Modeling and Simulation of an Energy Efficient Skid

Conveyor using ZIZO

Oussama Khlifi

1,2,4

, Christian Siegwart

2

, Olfa Mosbahi

3

, Mohamed Khalgui

3,5

and Georg Frey

1

1

Chair of Automation, Saarland University, Saarbrücken, Germany

2

ZeMA – Zentrum fur Mechatronik und Automatisierungstechnik gemeinnützige GmbH, Saarbrücken, Germany

3

LISI laboratory, INSAT, University of Carthage, Tunis, Tunisia

4

Polytechnic School of Tunisia, University of Carthage, Tunis, Tunisia

5

School of Electro-Mechanical Engineering, Xidian University, Xi'an 710071, China

Keywords: Petri Net, Energy Efficiency, Automotive Transport System, Modeling, Simulation.

Abstract: This paper introduces a method for modeling and simulation of a production system with different energy

modes. We aim to save the energy in an assembly automobile production line platform using sensitive sensors.

A new prototype model is proposed using an extension of Petri nets called GR-TNCES (generalized

reconfigurable timed net condition event systems). We also present a simulation of this model with a proposed

tool ZIZO to show the energy gain compared to standard production line model.

1 INTRODUCTION

As one key pillar of national economics,

manufacturing industry and information technology

create huge economic fortune,

but it also results in

serious environmental problems, such as energy

depletion problem (Wang et al., 2014). Consequently,

industry is forced to consider and initiate energy

efficiency for many types of systems. With about

47% the industry sector has the largest share of

electricity consumption in Germany (BDEW, 2014).

Since the German automotive industry is one of the

biggest industries, improving energy consumption in

this field is an important topic. Therefore, sustainable

economic activity and energy are one of the key

points in the new high-tech strategy of the German

government (BMBF, 2014). In order to improve the

energy efficiency of production systems, modeling

and simulation provides a good basis for such a

prototype system. It is a useful strategy to start with

the control and the energy evaluation in such a

system. Components of production plants can operate

in different modes (on, standby, off mode) that

consume a different amount of energy. Intelligent

switching between these modes can lead to an

optimization of the energy demand. The purpose of

this paper is to optimize the energy consumption of

an automotive transport system prototype. The

authors introduce a system plant model with the aim

to save energy.

State machine based approaches such as

StateCharts (Chen et al., 2014) are best suited for

control dominated systems besides it suffers from

their inability to express data flow. Discrepancy

between a system and its model representation can be

found looking at all the tools that do not allow

expressing structural similarity between a system and

its model. Recently, the use of object-oriented (OO)

modeling (Bastide and

Buchs, 1998) becomes more

and more common. Although OO-formalisms contain

several features to produce detailed models, they are

not intended to be executable. Place/transition Petri

nets (Andrade et al., 2009) have several desirable

properties, such as being intuitive, graphical, and able

to express concurrency and data flow. However, they

are confined to the use in small scale models since a

concept of hierarchy is missing. High-level Petri nets

such as colored Petri nets (Cai et al., 2015) are better

suited, since they have an expressive inscription

language and also some structuring features.

Distributed discrete event system specification is a

modular and hierarchical formalism for modeling and

analysing discrete-event system to be distributed on

networked devices. It can be described by state

transition tables and continuous state systems which

Khlifi, O., Siegwart, C., Mosbahi, O., Khalgui, M. and Frey, G.

Modeling and Simulation of an Energy Efficient Skid Conveyor using ZIZO.

DOI: 10.5220/0006002305510558

In Proceedings of the 13th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2016) - Volume 1, pages 551-558

ISBN: 978-989-758-198-4

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

551

might be represented by differential equations, and

hybrid continuous state. To improve and evaluate the

energy consumption of a modular system, an

expressive formalism is needed to model the system’s

behaviours, time constraints and energy resources. It

is essential that the formalism can supervise the

consumed resources and energy reserves. Recently,

generalized reconfigurable timed net condition

systems (GR-TNCES) (Khlifi et al., 2015) is

introduced by the authors to model and control

adaptive probabilistic systems under memory and

energy constraints. It is a useful and practical

formalism to model distributed discrete event

systems. It is very expressive and it can describe

several constraints. Thanks to this formalism, it is

simple to interconnect condition/event signals to the

system’s components. It is also useful to model and

supervise the energy consumption during run-time

simulation. Moreover, the authors present a new

extension of the tool, baptized ZIZO (Salem et al.,

2015), a GR-TNCES modeling and probabilistic-

simulating software. It could model reconfigurable

probabilistic and distributed discrete events systems

and control their resources consumption at run-time

process. Then, it exports the model which already

built to the probabilistic model checker PRISM

(PRISM 4.3, 2015)

for the formal certification.

Precisely, the authors describe the model of a

distributed control system: An assembly-line

conveyor controlled by a programmable logic

controller PLC using a GR-TNCES. The model

contains information about the energy consumption

of the system parts in different operation modes

(running, standby, off). The system’s energy

consumption is evaluated via the token number

consumed by the system during simulation.

The remainder of this paper is organized as

follows. The next Section describes the preliminaries

on top of modeling formalism and simulation. Section

3 introduces the case study. The new environment

ZIZO, the system’s model, the simulation and the

optimization are introduced in Section 4. A

discussion is provided in Section 5. Finally, Section 6

concludes the paper.

2 BACKGROUND

For the better understanding of modeling formalism

and simulation, basic preliminaries are briefly called

here. We present also the new formalism introduced

in the previous work GR-TNCES (Khlifi et al., 2015)

to model and control adaptive probabilistic discrete

event systems.

2.1 Petri Nets

Petri nets are extensively used to model, analyze, and

control discrete event systems. Different classes of

Petri nets can present different types of systems.

Specifically, place/transition nets can be used to

represent the logical level of a discrete event system

(Li and Zhou, 2009). Deterministic timed event

graphs which represent a subclass of Petri nets are

equivalent to linear systems (Chen et al., 2014). More

general timed deterministic and stochastic Petri nets

can be used for performance evaluation. High-level

nets can offer a compact model for complex systems.

Hybrid nets can represent hybrid systems that involve

both discrete and continuous processes (Li and Zhou,

2009).

2.2 Simulation

Simulation-based approaches ensure that a limited

number of the defined system paths meet the desired

specification. Even though computationally

inexpensive simulation is used in system design, it

does not lead to completeness as it is impossible or

impractical to prove all system trajectories.

Simulation is a semi-automatic testing method since

the user must provide a large number of test cases (Li

and Zhou, 2009).

2.3 Existing Tools

Several tools already exist to model and/or simulate

Petri nets and their extensions. For example, CPN

tools is a software package for editing, simulating and

analyzing colored Petri nets. It features a fast

simulator that efficiently handles both timed and

untimed nets. Full and partial state spaces can be

generated and analyzed (Ratzer et al., 2003). Petri

.NET allows the modeling, simulation and real-time

implementation of static and dynamic Petri nets. Its

results are presented in the form of a graphical token

game animation (Genter et al., 2007). Nevertheless,

neither CPN tools nor Petri.NET can support GR-

TNCES with their condition and event signals. The

TNCES-Editor, developed at Martin Luther

university Halle-Wittenberg, allows the graphical

modeling of all NCES based subtypes (Dubinin et al.,

2006). To support interpretation and reachable state

analysis, the TNCES-Editor offers an optional

labeling of transitions. However, TNCES-Editor does

not feature the simulation of a built model.

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

552

2.4 GR-TNCES Formalism

The formalism GR-TNCES is recently introduced in

(Khlifi et al., 2015). It is used to model and control

memory and energy resources of adaptive

probabilistic systems as well as discrete event

systems. A GR-TNCES is a network of R-TNCES

(Zhang et al., 2013). It is a structure G = ∑ R-TNCES

where R-TNCES = (B, R), such that R is the control

module consisting of a set of reconfiguration

functions {r

1

,…,r

n

} managed under a memory and

energy controllers, and B is the behavior module

which is a union of multi TNCES (Zhang et al., 2013),

represented as follows: B = (P, T, F, QW, CN, EN,

DC, V, Z

0

) where:

(i). P (respectively, T) is a non-empty finite set of

places (respectively, transitions);

(ii). F is a set of flow arcs with F ⊆ (P × T) ∪ (T ×

P);

(iii). QW=(Q,W) where Q: F→[0, 1] is the

probability on the arcs and W: (P × T) ∪ (T ×

P) →{0, 1} maps a weight to a flow arc.

Specifically, W(x, y) > 0 if (x, y) ∈ F, and W(x,

y)=0 otherwise, where x, y ∈ P ∪ T;

(iv). CN (respectively, EN) is a set of condition

(respectively, event) signals with CN ⊆ (P × T)

(respectively, EN ⊆(T × T));

(v). DC: F ⊆ (P × T) → [l, h] is a superset of time

constraints on output arcs;

(vi). V: T→{∨, ∧} maps an event-processing mode

(AND or OR) to each transition;

(vii). Z

0

= (T

0

, D

0

) where T

0

: P → {0, 1} is the initial

marking and D

0

: P → {0} is the initial clock

position.

Let TN = P ×T ×F ×QW ×CN ×EN ×DC ×V be the

set of all feasible net structures that can be performed

by a system. Let

•r (respectively, r•) denotes the

original (respectively, target) R-TNCES before

(respectively, after) the reconfiguration function r is

applied, where TN(

•r), TN(r•) ∈ TN. Each

reconfiguration is controlled by the controller module

R. It is a structure: R = {Condition Cond, Probability

Q, Energy E’, Memory M’, Structure S, State X}. A

reconfiguration function r is a structure r = (Cond, Q,

E

0

’, M

0

’, S, X), where:

(i). Cond: CN → {true, false}: the precondition

Cond of r can be evaluated to true or false and

can be modeled by external condition signals;

(ii). Q: F → [0..1]: TNCES probability which

could be a functional (internal to the TNCES)

or a reconfiguration probability. It is a new

parameter for GR-TNCES;

(iii). E

0

’: P → [0..max]: controls the energy

requirements by the TNCES to the energy

reserves;

(iv). M

0

’: P → [0..max]: controls the memory

requirements by the TNCES to the memory

reserves;

(v). S: TN(•r) → TN(r•): is the structure

modification instruction of the reconfiguration

scenario;

(vi). X: last state (•r) → initial state (r•): is the state

processing function, where last state (•r)

(respectively, initial state (r•)) denotes the last

(respectively, initial) state of •r (respectively,

r•) before (respectively, after) the application

of r.

A state machine specified by an R-TNCES, which is

called Structure_changer, is introduced to describe

the control module. In this state machine, each place

corresponds to a specific TNCES of the GR-TNCES

model. Thus, each transition corresponds to a

reconfiguration function. A place sp gets a token

implies that the TNCES to which sp corresponds, is

selected. If a transition st (∀ st ∈ sp•) fires, then it

removes the token away from sp and brings it into a

place sp’ with sp’ ∈ st•. Firing st implies that a

reconfiguration function is applied. Then, the TNCES

is changed into another one corresponding to sp’. The

Structure_changer is formalized as follows:

Structure_changer = (P, T, F, Q, E’, M’)

where ∀

t ∈ T, |•t| = |t•| =1, and only one TNCES is

performed at any time. Each place of this structure

contains the whole information about the

corresponding TNCES e.g. its energy and memory

requirements (number of states in this TNCES). Thus,

this formalism will be used to model the system and

its resources. The tool is used to simulate the model

and evaluate its energy resources.

3 TEST CASE: SKID CONVEYOR

Skid conveyors are one type of transport systems that

are widely used in the automotive industry.

Transporting a body in the paint shop or transporting

chassis from one workstation to another in the final

assembly are typical use cases. For this purposes, we

use an extended skid conveyor system, which is one

part of the automated commissioning line built up in

Modeling and Simulation of an Energy Efficient Skid Conveyor using ZIZO

553

Figure 1: CAD model of the skid conveyor.

the “Zentrum für Mechatronik und

Automatisierungstechnik” in Saarbrücken, Germany

(ZeMA, 2015). Energy efficiency of this plant model

is one important topic of the researchers.

3.1 Structure

Figure 1 shows a CAD model of the transport system.

It consists of three conveyor parts: Each one is

equipped with one motor. The overall length is

18.14m and each part has the length of 5.45m. Each

motor drives five rollers transporting a skid of 3.90m

with a chassis on it. In order to realize energy efficient

operations, the system is extended by a control unit

and six inductive sensors. The first sensor is placed

2.62m and the second one 4.69m from the start point

of each conveyor part. Using these sensors, it is

possible to detect the skid position on the conveyor.

Inactive components are switched into an energy

efficient state. We differentiate three different cases:

(i).

If a rising edge is detected by the first sensor,

then the skid reaches the conveyor and the

associated motor must be turned on,

(ii).

If there is a rising edge at the second sensor,

then the skid is in the middle of the conveyor

part. The motor is switched off for an

exemplary cycle time of 10 seconds,

(iii).

If a falling edge is detected by the second

sensor, then the skid leaves the conveyor part

and the associated motor must be switched off.

Monitoring the skid position has a further advantage.

Since we have a fixed chassis position on the skid, the

inductive sensors enable us to determine the chassis

position. This information can be used in the

assembly task for example.

3.2 Control System

In order to realize any energy efficient operation of

the system, we have to install a control system to

allow switching on and off all components at the right

time. The central unit of the system forms a

programmable logic controller (PLC). All sensors are

connected to this unit. The PLC communicates via

PROFINET with the drives and a mobile panel. The

Siemens PROFIenergy (PROFIBUS

Nutzerorganisation e.V., 2010) profile is based on

PROFINET and allows active standby modes for the

non-used loads during non-productive periods. The

drive system is a modular component that ranges

from the control unit and the power modules to the

motors. The user handling and control is realized with

the mobile panel. It is easy to command the system

via touchscreen and buttons. Figure 2 shows the

layout within the control components. It represents

the control system and the connection among its

modules.

Figure 2: Control system of the skid conveyor.

4 ZIZO TOOL: MODELING AND

SIMULATION

We present in this section the tool ZIZO and its

usefulness for the modeling and simulation

distributed control systems. It allows modular

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

554

Figure 3: Production line plant model.

architectures communicating using condition/event

signals. ZIZO can establish the following operations:

(i). Modeling distributed system respecting the

GR-TNCES formalism,

(ii). Editing and connecting modules throw

condition and event signals,

(iii). Simulating the global model with a token game

animation, control the simulation depending

on energy reserves and showing the evolution

of reserve state at run-time: consumed as well

as the energy reserves,

(iv). Extracting curves for energy consumption

during the simulation time,

(v). Exporting the model to PRISM model checker

by the generation of the model’s code, loading

and saving a model.

4.1 Modeling the System

In this Section, we expose the automotive transport

system model. We model the new system model with

GR-TNCES formalism using the environment ZIZO.

We also model the old system (without control and

inductive sensors). To evaluate the energy

optimization of the proposed plant model, it should be

compared to the energy needed by the existent

production line model. Figure 3 describes the

proposed model which is a distributed discrete event

system composed of four modules: The car in the

conveyor, the sensors, PLC and the three motors. If

the sensitive sensor detects the entrance of a car in the

conveyor, then it sends an event signal to the PLC. It

activates and deactivates the corresponding motors

according to the car position in the conveyors. The

first module contains six events which correspond to

the six sensors installed in the skid conveyor. For the

Sensors module, it receives the events sent by the

conveyor then transfers them to PLC. It has three

extra-events denoted by “No-Car2”, “No-Car4”, and

“No-Car6” which correspond respectively to events

received from sensors number two, four and six to

notify the PLC about the car’s availability. The third

module corresponds to the PLC module that controls

the whole system. The PLC receives signals from the

sensors to control the state of the motors (active,

standby, off). The events “M1.ON”, “M1.SB”,

“M1.Act”, and “M1.Off” correspond respectively to

control the states of the motors “Start, Standby, Active

and Off”. Figure 4 shows two Motors’ model.

Figure 4: Model on motors.

Modeling and Simulation of an Energy Efficient Skid Conveyor using ZIZO

555

Figure 5: Model of the PLC.

This model describes the transition between the

different states of the motors. The pink rectangles

correspond to events-in received from the PLC to fire

the corresponding transitions. The motor keeps the

running mode till it receives a PLC signal. The event-

in “M1.SB” initiates the motor to switch from active

to standby mode; “M1.Act” is used to reactivate the

motor after the energy efficient mode standby. Figure

5 shows the PLC model that corresponds to the

transition between the system’s different states. The

pink rectangles correspond to event-in signals

received from the different sensors. The red

rectangles correspond to events-out signals that

control the motors’ states. The PLC model represents

the logical and the temporal control unit to manage

the entire system. Basically, it has to ensure the

following states: “Start”, “Car in conveyor 1”, “Wait

10 seconds”, “Activate Motor 1”, “Car in conveyor

2”, “Wait 10 seconds”, “Activate Motor 2”, “Car in

conveyor 3”, “Wait 10 seconds”, “Activate Motor 3”,

“End”. During the wait time states, the motor is in the

standby mode while there is another robot working on

the car’s chassis. Then, the motors move the car to the

next skid conveyor. There are additional sensors to

detect the workpiece’s position on the conveyor. The

control strategy is based on the sensors’ optimal

position to reduce the period in which it is essential to

activate two motors for the car movement tasks. We

detect exactly the suitable time for deactivating the

current motor and activating the next one.

4.2 Simulation and Optimization

Figure 6: Standard system’s model.

There are two system/model variants: an old one

where all the motors could be switched together and

manually from one mode to another operation mode

and another model where each motor can be

monitored and switched independently. The new

model also features additional sensors to detect the

position of the workpiece on the conveyor.

Accordingly, those motors need to be put into

operation mode, are automatized by means of the

PLC. To evaluate the energy optimization of the

proposed model, we refer to the old system’s model

to compare it. Thus, it is possible to calculate the

energy gain. The standard plant model contains only

touch screen for the control of the three motors. It is

used to activate and deactivate all the motors which

are continuously in a running mode except the delay

to work on the chassis by another robot. As showed

in Figure 6, the basic model contains only two

modules: “Control Panel” and “Motors”. The red

signals between these modules correspond to the

activation and deactivation control events of the

motors. We suppose that the motor consumes four

energy units (tokens) per second in the running mode,

one token in the standby mode and zero unit if it is

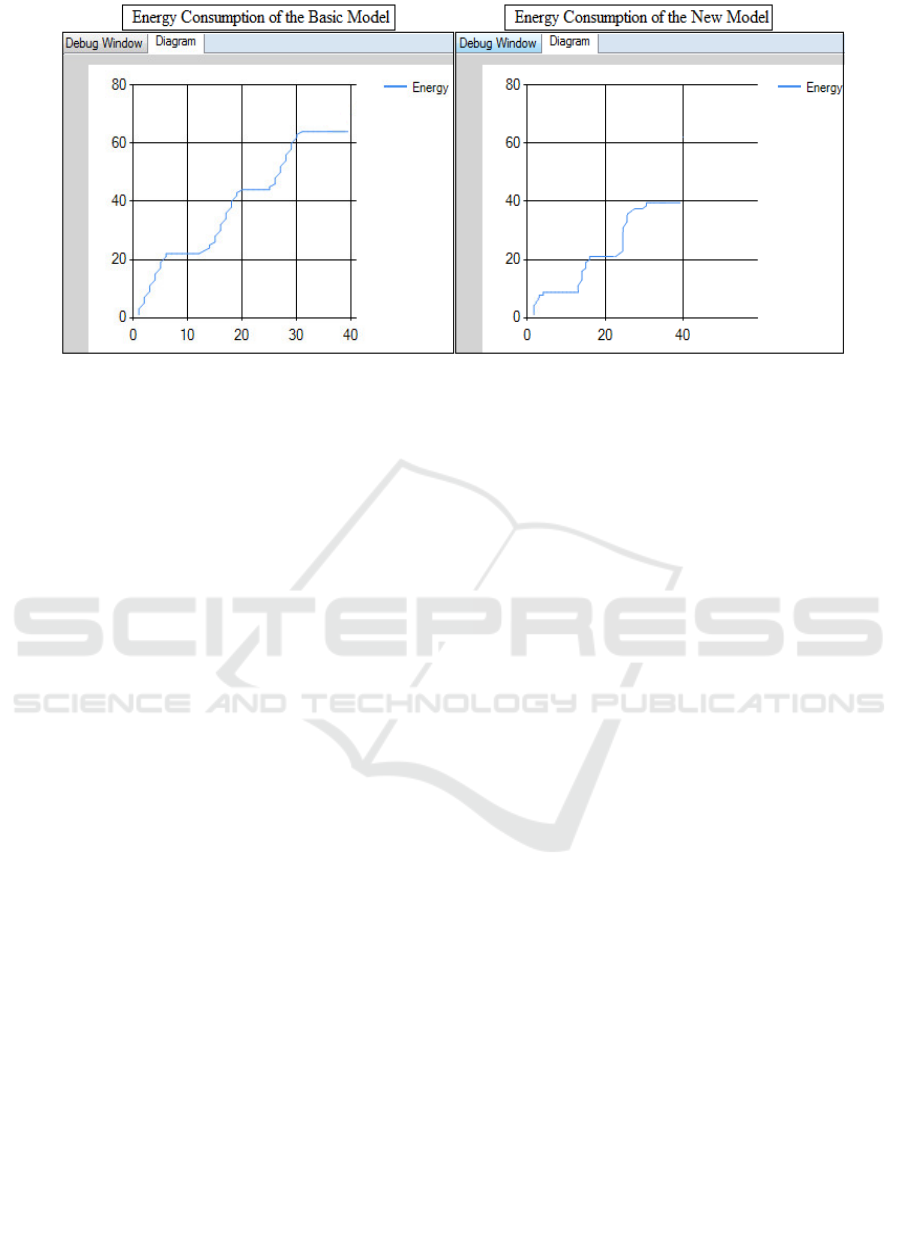

off. The energy consumption curves are showed in

Figure 7 during a simulation time (40 seconds). This

figure illustrates the evolution of the token number

needed by the system in this period. The curves

present three horizontals parts. It corresponds to the

period in which the motors are deactivated in the old

model and the standby mode in the proposed model.

The other portions correspond to the motors’

activation period and the energy consumed by the

three motors to move the car from one position to the

next one.

5 DISCUSSION

In Figure 7, we show the curves that describe the

proposed energy efficiency mode in the right graph

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

556

Figure 7: Energy consumption.

and the curves of the energy consumption of the old

model in the left one. In the energy efficiency mode,

usually there is only one motor which is active. The

idea is based on the detection of the car position to

activate and deactivate the corresponding motors. We

aim to reduce the period in which we need two motors

to move the car from one skid to the next one through

the optimal position of the sensors. We simulate the

new model shown in Figure 3 and the basic one

shown in Figure 6 for the evaluation of their energy

resources consumption. The curves describe the

energy needed by each system during the simulation

time. We notice that there is an important reduction

of the energy consumed in the proposed model. For

the first part (2-4 seconds), the consumption is highly

reduced (22 to 9 tokens) since only one motor is

activated instead of three motors compared to the old

model. To move the car to the second position (13-

16s), the proposed system model consumed 22

tokens. On the other hand, the basic model needs 44

energy units for the same task. It is a valuable

optimization. In fact, the sensors detect the car

position and the PLC controls the activation and

deactivation of the motors: It deactivates the first

motor and turn on the second one. For the third part

of the system, this strategy enables us to save 24

energy units compared to the basic plant model.

6 CONCLUSION

This paper presents a method for modeling and

simulation of a transport system model. The

presented case study is an assembly automobile

production line platform with the aim to save energy.

For the modeling, an extension of Petri nets called

GR-TNCES (generalized reconfigurable timed net

condition event systems) is used: The simulation of

this model is performed with a specific tool named

ZIZO. Compared with the existent plant model, this

model is based on the introduction of new sensors to

detect the car position in the skid conveyor. The

authors simulate both the old and the new model to

evaluate the energy gain of the new system

(additional sensors and independent switching of the

motors). The reported result of the improved system

shows energy savings quite nicely. Using Petri net

tokens to model energy consumption is intuitive and

appears a reasonable choice. Thus, we are satisfied by

the proposed method. During the next step of this

project, we will work on the validation of the

proposed model through a real energy data

measurement of the skid conveyor. The strategy

presented in this paper is realized with the

PROFIenergy profile by switching inactive

components into energy efficient modes.

REFERENCES

Wang, Q., Wang, X., and Young, S., (2014). “Energy

consumption modelling of the machining system based

on Petri net,” Advances in Mechanical Engineering,

Article ID 324819.

BDEW, (2014). “Verteilung des Stromverbrauchs in

Deutschland nach Verbrauchergruppen”, (Distribution

of Energy Consumption among the Individual

Consumer Groups in 2014).

Bastide, R., Buchs, D., (1998). “Models, Formalisms and

Methods for Object-Oriented Distributed

Computing,” in Object-Oriented Technologys, Berlin

Heidelberg: Springer, pp 221-255.

Modeling and Simulation of an Energy Efficient Skid Conveyor using ZIZO

557

BMBF, (2014). Bundesministerium für Bildung und

Forschung, “Die neue Hightech-Strategie–

Innovationen für Deutschland”, (Federal Ministry of

Education and Research, The new High-Tech Strategy

– Innovations for Germany).

Chen, Y. F., Li, Z. W., and Zhou, M. C., (2014). “Optimal

supervisory control of flexible manufacturing systems

by Petri nets: A set classification approach,” IEEE

Trans. Autom. Sci. Eng., vol. 11, no. 2, pp. 549-563.

Khlifi, O., Mosbahi, O., Khalgui, M., and Frey, G., (2015).

“GR-TNCES: New extensions of R-TNCES for

modeling and verification of flexible systems under

energy and memory constraints,” in Proc. of Int. Conf.

on Soft. Eng. and App, ICSOFT-EA, Colmar, France,

pp. 373-380.

Salem, M. O. B., Mosbahi, O., Khalgui, M., and Frey, G.,

(2015). “ZiZo: Modeling, simulation and verification of

reconfigurable real-time control tasks sharing adaptive

resources: Application to the medical project BROS,”

in Proc. of the Int. Conf. on Health Informatics,

Portugal, pp. 20-31.

Andrade, E., Maciel, P., Callou, G., and Nogueira, B.,

(2009). “A methodology for mapping SysML activity

diagram to time petri net for requirement validation of

embedded real-time systems with energy constraints,”

in Proc. of the 3

rd

Int. Conf. on Digital Society, Cancun,

Mexico, pp. 266-271.

Cai, K., Zhang, R., and Wonham, W.M., (2015). “Relative

Observability of Discrete-Event Systems and its

Supremal Sublanguages,” IEEE Trans. on Automatic

Control, vol. 60, no.3, pp. 659-670.

Li, Z. W., and Zhou, M. C., (2009). “Deadlock Resolution

in Automated Manufacturing Systems: A Novel Petri

Net Approach,” London, U.K.: Springer, pp. 20-28.

Zhang, J., Khalgui, M., Li, Z.W., Mosbahi, O. and Al-

Ahmari, A. M., (2013). “R-TNCES: A novel formalism

for reconfigurable discrete event control systems,”

IEEE Trans. Systems, Man, and Cybernetics: Systems,

vol. 43, no. 4, pp. 757-772.

Ratzer, A. V., Wells, L., Lassen, H. M., Laursen, M.,

Qvortrup, J. F., Stissing, M. S., Westergaard, M.,

Christensen, S., and Jensen, K. (2003). “Cpn tools for

editing, simulating, and analysing coloured Petri nets,”

in Applications and Theory of Petri Nets, Berlin

Heidelberg: Springer, pp. 450-462.

Genter, G., Bogdan, S., Kovacic, Z., and Grubisic, I.,

(2007). “Software tool for modeling, simulation and

real-time implementation of Petri net-based

supervisors,” in IEEE Int. Conf. on Control

Applications, pp. 664-669.

Dubinin, V., Hanisch, H., and Karras, S., (2006). “Building

of reachability graph extractions using a graph

rewriting system,” in Proc. of the 7

th

Int. Conf. of

Science and Technology, NITis, pp. 160-171.

PROFIBUS Nutzerorganisation e.V., (2010). “Pi White

Paper: The PROFIenergy Profile,” Karlsruhe,

Germany, pp. 10-11.

PRISM 4.3 (July, 2015). PRISM Model checker, [Online].

Available: http://www.prismmodelchecker.org/.

ZeMA, (2015). [Online]. Available: http://zema.de.

ICINCO 2016 - 13th International Conference on Informatics in Control, Automation and Robotics

558