Real-time Simulation of Distributed Control Systems: The example of

Functional Electrical Stimulation

Daniel Simon

1

and David Andreu

2

1

CAMIN team, INRIA, LIRMM Bat 5 CC05 017, 860 Rue Saint Priest, Montpellier Cedex 5, France

2

CAMIN team, Univ. Montpellier, LIRMM Bat 5 CC05 017, 860 Rue Saint Priest, Montpellier Cedex 5, France

Keywords:

Hybrid Simulation, Real-time Control, Control Architecture Validation.

Abstract:

The paper presents a real-time open software simulation framework, dedicated to the analysis of control sys-

tems deployed over distributed execution resources and wireless links. It is able to consistently simulate in

parallel the numerical devices (real-time tasks and communication links) and the evolution of the controlled

continuous time plant. It is applied to foresee future enhancements of a Functional Electrical Stimulation

(FES) system used in therapy for rehabilitation or substitution for disabled people. It is a distributed control

system using electrodes to interface a digital control system with livings. Hence the whole system gathers

continuous-time (muscles and nerves) and discrete-time (controllers and wireless links) components. During

the design process, realistic simulation remains a precious tool ahead of real experiments to check without dan-

ger that the implementation matches the functional and safety requirements. The simulation tool is especially

devoted to the joint design and analysis of control loops and real-time features.

1 FROM CONTROL DESIGN TO

REAL-TIME EXPERIMENTS

The design and validation of complex systems, like

cyber-physical systems which include both physical

and computational devices, is costly, time consum-

ing and needs knowledge and cooperation of different

disciplines (Ben Khaled-El Feki, 2014). For example,

medical robotics belong to such category and require

the coordinated design of both bio-mechanical, elec-

trical, and chemical models (from a physical point of

view) and many-sided controllers (from a computa-

tional point of view).

Simulations, handling both the components and

their interaction, are needed from the early stage

to speed-up the design, development and validation

phases, especially when real experiments are costly

or dangerous for human beings.

1.1 Simulation Needs

Understanding and modeling the influence of an im-

plementation (support system) on the QoC (Qual-

ity of control) is a challenging objective in con-

trol/computing co-design process. Real-time prop-

erties (task response times) and the network Qual-

ity of Service (QoS) influence the controlled system

properties and QoC. However real-life size problems,

involving non-linear systems and uncertain compo-

nents, still escape from a purely theoretic framework.

In this design process, simulation is an indisputable

step between concept design and prototype validation.

Models are needed to describe the mechatronic

continuous system, to compute the discrete time con-

trol laws and diagnosers, and to handle the network

behavior. As usual, choosing the right model results

of a trade-off between complexity and fidelity. Indeed

several models with different granularity are used dur-

ing the design and validation process, from fast proto-

typing until real-time simulation and implementation.

1.2 Numerical Simulation of Control

Process

The main purpose of the numerical simulation is to

approximate as faithfully as possible the behavior of

the complex dynamic system. In other words, bound-

ing the simulation errors is an important goal of nu-

merical simulations so that the designers can be con-

fident with the prediction.

A distinctive feature of real-time control systems

is that they are hybrid. Indeed, they gather compo-

nents with different time nature. Digital components,

Simon, D. and Andreu, D.

Real-time Simulation of Distributed Control Systems: The example of Functional Electrical Stimulation.

DOI: 10.5220/0005967804550462

In Proceedings of the 13th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2016) - Volume 1, pages 455-462

ISBN: 978-989-758-198-4

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

455

such as CPUs and networks, run over discrete time

scale while handling real-time tasks and communica-

tion packets. Digital components can be easily exe-

cuted on the CPUs, using the multitasking capabili-

ties of the simulation cores to simulate the concurrent

nature of the distributed control system.

On the other hand, the physical components of

the control system – such as actuators, sensors and

mechatronic parts – are continuous time components

which can be described by some kind of non-linear

differential equations. As real system are too complex

to lead to explicit solutions of their dynamic behavior,

they must be integrated on computers using a numeri-

cal solver. Numerical integration is still an active field

in numerical analysis, and provides many effective

numerical solvers and associated software suites, able

to solve the continuous models either using time dis-

cretization or state quantization (Ben Khaled-El Feki,

2014).

Finally, all the components of the simulated sys-

tem must be carefully interconnected, and their time

scales must be meshed to provide consistent simula-

tion results over the different time representations and

scales. Both modeling and numerical integration deal

with approximations, hence it is first needed to find

a satisfactory trade-off between the simulation speed

and precision.

Real-time simulation needs to consider two time

scales:

• Real-time: it is the time reference of the real physical

system that is modeled and simulated, e.g. as mea-

sured by an absolute wall clock;

• Simulated time: it is the time elapsed during the exe-

cution of the simulation that can be measured by the

numerical integrator clock (i.e., by the accumulation

of integration steps).

To be consistent, the simulated time and real-time

must be carefully meshed to meet at some precise

points (Ben Khaled-El Feki, 2014).

Several simulation steps of growing accuracy and

fidelity to the real implementation can be processed,

from basic functional investigation in continuous time

until hardware-in-the-loop setups including parts of

the final components, just prior to real tests.

Model-in-the-loop. A first step is the choice of a

control structure, based on a model of the plant and

on the control objective. The control toolbox now

contains many tools to state and solve a large vari-

ety of control problems applied to various plants. Be-

sides control theory, preliminary design and tests of-

ten rely on simulation tools such as Scilab/Scicos or

Matlab/Simulink.

Software-in-the-loop. As for MIL, the SIL phase

considers only simulated (i.e. software) elements,

but it takes into account the actual production code,

including implementation related constraints such as

fixed-point computations and memory size limits.

Hardware-in-the-loop. After validating the soft-

ware in a real-time SIL simulation, the production

hardware can be checked in a real-time Hardware-

In-the-Loop (HIL) simulation. A HIL simulation is

made of mixed simulated and real components, which

means that some real components –usually the phys-

ical control target– are replaced by their software

avatar.

The next sections are devoted to the development

of a simulation framework dedicated to the case of a

distributed electrical functional electrical system.

2 THE FES FRAMEWORK

Functional electrical stimulation (FES) is one of ex-

isting rehabilitation techniques to restore lost motor

functions for motor-impaired people. For example, in

case of spinal cord injuries, the natural pathways be-

tween the central nervous system (CNS) and periph-

eral nerves are open under the lesion level. Therefore

such lesions forbid both the activation of movements

through motor nerves and the collection of sensory

information by the CNS.

In FES systems, electrodes are connected to

nerves or muscles and generate electrical pulses to in-

duce contractions of muscles. Similar electrodes can

be used to collect activity signals from muscles (Elec-

troMyoGrams EMG) or from nerves (ElectroNeuro-

Grams ENG). FES is primarily used for rehabilitation

of functions for people with disabilities. Until now

FES is mainly used in open-loop mode, where the

therapist selects predefined currents patterns (e.g., fre-

quency, intensity) according to the desired effect on

the patient. It is argued, e.g. (Zhang et al., 2013), that

closed-loop FES is necessary to safely control and co-

ordinate the numerous electrodes and muscles needed

to generate complex movements such as walking.

Sensors 1

st

ctrl Sensors 2

nd

ctrl

Actuators Ctrl 1 Actuators Ctrl 2

Ctrl law 1

POD

EMG

POD

STIM

Set-point

Controller

Ctrl law 2

Set-point

POD

EMG

POD

EMG

POD

STIM

Shared

sensors

Mutual exclusion

between

Controllers

Figure 1: Feedback FES.

In that case (Figure 1), the stimulation controller

is fed back by various sensors, such as limbs joints

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

456

angles, IMUs providing accelerations, EMG sig-

nals. . . These signals are used by feedback controllers

to accurately control the artificially actuated limbs.

Indeed it is well known that feedback control pro-

vides adaptability w.r.t. varying operation conditions

and robustness w.r.t. the uncertainties spoiling the

control loops components.

Compared with mechanical devices, the large un-

certainties and variability of livings make them espe-

cially difficult to be accurately modeled and safely

controlled. Conversely, considering humans in the

loop, the safety of the technology must be validated,

e.g. formally assessed, to allow for its certification

and usage in everyday life on a large scale.

2.1 The Phenix Liberty FES System

The Phenix Liberty FES system has been developed

along a partnership between the Demar research team

and the Vivaltis company

1

. It is devoted to external

stimulation, i.e. the electrodes are glued on the skin,

facing the target muscle or nerve. Compared with

its competitors, a distinctive feature of the system is

its wireless implementation. Considering the multi-

ple sensors and actuators needed to control complex

motion, distributed systems over wireless links com-

ply with mobility constraints, leading to acceptance

from the human users. The marketed system executes

a preset stimulation sequence in open-loop. Although

it is fluently used to correct, e.g., foot drop, finite-

state controllers typically are not adequate to adapt

stimulation patterns for frequent changes of walking

speed. FES also fastly involves muscular fatique,

thus needed an on-line detection and adaptation of the

stimulation profiles. Current research aims to design

and implement closed-loop FES using this system.

PC

Control device

Stimulation unit

Electrode

Micro sensor

Acquisition unit

Figure 2: The Phenix FES system.

The main components are:

• A main PC is used as a end-users (i.e. a therapist)

interface, to select the stimulation pattern out of a li-

brary of pre-defined profiles, and to provide the gate-

way with the controller using an USB link;

• The control device manages the communications with

the distributed stimulation units through the wireless

1

http://www.vivaltis.com/

network running the protocol stack. For future feed-

back controlled stimulation it will also run the real-

time control loops. The controller board is equipped

with a Freescale MC1322X micro-controller and an

integrated IEEE802.15.4 2.4 GHz Radio Frequency

(RF) emitting/receiving chip.

There are several kind of distributed units (DSUs, also

named PODs) :

• The ”Stim/Bio” DSUs allows for both the stimula-

tion of muscles for movement generation and for the

acquisition of EMG signals for biofeedback purpose.

They are made of two electronic boards :

– A generic board embeds the housekeeping hardware

and software to provide the electrical supply (bat-

tery), switches and LEDs, and a physical network

transceiver. The protocol stack and the requests (stim-

ulation and acquisition) processing are handled by a

Freescale MC1322X micro-controller.

– A daughter board executes the stimulation patterns or

the acquisition requests through two input/output ana-

logue channels.

• The ”universal” DSUs use the same generic board, but

embeds in its daughter board specific sensors. For ex-

ample, IMUs or goniometers are planned to be em-

bedded in a near future.

The communication architecture uses a specifi-

cally designed 3-layer protocol stack, compliant with

the reduced OSI model. These layers are the Applica-

tion layer, the MAC layer and the Physical layer. The

physical layer manages the wireless medium. The

MAC layer ensures a deterministic medium sharing,

so that only one unit can speak at a time (no colli-

sion), to provide known and bounded response times.

It allows for either a single (unicast) or a group of tar-

get DSUs (multicast) by using an individual or group

identifier (Godary-Dejean et al., 2011).

These various tasks run on the µcontrollers under

control of a CMX real-time multi-tasking executive.

3 SIMULATION SETUP

The long term objective is the safe and efficient im-

plementation of motion control using FES feedback

loops. As the analysis of such complex hybrid system

is out of scope of pure theoretic analysis, we need a

software tool to help for the design, sizing, analysis

and tuning of the components and of their interaction,

w.r.t. specified performance and safety levels.

More precisely, we need that the system uses an

open source framework and run in real-time on stock

Real-time Simulation of Distributed Control Systems: The example of Functional Electrical Stimulation

457

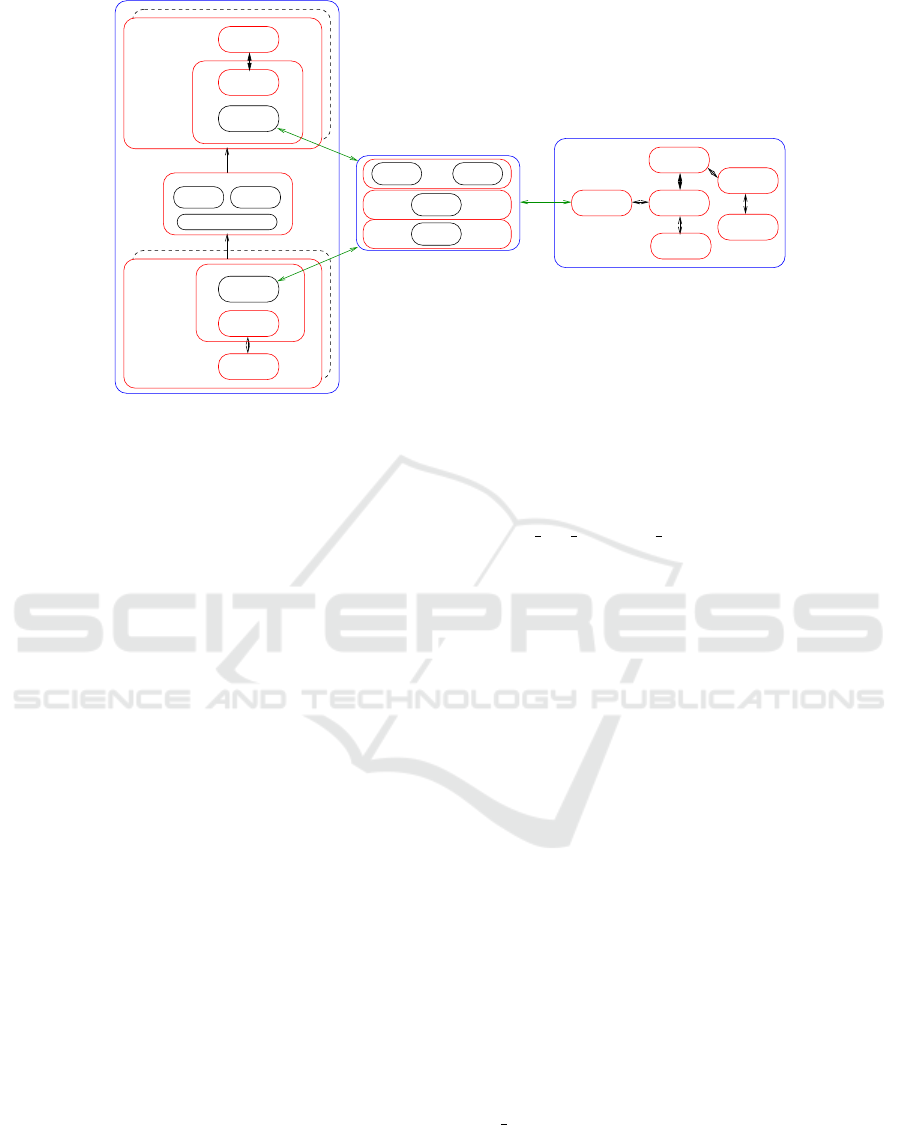

Medium Process

Controler Process

POD Process

Acquisition DSU

threads

Stimulation DSU

threads

Spy

C−>P

P−>C

Patient

model

thread

UDP sockets

Unix process

Posix thread

Sensor

processing

Comm.

manager

functions

FES

protocol stack

MAC layer

Motion

sensing

Biomechanical models

Muscles

Joints

kinematics

Comm.

manager

Stimulation

processing

FES

functions

Probes

MAC layer

protocol stack

control

FES

laws

Messages

scheduler

Task

scheduler

Scheduling

controler

Control

supervision

Disturbances

medium

medium

model

model

protocol stack

MAC layer

Communication

Communication

Numerical integrator

Stimulation

Currents

Figure 3: Simulation architecture.

PCs. It must easily evolve from functional simula-

tion to HIL to cover the different phases of software

development. Hence, according to the design cur-

rent phase, some simulated components might use

quite simple models while others should be more de-

tailed. For example, a preliminary analysis of the con-

trol loops sampling rate do not need a very detailed

physical model of the communication medium (which

could be added later on for refined tuning).

3.1 Simulation Architecture

Processes and Threads. Based on previous expe-

rience the simulation software is designed as a set

of Unix processes and Posix threads running under

Linux on stock multi-core PCs. The first version of

the simulator is a pure software which does not inte-

grate any piece of real hardware, and calculations are

performed with the usual floating point capabilities of

the PC.

However, to mimic the real distributed architec-

ture, it is split in 3 processes so that it can be run on

a multi-core PC (see Figure 3), for example one core

simulates the controller and each DSU is simulated on

another core :

• the ”Controller” process executes the FES controllers

running on the control chip under supervision of

a multitasks O.S.; it also simulates the network

transceiver through a simplified model of the commu-

nication stack;

• the ”Medium” process is used to simulate the physical

features of the wireless link;

• the ”DSU” process handles models of the Stim and

Acquisition DSU fonctions in dedicated threads. It

also handles the computation thread running the nu-

merical integrator.

Using the (non portable)

pthread attr setaffinity np CPU allocation state-

ment, each of these process can be run on a different

core. In the future these processes might be easily

allocated on different chips connected by the real

transceivers to enhance the simulation framework

towards an HIL simulation.

Communication and Synchronization. A simpli-

fied version of the communication protocol stack is

implemented in dedicated communication threads.

The data exchanged between the controller and the

DSUs are encapsulated in packets whose structure is

similar to those handled by the real network. In the

simulation, the packets are handled in two steps by

UDP Unix sockets (Figure 4):

• the packet is first transmitted using a point-to-point

UDP socket from the communication manager of the

controller (or of the Pod) to the medium process re-

ceiving thread;

• in the current version, the model of the medium just

add a constant delay to the packet transmission, and

data loss are handled by a simple random process.

• after being delayed, the packet is sent to all re-

ceivers using a diffusion UDP socket (using the

”so broadcast” parameter of UDP sockets). This fea-

ture allows for sending data with a unique time stamp

to groups of Pods.

Timing Values. All threads in the simulation can be

unlocked either by signals from clocks (e.g. for pe-

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

458

broadcast socket

point−to−point

DSU

Stimulation

DSU

Acquisition

Medium Control Device

sockets

Figure 4: Communication sockets.

riodic control tasks), by blocking waiting messages

on an incoming socket or by semaphores signaled by

communication requests sent by another thread. The

threads are scheduled by the Linux kernel, set with the

RT FIFO real-time mode, according to their priorities

and locks. However stock Linux kernels sometimes

provides inconsistent behaviors, although the simula-

tion works coherently with kernel compiled with real-

time options, i.e. with high resolution timers and low

latency preemption model under superuser privilege.

The transmission delays on the wireless links are

simulated by pure delays in the medium component.

Probes using functions of the Posix real-time library

can be inserted anywhere in the threads to measure,

e.g., communication delays between two tags or to

record missed deadlines.

Solver Triggering. The numerical integration

thread is a special case. Indeed this thread is not

the ghost of a real time task existing in the real

implementation.

In real life the state of the physical process nat-

urally evolves in parallel with the numerical execu-

tion of the control and communication systems. The

time scales of the continuous and numerical entities

are meshed at some meeting instants at the occurence

of different kind of events :

• when a control system requests an updated sensor

value;

• when a control system sends a new control value;

• when the simulation system needs a snapshot of the

controlled process and of its environment;

• when the continuous process raises an event (e.g., via

an asynchronous sensor or crossing a model disconti-

nuity).

The integration thread is triggered by any of these

events. At each triggering event the integrator is first

run from the last interruption until the current time

to update the state of the continuous process, then it

delivers the new state or accept new control inputs.

In practice, for the current set-up the simulation

runs very comfortably faster than real-time on a mod-

ern laptop (e.g., 100 times faster on a i7 CPU). Com-

putation times and overruns can be easily checked by

software probes and reported to provide information

and warnings about the timing behavior and quality

of the simulation.

Note that, if the numerical integration cost be-

comes prohibitive to run the simulation on a single

CPU w.r.t. real-time, the model can be split over

several CPUs. Slackened synchronization between

decoupled sub-models allows for significant speed-

ups while keeping the integration errors under control

(Ben Khaled-El Feki, 2014).

3.2 Continuous Plant and Numerical

Integration

Continuous Model. The model of the continuous

plant is usually given as a set of ordinary differ-

ential equations (ODEs), differential algebraic equa-

tions (DAEs) or partial derivative equations (PDEs),

where the continuous (physical) time is an indepen-

dent variable.

Building high fidelity system-level models of

complex systems, like mechatronic systems and even

more systems involving livings, is a challenging duty.

One problem is the diversity of modeling and simula-

tion environments used by the various involved multi-

disciplinary teams. Particular environments are pre-

ferred for a specific use due to distinctive strengths

(modeling language, libraries, solvers, cost, etc.), for

example the automatic derivation of the kinematic and

dynamic equations of a multi-body system can be a

distinctive feature.

Perfect modeling must be forgot. A model is al-

ways an approximation of reality, both in its structure

and in its parameters values. A problem for simula-

tion, due to both model complexity and fast system

dynamics, is the prohibitive CPU times which can be

observed when high-fidelity models are run, therefore

preventing any real-time simulation. It is needed to

find a satisfactory trade-off between the simulation

speed and precision. A good model captures the es-

sential behavior of the physical plant. Therefore, ac-

cording to its user and objectives (e.g. an control sci-

entist dealing with gains tuning, or a therapist willing

to choose the stimulation frequency), different models

of a given physical plant can be chosen.

Building a high-fidelity model needs precise

knowledge about the plant itself, here coming from

bio-mechanics and neuroscience. The simulation

setup has been tested using the model of a human knee

controlled by electrostimulation, a topic for which

the Demar team developed a strong experience over

years. The main structure and parameters of the

Real-time Simulation of Distributed Control Systems: The example of Functional Electrical Stimulation

459

model were mainly taken from (Benoussaad, 2009)

for artificially excited muscles and from (McFaull and

Lamontagne, 1998) for the joint non-linear parame-

ters.

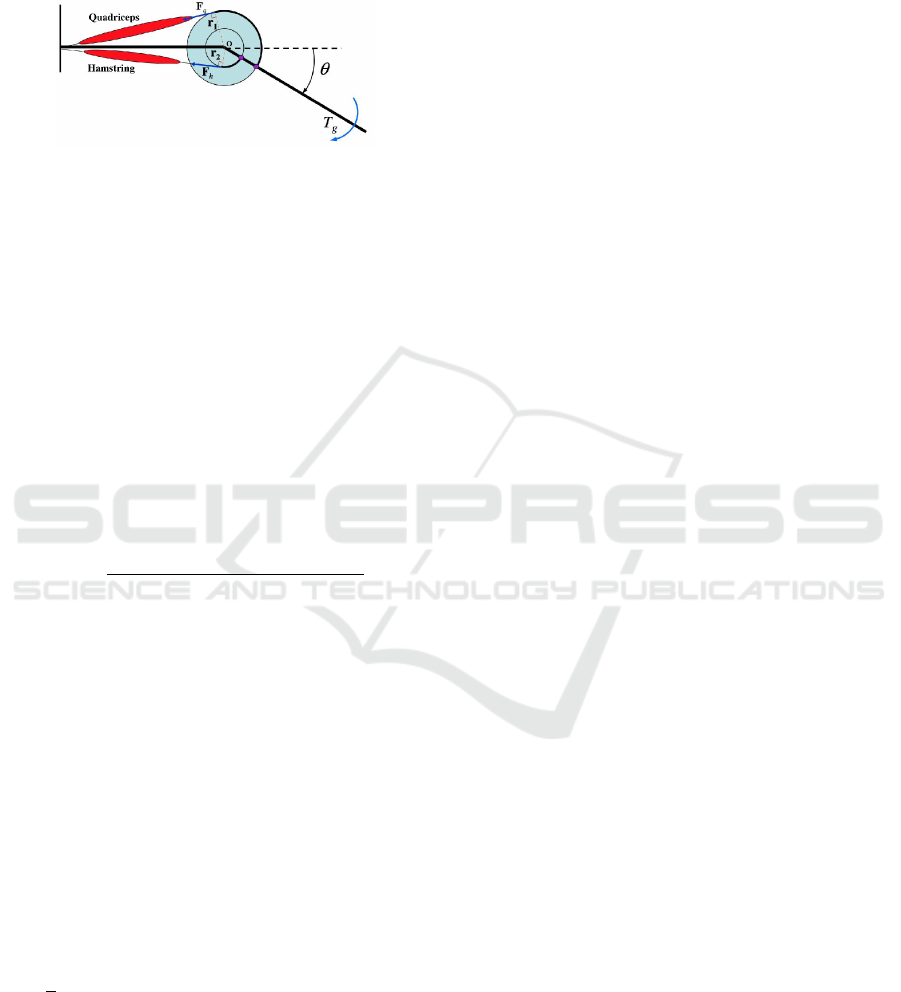

Figure 5: Simplified knee kinematics.

It is given as a small set of non-linear ODEs. A

contractile element (CE) dynamics is given by (Be-

noussaad, 2009) :

˙

K

c

= −K

c

|u| + αK

cm

Fl

c

(ε

c

)|u|

+

− K

c

|

˙

ε

c

| (1)

˙

F

c

= −F

c

|u| + αF

cm

Fl

c

(ε

c

)|u|

+

− F

c

|

˙

ε

c

| + L

c0

K

c

˙

ε

c

where K

c

and F

c

are the stiffness and force devel-

oped by the CE, K

cm

and F

cm

their maximum values,

u and |u|

+

chemical control variables coming from an

activation model, Fl

c

(ε

c

) the force/length relation of

the CE, α the recruitment rate, and

˙

ε

c

the contraction

speed of the CE.

The numerical integration of the later variable,

given by

˙

ε

c

=

k

s

L

0

˙

ε + F

c

|u| − αF

cm

Fl

c

(ε

c

)|u|

+

k

s

L

c0

+ K

c

L

c0

− s

v

F

c

(2)

needs a special attention as it involves the sign func-

tion :

s

v

= sign(k

s

L

0

˙

ε + F

c

|u| − αF

cm

Fl

c

(ε

c

)|u|

+

) (3)

Correctly handling this non-linearity needs an inte-

grator enabled with a root-finding capability to pro-

vide a fast and stable integration (see next section).

The two muscles involved in the knee flex-

ion/extension, i.e. the quadriceps and hamstring, have

similar models with different parameters and are ac-

tuated by their own electrode. For our purpose, the

knee joint is considered to be a perfect cylindrical

d.o.f. leading the usual equation of motion (Figure

5

¨

Θ =

1

J

(F

2

r

2

− F

1

r

1

− MgL

og

sin(Θ − Θ

0

) − B

˙

Θ + T

e

)

(4)

where F

i

is the force induced by muscle i, B a non-

linear damping and T

e

a passive elasticity torque.

Finally the model is encoded for integration as a

set of 8 first order non-linear ODEs, three for each

muscle and two for the joint dynamics.

Numerical Integration. The non-linear model of

a robot (or of most mechatronic systems involv-

ing mechanical and electrical components) is usu-

ally described by a set of ordinary differential equa-

tions (ODEs) (or sometimes by a set of differential-

algebraic equations (DAEs)) (Arnold et al., 2011).

There already exist a broad family of algorithms

and corresponding software used to numerically solve

such a set of ODEs.

With most existing integration packages, the end-

user’s choices can be :

• set the value of a fixed-step integrator, leading to a

predictable number of steps and computing time, but

the precision cannot be controlled and may lead to

false results;

• specify the precision of the integration and delegate

the adaptive step management to the integrator, but in

that case the computing time cannot be predicted.

With an adaptive step integration method the con-

trolled variable is the precision (or more exactly the

estimate of the integration error). The open-source

LSODAR package we have elected (Hindmarsh and

Petzold, 1995) for this experiment uses a variable

step, variable number of steps integration algorithm.

It is suitable for both stiff and non-stiff systems,

and automatically selects between non-stiff and stiff

methods.

It is associated with a root-finding stopping cri-

teria : when it detects a sign change in a particular

function of the states (root detection), it runs a root-

finding algorithm to find the exact time point at which

the sign change occurred. The later feature is essential

to correctly integrate continuous plants with disconti-

nuities, i.e. where the values of some states or pa-

rameters, or even the model structure itself, suddenly

change where a given threshold is crossed (zero-

crossing). It is for example the case for models of

impacts, dry friction, and here for muscles contrac-

tion (due to eq. (3)).

3.3 Control Design

To generate movement for a joint, two muscles (an ag-

onist and antagonist pair) must be stimulated. For the

knee these two muscles are the quadriceps on the an-

terior face (extension actuator) and the hamstring on

the posterior face (flexion actuator). In a first simple

control approach, the two muscles will be actuated in

mutual exclusion according to the flexion and exten-

sion phases of the movements, see Figure 6.

As usual, the first control algorithm to be consid-

ered is a PID, a simple controller able to control many

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

460

Angle desiré

PID

-1

Sat

Sat

Muscle agoniste

—————————

Muscle antagoniste

Capteur

Goniometre

-

+

Angle

U1

U2

Figure 6: Control scheme.

single input/single output (SISO) systems through a

very simple modeling and tuning effort.

Here it is discretized using a backward difference

method (with T

s

the sampling period), yielding

u

k

= u

k−1

+ K[e

k

− e

k−1

] +

K · T

s

T

i

e

k

+

K · T

d

T

s

[e

k

− 2e

k−1

+ e

k−2

] (5)

4 PRELIMINARY EXPERIMENTS

In this preliminary version, the simulation system is a

”Model-in-the-loop” simulation, where all the objects

are modeled, the physical plant state is evaluated by

a numerical integrator and the control functions are

encoded in plain C and executed using the floating

point features of a modern laptop. Anyway, it goes

beyond usual simulations with Scicos or Simulink as

it handles quite precisely some implementation and

scheduling related features such as tasks and events

interleaving, or computation and communication in-

duces delays. Hence it can be already used to explore

the possible performance of FES feedback loops ac-

cording to various scheduling parameters.

4.1 PID Tuning and Sampling Rate

A simple PID controller has been setup for prelimi-

nary tests of the simulation platform. Indeed a PID

with fixed gains would perform uniformly for a linear

system, which is not the case for the knee joint, where

even a simplified model shows several sources of non-

linearities. Hence the PID has been empirically tuned

to provide acceptable responses for the whole reach-

able motion amplitude.

Initially simulations were made with a 40 msec

sampling rate, i.e. the one used by the marketed

version of the Phenix system. In fact, the end-to-

end communication time (including control tasks ex-

ecution and messages transmission and acknowledg-

ment) between the controller and the DSUs is lower

than 5 msecs (Figure 7b). Lowering the sampling

rate to 5 msecs shows an improved performance of

the joint controller (Figure 7a). Note that, as the net-

work model is included in the simulation, sampling

rates smaller than 5 msec induce data loss and poor

control performance. Hence the real-time simulator

allows for a fine tuning of control gains w.r.t the exe-

cution resources at hand, far beyond the usually rec-

Knee angle (rad)

Time (sec)

sampling 40 msec

sampling 5 msec

sampling 2 msec

Time (sec)

End−to−end communication time (msec)

Figure 7: a) Knee position – b) End-to-end delay.

ommended sampling rates between 3 and 10 times the

Shannon sampling rate.

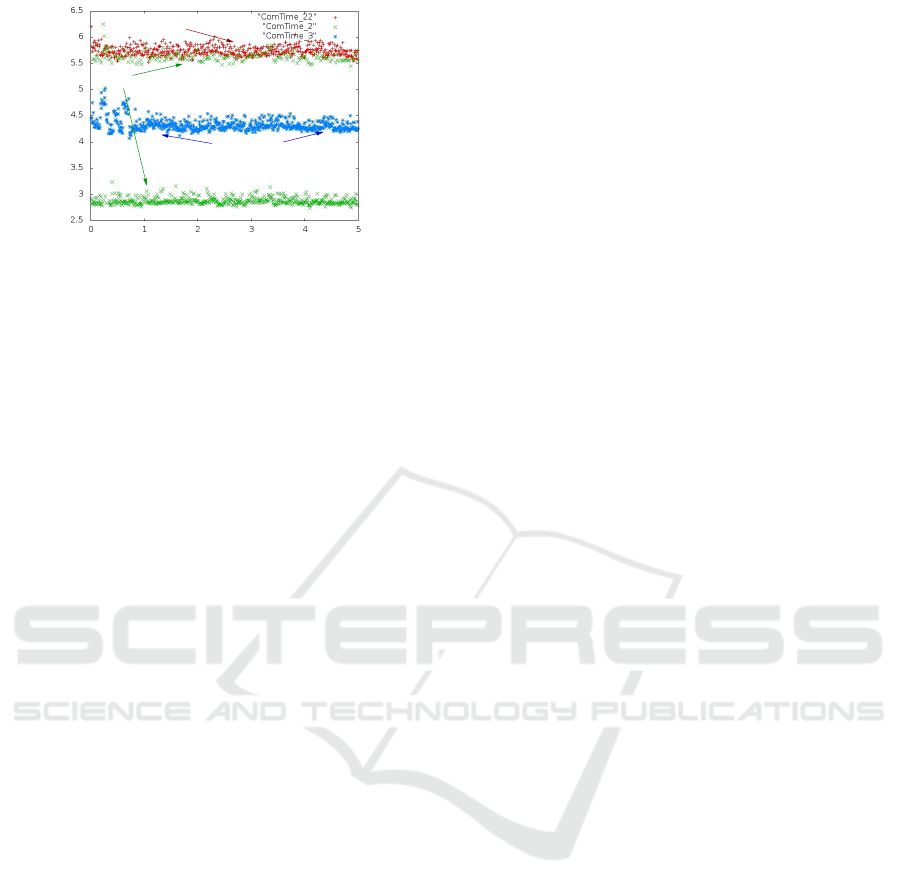

4.2 Network Protocol Enhancements

The current communication threads do not implement

the production code of the full protocol stacks, but

only its main features. The simulated transceiver en-

capsulates data in frames according to the STIMAP

protocol (Godary-Dejean et al., 2011) used to con-

nect the controller and DSUs. The frames are further

sent/received over UDP sockets. Several versions of

the communication frames were tested, and their im-

pact on the feedback control performance and on the

communication load was evaluated (see Figure 8).

Single Receiver (Production Version) (in red). A

data frame issued by the controller contains the ad-

dress of a single receiving/answering DSU, and the

payload only contains the stimulation parameters for

this particular DSU (red plot, 6 ms average delay);

Single Receiver with Optimization (in green). The

optimization uses the mutual exclusion between the

agonist/antagonist muscle and send only frames to the

active muscle in the current motion phase. However

some safety messages are sent (at a slower rate com-

pared with control messages) to keep alive the DSU

of the passive muscle, leading to irregular timing pat-

terns (green plot, 75% of samples near 3 ms and 25%

of samples near 6 ms);

Multiple Receivers (in blue). Messages are ad-

dressed to a group of DSUs, with a payload made of

the concatenation of the individual stimulation param-

eters: the frame is longer than a single receiver frame

but shorter than the concatenation of the single re-

ceiver frames, thus saving communication bandwidth

(blue plot, 4.5 ms average delay);

The observation of the simulations traces show that

using optimized versions of the protocol may signif-

icantly save bandwidth and decrease the end-to-end

communication delay between sensing and actuation,

leading to improvements in the performance and ro-

bustness of the FES control law. Such results are use-

ful to motivate (even costly) modifications of the pro-

duction hardware and software.

Real-time Simulation of Distributed Control Systems: The example of Functional Electrical Stimulation

461

Time (sec)

End−to−end communication time {msec)

Multiple receivers

Single receiver

Single receiver, optimized

Figure 8: End-to-end communication time.

5 SUMMARY AND FUTURE

DEVELOPMENTS

Realistic simulations are effective tools to design and

tune complex systems whose analysis cannot be pro-

vided only by theory. Several simulation steps can be

explored, from simple functional analysis until HIL,

to design, test, tune and validate both the single com-

ponents of the system and their interactions in a dis-

tributed architecture. Simulations are precious, as

they allow for non-destructive trials, anticipation for

future technological development at lowered cost and

exploration of a system behavior until its limits with

no danger.

For the particular setup presented here, it is ex-

pected that such simulator will provide inputs in two

main directions. Firstly it allows for preliminary test-

ing new FES protocols prior to experiments with pa-

tients, and may help for writing the ethical protocols

needed for any experiments involving livings. Sec-

ondly it can be used for preliminary evaluation of new

technologies or implementations, without costly re-

working of existing electronic chips or certified com-

ponents.

The simulation software is open, so that enhance-

ments w.r.t. to the original release can be added upon

request of various designers and to fulfill various de-

sign objectives. For example, some future enhance-

ments may be :

• Development and test of feedback schedulers for au-

tomatic adaptation of the CPU and communication

loads in complex FES applications such as walking;

• Refinement of the physical communication medium

model, so that the wireless link fading due to of

obstacles can be evaluated, leading to the design

of a feedback control of the emission power of the

transceivers;

• Integration of others continuous plants. The dynamic

model of a human hand with 23 d.o.f. is currently

developed to provide a complex case for numerical

integration and control coordination;

• Progressive integration of the production code of

some components, e.g., the full protocol stack, and of

some real components, e.g., wireless transceivers be-

tween simulated nodes, to incrementally provide HIL

simulation setups.

As for any simulation, a crucial problem is the cal-

ibration of the models and the validation of the over-

all simulation system. This process needs, at some

points, comparisons with observations of real experi-

ments, which is costly but necessary. Anyway this is

needed to gain the confidence of the various users of

the system.

REFERENCES

Arnold, M., Burgermeister, B., F

¨

uhrer, C., Hippmann, G.,

and Rill, G. (2011). Numerical methods in vehicle

system dynamics: State of the art and current devel-

opments. Vehicle System Dynamics.

Ben Khaled-El Feki, A. (2014). Distributed real-

time simulation of numerical models: applica-

tion to powertrain. PhD thesis, EEATS, Au-

tomatique Productique, Universit

´

e de Grenoble.

http://www.theses.fr/2014GRENT033.

Benoussaad, M. (2009). Protocole d’identification sous

FES et synth

`

ese des s

´

equences de stimulation chez le

bless

´

e m

´

edullaire. PhD thesis, Univ. Montpellier II.

Godary-Dejean, K., Andreu, D., and Romain, R. (2011).

Temporal bounds verification of the STIMAP proto-

col. In RTNS 2011 : 19th International Conference

on Real-Time and Network Systems, page 10, Nantes,

France.

Hindmarsh, A. C. and Petzold, L. R. (1995). Algo-

rithms and software for Ordinary Differential Equa-

tions and Differential-Algebraic Equations, part II:

Higher-order methods and software packages. Com-

put. Phys., 9:148–155.

McFaull, S. R. and Lamontagne, M. (1998). In vivo

measurement of the passive viscoelastic properties of

the human knee joint. Human Movement Science,

17(2):139 – 165.

Zhang, Q., Hayashibe, M., and Azevedo Coste, C.

(2013). Evoked Electromyography-Based Closed-

Loop Torque Control in Functional Electrical Stimula-

tion. IEEE Transactions on Biomedical Engineering,

60(8):2299–2307.

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

462