Query-based Risks Management of Manufacturing Processes

Christophe Ponsard

1

, Renaud De Landtsheer

1

, Gustavo Ospina

1

,

Stephan Printz

2

and Johann Philipp von Cube

3

1

CETIC Research Centre, Charleroi, Belgium

2

Institute for Management Cybernetics (IfU), RWTH Aachen University, Aachen, Germany

3

Fraunhofer Institute for Production Technology (IPT), Aachen, Germany

Keywords:

Discrete Event Simulation, Manufacturing, Supply Chain, Procurement Risks, Risk Management.

Abstract:

Managing risks in supply chains is challenging for most companies, given the globalisation process which

is strengthening the production constraints and also introducing more procurements risks. This is especially

difficult for smaller companies because they generally lack resources to develop a specific expertise or buy

expensive tools. Our research aims at addressing those issues by proposing an easy to use, yet powerful

simulation framework based on Discrete Event Simulation. In our previous work we demonstrated the expres-

siveness of our modelling language and the efficiency of our simulation framework. The focus of this paper is

on the usability dimension of the developed tool. We describe the global process driving the company through

the whole risk control process, from identification, modelling, simulation and analysis. We demonstrate our

ideas on a web-based prototype composed on a number of wizards and component supporting the structured

analysis of simulation outcome in direct relation with the risks.

1 INTRODUCTION

Supply chain risk management (SCRM) is the im-

plementation of strategies to manage both everyday

and exceptional risks along the supply chain, based

on continuous risk assessment with the objective of

reducing vulnerability and ensuring the process con-

tinuity (Wieland and Wallenburg, 2012). Such risks

can occur for several reasons, both external (procure-

ment risks of geographic, political, social nature, etc.)

or internal (machine reliability, nature of specific op-

erations, etc.). Helping company managers make the

right decisions in the face of risks is not an easy task.

Small and medium enterprises (SMEs) are especially

challenged, because they have limited resources, and

failing to address such risks can have dramatic effects

on their business. This was confirmed by a survey

we conducted on-line, related to the practice of eval-

uation of risks in an industrial context (Printz et al.,

2015). The results of this survey showed that nearly

66% of the companies consider risk evaluations, but

only 10% rely on dedicated software tooling and most

of SMEs only rely on spreadsheets as tools.

Whilst analytical reasoning is impractical, model-

based simulation has proved to be a adequate ap-

proach (Deleris and Erhun, 2005). A common char-

acteristic is that the impact of risks can generally only

be assessed at the output of the supply chain while

some risks, like procurement risks, occur at the very

beginning. Therefore, this requires to be able to rea-

son throughout the whole manufacturing process.

Figure 1: Risk management process.

Our ultimate goal is to produce a user-friendly,

tool-supported methodology that will guide the user

through the whole process of risk assessment shown

in Figure 1. In order to reach this goal, our research

is structured as follows:

• Identifying a taxonomy of risks related to supply

chain in manufacturing, based both on literature

review and feedback from our survey (Printz et al.,

2015).

Ponsard, C., Landtsheer, R., Ospina, G., Printz, S. and Cube, J.

Query-based Risks Management of Manufacturing Processes.

DOI: 10.5220/0006011103390344

In Proceedings of the 6th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2016), pages 339-344

ISBN: 978-989-758-199-1

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

339

• Developing a modelling and simulation tool for

identifying risks, quantifying them and deciding

on how to mitigate them. This technical part of

the work relies on a Discrete Event Simulation

(DES) engine provided by the OscaR library (Os-

caR, 2012) and combined with Monte Carlo Sim-

ulation (MCS) techniques. It is fully described

and benchmarked in (Landtsheer et al., 2016).

• Building a user-friendly interface to support the

global risk management workflow depicted in

Figure 1. This is the scope of the present paper.

• Validating our work through a group of companies

that are already trying out the tool.

Our modelling framework includes concepts such as

storages and several types of production processes.

In addition, we defined a query language on models.

It is fully declarative and includes arithmetic, tempo-

ral, and logic operators, as well as basic queries on

the elements of our factory model (contents of a stor-

age, running state of a process, etc). Based on this

query language, the software tool is able to estimate

the probabilities of different scenarios (e.g. delay in

deliveries, defective parts or poor quality) and their

impact.

In this paper, we show how the modelling con-

cepts and simulation tool are supporting the global

risk management process in an efficient, consistent

and user-friendly way using a web-based interface.

The main steps of the process support are as follows:

• Risk-oriented process modelling: the model is

built with the aim to express the required risks and

not especially to be a full scale model. As risks are

fully identified in the next step, it may need to be

refined to reach the right granularity.

• Risk identification: in this key step, a hierarchi-

cal risk model is defined using a structured wiz-

ard covering major risk categories such as qual-

ity, quantity and delay risks. Different queries are

used to express the risks for each category.

• Risk-oriented simulation: the model instrumented

with queries is run using the DES and MCS, and

raw results (collected traces or statistics) can be

explored directly in the tool.

• Risk analysis and measures: the measurements

collected using the risk queries are presented in

a risk dashboard according to the structured risk

model. It allows the risk analyst to zoom in spe-

cific risk categories or look at the behaviour of

specific element according to specific risk cate-

gories. Based on this, some risk control measures

can be identified and validated using a new round

of simulation. The best value of specific parame-

ters can also be determined, e.g. the threshold or

the quantity for an order policy.

The paper is structured as follows. Section 2 gives

some background on our framework. Section 3 de-

scribes a short case study consistently used in the next

sections. Section 4 to 7 describe our modelling, risk

identification, simulation and analysis steps, respec-

tively. Finally, section 8 draws some conclusions and

describes some future work.

2 BACKGROUND: SIMQRI

SIMULATION META-MODEL

All the main elements of manufacturing processes are

represented in our simulation meta-model, which al-

lows us to define concrete models that are simulated

in a DES engine. In addition to this, we designed a

Query Language over concrete simulations in order

to collect and analyse data.

2.1 Meta-model Overview

This section introduces the basic blocks for represent-

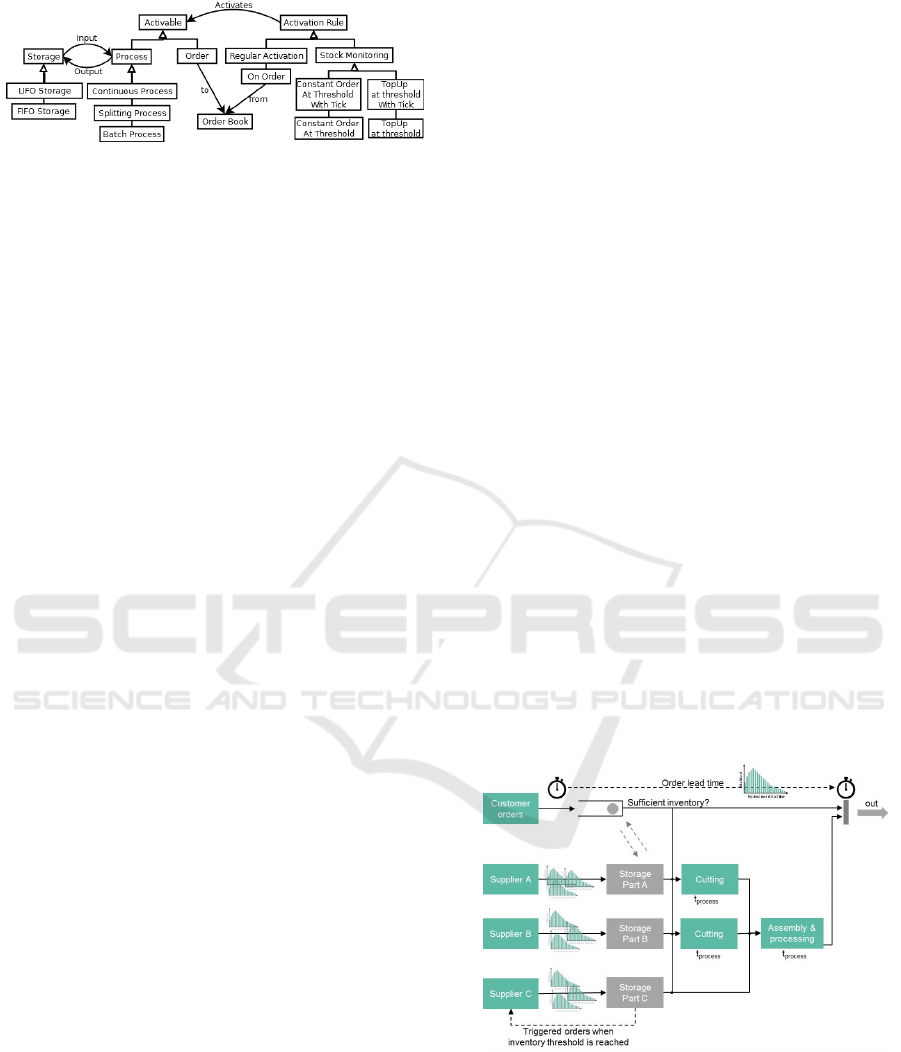

ing factories. Figure 2 summarises the meta-model of

concepts used at that purpose. It is composed of ac-

tivatable components such as storages and processes

through which items can flow.

• Storages represent any kind of storage device or

place for raw materials, like a warehouse, a barrel

or a silo. They have a maximum capacity. When

this capacity is reached, they either overflow, or

processes trying to put more items into them are

blocked, depending on the settings of the storage.

If a full storage overflows, any exceeding material

is lost.

• Batch processes are factory processes that work in

a batch fashion; supplies are collected from vari-

ous storages, the process then runs for some time,

and finally the produced outputs are dispatched to

their respective storages before this whole cycle

starts again. They exist in different flavours: with

a single or multiple production lines.

• Splitting processes are similar to batch processes,

except that they have several sets of outputs that

can be selected according to some rules. It can be

used to model failing processes and quality assur-

ance process.

• Continuous processes are factory processes that

typically run on a conveyor belt. Items are contin-

uously picked from input stocks and undergo the

process taking some time. Continuous processes

SIMULTECH 2016 - 6th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

340

Figure 2: Meta-model of our tool.

act like pipeline; they can process several items in

a queue.

The flow is controlled through activation rules that

relates to order books and procurement policies.

• On Order activation represents on-demand pro-

duction triggered by a specific order book.

• Stock monitoring are used to implement different

procurement policies (or possibly internal stock

transfers) based on different possible models.

2.2 Query Language Overview

We remind here the main operators that can be used

to express queries allowing the risk analyst to evalu-

ate specific risks on the model. The language can also

be used to collect other kinds of Key Performance In-

dicators (KPIs) that are also useful to quantify and

reason about the risk impacts.

Queries for Processes

These are atomic operators that extract basic metrics

from processes of the simulation model. Suppose that

p is such a process:

• t |= completedBatchCount(p) the total number of

batches performed by p until time t.

• t |= startedBatchCount(p) the number of batches

started by p until time t. For a multi-line process,

it sums up the started batches of each line.

• t |= totalWaitDuration(p) the total duration where

p was not running until time t. For a multi-line

process, it sums up the waiting time of each line.

• t |= meanLoad(p) is the ratio between of the com-

pleted batches and the total capacity until time t.

• t |= anyBatchStarted(p) true if a batch was started

by the process at time t.

Queries for Storages

These are atomic operators that extract basic metrics

from stores of the simulation model. Suppose that s is

such a store:

• t |= empty(s) true if s is empty at time t, false oth-

erwise.

• t |= content(s) the number of items in s at time t.

• t |= capacity(s) the (fixed) maximal capacity of s.

• t |= totalPut(s) the number of items put into s until

time t, not counting the initial ones.

• t |= totalFetch(s) the number of items fetched

from s until time t.

• t |= totalLostByOverflow(s) the number of items

lost by overflow from s until time t.

Operators

Complex queries can be built using following opera-

tors, some of them also referring to one or more states

of the considered trace:

• logical: true,false,not(!),and(&),or(k),<,>, ...

• temporal logic: hasAlwaysBeen,hasBeen,since, ...

• arithmetic: +,−,∗,/, sum,...

• temporal arithmetic: delta,cumulatedDuration,

time,min,max, avg,integral...

3 COMPLEX ASSEMBLY CASE

STUDY

The product under investigation is relatively simple, it

consists of three components, which are procured ex-

ternally. The production process can be characterised

as an order-driven, small batch, job shop production

as depicted in Figure 3.

Figure 3: Complex Assembly Case Study.

Materials A and B are delivered on a regular basis

and kept on stock, whereas component C is ordered

based on the current demand. Whenever a new cus-

tomer order arrives, inventory is checked. If enough

parts are available, the order is released and the pro-

duction process starts. If not, the order has to wait

until new supplies arrive causing a delayed start of

Query-based Risks Management of Manufacturing Processes

341

production and potentially delayed deliveries. Mate-

rials A and B are polymer materials stocked as mats

out of which single components need to be cut in a

first production step prior to assembling and process-

ing all three components. Completed orders are di-

rectly shipped and no final products are kept in stock.

4 RISK-ORIENTED MODELLING

The modelling tool is based on a web-based graphical

editor using the JointJS (ClientIO, 2016) JavaScript

library. The modelling is done using drag and drop

and a property editor can be used to specify the re-

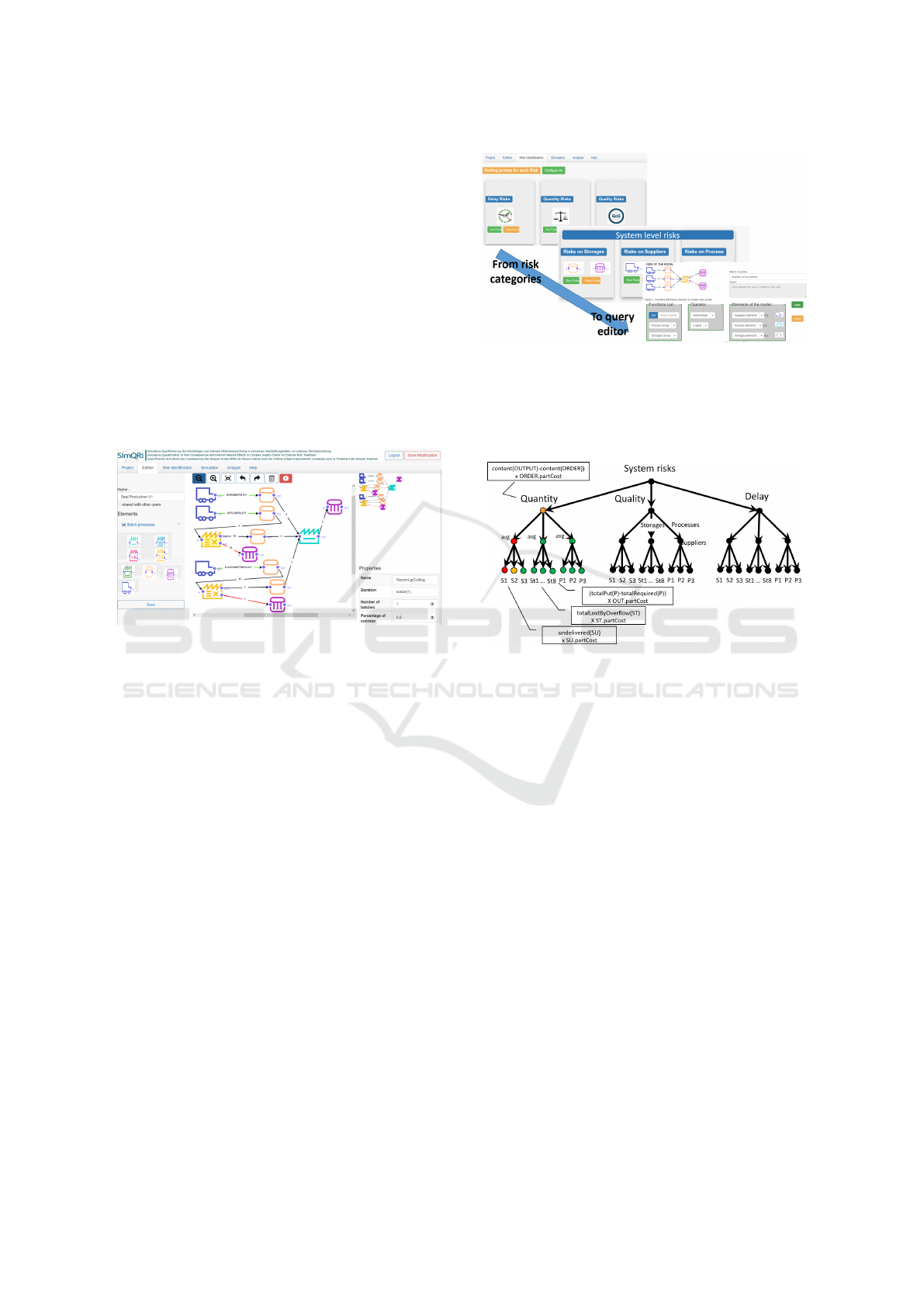

quired parameters. Figure 4 shows the modelling tab

of the user interface for our case study.

Figure 4: Risk-oriented modelling.

Stochastic values can be introduced in several

places, either integer (e.g. delivered quantity) or

real (e.g. delay) data types can be instantiated us-

ing respectively discrete and continuous probability

distributions. Specific components also have a na-

tive stochastic behaviour (e.g. processes with a failure

rate).

5 RISK IDENTIFICATION

After modelling a factory, the analyst can then move

to the risk identification tab of the interface. The tool

includes a wizard helping the user to express risk us-

ing our query language. A succession of screenshots

of this wizard is shown in Figure 5. It starts from

the main risk categories (quantity/quality/delay), then

guides the user into specifying how the risk can be

measured both at system level and then at component

level. At system level, the risk impact will be mea-

sured in monetary terms in order to allow the aggre-

gation and comparison of different kinds of risks. Of

course, component level risks does not always involve

a system: the goal is actually to design the system to

be resistant to component level risk occurrence. Fig-

ure 6 shows our simple generic risk model. With this

Figure 5: Encoding a query for a quantity risk.

model, generic queries can be defined for component

level while the risk analyst has to provide problem

specific queries that computes the mitigated risk at

system level.

Figure 6: Overview of our generic hierarchical risk model.

In the context of our case study, we defined the

following quantity risks:

• at system level, the global OUTPU T stor-

age can be compared with an ORDER book:

(content(OUT PUT ) − content(ORDER)) ∗

ORDER.partCost. We here use the agreed order

cost which may differ from the production cost.

• at component level, specific risks indicators

might, for a storage can be an overflowing

or full storage, raise quantity risk flags with

totalLostByOver f low(ST ) ∗ST.partCost. A sup-

plier might also fail to deliver the required quan-

tity undelivered(SU) ∗ SU.partCost. For a pro-

cess, meanLoad(P) can be an indicator if it is sat-

urating at 100%. The loss can be evaluated us-

ing the difference between measured and expected

production for a given process: (totalPut(P) −

totalRequired(P)) ∗ OUT.partCost

A number of predefined queries are available in each

context. Queries can also be edited and designed from

scratch using a plain text editor. Figure 5 shows the

encoding of a quantity risk measuring the number of

lost pieces in a factory.

SIMULTECH 2016 - 6th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

342

6 RISK-ORIENTED SIMULATION

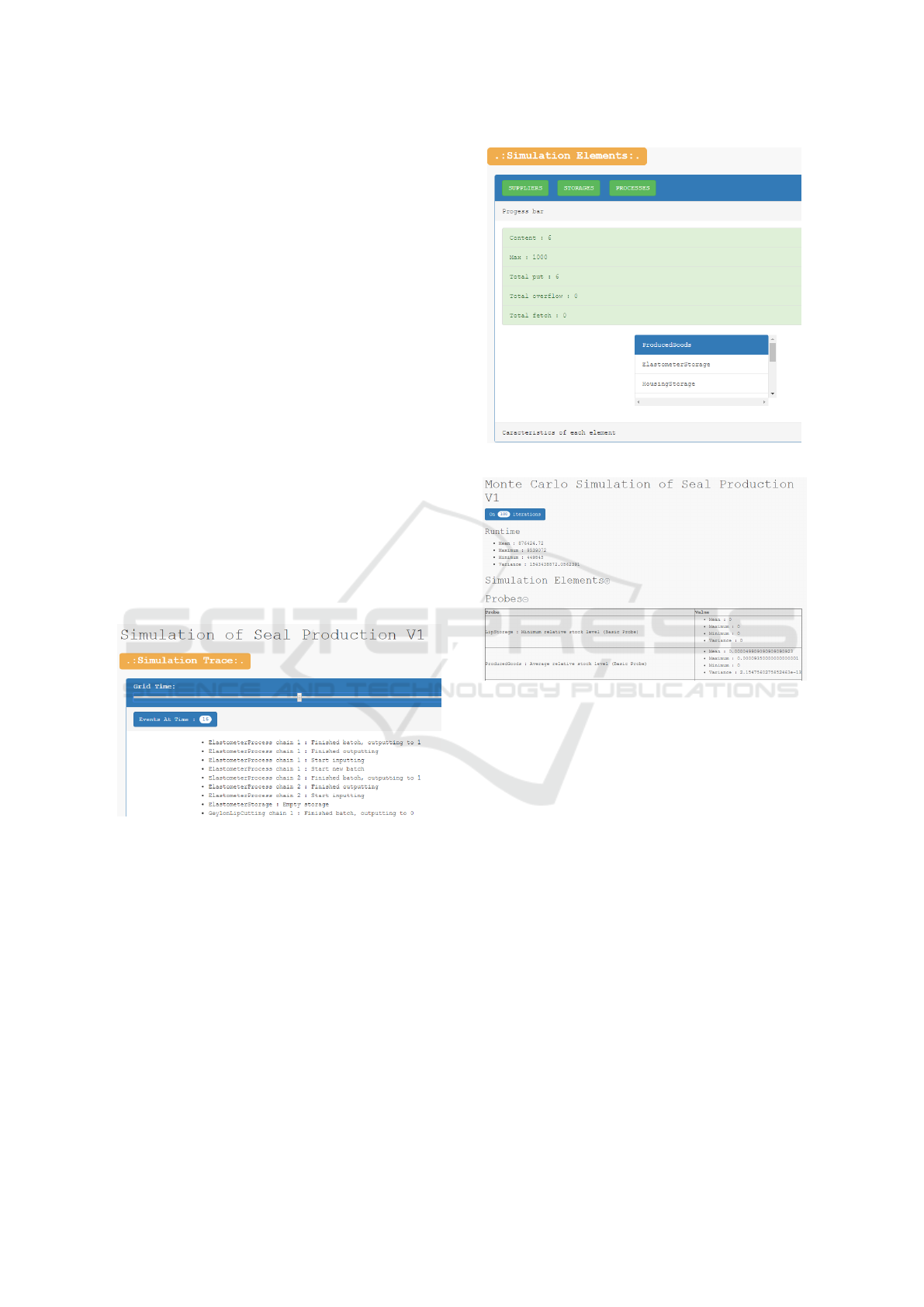

The next tab is devoted to running the simulator on

the model together with the queries to collect all the

required risk information. The simulator can be run in

two modes that are detailed in the rest of this section:

• in ”One Shot” mode, the simulator will return a

single trace with no statistical meaning. The trace

can be analysed to make sure about the general

behaviour of the supply chain and factory.

• in ”Monte Carlo” mode, the simulator will not

collect individual traces. Instead, it will compute

statistical information over the set of traces.

6.1 Trace Analysis

Different tools are available for trace analysis. The

first tool enables to explore a single trace using a

slider. At each event occurrence, the slider shows the

time and what occurred at that specific time. Time

is continuous, and expressed in an arbitrary unit, de-

cided for the whole model (it can be hours, seconds or

milliseconds depending on the domain and the risks).

Figure 7 shows the trace tool displaying a specific

time of a simulation of our case study.

Figure 7: Trace analysis tool.

Focusing on this specific time, it is possible

to zoom on any specific element or any query.

Figure 8 shows the state of the final storage for

ProducedGoods at time 11.

6.2 Statistics Overview

In Monte Carlo mode, the risk analyst can check

some key statistic indicators of the model elements

and queries, such as minimum, maximum, mean and

standard deviation (Figure 9). The full distribution of

the simulation data is available to the client for more

complex analysis.

Figure 8: Element detail at a specific time of a trace.

Figure 9: Overview of statistical data on queries and ele-

ments.

7 RISK ANALYSIS AND

MITIGATION ACTIONS

7.1 Risk Dashboard

Figure 10 shows the risk management dashboard at

the top-level for our case study. It displays a pie chart

representing the relative importance of the three main

risks (quality, quantity and delay) estimated at the sys-

tem level. The probability distribution of those three

risk factors are displayed in the bottom part. A dia-

gram on the left part also displays the evolution over

time of specific queries (by default the total risk). Two

curves are drawn: one displaying the expected value

(mean) of the indicator and the other displaying the

Value at Risk (VaR), i.e. the threshold loss value,

such that the probability that the loss over the given

time horizon exceeds this value is p (e.g. 5%) (Jorion,

2006). It is then possible to zoom in specific risk cate-

gories and explore how specific processes, storage or

Query-based Risks Management of Manufacturing Processes

343

Figure 10: Top-level dashboard of the risk analysis.

suppliers behaves with respect to a specific risk.

7.2 Risk Control

Controlling the risks requires tuning the model in or-

der to minimise the estimated costs induced by risks.

However, changing a parameter in the model might

have multiple and possibly conflicting effects. The

tool supports a simple way to change the values of

some parameters to find out their optimal values,

given that other parameters remain constants. The

risk analyst can then perform a tuning-simulation-

analysis process on the model in order to find out the

best alternative to control the risk.

Table 1: Optimisation of the ordering threshold.

Ordering Threshold Size Process Idle Time

0 (wait empty) 70%

10 34%

20 5%

30 0.01%

40 0%

Table 1 shows the effect of the ordering thresh-

old on the idle time of the process directly fed by that

supplier. A zero threshold will result in a quite high

idle time as the process will have to wait the whole

delivery time. As the threshold is increased, the pro-

cess idle time is decreasing, but beyond the threshold

of about 30 parts, it reaches its full rate. There is no

reason to increase it more, since it will result in more

frequent deliveries and thus higher procurement costs.

8 CONCLUSIONS

In this paper, we presented a web-based interface al-

lowing to support risk assessment for supply chains

based on a simple risk model and a supply chain

model instrumented with risk queries. The risk model

can be easily instantiated using wizards and results

in an easy to interpret risk dashboard after the model

simulation. The tool relies on an efficient engine

able to perform large number of simulations includ-

ing stochastic parameters.

Our current experience with the tool is quite pos-

itive. We are carrying out a validation of the tool

on real-world cases provided by SMEs from Wallo-

nia and Germany. We are also enhancing the wizards

to help formulating common system-level risks. An-

other demand is to support a desktop-based interface.

To this purpose, we are implementing another front-

end relying on the Eclipse using EMF modelling and

the Sirius editor (Obeo, 2016).

ACKNOWLEDGEMENTS

This research was conducted under the SimQRi

research project (ERA-NET CORNET, Grant No.

1318172). The CORNET promotion plan of the Re-

search Community for Management Cybernetics e.V.

(IfU) has been funded by the German Federation of

Industrial Research Associations (AiF), based on an

enactment of the German Bundestag.

REFERENCES

ClientIO (2016). JointJS website. http://jointjs.com.

Landtsheer, R. D., Ospina, G., Massonet, P., Ponsard, C.,

Printz, S., Hrtel, L., and von Cube, J. P. (2016). A

Discrete Event Simulation Approach for Quantifying

Risks in Manufacturing Processes. In Int. Conf. on

Op. Research and Enterprise Systems (ICORES).

Deleris, L. and Erhun, F. (2005). Risk management in sup-

ply networks using Monte-Carlo simulation. In 2005

Winter Simulation Conference, Orlando, USA.

Jorion, P. (2006). Value at Risk, 3rd Ed.: The New Bench-

mark for Managing Financial Risk. McGraw-Hill.

Obeo (2016). Sirius Obeo Designer.

http://www.obeodesigner.com/sirius.

OscaR (2012). OscaR: Scala in OR.

https://bitbucket.org/oscarlib/oscar.

Printz, S., von Cube, P., and Ponsard, C.

(2015). Management of procurement risks

on manufacturing processes - survey results.

http://simqri.com/uploads/media/Survey Results.pdf.

Wieland, A. and Wallenburg, C. M. (2012). Dealing with

supply chain risks: Linking risk management prac-

tices and strategies to performance. Int. Journal of

Physical Distribution & Logistics Mngmt, 42(10).

SIMULTECH 2016 - 6th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

344