudes of all eigenvalues in the frequency domain (con-

sist with PSD of the random noise), and Fig. 9 repre-

sents deterministic data, showing predicted behavior

in the time domain and expressive peaks on the fre-

quency domain (consist with deterministic pattern be-

havior). It just confirms that after the null hypothesis

testing the determined threshold is found correctly.

6 CONCLUSIONS

We present and analyze microcantilever data denois-

ing technique using one of the more advanced orthog-

onal transforms – Karhunen-Lo

`

eve Transform (KLT),

which helps to split the eigenvalue decomposition of

measured data covariance matrix by two independent

subsets – subset of useful signal that contains the

larger eigenvalues, and subset of unwanted signal that

contains the rest of eigenvalues. Processing of data

with the first three larger eigenvalues and discarding

the rest of them we perfectly determined the first and

second resonance frequencies of the microcantilever

with high precision.

We proposed to use the correlation analysis and

the null hypothesis testing to determine the optimum

threshold between subsets of deterministic eigenval-

ues and eigenvalues that belong to the random fluctu-

ations. The simulation result confirm the truthful of

proposed approach.

The KLT has been demonstrated the ability of ef-

fective improvement of the spectral identification of

the micro cantilever resonances that were driven by

the Brownian noise (thermal, mechanical, electronic

and other type of random fluctuations). The simula-

tion results and analytical analysis illustrate that KLT

can be adapted as a powerful data denoising tool for

the cantilever based sensing applications.

Wireless Sensor Network Microcantilever Data Processing using Principal Component and Correlation Analysis

103

0 500 1000 1500 2000

-6

-4

-2

0

2

4

6

x 10

-5

Residual data, discarding 110 largest eigenvalues

Time (Samples)

Amplitude of noise,V

0 2 4 6 8 10

x 10

5

-50

-45

-40

-35

Frequency, (Hz)

Noise spectral density, dBW/Hz

KLT of resifual data

Figure 8: Residual noise after discarding of 110 larger eigenvalues a) time domain, b) frequency domain.

0 500 1000 1500 2000

-0.015

-0.01

-0.005

0

0.005

0.01

0.015

Output data, including 109 largest eigenvalues out of 10,000

Time (Samples)

Amplitude of cantilever,V

0 2 4 6 8 10

x 10

5

-30

-25

-20

-15

-10

X: 6.675e+04

Y: -17.29

Frequency, (Hz)

Spectral density, dBW/Hz

KLT of 109 largest eigenvalues out of 10,000

X: 1.93e+05

Y: -21.11

X: 3.813e+05

Y: -21.66

X: 6.295e+05

Y: -28.51

Figure 9: Deterministic pattern involving 109 larger eigenvalues a) time domain, b) frequency domain.

ACKNOWLEDGEMENTS

This work was supported by the laboratory directed

research and development (LDRD) fund at Oak Ridge

National Laboratory (ORNL). Viktor Zaharov ac-

knowledges the financial support received from the

Department of Energy (DOE) Visiting Faculty Pro-

gram (VFP). ORNL is managed by UT-Battelle,

LLC, for the US DOE under contract DE-AC05-

00OR22725.

REFERENCES

Ahmed, N. and Rao, K. (1975). Orthogonal transforms for

digital signal processing. Springer-Verlag.

Albrecht, T. R., Grtitter, P., Horne, D., and Rugar, D.

(1991). Frequency modulation detection using highd-

kantilevers for enhanced force microscope sensitivity.

J. Appl. Phys., 69(2).

Bengtsson, M., Gr

¨

onlund, R., Lundqvist, M., Larsson, A.,

Kr

¨

oll, S., and Svanberg, S. (2006). Remote laser-

induced breakdown spectroscopy for the detection and

removal of salt on metal and polymeric surfaces. Ap-

plied Spectroscopy, 60:1188–1191.

Buchapudi, K. R., Huang, X., Yang, X., Ji, H. F., and Thun-

dat, T. (2011). Microcantilever biosensors for chemi-

cals and bioorganisms. Analyst, (136(8)):1539–1556.

Dada, O. O. and Bialkowski, S. E. (2011). A compact,

pulsed infrared laser-excited photothermal deflection

spectrometer. Applied Spectroscopy, 65(2):201–205.

Farahi, R. H., Passian, A., Jones, Y. K., Tetard, L., Lereu,

A. L., and Thundat, T. G. (2012). Pumpprobe pho-

tothermal spectroscopy using quantum cascade lasers.

Journal of Physics D, 45:125101.

Karhunen, K. (1947).

¨

Uber lineare methoden in der

wahrscheinlichkeitsrechnung. Ann. Acad. Sci. Fen-

nicae, Ann. Acad. Sci. Fennicae. Ser. A. I. Math.-

Phys.(37):1–79.

Kawakatsu, H., Kawai, S., Saya, D., Nagashio, M.,

Kobayashi, D., Toshiyoshi, H., and Fujita, H. (2002).

Towards atomic force microscopy up to 100 MHz. Re-

view of Scientific Instrument, 73(2317).

Kendall, M. G., Stuart, A., and Ord, J. K. (1977). The ad-

vanced theory of statistic. Griffin.

Konstantinides, K. and Yao, K. (1988). Statistical analysis

of effective singular values in matrix rank determina-

tion. Acoustics, Speech and Signal Processing, IEEE

Transactions on, 36(5):757 – 763.

Labuda, A., Bates, J. R., and Gr

¨

utter, P. H. (2012). The noise

of coated cantilevers. Nanotechnology, 23(025503).

Lo

`

eve, M. (1978). Probability theory. Graduate Texts in

Mathematics, volume 2. Springer-Verlag, 4th edition.

Lozano, J. and Garcia, R. (2009). Theory of multifrequency

atomic force microscopy. Phys. Rev. B, 79(014110).

Maccone, C. (2009). Deep Space Flight And Communica-

tion. Springer.

WINSYS 2016 - International Conference on Wireless Networks and Mobile Systems

104

Marple, S. L. (1987). Digital Spectral Analysis with Appli-

cation. Prentice-Hal.

Measures, R. M. (1984). Laser Remote Sensing: Funda-

mentals and Applications. Wiley-Interscience.

Mokrane, B. and et al (2012). Study of thermal and acous-

tic noise interferences in low stiffness atomic force

microscope cantilevers and characterization of their

dynamic properties. Review of Scientific Instruments,

83(1).

Parmeter, J. E., editor (2004). The challenge of standoff

explosives detection. 0-7803-8506-3/02. IEEE.

Passian, A., Lereu, A. L., Yi, D., Barhen, S., and Thun-

dat, T. (2007). Stochastic excitation and delayed os-

cillation of a micro-oscillator. Physical Review B,

75:233403.

Reed, I. S. and Lan, L.-S. (1994). A fast approximate

karhunen-lo

`

eve transform (aklt) for data compression.

Journal of Visual Communication and Image Repre-

sentation, 5:304–316.

Sakamoto, Y., Ishiguro, M., and Kitagawa, G. (1986).

Akaike Information Criterion Statistics. Springer.

Van Neste, C. W., Senesac, L. R., and Thundat, T. (2009).

Standoff spectroscopy of surface adsorbed chemicals.

Analytical Chemistry, 81(5):1952–1956.

Wang, R. (2012). Introduction to Orthogonal Transforms:

With Applications in Data Processing and Analysis.

Cambridge University Press.

Wig, A., Arakawa, E. T., Passian, A., Ferrell, T. L., and

Thundat, T. (2006). Photothermal spectroscopy of

bacillus anthracis and bacillus cereus with microcan-

tilevers. Sensors and Actuators B, 114:206.

Wireless Sensor Network Microcantilever Data Processing using Principal Component and Correlation Analysis

105