Middleware Communication System for Fixture based Flexible

Manufacturing Systems

N. Chiraga, A. Walker and G. Bright

Discipline of Mechanical Engineering, University of KwaZulu-Natal, Durban, South Africa

Keywords: Distributed Flow Control, Wireless Communication in Manufacturing, Middleware, Mass Customization.

Abstract: Today’s factory floors are a distributed system of heterogeneous components. They exist a high degree of

production customization to cater for this most factory floor systems are being adapted for customization.

Most current manufacturing communication systems do not have a flexible architecture to serve the

changeable and dynamic market needs thus presenting a research gap in flexible communication. This paper

discusses a middleware communication system that allows for flexible optimal control of information flow in

a fixture based production system. The architecture of the system aims to integrate seamlessly a heterogeneous

factory environment, for autonomous monitoring and control of information on the factory floor.

1 INTRODUCTION

The manufacturing industry is currently experiencing

a paradigm shift into the Fourth Industrial Revolution

in which customers are increasingly at the epicentre

of production (EFFRA, 2013). This revolution has

prompted major research into factories of the future;

forcing industries to re-examine their systems (Bloem

et al., 2014). Schwab et al stated in the recent world

economic forum stated that the Fourth Revolution is

evolving at an exponential rather than linear pace

(Schwab, 2016).The high degree of production

customization and personalization requires a flexible

manufacturing system that will rapidly respond to the

dynamic and volatile changes driven by the market

(Qiao et al., 2000). Mass customization has seen

limited adoption, thus giving raise to research into the

implementation of manufacturing systems that are

highly responsive to these rapid changes in market

demands. They is a gap in technology that allows for

optimal flow of information and optimal

manufacturing operations on the shop floor regardless

of the rapid changes in fixture and part demands. The

mass customisation manufacturing (MCM) paradigm

has created a problem in manufacturing control

implementations, as each customer has the potential

to disrupt production operations resulting in

downtime (Walker and Bright, 2013). Factory

communication systems now also have to cater for the

high degree of production customization and

personalization.

It is essential to attain at least 99.99% uptime or

better on the shop floor during these rapid changes

(Qiao et al., 2000). Depending on the size and nature

of business, indirect costs due to downtime can range

from tens of thousands to hundreds of thousands of

dollars (Qiao et al., 2000). A reliable advanced

factory communication system architecture is critical

for optimal network performance. A deep and

efficient integration of information flow, information

analysis, and customer input in the production

network is necessary. There is a need to provide the

right information at the right time and show the

manufacturing decision maker how current

conditions on the plant floor can be optimised to

improve customized production output. Salvador et

al. identified three fundamental capabilities

determining the ability of a factory to mass-customize

its offerings, i.e. solution space development, robust

process design, and choice navigation (Salvador et

al., 2009).

This paper aims to develop the robust process

design capability in Factory Communication

Systems; the capability to create, reuse, or recombine

existing factory shop fixture resources to fulfil a

stream of differentiated customer needs (Salvador et

al., 2009). Flexible automation, process modularity,

and adaptation are approaches that can be taken to

develop robust process design. Flexible automation

can be described as automation that is not fixed or

rigid and can handle the customization products.

While process modularity is the segmentation of

146

Chiraga, N., Walker, A. and Bright, G.

Middleware Communication System for Fixture based Flexible Manufacturing Systems.

DOI: 10.5220/0005972201460152

In Proceedings of the 13th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2016) - Volume 1, pages 146-152

ISBN: 978-989-758-198-4

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

existing organizational and factory shop resources

into modules that can be reused or recombined to

fulfil differentiated customers’ needs (Salvador et al.,

2009).

To facilitate the flexible communications between

the high-level software systems Enterprise Resource

Planning (ERP), SCADA and Manufacturing

Execution System (MES)) and users (control and

industrial engineers), and the heterogeneous factory

floor environment middleware technology is needed.

This paper details an advanced Factory Middleware

Communication System (FMCS) that uses a

middleware communication system to allow for

flexible control and information exchange in a factory

environment driven by the dynamic customer needs

for production execution. The aim of this study was

to seamlessly integrate manufacturing floor

communication with the customers’ decisions in

product configuration.

2 AN OVERVIEW OF THE

FACTORY MIDDLEWARE

COMMUNICATION SYSTEM

(FMCS)

Traditional Supervisory Control and Data

Acquisition (SCADA) systems collect data from

various sensors nodes deployed in remote locations

and then transmit it to a central controller which then

manages and controls this data ("SCADA").While the

Manufacturing Execution System(MES) tracks and

documents the transformation of raw materials

through finished goods("Manufacturing Execution

System"). The Enterprise Resource Planning (ERP)

tracks the factory’s resources, i.e. raw materials

supply and production capacity ("Enterprise

Resource Planning"). This Factory Middleware

Communication system is an advanced

manufacturing strategy aiding the SCADA system,

MES and ERP; and equipping them with intelligent

handling capabilities for the rapidly changing

customer needs, which in turn result in the production

processes experiencing rapidly varying fixture and

part demands. The figure below illustrates where the

developed system exits in a manufacturing pyramid.

Figure 2 shows the general overview of the

system. The system solution copes with a demand

characterized by at least a subset of the following

properties: low-mid demand volumes, mid-high

variety of the part mix, short product lifecycle, and

mid-high customization. The following sections

explain each module in the system.

Figure 1: Manufacturing production levels.

Figure 2: Factory Middleware Communication System

(FMCS) Overview.

2.1 State Detection Module

The FMCS operates using state detection modules

(SDM) attached to each factory cell to determine the

state of each cell at any given time on the production

floor. The distributed SDMs; microcontroller-based

modules form a sensor network, with state detectation

capabilities. In this research, we are primarily

interested in the information presented at each factory

cell. The aim is to create an information intense

environment rather than just transmit instructions.

Information is the reduction of uncertainty; it gives

meaning and context on the state of each cell. In

information theory Shannon describes entropy as the

average value of information contained by a system

(Lesne, 2011).

Suppose that a discrete variable X, has n possible

outcomes;

,

,

,…..,

the probability for each

outcome being

. Shannon entropy is defined as:

log

(1)

Middleware Communication System for Fixture based Flexible Manufacturing Systems

147

Where:

0 And

∑

1

The variable denotes a system, which is the cell in

our case,

and

1,2,…., are its n possible

states and their probabilities in the cell respectively.

The amount of information needed to describe the

cell, is i.e. information entropy (Lesne, 2011).

Considering a factory cell X on a factory floor, six

states can be defined;

i. Optimal working state

ii. Running slow state

iii. Idle state

iv. Scheduled maintenance state

v. Unscheduled maintenance state

vi. Downtime state

Based on the probabilities of each state, using

Shannon Theorem the entropy for each cell can be

calculated and hence the overall entropy of the entire

information system.

2.2 The State Communication Module

(SCM)

The SCM facilitates the communication link between

the state detection modules and the central control

computer, which runs the Central FMCS Control

(CFC) software.

Communication techniques range from wired to

wireless communication protocols. Publications have

shown emerging work ushering in the wireless

communication protocols into industrial networks.

(Buda et al., 2010). To keep up with technological

trends wireless technology was used for the

development of the communication network.

Wireless technology offers flexibility; modules can

be introduced to the system in a plug and play manner

without having to worry about re-wiring. Factory

propagation environments however, have many

metallic surfaces and moving objects, which can be

characterised as harsh conditions that can affect the

operational quality of radio based communication

systems (Buda et al., 2010). Wireless communication

is implemented with ZigBee wireless protocol, a

well-adapted technology for industrial applications.

ZigBee operates at 2.4GHz frequency, which lays in

the bandwidth of frequency not affected by the

interference in factories. (Buda et al., 2010). ZigBee

is based on an IEEE 802.15.4 standard. XBee Series

2 are used for the Zigbee wireless communication.

The SCMs help us achieve process modularity; state

information is continually transmitted wirelessly to

the central control.

2.3 Central FMCS Control (CFC)

2.3.1 Middleware Communication Layer

Today’s factory floors are a distributed system of

heterogeneous components. There exist a wide range

of applications and system platforms, making

heterogeneity in factories predominant. Each SDM

stands out as a heterogeneous component in a cellular

configuration. This is where middleware technology

comes in; middleware masks heterogeneity on the

factory floor and allows for flexible control and

exchange of information. Using a thick software-

intensive middleware layer negates the need for a

hardware supported middleware system in the control

system. The objective is maintain optimal

manufacturing operations on the shop floor during

model definition changes of customer-desired

products. Internet Communications Engine (Ice) is a

modern object-oriented middleware platform that

enables you to build distributed applications with

minimal effort (Roulet-Dubonnet et al., 2013).

With Ice, there is no need to worry about details

such as opening network connections, serializing and

deserializing data for network transmission, or

retrying failed connection attempts. Its features

include location independence; the client does not

need to know of the specifics of the target object’s

address, platform independence; multi-vendor

manufacturing devices can integrate seamlessly,

programming language independence; does not

matter if client and server processes are implemented

with the same language or different languages. The

middleware layer works as the workflow manager,

the nervous system of the network created allowing

for interoperability and seamless flow of information.

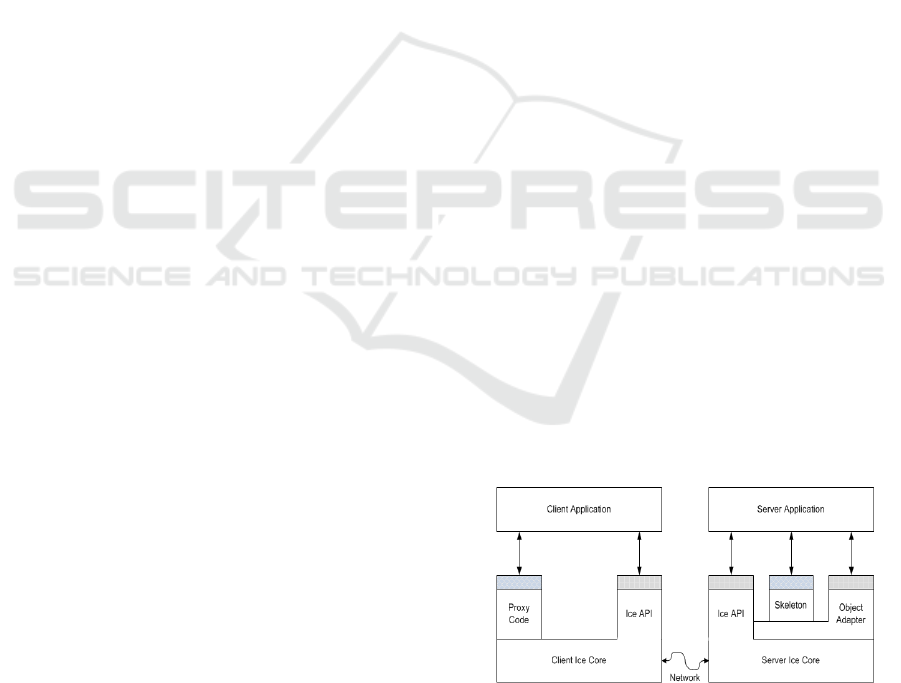

Figure 3 shows the middleware client; sever

structure (Roulet-Dubonnet et al., 2013).The CFC

acts as the client and the SCMs as the server.

Figure 3: Ice Client and Server Structure.

When a client i.e. central control invokes an

operation, the following steps take place:

i. Locates target object i.e. the SCMs located at

each cell in the network

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

148

ii. Activates the server application in the SCMs,

if the server is not already running

iii. Transmits any arguments for the call to the

object via the ZigBee wireless network

iv. Waits for request to complete

v. Returns any out parameters or return value to

the client when a call completes successfully.

The return parameters in our case is the state

information gathered by the SDMs, fixture

information from the fixture reconfiguration

system and machine orientation from the

reconfigurable machine system.

vi. Returns an exception to the client when a call

fails

2.4 Intelligent Processing and Program

Assignment in the Central Control

(CFC)

The CFC is the middleware and intelligence layer of

the system, the workflow manager. It continually

polls for information from the factory floor and stores

it into a database. Based on the factory floor state,

fixture configuration, availability, and the machine

configuration an order is processed and control

instructions are assigned to the work cells. Through

this intelligence of raw factory floor state data fed by

the SCMs, an information-based configuration is set-

up. Sequences of job arrive, entering the shop floor

input buffer and are logged in through the graphical

user interface and order parameters are noted

according to the customers’ decisions in product

configuration. Jobs are dealt with using the MIMO

queue concept. The product specifications make up

the procedural rules for the workflow decision tree.

The ability to effectively communicate the factory

floor state and the characteristic response of the

system to a new product configuration are of utmost

importance in this research. The EPR keeps track of

the available raw materials i.e. fixture database on the

factory, if a new product configuration requires a new

fixture, instructions are sent to the 3D Printing cell to

produce a new fixture. Once the fixture production is

done, the fixture database is updated and the

production plan and control instruction are sent to

each cell on the factory floor. Figure 4 below

explains the procedural steps in the intelligent process

up until the order program is assigned to the factory

floor for manufacture.

Figure 4: Procedural steps in the intelligent processing of

an order.

3 EXPERIMENTATION ON THE

SYSTEM

The system was implemented and tested in the UKZN

Manufacturing and Mechatronics Laboratory. The

laboratory layout depicts a factory floor environment;

it is made up of a cellular configuration. The cellular

make-up of the configuration includes; a Material

handling cell, 3D Printer cell, Assembly cell,

manufacturing cell and Quality control cell. State

detection modules as well as state communication

modules were placed in each cell, forming a star

network. The CFC software layers links up with two

pre-existing systems in the laboratory i.e.; the

machine reconfiguration system and the fixture

reconfiguration system. The machine reconfiguration

system provides the CFC with the physical

configuration of the machines on the factory floor and

allows the machines to be reconfigured accordingly.

While the fixture reconfiguration system provides the

current fixture configuration at any given time and

again allows for fixture reconfiguration.

The flexibility of this system is random-order,

there are substantial variations in part configurations,

new part designs are continually being introduced to

the system. It is a recognition that a factory cannot

do everything; it must limit its options to a certain

Middleware Communication System for Fixture based Flexible Manufacturing Systems

149

scope of products activities in which it can best

compete.

Table 1: Hypothetical initial scope of product variety.

Hard Product Variety Soft Product Variety

Product 1 5 variations

Product2 3 variations

3.1 Aim

The experiment associated with the situation

described above aimed to prove that it was possible,

using the technology developed in this research, to

rapidly respond to customer demands by intelligently

and effectively communicating information on the

factory floor. It aimed to increase the performance of

downstream production instructions flow fed from

parallel upstream flow of information on the factory

state.

3.2 Method

To verify the success of the system, the system

needed to respond rapidly to both the initial scope on

product variations as well as the randomly introduced

new customized product variations. In addition, the

system needed to facilitate the appropriate fixture and

machine configurations and assign program

instruction to the factory floor.

The following method was followed:

1. Use the Central FMCS Control software to

initiate a factory floor scan.

2. Input order’s product configuration into the

system using the graphical user interface.

Randomly input new customized product

specifics.

3. Check the response time, the time between

lodging of order into system and dispatcher of

order program instruction.

4. Repeat steps 2-3, varying the order specifics each

time.

5. Check fixture database updates in the case of a

new product configuration.

3.3 Results

As shown in Table 1, the system managed to

successfully respond to new customized orders,

seamlessly integrate systems and communicate

information on the factory floor. The FMCS had an

80% success rate.

3.4 Discussion of Results

The experiment was successful in identifying the

states of each cell at any given time. Each process,

from the initialisation of the program to when the

assignment of program production control

instructions took place in real time with delays of less

than 3mins. The system was able to obtain real time

responses for the factory states data. The processes

where a new product configuration was introduced

responded within a 2min to 5min response time.

Extra time was needed for the 3D printing of the

fixture. The cellular configured SCMs were able to

communicate within a radius of up to 1,2km

approximately 99% of the time. This process is still

very quick in industrial terms and is far more time and

labour efficient than manual methods. The product

variety was quantified using the equation given

below.

(2)

Where P refers to the different product designs or

types that are produced in the factory.

the number

of distinct products lines, hard product variety and

the number of number of models in a product line,

soft product variety. Subscript j identifies the product

line (Groover, 2008).

Table 2: Results of FMCS Test.

Order

#

Run

#

Identified

Factory

floor state

correctly

Communicated

with Fixture

reconfiguration

system correctly

Communicated

with machine

reconfiguration

system correctly

New

Fixture

Produced

Assigned

Program

instructions

correctly

Time Result

1 1 Yes Yes Yes N/A Yes 8:30 Pass

2 1 Yes Yes Yes Yes Yes 9:45 Pass

3 2 Yes Yes Yes No N/A 11:18 Fail

4 1 Yes Yes Yes N/A Yes 11:30 Pass

5 1 Yes Yes Yes Yes Yes 14:03 Pass

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

150

The graph below shows how the product variety of a

factory overtime using the Factory Middleware

Communication System (FMCS).

Figure 5: Graph of Product variety versus time.

From the graph, we can see that the system increase

the scope of product variety of a system, making it

well equipped to handle volatile changes driven by

the market.

3.4.1 Performance and Scalability of

Middleware Software

Further test were done to measure the performance of

the middleware layer. A fundamental measure of

middleware performance is latency. Latency is the

time it takes for a two-way operation to be invoked

between a client and server and obtain the results of

the operation (Roulet-Dubonnet et al., 2013). When

we run the client and server on the Core i7 machine,

with the client and server running on different

machines and communicating over a network. The

latency is 2,500 messages per second (400µs per

message).

4 CONCLUSIONS

The flexibility of the system means that users have an

almost limitless expandability and engineers can

adapt and upgrade the system’s features and

capabilities to meet immediate and future

requirements. The middleware communication

system allows for flexible control and information

exchange in a heterogeneous factory environment

driven by the dynamic customer needs for production

execution. The performance of downstream

production instructions flow fed from parallel

upstream flow of information on the factory state that

were increased with the use of this system.

REFERENCES

European Factories of the future assosiation EFFRA

(2013). Factories of the future.

Bloem, J.,Van Doorn, M., Duivestien, S.,Excoffier, D.,

Mass, R., and van Ommeren, E.,(2014). The Fourth

Industrial Revolution. In:Sogeti. Vint.sogeti.com/[

Accessed 5 Mar. 2016].

Schwab, K., (2016). The Fourth industrial revolution. In:

World Econimic Forum. http://www.weforum.org/

agenda/2016/01/the-fourth-industrial-revolution-what-

it-means-and-how-to-respond.

Qiao, G., Lu, R., and McLean, C., (2000)”Flexible

Manufacturing System for Mass Customization

Manufacturing”

Walker, A., and Bright, G., (2013) Distributed Control

Synthesis for Manufacturing Systems using Customers’

Decision Behaviour for Mass Customisation.

Salvador, F., Martin, P., and Piller, F., (2009) Cracking the

Code of Mass Customization. In MIT Sloan

Management Review, Massachusetts.

"SCADA". Wikipedia. N.P., 2016. Web. 17 Mar. 2016.

D. Bailey and E. Wright, “Practical SCADA for Industry”,

(2003).

R. J. Robles, M. -k. Choi and T. -h. Kim, “The Taxonomy

of SCADA Communication Protocols”, Proceedings of

the 8th KIIT IT based Convergence Service workshop

& Summer Conference, Mokpo Maritime University

(Mokpo, Korea), ISSN 2005-7334, pp. 23.

M Choi, “Wireless Communications for SCADA Systems

Utilizing Mobile Nodes”, International Journal of

Smart Home Vol. 7, No. 5 (2013), pp. 1-8.

"Manufacturing Execution System". Wikipedia. N.p.,

2016. Web. 17 Mar. 2016.

"Enterprise Resource Planning". Wikipedia. N. P., 2016.

Web. 17 Mar. 2016.

Lesne, A., (2011) “Shannon entropy: a rigorous

mathematical notion at the crossroads between

probability, information theory, dynamical systems and

statistical physics,” Pierre and Marie Curie University,

France.

Buda, A., Schuermann, V., Wollert, J., (2010) “Wireless

Technologies in Factory Automation,” University of

Applied Sciences Bochum Germany.

Roulet-Dubonnet, O., Lund, M., and Skavhaug, A., (2013),

“IceHMS, a Middleware for Distributed Control of

Manufacturing Systems," in Industrial Applications of

Middleware Communication System for Fixture based Flexible Manufacturing Systems

151

Holonic and Multi-Agent Systems, 1 ed Berlin,

Germany: Springer Berlin Heidelberg, pp. 95-105.

Mikell P. Groover. (2008). Automation, Production

Systems and Computer-Integrated manufacturing, New

Jersey: 3rd edition, Pearson International Edition.p. 55.

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

152