A Novel Implementation Approach for Resource Holons in

Reconfigurable Product Manufacturing Cell

Ahmed R. Sadik

1,2

and Bodo Urban

1,2

1

University of Rostock, Universitätsplatz 1, 18055, Rostock, Germany

2

Fraunhofer Institute for Computer Graphic Research IGD, Joachim-Jungius-Str. 11, 18059, Rostock, Germany

Keywords: Holonic Control Architecture, Reconfigurable Manufacturing System, Human-Robot Cooperation Planning,

Autonoumos Multi-Agent System, IEC 61499 Model.

Abstract: Holonic Control Architecture is a successful solution model for reconfigurable manufacturing problems. Two

well-known different technologies have been used separately to implement the holonic control model. The

first technology is IEC 61499 standard, and the second is autonomous reactive agent. Both of the previous

mentioned technologies have its own pros and cons. Therefore this research is merging the two technologies

together in one solution body, to magnifying their pros and reduce their cons. Ultimately; it provides a novel

implementation model for the manufacturing holons, to be followed in similar reconfigurable manufacturing

problems. A human worker in cooperation with a safe industrial robot, has been selected as a case study of a

reconfigurable manufacturing problem. The proposed holonic control solution has been applied to the case

study, to evaluate the ability of the solution to satisfy the requirements of the case study. The results show the

ability of the proposed control solution to provide a flexible physical and logical interaction framework, which

can be scaled over more workers in cooperation with more industrial robots.

1 INTRODUCTION

Reconfigurable Manufacturing System (RMS) is a

system where production components and functions

can be modified, rearranged and/or interchanged in a

timely and cost-effective manner to quickly respond

to production requirements (Koren, 1999). The

concept of RMS has been formed in response to the

fast continuous changes in the market requirements.

The goal of the RMS is to reduce the lead time when

the production switches from one product to another,

moreover to reliably handle the fluctuation in the

production volume (Kruger, 2015). A Reconfigurable

Manufacturing Cell (RMC) is the elementary unit of

an RMS. An RMC should be able to produce different

customized products, this can be achieved if the RMC

control system understands the product task plan (i.e.

recipe), and the capabilities of the work resources (i.e.

machines, robots, workers). Then it matches the

product task plan to the capabilities of the work

resources.

A Holonic Control Architecture (HCA) is an agile

solution for RMS problems (Chirn, 2000). The

solution provides a distributed control model which

defines the hierarchy, structure, and functions of all

the elements in a manufacturing system. HCA is

based on the autonomy concept. Autonomy is the

ability of the system to act without a direct

intervention from humans, as it should have control

over its own actions and internal state (Anumba,

2005). Many different autonomous technologies can

be used to implement the HCA model. Most of the

researchers who implement the HCA model, either

use autonomous agent specifications (Wang, 2005) or

IEC 61499 standard (Vlad, 2010). During this

research both the technologies will be highlighted.

Then they will be combined together to get the best

possible solution, to implement an HCA model to

control an RMC. A safe industrial robot in flexible

cooperation with a human worker is a novel case

study of an RMC, the proposed HCA solution will be

tested on this case study to show the solution

viability.

This paper is structured as follows. Section 2

explains the main concepts and technologies that will

be utilized during this research, such as HCA,

autonomous agent technology, and IEC 61499

standard. Section 3 is a review for the most related

work. Thus it is easier for the reader to understand the

problem formulation in section 4. Section 5

130

Sadik, A. and Urban, B.

A Novel Implementation Approach for Resource Holons in Reconfigurable Product Manufacturing Cell.

DOI: 10.5220/0005956801300139

In Proceedings of the 13th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2016) - Volume 1, pages 130-139

ISBN: 978-989-758-198-4

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

introduces an RMC case study and the proposed

solution structure, which is tested and evaluated in

section 6. Finally section 7 wraps up the work

summary with the conclusion and the future research.

2 PRELIMINARY CONCEPTS

2.1 Holonic Control Architecture

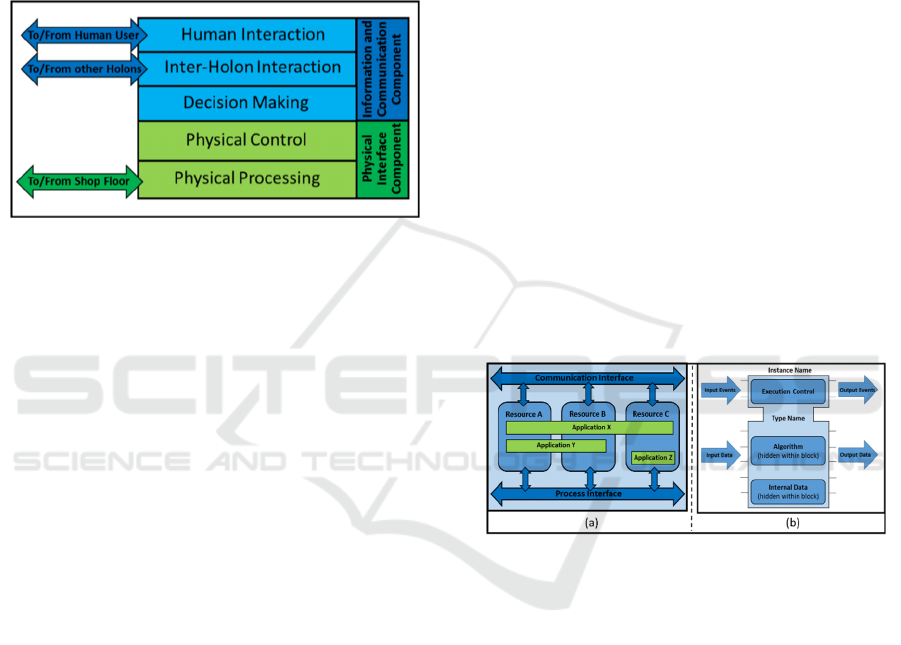

Figure 1: Holon General Architecture.

In the late of sixties, the term holon has been

introduced for the first time by philosopher Koestler

(Koestler, 1967). Koestler developed the term as a

basic unit in his explanation for the evolution of

biological and social structures. Based on his

observations that organisms (e.g., biological cells) are

autonomous self-reliance units, which have a certain

degree of independent control of their actions, yet

they still subject to higher level control instructions.

His conclusion is that any organism is a whole

“holos” and a part “on” in the same time, which

derived the term holon (Giret, 2008). The concept of

holon has been adopted in the early of nineties by the

Intelligent Manufacturing Systems (IMS)

consortium, to define a new paradigm for the factory

of the future. IMS defined the holon as an

autonomous cooperative building block of the

manufacturing system, that can be used to transform,

transporting, store and/or validate the information and

the physical objects (Radu and Frank, 2006).

The generic structure of the holon has been

constructed as shown in Figure 1 (Bussmann, 1998).

A holon is mainly composed of two components. First

the physical interface component, this is the

component which physically connects the holon to

the automation devices input/output (I/O) on the

factory shop floor. The holon physical component is

responsible for controlling the data transfer from the

automation devices to the holon and vice-versa.

Furthermore it translates these data into useful

information which can be processed by the holon. The

second holon component is the information and

communication component, this component contains

the holon kernel. As it is responsible for

communicating with other holons in the HCA, and

interacting with the humans in the manufacturing

system. All the information gathered from the other

holons, the humans, and the automation devices are

processed by the holon decision making algorithm, to

produce a proper action based on the function of this

holon in the HCA.

The functions and the responsibilities of each

holon, depend on the category of this holon. Product-

Resource-Order Staff Architecture (PROSA) (Van

Brussel, 2003), and ADAptive holonic COntrol

aRchitecture (ADCOR) (Leitao, 2006) are the most

popular HCA models. Regardless the difference

between the two models, they are addressing four

holon catagories which are: resource holon, product

holon, task holon, and supervisory holon (Su, 2007).

However our concern in this research will focus on

the resource holons. The resource holon is a physical

entity within the manufacturing system, it can

represent a robot, conveyor, machine, etc.

2.2 IEC 61499 Function Block

Standard

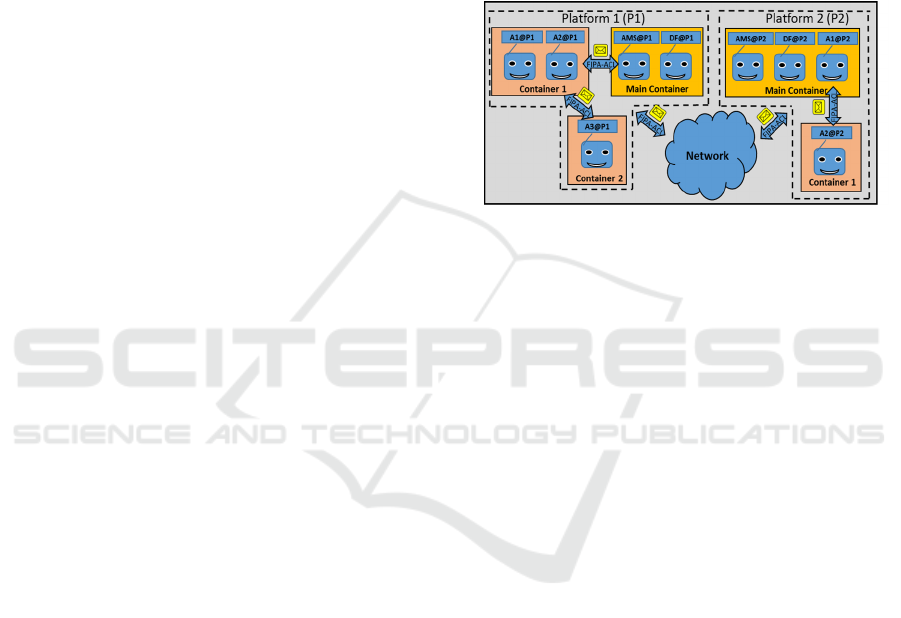

Figure 2: (a) IEC 61499 Distributability – (b) IEC 61499

Function Block.

IEC 61499 standard is an implementation model for

distributed control systems on embedded devices,

which extends the capabilities of IEC 1131-3

standard. It defines a reference model for

development, reusing and deployment of Function

Blocks (FBs) in distributed embedded industrial

control (Fischer, 2010). Figure 2-a illustrates the

distributability of IEC 61499. The automation devices

share the control of different applications

simultaneously. IEC 61499 power of distributability

originates from using the FB as a main building unit.

Figure 2-b shows the structure of an FB, The FB

consists of three fields: events I/O, data I/O, and an

internal algorithm. An FB does not apply scanning

cycle technique. Therefore different algorithms can

run simultaneously on the same FB. An algorithm

will be triggered on arrival of an input event, the

A Novel Implementation Approach for Resource Holons in Reconfigurable Product Manufacturing Cell

131

algorithm is processing the input data to produce

output data and output events (Pang, 2014).

FB technique does not only empower the

customizability and the distributability concepts. But

also it supports other concepts such as: reusability,

modularity, extensibility, and diagnosability.

Reusability points to the capability of the software

components to be reused over different

manufacturing demands and configurations. While

modularity is the degree of those software

components to be separated and recombined

(Sturgeon, 2002). Extensibility is another

synonymous of “plug and play” concept, it can

express the ability of the system to be extended to

intra/inter enterprise level by including or integrating

with more manufacturing functions (Su, 2007).

Finally diagnosibility is the ability to automatically

read the current state of a system and controls, so as

to detect and diagnose the operational defects, and

subsequently correct them quickly (Koren, 2005).

Many software tools are using IEC 61499 as a

reference control architecture. Examples of those

tools are FBDK, ISaGRAF, 4DIAC, nxtStudio. Those

tools differ in minor variations, such as the

programming language they build in. This research is

using Function Block Development Kit (FBDK) as

part of the implementation and testing phase. FBDK

is not only an IEC 61499 development tool, but also

it can be used to emulate the manufacturing system

before the deployment phase. Manufacturing system

emulation is a real time simulation, which refers to

the ability of the logical model to identically imitate

the time responses and behaviours of the real physical

manufacturing system, to gain insight into it, before

the actual implementation (Peters, 1996).

2.3 Autonomous Agent Technology

A software agent is a computer system situated in a

specific environment; that is capable of autonomous

actions in this environment in order to meet its design

objective (Jennings, 1998). An agent is responsive,

proactive and social. Responsive means the agent can

perceive its environment and respond in a timely

fashion to the changes occurring in it. Proactive

means the agent is able to exhibit opportunistic, goal

directed behaviour and take initiative. Social means

the agent can interact with other artificial agents or

humans within its environment in order to solve a

problem. A Multi-Agent System (MAS) is a

collective system composed of a group of artificial

agents, teaming together in a flexible distributed

topology, to solve a problem beyond the capabilities

of a single agent (Shen, 2006). An agent can be

designed based on a reactive or cognitive model.

Reactive agents have knowledge compiled from the

actions to be carried out. They do not need to

construct a mental representation of their

environment, since it is merely sufficient for them to

react to the situations (Wooldridge, 1995). On the

other hand cognitive agents have reasoning capacity

based on their environment representation. They are

capable of memorizing situations, and analysing

them. To foresee possible reactions to their actions,

thus they can plan their behaviours (Franklin, 1998).

Figure 3: Java Agent Development (JADE) Framework.

JAVA Agent Development (JADE) is a

distributed MAS middleware framework

(Bellifemine, 2007). JADE applies reactive agent

architecture which complies with the Foundation for

Intelligent Physical Agent (FIPA) specifications, and

provides a graphical interface to deploy and debug a

MAS (Italia, n.d.). JADE agents use FIPA-Agent

Communication Language (FIPA-ACL) to exchange

messages either inside its own platform or with

another platform in a distributed MAS. Figure 3

shows a scheme example of JADE (Poslad, 2007).

Each JADE instance is an independent thread

contains a set of Containers. A Container is a group

of JADE agents run under the same JADE runtime

instance. Every platform must contain a Main

Container. A Main Container contains two necessary

agents which are: an Agent Management System

(AMS) and a Directory Facilitator (DF). AMS

provides a unique ID for every agent under its

platform, to be used as an agent communication

address. While the DF announces the services every

agent can offer under its plateform, in order to

facilitate agent service exchange, so that each agent

can obtain its specific goal (Caire, 2009). A JADE

agent can implement one or a group of FIPA standard

behaviours. A behaviour is a set of action/reaction

routines triggered by the agent due to its perception

for its environment (Teahan, 2010).

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

132

3 RELATED WORK REVIEW

The research in (Vlad, 2010) is proposing an IEC

61499 solution for modeling and implementing

holons dynamic interaction. The paper used FBDK

visualization capabilities to emulate the holons

interaction dynamics. The research also is providing

an extensive guidance for designing both the physical

and communication components of a resource holon,

based on a comprehensive explanation of the

responsibilities of each holon category within the

manufacturing system. The holon communication

component has been implemented using FBDK

publish/subscribe technique, which is very static and

primitive communication approach. Therefore the

paper was very successful to emulate the holons

physical dynamics, however it failed to show any

communication interaction. Also the paper did not

apply its described theoretical solution to any

practical case study.

(Kruger, 2013) is evaluating two different

solution approaches. One uses IEC 61499 and the

other uses agent technology. To implement a holonic

control for modular feeder subsystem of an

experimental reconfigurable assembly system (RAS).

The research does not combine the two technologies

together, but it compares them. Then it evaluates

them based on the qualitative and quantitative

performance of four different hardware

configurations of the RAS. The research results state

that agent technology requires less effort and time

than IEC 61499 to implement three configurations of

the RAS. The IEC 61499 has inherent simplicity

because of its visualization capabilities, however the

lacks in IEC 61499 inter-platform communication

flexibility restricted the hardware reconfigurability.

An Intelligent control of an Airport Baggage

Handling System (BHS) has been deeply studied in

(Black, 2008). It provides an extended customized

MAS solution, by modeling every component in the

BHS as an IEC 61499 FB. Basically it is dividing the

whole conveyor transportation system into many

segments. Every conveyor segment is presented as a

customized FB. Moreover it models every bag over

the BHS as another customized autonomous FB. All

the instances of the conveyor segment FB and the bag

FB are communicating together using IEC 61499

standard communication FBs, which made the final

model so crowded and complex. Two important

points are distinguishing this research. First the

reusability of one customized FB to handle all the

instances of the conveyor segments or bags. Second

is the viability of the solution to be practically

applied, as finally it has been implemented on IEC

61499 FB compliant controller produced by TCS-NZ.

4 PROBLEM STATEMENT

The main focus of this paper is to design the resource

holons in an RMS. The resource holons function is to

autonomously adapt to the product changes, therefore

the manufacturing cell is able to continuously

produce the product without stopping. The resource

holon design must meet finite criteria to achieve RMS

concept. Those criteria are: distributability,

customizability, reusability, modularity,

extensibility, scalability and diagnosability. Also the

holon design should achieve the interoperability

concept, this means that the resource holons can

communicate with each other regardless the running

operating system (OS). Finally they should be

capable of handling the shop floor I/Os and

anticipating them to useful information. Most of other

researches tried to design HCA either using IEC

61499 standard or intelligent agent based system.

However each of those solutions has its own

advantages and drawbacks (Vlad, 2010; Kruger,

2013; Black, 2008).

IEC 61499 offers a standard component-based

framework, which promotes the encapsulation

concept. Therefore it can be easily scaled, moduled,

and integrated. Furthermore IEC 61499 is a modeling

language which allows the designer to offline emulate

his solution, before transferring it to the hardware.

This gives The IEC 61499 model very high

diagnosability characteristic comparing to other

distributed control frameworks. However IEC 61499

does not provide an intelligent communication

services, therefore it lacks of a high degree of

adaptability, and this leads to increase the complexity

of the overall solution model. Moreover IEC 61499

model can be customized in offline mode only to

solve one version of a pre-known problem.

On the other hand, agent based system is far

superior to IEC 61499 in information

communication, as it characterized by a high level of

flexibility and low degree of complexity. Agents are

using standard communication languages to enable

them to cooperate, collaborate, or negotiate.

Furthermore an agent based system is using service

oriented architecture (SOA) to announce the services

every agent can offer within its platform. Therefore

adaptability can be easily achieved. Nevertheless an

agent based system can be very sophisticated when it

deals with external physical control events.

In a plain English, the drawbacks of both of the

control models can be compensated by merging them

in a win-win paradigm. The missing gap in IEC

61499 model concerns adaptability, will be imported

from the agent model. Yet the agent system will be

privileged by the superiority of IEC 61499 model to

deal with sophisticated I/O events and data.

A Novel Implementation Approach for Resource Holons in Reconfigurable Product Manufacturing Cell

133

5 CASE STUDY AND SOLUTION

STRUCTURE

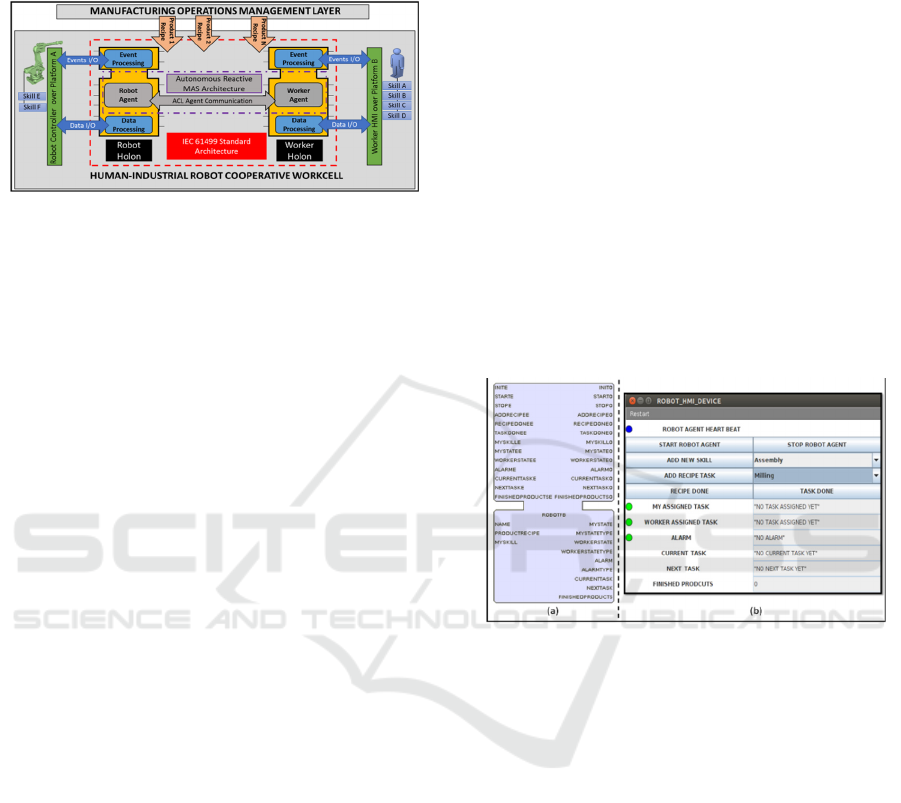

Figure 4: Holonic Human and Industrial Robot Cooperative

Production Cell.

Human & Industrial Robot (HIR) cooperative

workcell is a novel trend in industry, which integrates

the human worker along with the industrial robot in

the same working space, therefore they can perform

together a cooperative industrial process (Nilsson,

2005). The idea behind this integration is to combine

the advantages of both the human and the robot in the

same production cell. Workers add the flexibility to

the production cell, as they can easily adapt to many

unexpected situations. Yet industrial robots are

reliable in terms of speed, payload, and accuracy.

Furthermore many industrial robot manufacturers are

supporting this novel trend by producing safe

industrial robots, such as KUKA lightweight, Rethink

Baxter, YuMi ABB dual arm, and Universal Robots

(Lasota, 2014). An HIR cooperative workcell is a

direct application of the RMS. Thus the research will

address it as a case study to apply an HCA solution.

Figure 4 shows the proposed HCA solution on a

single robot – single worker cooperative workcell.

The holon physical interface component

implemented using IEC 61499 FB, while the

communication component implemented as an

autonomous reactive agent. Two different resource

holons have been implemented, a robot holon and a

worker holon. A customized IEC 61499 FB handles

all I/O events and data to/from the robot controller,

another customized FB handles the worker user

interface I/Os. Each FB is embedding a reactive

autonomous agent, the robot agent is communicating

with the worker agent to form a simple MAS. The two

holons are using FIPA-ACL standard protocol for

sending/receiving their interaction messages. Each

holon is dynamically acquiring its resource skills.

Concurrently the robot holon is acquiring the product

recipe. Thus the robot agent is able to negotiate with

the worker agent by following a searching algorithm,

to distribute the product recipe tasks between them.

The product recipe within the context of this case

study refers to, the order of the tasks to produce a

certain product. While a skill refers to the capability

of the work resource to perform a certain task.

For demonstration it has been assumed that the

resources skills are unique, in other words the robot

and worker do not share any similar skill. For the

same reason, we selected a simple case scenario for

one worker in cooperation with one industrial robot,

only to show the applicability of the HCA solution.

The solution approach can be extended to more than

one worker or robot. The same issue with the

searching algorithm, it can be more sophisticated

based on the case study size and requirements.

However the searching algorithm is beyond the paper

goals, we just want to show the ability of the HCA

solution to implement an algorithm, to provide some

of the research goals such as adaptability.

5.1 Holon Physical Component Design

Figure 5: (a) Robot FB – (b) Robot I/O Interface.

FBDK is a pioneer software tool which applies IEC

61499. It is used under the umbrella of this research,

to implement the physical component for the holon.

Figure 5-a&b shows the design of a robot FB and a

running interface of it respectively. INITE event is

meant to initialize the robot FB input data. STARTE

starts an agent in JADE, which holds the NAME input

of the FB, while STOPE vanishes this agent.

ADDRECIPEE event captures a PRODUCTRECIPE

input. One product is composed from many tasks,

which can vary from one product to another. RECIPE

DONE indicates that a complete product recipe has

been defined. TASKDONEE informs the FB that an

assigned task has been accomplished. MYSKILLE is

an event associated with MYSKILL input to capture

the robot skills, considering an industrial robot can

perform more than one task.

MYSTATEE is associated with MYSTATE and

MYSTATETYPE outputs, to constantly display robot

current state (e.g. Busy/Free and robot assigned task).

Similarly WORKERSTATEE is associated with

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

134

WORKERSTATE and WORKERSTATETYPE

outputs, to constantly display worker current state.

ALARME is linked with ALARM and

ALARMTYPE outputs, to occasionally display any

alarm that could occur during the cooperation (e.g.

required skill is not found within the production cell).

CURRENTTASKE and NEXTTASKE are

associated with CURRENTTASK and NEXTTASK

outputs respectively, to display the current task in

execution and the next task needed to be executed.

Finally FINISHEDPRODUCTSE and

FINISHEDPRODUCTS output are linked to display

the number of produced products.

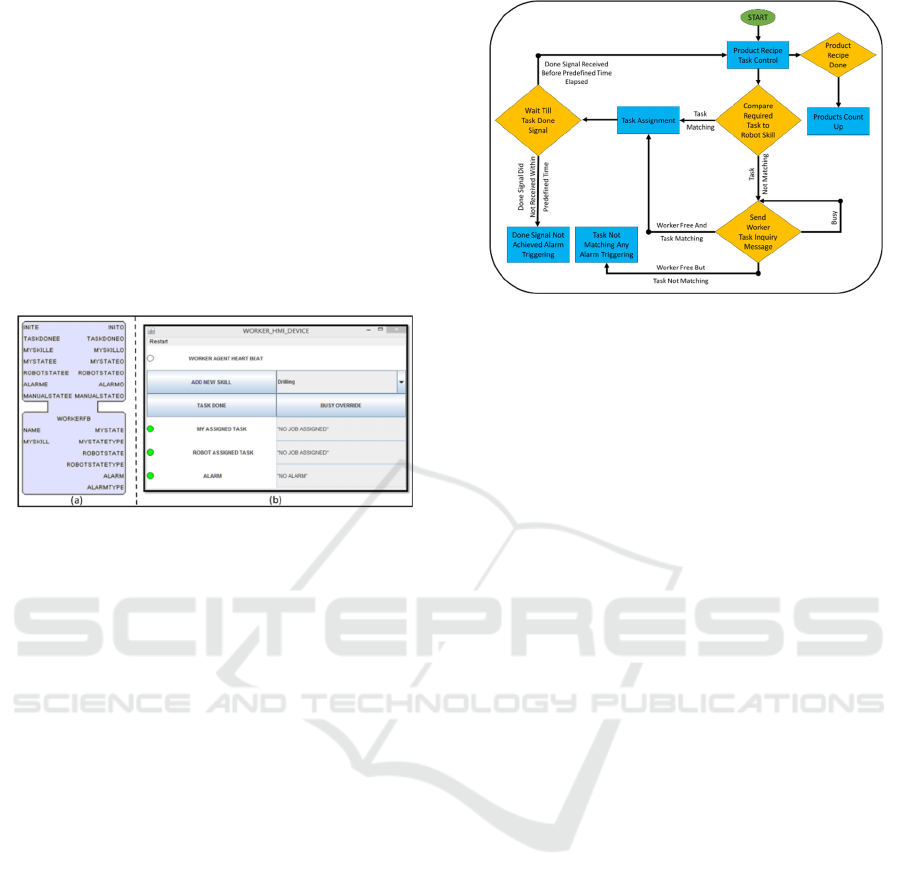

Figure 6: (a) Worker FB – (b) Worker I/O Interface.

Worker FB design and interface are shown in

Figure 6. The difference between the worker and the

robot FB, is that the robot FB defines the product and

the robot I/O parameters together. However the

worker FB concerns only the worker I/Os. One extra

event has been added to the worker FB which is

MANUALSTATEE, to be triggered manually by the

worker if he is busy. Another difference is that the

worker FB has been designed and deployed over

Windows OS, while the robot FB has developed and

deployed over Linux OS, to test/verify the

interoperability of the solution on different OSs.

5.2 Holons Communication Algorithm

A communication algorithm is needed in order to

design the holon communication component. Based

on this communication algorithm, the agent

behaviours can be programmed. Figure 7 illustrates

an algorithm implemented with JADE to manage the

cooperation between an industrial robot and a human

worker, to produce variable recipe product. The

algorithm starts automatically after defining the

product recipe and both of the robot and the worker

skills. In the very beginning it compares the product

first task to the robot skills. If the task matches one of

the robot skills, it assigns this task to the robot,

changes the robot status to be busy, and informs the

worker that this task has been assigned to the robot.

Figure 7: Interaction Algorithm between a Worker and an

Industrial Robot.

In case the robot does not have the required skills

to perform a product recipe task, the algorithm will

send to the worker an inquiry holding the name of the

required skill. If the worker is busy, the message will

be sent periodically until he becomes available. If the

worker is available and the proposed task matches

one of his skills, the task will be assigned to him and

his status will turn to be busy. All the information

about the task and worker status will be sent to the

robot FB. The algorithm will wait for a done signal,

to proceed in the recipe order. If the worker is free but

he does not have the inquired skill, an alarm will be

raised to announce the skill shortage.

A more sophisticated cooperation algorithm has

been intentionally avoided, otherwise it will be so

hard for the reader to see the cooperation test results.

Particularly, we offer a very generic solution, which

can implement different algorithm variations.

6 SOLUTION TESTING

To verify the applicability of the proposed HCA, a

simple cooperation scenario will be emulated, to

show the ability of the solution to achieve the HCA

definition. In this testing scenario we will order a

product using the robot FBDK interface. The product

recipe composes of three tasks, which are in order

Drilling, Milling and Assembly. We will add Drilling

as a robot skill and Milling as a worker skill.

Intentionally we will not add Assembly skill either for

the robot or the worker, to test the system behaviour

in case of a skill shortage. Figure 8 and 9 show the

first task of the product recipe (i.e. Drilling)

assignment process.

A Novel Implementation Approach for Resource Holons in Reconfigurable Product Manufacturing Cell

135

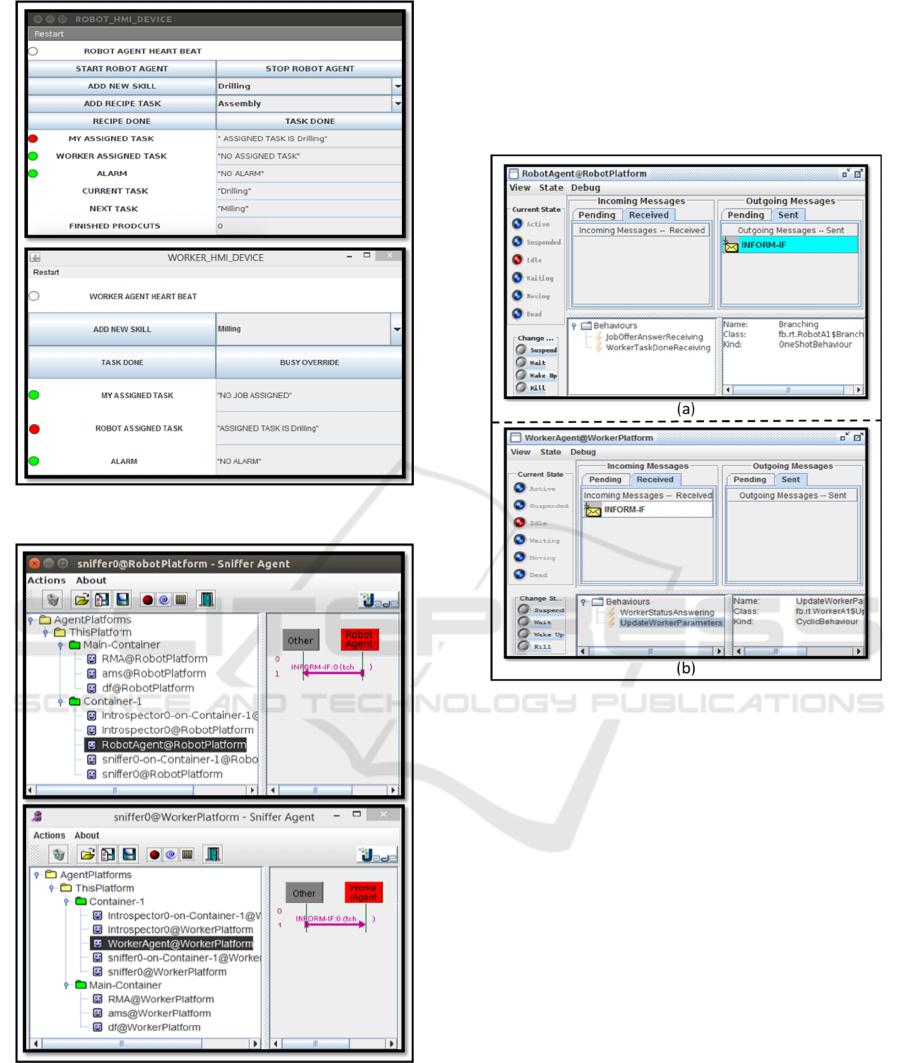

Figure 8: FBDK Interface for Drilling Task Assignment.

Figure 9: JADE Interaction for Drilling Task Assignment.

As been mentioned previously in the cooperative

algorithm, the first step in the cooperation algorithm

is to compare the robot skills with the product recipe

current task. When a Drilling task matches the robot

skills as shown in Figure 8, the MAS assigns the

Drilling task to the robot. Also it changes its status to

be busy, and sends an INFORM-IF message to the

worker, to inform about a task assignment to the

robot. Figure 9 shows the sending/receiving process

between the robot and the worker agents, over two

different OSs. Messages sending/receiving process is

accomplished as part of the agent behaviours.

Figure 10: (a) ACL Message Sent by the Robot Agent – (b)

ACL Message Received by the Worker Agent.

Figure 10-a shows three robot agent behaviours:

Branching, JobOfferAnswerReceiving and

WorkerTaskDoneReceiving. Branching behaviour is

a one shot behaviour which means it is executed once

when called (Ricci, 2011). Branching behaviour

checks if the task matches the robot. If so, it sends an

INFORM-IF message, which is received by the

worker agent using UpdateWorkerParameters cyclic

behaviour showing in Figure 10-b.

A cyclic behaviour is running all the time

periodically. If the task did not match the robot skill,

branching algorithm will offer the task to the worker

agent using QUERY-IF message. The worker agent

will receive QUERY-IF message then answers it with

INFORM-REF using WorkerStatusAnswering cyclic

behaviour. INFORM-REF will be received using

JobOfferAnswerReceiving behaviour on the robot

side. An INFORM message will be sent from the

worker agent to the robot agent, to inform that a task

has been done, WorkerTaskDoneReceiving cyclic

behaviour is responsible for receiving this message.

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

136

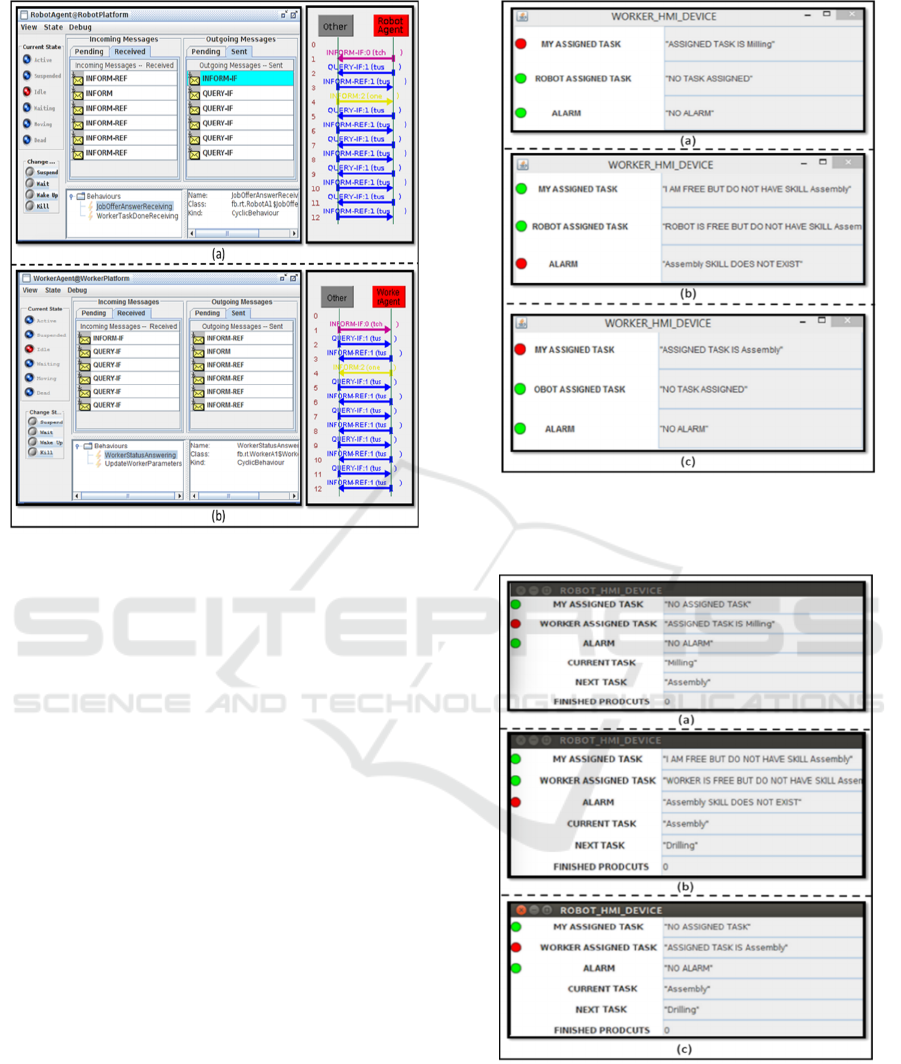

Figure 11: (a) Robot One Product Cycle JADE Interaction

– (b) Worker One Product Cycle JADE Interaction.

Figure 11-a&b show an overall worker-robot

FIPA interaction, to produce one product described in

the testing scenario. The rest of the task assignments

mentioned in the test scenario are shown in Figure 12

and 13. The same previously described mechanism of

message exchanging via agent behaviours is applied.

In Figure 12-a and 13-a; the Milling task matches the

worker skills and did not match the robot skills.

Therefore it is assigned to the worker. In Figure 12-b

and 13-b an Assembly task neither matches the robot

nor the worker skills. Thus an alarm has been

triggered in both the worker and robot FBDK

interfaces. Furthermore the MAS keeps looking for

an Assembly skill, till it is available in the production

cell. Figure 12-c and 13-c show the reaction of the

system when adding an Assembly to the worker

skills, the MAS clears the alarm and assigns the

Assembly task to the worker.

Figure 12: (a) Worker Milling Task Assignment Interface –

(b) Worker Assembly Task Alarm Interface – (c) Worker

Assembly Task Assignment Interface.

Figure 13: (a) Robot Milling Task Assignment Interface –

(b) Robot Assembly Task Alarm Interface – (c) Robot

Assembly Task Assignment Interface.

A Novel Implementation Approach for Resource Holons in Reconfigurable Product Manufacturing Cell

137

7 SUMMARY, CONCLUSION

AND FUTURE WORK

The goal of this research is to design an RMC control

system, which can adapt to a variable product recipe.

A new product can be introduced at any time to the

RMC, thus the work resources can rearrange their

cooperation to produce the product without stopping

the production process. An industrial robot in

cooperation with a human worker has been proposed

as an RMC case study. An HCA with two resource

holons has been chosen as a proper control solution

to be applied to the case study.

The research solution has combined two well-

known control architectures that have been applied

individually in previous researches as a design model

for the HCA. The two architectures are IEC 61499 FB

specifications and autonomous reactive agent

architecture. IEC 61499 FB has been used to build a

customized physical component for the holon. While

reactive agent architecture has been used as an

intelligent communication component. Merging the

two architectures together in one solution, maximized

their pros and minimized their cons. Therefore the

solution successfully achieved the characteristics,

which are highly required to deal with the mentioned

RMC problem.

Modularity, reusability, customizability,

extensibility, and diagnosability are the first set of

characteristics obtained by this solution. Modularity

has been achieved as the robot and the worker holons

have two independent designs, therefore they can

physically and logically separated. Furthermore the

same holons can be reused and extended as an

inherited property from IEC 61499 FB and agent

architectures. Also the holons can be easily

customized to fit more workers or robots into the

interaction, which guarantee the extensibility of the

solution. Diagnosability has been used during the

testing phase, as a part of emulating the control

system. Different combinations of the product recipe

and the worker/robot skills inputs can be tested.

Simultaneously the communication between the

agents can be tracked within every different test.

Platform-independency is one of the most

important results obtained by this solution. As it is

shown in the testing phase, an MAS is formed

between a robot holon running on Linux OS and a

worker holon running on Windows OS. Thus

interoperability, scalability, distributability, and

integrity are no longer a problem during the final

deployment phase. Finally the solution successfully

achieved the adaptability concept during the testing

scenario emulation. The MAS was able to adapt the

existing work resources skills to a variable product

recipe definition, and deal with some unexpected

ambiguous situations such as skill shortage in the

workcell.

Even the tested case study and its applied

algorithm were simple, the required solution

characteristics were completely fulfilled. Therefore

the solution can be a good base model to follow, in

solving more sophisticated interaction scenarios, with

more cooperative work resources. In the future work

more complicated testing case scenarios and

algorithms can be tested and verified.

REFERENCES

Anumba, C. J., Ugwu, O., Ren, Z., 2005, Agents and Multi-

agent Systems In Construction, Taylor & Francis

Group.

Bellifemine, F., Caire, G., Greenwood, D., 2007,

Developing multi-agent systems with JADE. Vol 7 ed.

John Wiley & Sons.

Black, G., Vyatkin, V., 2008, ‘Intelligent Component-

Based Automation of Baggage Handling Systems with

IEC 61499’, IEEE Transactions on Automation Science

and Engineering, Vol 7, pp. 699–709.

Bussmann, S., 1998, An agent-oriented architecture for

holonic manufacturing control, Proceedings of the 1st

international workshop on Intelligent Manufacturing

Systems, pp. 1-12.

Caire, I., 2009, JADE Tutorial: JADE Programming for

Beginners, TILAB & West Sussex.

Chirn, Jin-Lung, C.McFarlane, Duncan, 2000, A holonic

component-based approach to reconfigurable

manufacturing control architecture, 11th International

Workshop on Database and Expert Systems

Applications (DEXA’00), pp. 219-223.

Fischer, J., Boucher, T.O., 2010, Workbook for Designing

Distributed Control Applications using Rockwell

Automation’s HOLOBLOC Prototyping Software,

Working Paper No. 05-017.

Franklin, S., Kelemen, A., McCauley, Lee, 1998, IDA: a

cognitive agent architecture, IEEE Systems, Man, and

Cybernetics, Vol 3, pp. 2646-2651.

Giret, A., Botti, V., 2008. Holonic Manufacturing Systems,

ANEMONA - A Multi-agent Methodology for Holonic

Manufacturing Systems, Springer Series in Advanced

Manufacturing, pp. 7-20.

Italia, T., n.d., jade. [Online] Available at:

http://jade.tilab.com/.

Jennings, N.R., Wooldridge, M.J., 1998, Applications of

intelligent agents, Agent Technology: Foundations,

Applications, and Markets, Springer, pp. 3–28.

Koestler, A., 1967, The Ghost in the Machine, Hutchinson.

Koren, Y., 2005, Reconfigurable Manufacturing and

Beyond, Keynote Paper - CIRP 3rd International

conference on Reconfigurable Manufacturing.

Koren, Y., Heisel, U., Jovane, F., Moriwaki, T., Pritschow,

G., Ulsoy, G., Brussel H., 1999, Reconfigurable

Manufacturing Systems, CIRP Annals, Vol 48, pp. 527-

540.

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

138

Kruger, K., Basson, A., 2015, Implementation of an Erlang-

Based Resource Holon for a Holonic Manufacturing

Cell, Studies in Computational Intelligence, Vol 594,

pp. 49-58.

Kruger, K., Basson, A., 2013, Multi-Agent Systems vs IEC

61499 for Holonic Resource Control in Reconfigurable

Systems, Forty Sixth CIRP Conference on

Manufacturing Systems, Vol 7, pp. 503–508.

Lasota A., Rossano F., Shah A., 2014, Safe Close-

Proximity Human-Robot Interaction with Standard

Industrial Robots, IEEE International Conference on

Automation Science and Engineering (CASE).

Leitao, P., Restivo, F., 2006, ADACOR: A holonic

architecture for agile and adaptive manufacturing

control, Computers in Industry, Vol 57, pp. 121-130.

Nilsson, K., Johansson, R., Robertsson, A., Bischoff, R.,

Brogårdh T., Hägele M., 2005, Productive robots and

the SMErobot project, Third Swedish Workshop on

Autonomous Robotics.

Pang, C., Patil, S., Yang, Chen-Wei, Vyatkin, V., Shalyto,

A., 2014, a Portability Study of IEC 61499: Semantics

and Tools, 12th IEEE International Conference on

Industrial Informatics (INDIN), pp. 440-445.

Peters, B.A., Smith, J.S., Curry, J., LaJimodiere C., 1996,

Advanced Tutorial - Simulation Based Scheduling and

Control, Proceedings of the 1996 Winter Simulation

Conference, pp. 194-198.

Poslad, S., 2007, Specifying Protocols for Multi-Agent

Systems Interaction, ACM Transactions on

Autonomous and Adaptive Systems, Vol 2.

Radu, F., Frank, F., 2006, Development and applications of

holonic manufacturing systems: a survey, Journal of

Intelligent Manufacturing, Vol 17, pp. 111-113.

Ricci, A., Santi, A., 2011, Agent-oriented computing:

Agents as a paradigm for computer programming and

software development, The 3

rd

Conference on

Manufacturing Systems, Vol 7, pp. 503–508.

Shen, W., Hao Q., Yoon, H. J., Norrie, D. H., 2006,

Applications of agent - based systems in intelligent

manufacturing: An updated review, Advanced

Engineering Informatics, Vol 20, pp. 415-431.

Sturgeon, J., 2002, Modular production networks: a new

American model of industrial organization, Industrial

and Corporate Change, pp. 451- 496.

Su, J., 2007, Component-based intelligent control

architecture for reconfigurable manufacturing systems,

Ph.D. Thesis, Virginia Polytechnic Institute and State

University.

Teahan, W., 2010, Artificial Intelligence – Agent

Behaviour, BookBoon.

Van Brussel, H., Wyns, J., Valckenaers, P., Bongaerts, L.,

Petters, P., 2003. Reference Architecture for Holonic

Manufacturing Systems: PROSA. Computers in

Industry, Volume 37, p. 95–108.

Vlad, V., Graur, A., Ciufudean, C., Buzduga, C., 2010,

Towards Using the Reconfiguration Capability of IEC

61499 Specifications for Modeling and Implementing

Dynamic Holonic Interactions, 12th WSEAS

International Conference on Automatic Control,

Modelling & Simulation, pp. 213-218.

Wang, F., Hou, Z.G., Xu, D., Tan, M., 2005, An Agent-

Based Holonic Architecture for Reconfigurable

Manufacturing Systems, Advances in Natural

Computation, pp. 622-627.

Wooldridge, M.J., Nicholas, N.R., 1995, Intelligent agents:

Theory and practice, The knowledge engineering, pp.

115-152.

A Novel Implementation Approach for Resource Holons in Reconfigurable Product Manufacturing Cell

139