Development of a Simulink Dynamic Matrix Control (DMC) Block for

Use with an RCP System and Its Application to Motor Control

Young Sam Lee, Jinsuk Choi, Sugkil Seo and Yeong Sang Park

Department of Electrical Engineering, Inha University, Incheon, Korea

Keywords:

Dynamic Matrix Control, Rapid Control Prototyping, DC Motor Control, Realtime Control.

Abstract:

In this paper, we present the implementation method of a Simulink block for dynamic matrix control (DMC)

that can be used in a rapid control prototyping (RCP) environment and consider the speed control of a DC mo-

tor using the developed DMC block. Firstly, we introduce a lab-built RCP system briefly. Secondly, we present

a method to implement the DMC block using C-language, which enables DMC algorithm to be represented

in a library block that can be used in Simulink environment. Finally, we use the developed DMC block for

the speed control of a DC motor, through which we show that the DMC-based control system can be easily

implemented and it can be applied to real-time control of systems with relatively fast sample rates.

1 INTRODUCTION

Predictive control is the optimization-based control

strategy, where we try to find the optimal future con-

trol trajectory that minimizes the cost function on the

future response predicted using the model informa-

tion of the controlled system. Predictive control is a

computation-intensive control method because it has

to solve the constrained optimization problem at each

sample time.

In predictive control, we need to construct a pre-

dictor to predict the future response of a controlled

system. A certain predictive control utilizes the state

space model for the predictor (Lee et al., 1994) while

the other predictive controls are based on the trans-

fer function model (Clarke et al., 1987a; Clarke et al.,

1987b) or on a step response model (Garcia and Mor-

shedi, 1986). Dynamic matrix control, one of many

predictive control methods, needs just a step response

to construct a predictor while other predictive con-

trol requires a state space model or a transfer function

model, which is not available in real situations. In that

respect, DMC has good practical value.

Merits of the predictive control include the sys-

tematic consideration of the input/output constraint

of the system and easy extension of its principle to

multivariable systems. The ability of handling the in-

put/output constraint comes from the fact that the

computation of the control value is formulated into

an optimization problem subject to constraints. In

most cases, the optimization problems reduce to the

quadratic programming (QP) problem. The solution

to the quadratic programming is obtained after some

complicated procedures and hence the predictive con-

trol is computation-intensive methodology. Due to

this fact, predictive controls have been majorly used

in process control area, where systems are fairly slow

in response. Some mathematical software, such as

Matlab, provides a command to solve the quadratic

programming.

Despite the merits mentioned above, it is not easy

for one to apply the predictive control to real control

systems. Firstly, one needs the C-code solution to the

QP problem for the implementation of the predictive

control. qpOASES, which is an open-source QP prob-

lem solver, can be good candidate solution to the QP

problem (Ferreau et al., 2014). Even with the C-code

solution, still the implementation of predictive control

in C-code is not an easy task for beginning engineers.

Recently, implementation of the control system is

done through RCP systems instead of conventional

manual coding. The most representative RCP system

includes the one based on Matlab/Simulink. One can

construct a controller model using the function blocks

supported in Simulink and then translate the con-

troller model into C-codes through the automatic code

generation tool. The generated codes can be com-

piled and downloaded onto a micro-controller board

for realtime execution. A certain RCP system does

not use the code generation approach. In that system,

the Simulink controller model perform as a real-time

controller (Lee et al., 2012). One can focus on the de-

Lee, Y., Choi, J., Seo, S. and Park, Y.

Development of a Simulink Dynamic Matrix Control (DMC) Block for Use with an RCP System and Its Application to Motor Control.

DOI: 10.5220/0005958004130420

In Proceedings of the 13th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2016) - Volume 1, pages 413-420

ISBN: 978-989-758-198-4

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

413

velopment of the control algorithm using the block

diagram editing and doesn’t have to be worried about

the input/output peripheral handling based on manual

coding.

In this paper, we propose a method to construct a

function block for the dynamic matrix control for use

with RCP system based on Simulink. The presented

block is implemented in C-code and thus has good

computation property. Due to this fact, the resultant

control can be applied to systems with relatively fast

sample rate. The DMC block can also translated into

C-code through the automatic code generation pro-

cess. In this paper, we will use a lab-built RCP en-

vironment for the application of the proposed DMC

block.

The paper is structured as follows: In Section 2,

we give brief introduction to a lab-built RCP system.

In Section 3, we present the method to construct a

DMC block. In Section 4, we summarize the proce-

dures about how to construct a speed control system

for a DC motor using the DMC block. Finally in Sec-

tion 5, we make conclusions on the presented results.

2 INTRODUCTION OF THE DAQ

RCP

Rapid control prototyping (RCP) system is a kind of

development environment that is used for the design,

development, and verification of the controller pro-

totype in an efficient way. Generally RCP systems

consist of a block diagram based modeling program

such as Simulink, library blocks to handle the hard-

ware input/output peripherals, automatic C-code gen-

erator, realtime target computer, and a host computer

communicating with the target computer. The design

and the simulation of the controller are done under

Simulink. If the simulation result is satisfactory, the

controller is constructed by using the input/output

peripheral library blocks. After the code generation

of the controller model, the compiled executable is

downloaded to a realtime target computer and the re-

altime control experiment is performed. While the ex-

periment is being performed, one can monitor signals

using a host computer connected to a target computer.

With the help of the input/output peripheral block li-

brary and code generation tool supported in the RCP

system, the controller designers have only to focus on

the algorithm itself without worrying about the error

prone manual coding.

Several RCP systems are available commer-

cially in the market. Matlab/Simulink is the most

well known and widely used among those sys-

tems. Realtime Workshop (RTW), the add-on prod-

uct of Simulink, generates C-code for the block

diagram-based model constructed by Simulink (Inc.,

2005b). Embedded coder, another add-on product of

Simulink, generates C-code specific to a certain em-

bedded processor and thus reduce the time for the de-

velopment (Inc., 2005a). Matlab/Simulink and RTW

are open architecture and thus several lab-developed

RCP systems for custom-developed hardware have

been proposed in academia (Rebeschieß, ; Hong et al.,

2000; Lee et al., 2004; Hercog and Jezernik, 2005;

Bucher and Balemi, 2006; Lee et al., 2012). Further-

more, several researches related with the application

of RCP system are published (Lin et al., 2006; Ken-

nel, 2006).

In this paper, we use the RCP system proposed in

(Lee et al., 2012). The RCP system proposed in (Lee

et al., 2012) utilizes a DAQ board with high speed

USB communication interface and Matlab/Simulink.

Because it uses a DAQ board with a microcontroller

as a basic component, we will call the system as

the DAQ RCP throughout the paper. The DAQ RCP

system consists of two subsystems as in Figure 1.

The first subsystem is a PC system on which Mat-

lab/Simulink is running and the second subsystem is

a DAQ board with high speed USB interface. The PC

and the DAQ board communicates the data (control

data and sensor data) with each other throughtheUSB

communication. Unlike the conventional RCP system

where the control algorithm is automatically gener-

ated in C-code from the Simulink controller model,

the DAQ RCP system has a feature that the Simulink

controller model acts as a realtime controller without

code generation. Measurement of the sensor data and

the application of the control data to output peripher-

als are taken care of by the DAQ unit with a microcon-

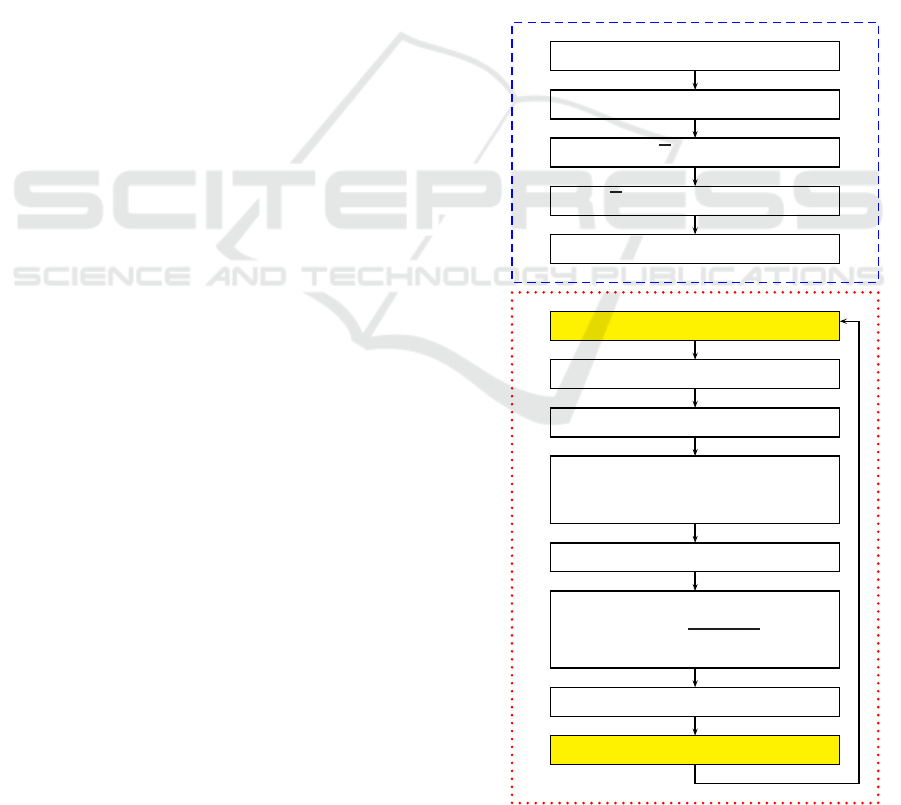

troller. Figure 2 Figure 2 is the flowchart that shows

how the control is performed. Each stage in the flow

chart can be summarized as follows:

S1: The DAQ unit measures all the required sensor

data and sends them to the PC through USB com-

munication.

S2: Simulink running on the PC receives the data

sent from the DAQ unit.

S3: Simulink performs the control computation using

the received sensor data.

S4: Simulink sends the computed control data to the

DAQ unit.

S5: The DAQ unit applies the received control data

from the PC to corresponding output peripherals

(DAC, PWM, etc).

It is noted that all the tasks performed in the DAQ unit

are handled by the microcontroller. As mentioned in

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

414

Driver

DriverDriver

Driver

Circuit

CircuitCircuit

Circuit

PC (Matlab/Simulink)

PC (Matlab/Simulink)PC (Matlab/Simulink)

PC (Matlab/Simulink)

Control

ControlControl

Control

algori thm

algori thmalgori thm

algori thm

Sensor

SensorSensor

Sensor

Interf ace

Interf aceInterf ace

Interf ace

Circuit

CircuitCircuit

Circuit

Real

RealReal

Real

P

PP

Pl

ll

la

aa

an

nn

nt

tt

t

Custom-built DAQ Unit

Custom-built DAQ UnitCustom-built DAQ Unit

Custom-built DAQ Unit

Figure 1: The conceptual diagram on a lab-built DAQ RCP system.

(Lee et al., 2012), the DAQ RCP system can handle

the control system with sample rates of up to 2 KHz.

Therefore, a good portion of control experiments per-

formed in undergraduate or graduate courses can be

supported by the DAQ RCP system. It provides use-

ful input/output function blocks that can handle in-

put/output peripherals in a graphical manner. The rep-

resentative input/output function blocks include an

encoder counter block, a digital input block, an ADC

block, a PWM block, a digital output block, and a

DAC block.

Initialization Initialization

Reception of the

sensor data from the

DAQ board

Control computation

Trasmission of the

control data to

the DAQ board

Sensor data

measurement

Transmission of the

data to the PC

Reception of the control

data from the PC

Application of the

received data to

peripherals

L

L

L

L

o

o

o

o

o

o

o

o

p

p

p

p

PC (Simulink) DAQ Board

USB

USB

USB

L

L

L

L

o

o

o

o

o

o

o

o

p

p

p

p

S1

S2

S3

S4

S5

Figure 2: The flow chart of the DAQ RCP system proposed

in (Lee et al., 2012).

3 IMPLEMENTATION OF A DMC

BLOCK

In this section, we present how to construct the DMC

function block using a C-code S-function. The S-

function provides a powerful mechanism for extend-

ing the capabilities of the Simulink environment. The

S-function is a computer language description of a

Simulink block written in Matlab, C, C++, or For-

tran. One can write an S-Function to describe a user-

defined function block. We use a lab-built DAQ RCP

system in this paper, where we don’t have to generate

the C-code for the model. However, to speed up the

computation, we develop the DMC block in C-code

S-function.

Figure 3 shows the control system diagram that

adopts the DMC as a control method. The main pur-

poses of this paper are as follows: to make the DMC

be used in Simulink environment by developing the

DMC function block in a C-code S-function; to make

the DMC be used in the RCP system using the devel-

oped DMC block; to give the environment in which

one can implement the realtime dynamic matrix con-

trol of real systems easily.

If we construct the speed control system for a DC

motor using the DMC block in the DAQ RCP system,

the controller model will look like Figure 4. To mea-

sure the speed of a motor and to generate the PWM

signal to a motor driver, we will use the encoder block

and the PWM block provided by the DAQ RCP sys-

tem.

DMC System

r

y

Figure 3: The block diagram of the DMC-based control sys-

tem.

DMC EncoderPWM

Ref

Mux

Figure 4: The block diagram of the DC motor control sys-

tem implemented in Simulink using the DAQ RCP.

The implementation of the DMC block includes

three stages. Firstly, we have to implement the solu-

tion to the QP problem. Secondly, we have to imple-

ment the DMC algorithm using the obtained QP so-

lution. Finally we define the DMC block in a C-code

S-Function.

3.1 Implementation of the QP solution

The most essential algorithm to implement the predic-

tive control may be the solution algorithm to the QP

problem. The dynamic matrix control is one of pre-

dictive control methods and thus we need to have a

C-code solution to the QP problem to implement the

Development of a Simulink Dynamic Matrix Control (DMC) Block for Use with an RCP System and Its Application to Motor Control

415

DMC block. In this paper, we adopt the method pre-

sented in (Lee et al., 2014) to develop the DMC block.

The general QP problem is stated as follows:

min

x

1

2

x

T

Px+ q

T

x subject to Ax ≤b. (1)

With P > 0, the problem reduces to a convex opti-

mization and the unique and global solution is always

guaranteed. The QP problem to be solved in predic-

tive control satisfies P > 0. So we use the solution

to the QP problem for the specific case P > 0. As

explained in (Lee et al., 2014), the QP problem can

be equivalently changed into the NNLS(Nonnegative

least-squares) problem after a series of equivalent

transformations. Therefore one can obtain the solu-

tion to the QP problem buy solving the following

NNLS problem:

NNLS: min

d

kQd −rk subject to d ≥0, (2)

where

Q =

¯

A

T

¯

b

T

, r =

0

.

.

.

0

1

and

¯

A = −AVS

−1

,

¯

b = −A¯q −b, ¯q = P

−1

q. Matri-

ces V and S are obtained by performing the singular

value decomposition (SVD) of

√

P and they satisfy

√

P = USV

T

. Letting the solution to the NNLS prob-

lem given in (2) be d

∗

, the solution to the original QP

problem given in (1), x

∗

, can be given as follows:

x

∗

= VS

−1

¯

A

T

d

∗

(1−

¯

b

T

d

∗

)

− ¯q

The following computations should be done to obtain

the solution to the QP problem given the matrices P,

q, A, and b:

(a) matrix addition, subtraction, and multiplication

(b) solving the NNLS problem

(c) singular value decomposition of

√

P

(d) matrix inversion to obtain P

−1

Computation for (a) can be easily programmed in C

code. Solving the NNLS problem in (b) can also be

implemented in C code using the algorithm presented

in (Lawson and Hanson, 1974). For the computation

of (c) and (d), we need to compute the square root

of a matrix, singular value decomposition, and matrix

inversion, which are somewhat complicated process.

However, the matrix P is a constant matrix as long as

the system model used to design the predictive control

does not change. Therefore, we don’t have to imple-

ment the C-code to compute (c) and (d). Instead, we

use Matlab to compute (c) and (d) and then use the

obtained results by generating array data for them in

a separate header file. One can use the Matlab com-

mand ‘fprintf’ for that purpose.

3.2 Implementation of the DMC

The DMC, one of predictive controls, utilizes the step

response of a system to construct a predictor. The

DMC solves the following optimization problem sub-

ject to constraints at every sample time to compute the

control value:

Minimize J =

N

p

∑

j=1

kw

k+ j

− ˆy

k+ j

k

2

+

N

c

−1

∑

j=0

k∆u

k+ j

k

2

Λ

(3)

subject to u

min

≤ u

k+ j

≤ u

max

,

∆u

min

≤ ∆u

k+ j

≤ ∆u

max

,

j = 0,1,··· ,N

c

−1. (4)

The subscripts used in variables denote the time step

and k denotes the current time step. Letting u be

the control value, u

k+ j

denotes the control value at

the moment j step away from the current time. w

is the reference input, ˆy is the predicted output, ∆u

is the control increment, N

p

is the prediction hori-

zon, and N

c

is the control horizon. Generally it holds

that N

p

≥ N

c

. Λ, a diagonal matrix, is the weight-

ing on the control increment. Hence the square of

the weighted norm can be represented as k∆u

k+ j

k

2

Λ

=

∆u

T

k+ j

Λ∆u

k+ j

. In the DMC, the control increment is

obtained up to the step k + N

c

−1 at every sample

time. However, only ∆u

k

is used to obtain the control

value, which is given as

u

k

= u

k−1

+ ∆u

k

.

In the DMC, the predicted output from the current

step to the moment which is N

p

steps away is given

by

ˆ

Y

k

= G∆U

k

+ f

k

, (5)

where

ˆ

Y

k

= [ ˆy

T

k+1

ˆy

T

k+2

··· ˆy

T

k+N

p

]

T

∆U

k

= [∆u

T

k

∆u

T

k+1

··· ∆u

T

k+N

c

−1

]

T

and G is a prediction matrix consisting of step re-

sponse data. f

k

is the free response, which can be

viewed as the contribution of the past data to the fu-

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

416

ture output, is given by

G =

g

1

0 ··· 0

g

2

g

1

··· 0

.

.

.

.

.

.

.

.

.

.

.

.

g

N

c

g

N

c

−1

··· g

1

.

.

.

.

.

.

.

.

.

.

.

.

g

N

p

g

N

p

−1

··· g

N

p

−N

c

+1

, (6)

f

k

=

¯y

k

¯y

k

.

.

.

¯y

k

+ M

∆u

k−1

∆u

k−2

.

.

.

∆u

k−(N−1)

+

h

2h

.

.

.

N

p

h

u

k−N

, (7)

where

M =

g

2

−g

1

g

3

−g

2

··· g

N

−g

N−1

g

3

−g

1

g

4

−g

2

··· g

N+1

−g

N−1

.

.

.

.

.

.

.

.

.

.

.

.

g

N

p

+1

−g

1

g

N

p

+2

−g

2

··· g

N

p

+N−1

−g

N−1

and ¯y

k

is the measurement of the output, g

i

is the step

response value at time step k = i obtained by apply-

ing a step input to the system at time k = 0. In case of

multivariable system with n

u

inputs and n

y

outputs, g

i

is a n

y

×n

u

matrix (Lundstrom et al., 1995). N is the

number of steps taken to reach the steady state when

the system is stable or it includes an integrating pro-

cess. In case of systems with integrating process, the

output at the steady state will show a constant slope

with time. At steady state, h = g

i+1

−g

i

. It holds that

h = 0 for stable systems and and h 6= 0 for systems

with integrating process. G does not have any sub-

script because it is constant. Let’s define the future

reference trajectory as follows:

W

k

= [w

T

k+1

w

T

k+2

··· w

T

k+N

p

]

T

.

Then, as explained in (Lee et al., 2014), obtaining

DMC control value reduces to a QP problem with ∆U

k

being an optimization variable. Here, the matrices P,

q, A, and b are given as follows:

P = G

T

G+ Ξ, q = −(W

k

− f

k

)

T

G,

A =

I

D

−I

D

I

L

−I

L

,b =

I

V

u

max

−I

V

u

min

I

V

(u

max

−u

k−1

)

−I

V

(u

min

−u

k−1

)

(8)

where

Ξ = diag{Λ,Λ,··· ,Λ}, I

D

=

I

m

0 ··· 0

0 I

m

··· 0

.

.

.

.

.

.

.

.

.

.

.

.

0 0 ··· I

m

,

I

L

=

I

m

0 ··· 0

I

m

I

m

··· 0

.

.

.

.

.

.

.

.

.

.

.

.

I

m

I

m

··· I

m

, I

V

=

I

m

I

m

.

.

.

I

m

and these matrices have appropriate dimensions de-

pending on the prediction horizon and the control

horizon. As shown in (8), among the matrices P, q,

A, b pertaining to the QP problem to obtain the DMC

control value, P and A remain unchanged while q and

b change at every step. Therefore, we can obtain the

data related with P and A offline using Matlab and

then generate a C-code header file containing the data.

Compute G from step response data

P = G

T

G + Ξ

√

P, P

−1

계산

SVD(

√

P = USV

T

)→ Compute S and V

¯

A = −AVS

−1

offlineonline

Measure the output values

Compute W

k

, f

k

, and b

k

q

k

= −(W

k

− f

k

)

T

G, ¯q

k

= P

−1

q

k

¯

b

k

= −A¯q

k

− b

k

, Q

k

=

¯

A

T

¯

b

T

k

d

∗

k

= NNLS(Q

k

)

∆U

∗

k

= VS

−1

¯

A

T

d

∗

k

(1 −

¯

b

T

k

d

∗

k

)

− ¯q

k

u

k

= u

k−1

+ ∆u

∗

k

Apply u

k

to the system

Figure 5: The flow chart of the algorithm.

Development of a Simulink Dynamic Matrix Control (DMC) Block for Use with an RCP System and Its Application to Motor Control

417

Furthermore, the generation of q and b should be done

online. To explicitly denote that q and b vary at each

time, let’s denote them by q

k

and b

k

, respectively. Fig-

ure 5 shows the flowcharts for the offline computation

part and the online computation part. We can imple-

ment the DMC algorithm by translating the algorithm

in the flowchart in C-code.

3.3 Implementation of the DMC Block

We can implement the DMC algorithm presented

above in C-code. However, it is never easy for stu-

dents or engineers who are not familiar with control

theory to implement the DMC algorithm in C-code

by themselves. If we can provide a function block for

DMC that can be used in a Simulink environment, one

has only to copy the DMC block to build a controller

in a graphical manner. In this respect, we implement

the DMC function block that can be used in Simulink.

Matlab allows the users to define a custom function

block through the S-function. In an S-function, one

has to define a block initialization function, a output

function, a termination function, etc to describe the

every aspect of a block. As in the concept diagram

given in Figure 4, the inputs to the DMC block are the

reference input and the measured output and the out-

put of the DMC block is the control value. The rela-

tionship between the inputs and output was described

in the previous subsection.

4 IMPLEMENTATION OF THE

DMC-BASED VELOCITY

CONTROL FOR A DC MOTOR

In this section, we will deal with the realtime dynamic

matrix control of the speed of a DC motor by con-

structing a controller using the DMC block in the lab-

built RCP environment.By doing so, we will illustrate

that the DMC-based control system can be easily con-

structed and can be applied to systems with somewhat

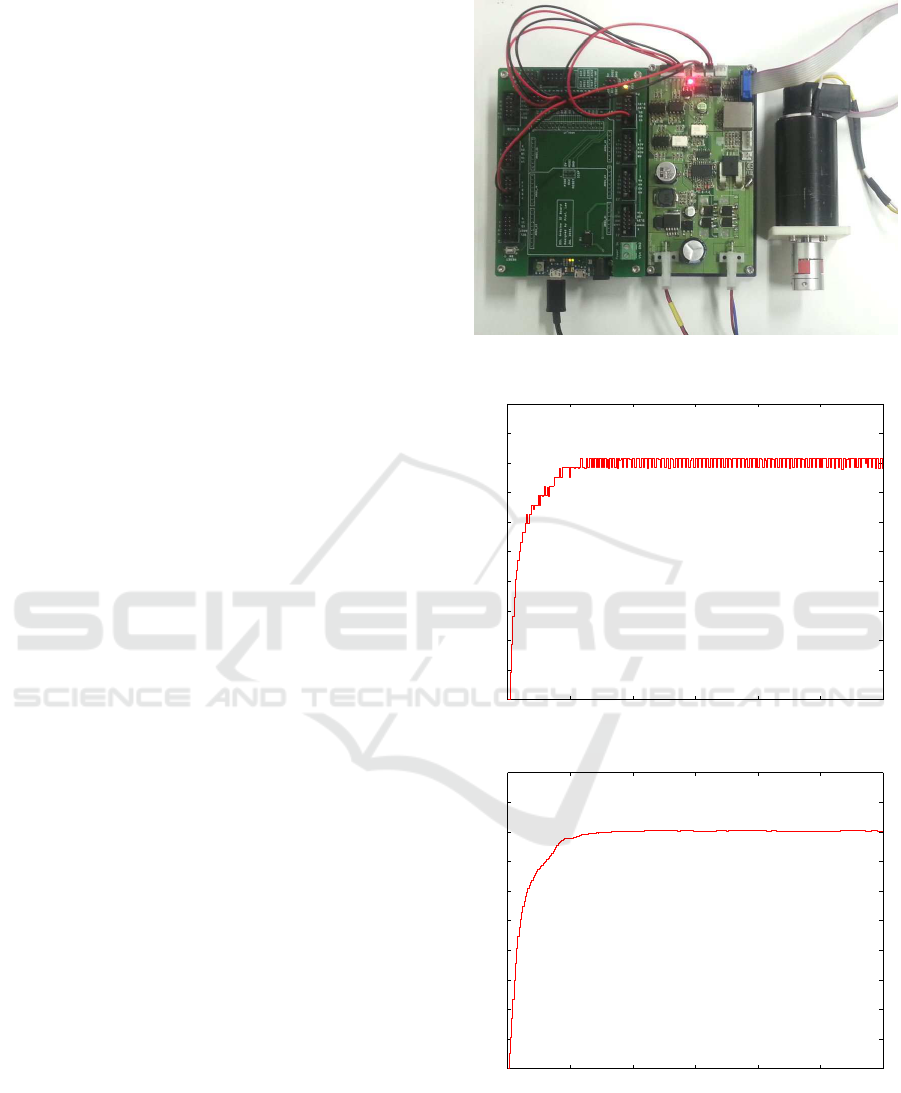

fast sample rates. We use a 150W Maxon DC motor

in the experiment. It has a rotary incremental encoder

with the resolution of 500 PPR to measure the posi-

tion and speed of a rotor. Figure 6 shows the experi-

mental setup, where the left part is a DAQ unit with

an Arduino Due being a main microcontroller and the

center is a DC motor driver using an H bridge, and the

right part is a Maxon DC motor. The DAQ unit is con-

nected to the PC through the USB interface. We use

the unipolar complementary PWM to drive the motor

driver.

Figure 6: The experimental set for the speed control of a DC

motor.

0 0.05 0.1 0.15 0.2 0.25 0.3

0

2

4

6

8

10

12

14

16

18

20

time(sec)

velocity(rad/sec)

Step response

Figure 7: A step response (raw data).

0 0.05 0.1 0.15 0.2 0.25 0.3

0

2

4

6

8

10

12

14

16

18

20

time(sec)

velocity(rad/sec)

Step response

Figure 8: A step response after post processing.

4.1 Acquisition of the Step Response

Data

In order to construct a DMC-based controller, we first

have to obtain the step response data of a system. For

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

418

(Due RCP)

ADC0

1

2

3

Maxon Motor

voltage

theta

dot theta

s+12

12

s+30

30

−K−

−K−

DMC

EclDmc

2

Figure 9: DC motor speed control system implemented using a developed DMC block.

this purpose, we applied a step input of 5 volt to the

motor and measured the resultant speed. We obtained

a unit step response through the normalization (i.e.,

division by 5). The sample rate of the Simulink model

is set to 1 KHz, which is relatively fast for DMC-

based control system.

It is not easy to get the reliable step response data

through just one experiment. Figure 7 shows the step

response data that has not gone through any post pro-

cessing. The rotary encoder has limited resolution and

thus quantization noise is clearly seen in the figure.

We performed 30 experiments and we compute the

average. Furthermore, we post-processed the data us-

ing a noncausal filter, which is supported by the Mat-

lab command ‘filtfilt’, to get smoother step response

data. Figure 8 shows the step response data that has

gone through this post-processing.

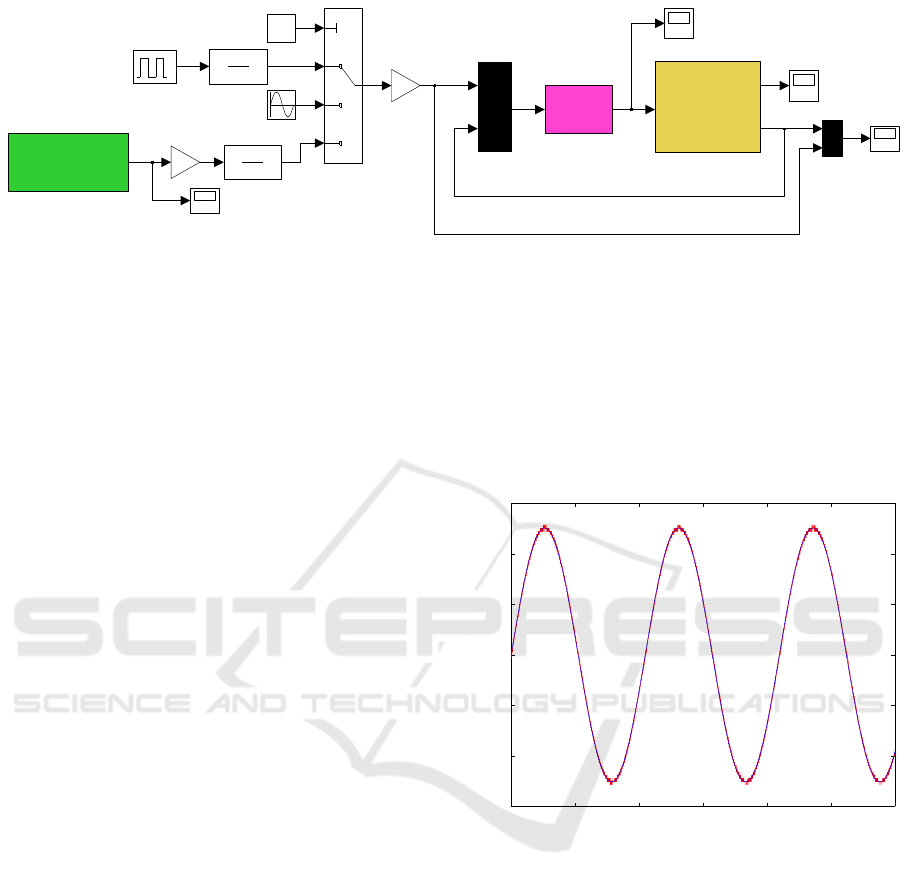

4.2 DMC-based Speed Control

We can decide the horizon N in (7) from the moment

when the step response reaches the steady state. From

Figure 8, it is seen that the step response goes into the

steady state from t = 0.3. Because the sample time

is 1 ms, we chose N = 0.3/0.001 = 300. The con-

trol horizon and the prediction horizon were chosen

to be N

c

= 3, N

p

= 3. We set the DC power supply

so that its output is 10 V. This leads to u

max

= 10

and u

min

= −10. Figure 9 shows the Simulink speed

control model implemented using the proposed DMC

bloc. It is constructed so that we can choose one out

of three possible reference trajectories, which are a

square wave, a sinusoidal wave, and external input

coming from the potentiometer. In Figure 9, a sinu-

soidal wave is chosen as the speed reference input.

Figure 10 shows the experimental result of the

DMC-based speed control with the sinusoidal wave

being a reference input. The blue line is the reference

input, the red line is the actual speed of the motor. It

is clearly seen that the motor speed tracks the speed

reference successfully.

The sample rate of this experiment is 1 KHz. Con-

sidering that the predictive control has been majorly

applied to sluggish systems, this sample rate can be

said fairly fast. This fast sample rate can be made han-

dled because the DMC block presented in this paper

is implemented through a C-cod S-function. Further-

more, we see that the DMC method can be easily im-

plemented by using the presented DMC block in the

RCP environment.

0 1 2 3 4 5 6

−150

−100

−50

0

50

100

150

time(sec)

velocity(rad/sec)

Motor velocity

Figure 10: Speed control response of DMC.

5 CONCLUSIONS

In this paper, we developed a Simulink function block

for the dynamic matrix control and applied the devel-

oped block to the speed control of a DC motor. For

the development of a DMC block, we firstly presented

how to program a solution to the quadratic program-

ming in C language. We also presented how to im-

plement the DMC algorithm using the presented solu-

tion. Furthermore, we implemented a DMC block that

can be used in Simulink environment using a C-code

S-function. By developing a DMC function block for

Simulink and using it in RCP system, the a realtime

dynamic matrix control of a system can be easily im-

plemented. In order to illustrate the usefulness of the

Development of a Simulink Dynamic Matrix Control (DMC) Block for Use with an RCP System and Its Application to Motor Control

419

proposed DMC block, we applied it to the speed con-

trol problem of a DC motor. Through the experiment,

we showed that the proposed DMC block can be ap-

plied to the realtime control system with relatively

fast sample rate.

ACKNOWLEDGEMENTS

This research was supported by the MSIP(Ministry

of Science, ICT and Future Planning), Korea, under

the ITRC(Information Technology Research Center)

support program (IITP-2016-H8601-16-1003) super-

vised by the IITP(Institute for Information & commu-

nications Technology Promotion)

REFERENCES

Bucher, R. and Balemi, S. (2006). Rapid controller proto-

typing with Matlab/Simulink and Linux. Control En-

gineering Practice, 14:185–192.

Clarke, D. W., Mohtadi, C., and Tuffs, P. S. (1987a). Gen-

eralized predictive control-Part I. The basic algorithm.

Automatica, 23(2):137–148.

Clarke, D. W., Mohtadi, C., and Tuffs, P. S. (1987b). Gen-

eralized predictive control-Part II. Extensions and in-

terpretations. Automatica, 23(2):149–160.

Ferreau, H. J., Kirches, C., Potschka, A., Bock, H. G., and

Diehl, M. (2014). qpOASES: a parametric active-set

algorithm for quadratic programming. Math. Prog.

Comp., 6:327–363.

Garcia, C. E. and Morshedi, A. M. (1986). Quadratic

programming solution of dynamic matrix control

(QDMC). Chem. Eng. Commun., 46:73–87.

Hercog, D. and Jezernik, K. (2005). Rapid control proto-

typing using Matlab/Simulink and a DSP-based motor

controller. Int. J. Engng Ed., 21(3):1–9.

Hong, K. H., Gan, W. S., Chong, Y. K., Chew, K. K., Lee,

C. M., and Koh, T. Y. (2000). An integrated environ-

ment for rapid prototyping of DSP algorithms using

and Texas Instruments’ TMS320C30 . Microproces-

sors and Microsystems, 24(7):349–363.

Inc., T. M. (2005a). Real-time workshop embedded code

user’s guide (ecoder

ug.pdf), Version 4.

Inc., T. M. (2005b). Real-time workshop user’s guide

(rtw

ug.pdf), Version 6.

Kennel, R. (2006). Improved direct torque control for in-

duction motor drives with rapid prototyping system.

Energy Conversion and Management, 47:1999–2010.

Lawson, C. L. and Hanson, R. J. (1974). Solving least

squares problems. Prentice-Hall, Englewood Cliffs,

New Jersey.

Lee, J. H., Morari, M., and Garcia, C. E. (1994). State-space

interpretation of model predictive control. Automat-

ica, 30(4):707–717.

Lee, W., Shin, M., and Sunwoo, M. (2004). Target-identical

rapid control prototyping platform for model-based

engine control. Proc. Instn Mech. Engrs Part D, J.

Automobile Engineering, 218:755–765.

Lee, Y. S., Gyeong, G. Y., and Park, J. H. (2014). QP So-

lution for the implementation of the predictive con-

trol on microcontroller systems and its application

method. Journal of Institute of Control, Robotics, and

Systems (in Korean), 20(9):908–913.

Lee, Y. S., Yang, J. H., Kim, S. Y., Kim, W. S., and Kwon,

O. K. (2012). Development of a rapid control protot-

pying system based on Matlab and USB DAQ boards.

Journal of Institute of Control, Robotics, and Systems

(in Korean), 18(10):912–920.

Lin, C. F., Tseng, C. Y., and Tseng, T. W. (2006). A

hardware-in-the-loop dynamics simulator for motor-

cycle rapid controller prototyping. Control Engi-

neerning Practice, 14:1467–1476.

Lundstrom, P., Lee, J. H., Morari, M., and Skogestad, S.

(1995). Limitations of dynamic matrix control. Com-

puters Chemical Engineering, 19(4):409–421.

Rebeschieß, S. MIRCOS-Microcontroller-based real time

control system toolbox for use with Matlab/Simulink.

In Proc. IEEE Int. Symp. Computer Aided Control

System Design, pages 267–272, 1999.

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

420