Ontological Approach to Share Product Design Semantics for an

Assembly

Baha Hasan

1

, Jan Wikander

1

and Mauro Onori

2

1

Machine Design Department, KTH University, Brinellvägen 85, Stockholm, Sweden

2

Department of Production Engineering, KTH University, Brinellvägen 68, Stockholm, Sweden

Keywords: Assembly Semantic, Assembly Feature, Feature-based Modelling, Ontology, Computer Aided Design

(CAD).

Abstract: The aim of this paper is to facilitate the transfer of product data semantics from Computer Aided Design

(CAD) program to assembly process planning (APP) in product life- cycle. In this paper, an approach to

capture, share and transfer assembly design semantic data from SolidWorks (SW) CAD software to

assembly device (robot Sony SRX series) is proposed. The proposed approach is based, on its first stage, on

defining and extracting assembly design semantics from a CAD model using SolidWorks Application

Programmable Interface (SW- API). The second stage of the proposed approach includes sharing and

integrating the extracted assembly design semantics with assembly robot device by using three-layer

ontology structure. In this layered ontology, different types of ontologies are proposed for each layer:

general foundation ontology for the first, domain ontologies for the second and application ontology for the

third. Each of these layers aids in defining concepts, relations and properties in assembly design domain and

APP domain. Ultimately, the proposed ontology will be used to integrate both domains in product-life cycle.

1 INTRODUCTION

During the last decades, the necessity of data sharing

and integration among different users and

applications in product-life cycle has been increased.

For example, the product / assembly design semantic

data stored in a specific CAD model needs to be

delivered to different CAD softwares or to be

analyzed by different softwares.

Two methods have been proposed to facilitate

product / assembly design data transfer among

different applications and users: external and

internal (Miao et al., 2002). In external method

product data is transferred using a standard neutral

data format, such as IGES or STEP, while in the

internal method API (application programmable

interface) functions have been used to recognize and

extract product design data from CAD model. Both

methods have some limitations in sharing product /

assembly data. In both methods data has been

transfer from user to user or from application to

application but not from domain to domain. Another

limitation is the data lost during conversion from

one format to another format in the external method

and the syntactical transfer of data in the internal

method. In order to overcome those limitations,

ontology approach to share product / assembly

design semantics has been proposed.

Recently, the ontology and semantic Web

technology has been widely applied in integrating

product design and different applications in product-

life cycle. Ontology can be regarded as “a data

model that represents a domain and is used to

reason about the objects in that domain and

relations between them” (Gruber, 1993). Ontologies

have been used to capture and share product design

knowledge, to integrate engineering applications and

to solve interoperability problems (Patil et al., 2005).

Ontologies specify “a domain-specific vocabulary of

entities, classes, properties, predicates, and

functions, and a set of relationships that necessarily

hold among those vocabulary items” (Fikes and

Farquhar, 1999). Ontological approach has been

used either in modelling or retrieving product /

assembly design semantics generated during design

process. By ontology querying, data can be retrieved

and by ontology reasoning, data that are not

expressed explicitly can be derived from the

ontology.

In this paper, a proposed approach, based on

ontology, to integrate SolidWorks (SW) CAD

104

Hasan, B., Wikander, J. and Onori, M.

Ontological Approach to Share Product Design Semantics for an Assembly.

DOI: 10.5220/0006051701040111

In Proceedings of the 8th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2016) - Volume 2: KEOD, pages 104-111

ISBN: 978-989-758-203-5

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

software in assembly design domain and assembly

robotic device in Assembly Process Planning (APP)

domain is introduced. The integration framework of

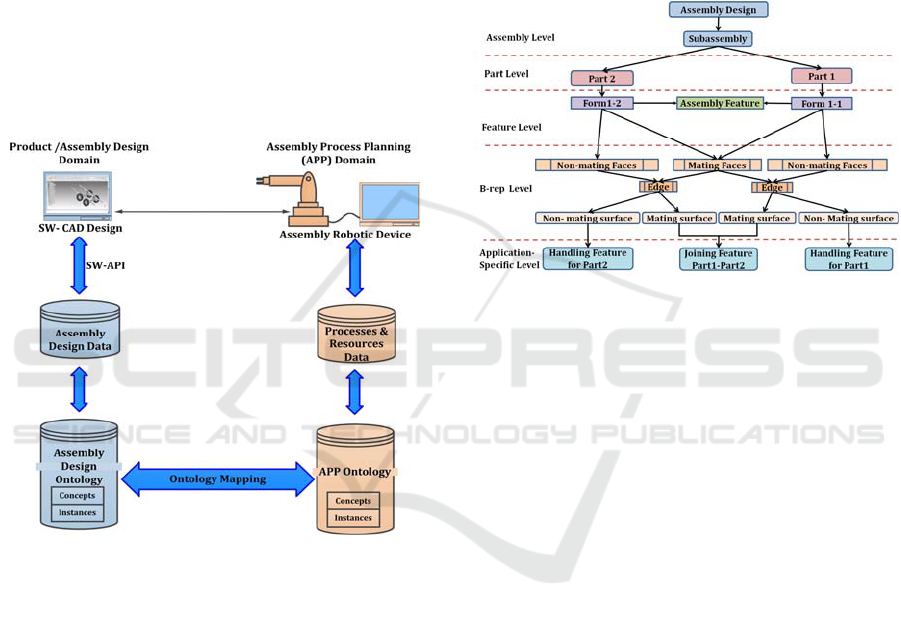

the proposed approach is illustrated in Figure.1. In

Figure 1, the first stage of integration is to extract

and model assembly design data from SW- CAD in

assembly design domain (using SW- Application

Programmable Interface (SW-API)), and processes

and resources data from assembly robotic device in

the APP domain. The second stage includes sharing

the extracted assembly design data by assembly

design ontology and processes and resources data by

APP ontology. The integration of the assembly

design domain and APP domain will be achieved by

ontological mapping between assembly design

ontology and APP ontology, which represents the

third and last stage in the integration framework.

Figure 1: Integration framework between assembly design

and APP.

This paper is mainly focused on the first and

second stages of the integration framework. This

paper is structured as follows: Section 2 introduces

briefly assembly design semantic model based on

assembly features. Section 3 introduces the proposed

ontology for sharing the extracted semantic data

from the previous section, and integrating SW CAD

software with assembly robotic device. Section 4

draws a conclusion and provides a summary.

2 ASSEMBLY SEMANTIC

MODEL

The most representative assembly design modelling

methods are based on features (Shah and Rogers,

1993), constraints (Ma et al., 2004) and assembly

semantics (Liu et al., 2000). According to Liu et al.

(2000) assembly semantics is defined as “the

abstract description of assembly relationships,

which implies the constraint between parts,

assembly rule, assembly knowledge and assembly

action”. In this paper, assembly semantic model,

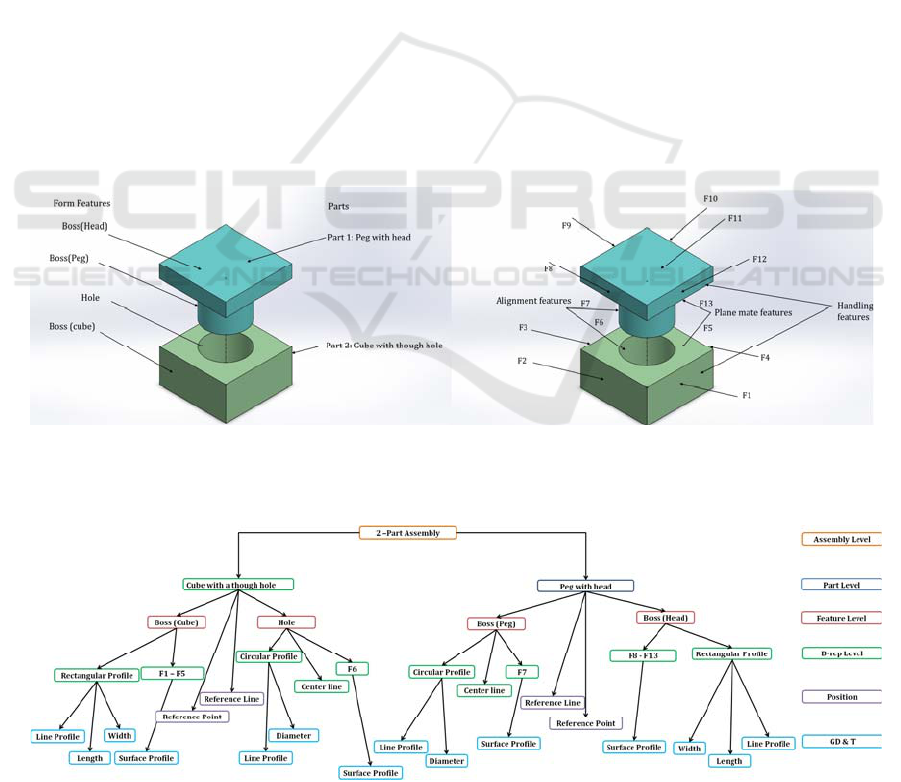

based on features, is developed (Figure 2) to model

assembly design data extracted from SW- CAD

software.

Figure 2: Assembly design semantic model.

In Figure 2, a multi-level assembly semantic

model is illustrated; each layer conducts different

details about assembly design. Assembly and part

levels concern about structural information of an

assembly, each product is composed of several

subassemblies, and each subassembly is composed

at least from two parts. The feature level is

concerned about geometrical and assembly

knowledge enclosed in form and assembly features.

Assembly feature is defined as an association

between two form features from different parts in a

product (Shah and Rogers, 1993), where form

feature is defined as “specific configurations on

surfaces, edges, or corners of a part such as holes,

slots etc. that carries some engineering meaning”

(Wingard, 1991).

Each part is composed at least of one form

feature, which is associated with another form

feature, from different part, via an assembly feature.

The next B-rep entity level conducts more specific

knowledge about geometrical entities involved into

assembly relation. B-rep modelling decomposes a

solid into its boundary surfaces or shells. Each shell

can be decomposed into individual faces. Each face

is described as a surface bounded by a loop of edges.

Each edge is bounded by two vertices. In the B-rep

level, each form feature is composed from mating

faces (faces with assembly relations) and non-

Ontological Approach to Share Product Design Semantics for an Assembly

105

mating faces (faces that are not involved in any

assembly relation). Mating and non-mating faces are

decomposed further into mating surfaces and non-

mating surfaces. The last level, which is the

application-specific level, will assign specific

functional features for each surface type to perform

assembly processes.

Mating surfaces will be involved in joining

processes (welding, screwing, fitting, etc.) so they

will be a part of joining features, which are proposed

by (Kim, 2003) to represent assembly/joining

relations, and it includes joining entities, joining

methods, constraints and groove shapes. The non-

mating surfaces will be involved in handling

processes (gripping, feeding and fixturing) so they

will be known as handling features- “characteristics

that give the locations on an assembly component

that can be safely handled by a gripper during

assembly!” (Van Holland, 1997). Further

illustration for the concepts of the assembly

semantic model is presented in peg and though-hole

cube assembly example in Figure 3, the assembly

semantics are illustrated in Figure 4 as well.

In Figure 3, a two-part assembly (part 1:

rectangular head peg and part 2: cube with through-

hole) is presented. The parts and form features of the

assembly are indicated in Figure 3 a. In Figure 3 a,

part 1 consists of two form features: the head and the

peg. Part 2 consists also of another two form

features: the hole and the cube. In Figure 3b, the

two-part assembly is further decomposed into its

elementary boundary faces (B-rep entity). The

mating faces are indicated as plane mate features for

rectangular faces (F13- F5) and alignment feature

for cylindrical faces (F7 –F6). An example about

handling features selected from the non-mating

surfaces is also indicated (F12 from part 1 and F1

from part 2). The assembly semantic model for the

two-part assembly is illustrated in Figure 4. A six-

layer semantic model is presented, where the first

layer is for the assembly, which is composed of parts

and features in the second and third layers. The

features are composed of the B-rep entities like

faces, profile, centerlines, and so on in the fourth

layer. The last two layers are for position/orientation

and geometrical dimension and tolerances (GD&T).

The position layer consists of reference line and

reference point for each part, while the GD&T layer

consists of dimensions and tolerances for each B-rep

entity

Assembly data semantics include well- definition

and usage of assembly design data. Practically,

(a) (b)

Figure 3: (a) Peg and though- hole cube assembly, parts and features (b) Peg and though- hole cube assembly, faces

assembly features.

Figure 4: Assembly semantic model for the two-part assembly.

KEOD 2016 - 8th International Conference on Knowledge Engineering and Ontology Development

106

assembly data semantics, which is built upon

assembly data, is represented by two layers:

knowledge layer and instance layer. The knowledge

layer describes the basic knowledge within any

domain by using a set of generic concepts, relations

between those concepts and axioms applied on

relations. The instance layer, which is more specific

layer, links product data into the knowledge layer by

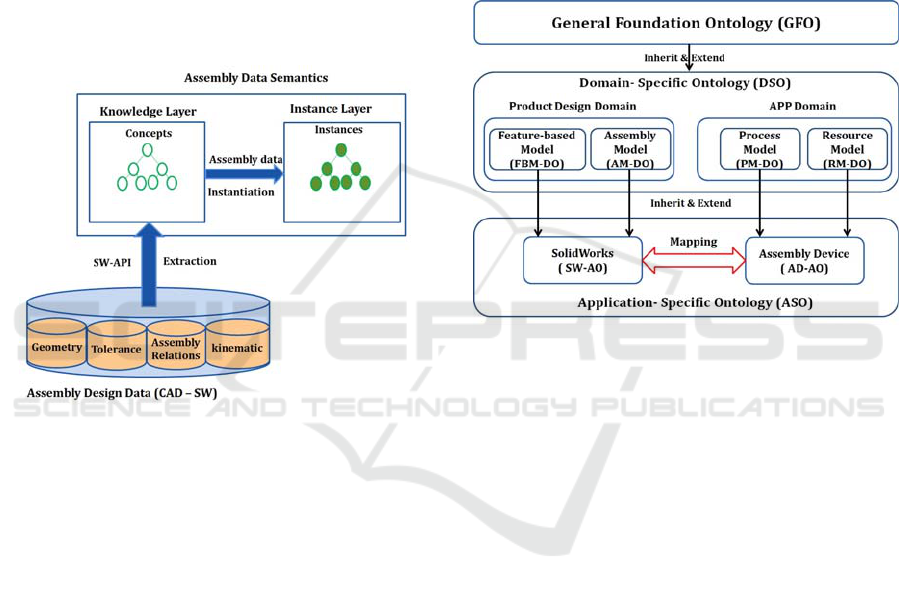

instantiating concepts of the knowledge layer. Figure

5 shows our proposed approach to create product

data semantics by extracting product data (geometry,

tolerance, kinematics and assembly design) from

SW- CAD software using SW-API. The relation

between the knowledge layer and instance layer is

illustrated as well.

Figure 5: Relationship between assembly data and

assembly data semantic knowledge and instance layers.

3 ONTOLOGY DEVELOPMENT

The literature points out that a significant amount of

work has been done on the use of ontologies either

to model assembly design data or to support

integration between design and process in assembly.

Lohse et al. (2006) proposed ontology to support

selection of assembly resources and to support

reconfigurablility of assembly system. Lanz et al.

(2008) proposed ontology to capture design and

process related assembly knowledge based on

assembly feature concept. Delamer and Lastra

(2006) developed an ontology to model assembly

processes. Kim et al. (2003) proposed an assembly

design ontology to support formalism of related

assembly knowledge in product design. Demoly et

al. (2012) proposed an ontology to capture the

product design and assembly sequence planning

knowledge. Mostefai et al. (2006) proposed

ontology to capture the product design data to

support the product development process. Zhan et al.

(2008) and Zhu et al. (2009) proposed layered

structure ontologies to integrate product design and

assembly simulation.

In this paper, a three-layered architecture of

engineering ontologies in product design and APP is

proposed (Figure 6). The proposed structure layered

ontology consists of:

General Foundation Ontology (GFO)

Domain Specific Ontology (DSO)

Application Specific Ontology (ASO)

Figure 6: Three-layered architecture of engineering

ontologies in product design and APP.

The GFO is the first upper layer ontology, which

is designed to provide common concepts, such as

product, feature, material, process, and resource

which are inherited by the DSOs such as FBM-DO,

AM-DO, PM-DO and RM-DO. The Domain

Specific Ontologies represent the second level of the

proposed architecture; those ontologies will add

domain-specific concepts which belong to that

particular domain. The third level is the ASOs (such

as SW-AO and AD-AO); those ontologies will

capture semantics specific to each application. Two

applications have been included: SolidWorks as

product design application and assembly robotic

device (ex. high speed assembly robot Sony SRX

series) as APP application. The knowledge transfer

between different ASOs can be accomplished

through mapping procedures which discovers similar

or matching concepts and properties.

All of the ontologies are implemented by using

the Protégé-OWL editor. In the following

subsections; the three different ontologies of the

layered ontology structure will be discussed.

Ontological Approach to Share Product Design Semantics for an Assembly

107

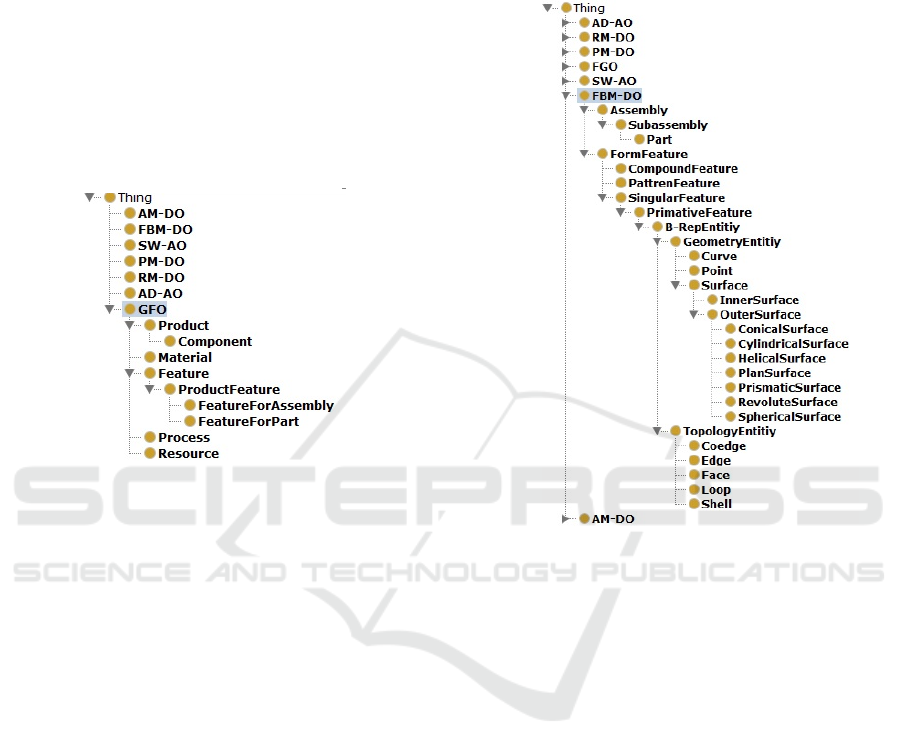

3.1 General Foundation Ontology

(GFO)

Foundation ontologies consist of generic, abstract,

and high level concepts which can be applied to a

wide range of domains. Foundation ontologies also

provide a knowledge base for more specialized

ontologies (Sanchez-Alonso and Garcia-

Barriocanal, 2006). The GFO contains the general

key concepts, which are common and applied to any

of the domains in product design and APP. The

concepts defined in GFO are product, feature,

material, process, and resource (see Figure 7).

Figure 7: Class hierarchy and concepts of the GFO.

The concepts in the GFO ontology have

attributes, which will be inherited by the different

domain ontologies. For example, the Component

subclass, which describes the basic structural design

entity under the product class, will be further

inherited by FBM-DO and SW-AO. FBM-DO will

further embody Component with Assembly,

Subassembly and Part subclasses. The same will be

applied to the Feature class and its subclasses:

FeatureForPart and FeatureForAssembly, which

will be further inherited by the FBM-DO and SW-

AO. The properties defined in FGO are: is-a, is-a-

part-of, is-composed-of and has-attribute-of. The

first two properties reflect the inheritance relations

between different concepts. The last two properties

define the relations between concepts and its

attributes. Each of these ontologies will be discussed

in the following subsections.

3.2 Domain Specific Ontology (DSO)

The DSO layer consists of four domain ontologies

(DO). Two of those are in the product design

domain, namely the Feature-based Model (FBM-

DO), and the Assembly Model (AM-DO), and the

other two are in the APP domain, namely Process

Model (AM-DO) and Resource Model (RM-DO).

Each DO reuses concepts and properties from the

FGO and defines more specified, expanded and

specialized concepts/ properties for a particular

domain.

Figure 8: Class hierarchy and concepts of the FBM-DO.

The FBM-DO is created to capture knowledge

about a product’s structure and form domain. In

Figure 8, the FBM-DO expands the product

structure and geometry based on feature modelling.

Assembly, Subassembly and Part classes represent

the product basic structure, where the Subassembly

is composed at least of two parts. The Part class is

further decomposed into its features. Each part is

composed at least of one form feature. The

FormFeature class is decomposed according to

complexity into: PatternFeature, SingularFeature,

and PrimitiveFeature. PrimitiveFeature, which is

considered as the basic form feature unit is further

decomposed into B-RepEntity class, which will be

decomposed further into the very basic geometrical

and topological entities: GeometryEntity and

TopologyEntity. GeometryEntity has attributes

Surface, Curve and Point. The Surface class includes

all different types of surfaces used in geometric

modelers. TopologyEntity has attributes Edge, Shell,

Loop, Face, and Co-edge.

AM-DO is created for assembly modelling as

part of the product design domain (see Figure 9). If

KEOD 2016 - 8th International Conference on Knowledge Engineering and Ontology Development

108

the FBM-DO represents the form attribute

(geometrical and structural information) of the

product design, AM-DO represents the behaviour of

the design unit during assembly. AM-DO includes

three major subclasses: SpatialRelationship,

DegreeOfFreedom, and AssemblyFeature.

SpatialRelationship expresses the relative positions

of parts in an assembly in their final state.

DegreeOfFreedom is used to describe the motion

(translation and rotation) of parts during assembly.

The third subclass, AssemblyFeature, is composed

of Mating, Alignment, Handling, Joining, and

Tooling features. The AssemblyFeature class

introduces necessary assembly design information to

establish a link with assembly processes and

resources for APP.

Figure 9: The class hierarchy and concepts of the AM-DO.

Joining features, with further specializations

(welding features, fastening features etc.); represent

a link for integration with joining processes.

Handling and tooling features represent a link for

integration with assembly resources. Handling

features represent the geometrical characteristics of

the part that are needed to determine the required

assembly transporting resources such as fixture,

feeder, and gripper. Tooling features represent the

geometrical characteristics of the part’s shape that

are needed to determine the required assembly

tooling resources. An example of the tooling

features is the shape and size of the screw’s head,

which are required to determine the suitable tool.

The next two DSOs are the PM and the RM of

the APP domain. The PM-DO is illustrated in Figure

10, where the process class in GFO is expanded and

inherited by PM-DO into AssemblyProcess and

ManufacturingProcess classes. The

AssemblyProcess class is further expanded into

JoiningProcess and HandlingProcess classes. The

JoiningProcess class is composed of subclasses

representing different joining processes in APP such

as Welding and Fastening. The HandlingProcess

class is composed of Gripping, Feeding, and

Fixturing subclasses.

Figure 10: The class hierarchy and concepts of the PM-

DO.

The RM-DO represents manufacturing and

assembly resources in APP (Figure 11). The

AssemblyResource class is further decomposed into

several subclasses according to complexity from

Enterprise and Factory subclasses into Area, Line,

Cell, DeviceCombination, and IndividualDevice.

Figure 11: The class hierarchy and concepts of the RM-

DO.

The IndividualDevice subclass is further

inherited by AD-AO in the ASO layer, which will be

discussed in the next subsection.

3.3 Application Specific Ontology

(ASO)

So far, the ASO represents the lowest/ level of the

proposed ontology. ASO defines more specified,

Ontological Approach to Share Product Design Semantics for an Assembly

109

expanded and specialized concepts/properties for a

particular application. ASO is used to transfer

product data semantics between different

engineering applications. In this paper, two ASOs

are developed: SW-AO to share product design data

semantics from SolidWorks CAD software, and AD-

AO to utilize assembly processes and resources in

converting product data semantics into an assembly

process plan for performing assembly of a finished

or semi-finished product.

SolidWorks, as a commercial product design

package, has been widely used as a 3-D geometrical

modeler in various product life-cycle and product

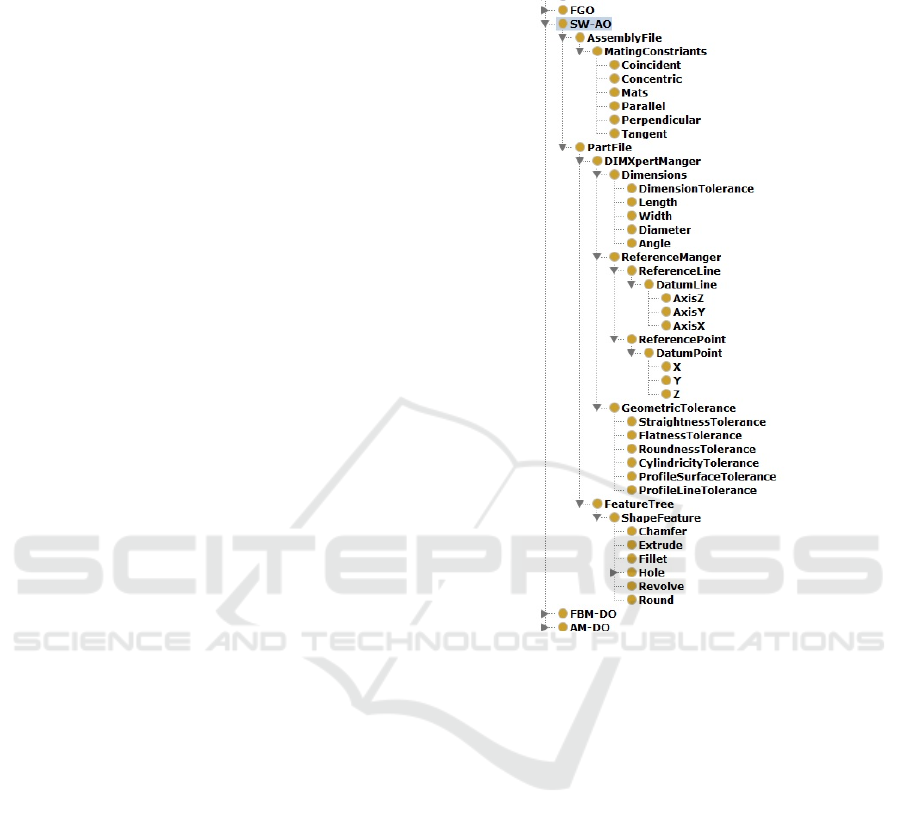

development applications. SW-OA (Figure 12)

inherits and expands concepts from ontologies at

higher levels such as FormFeature from FBM-DO

and MatingFeature from AM-DO. For example,

FormFeature from FBM-DO inherits and expands

into Round, Revolve, Hole, Fillet, Extrude, and

Chamfer under ShapeFeature class in the SW-AO.

MatingFeature from AM-DO inherits into

Concentric, Tangent, Perpendicular, Parallel and

Coincident under AssemblyConstriants in the SW-

AO. SW-AO also defines unique concepts, which

are only used in SW. An example of the unique

classes in SW-AO is the DimXpertManger. This

class is composed of several subclasses such as

ReferenceManger, GeometricTolerance, and

Dimensions. The ReferenceManger subclass

determines positional parameters of the features.

Data for lines and points have been determined

under Datumline and DatumPoint, respectively. The

two subclasses GeometricTolerance and Dimensions

include all different types of dimensions and

tolerances, which have a direct impact on

geometrical variations in the assembly design.

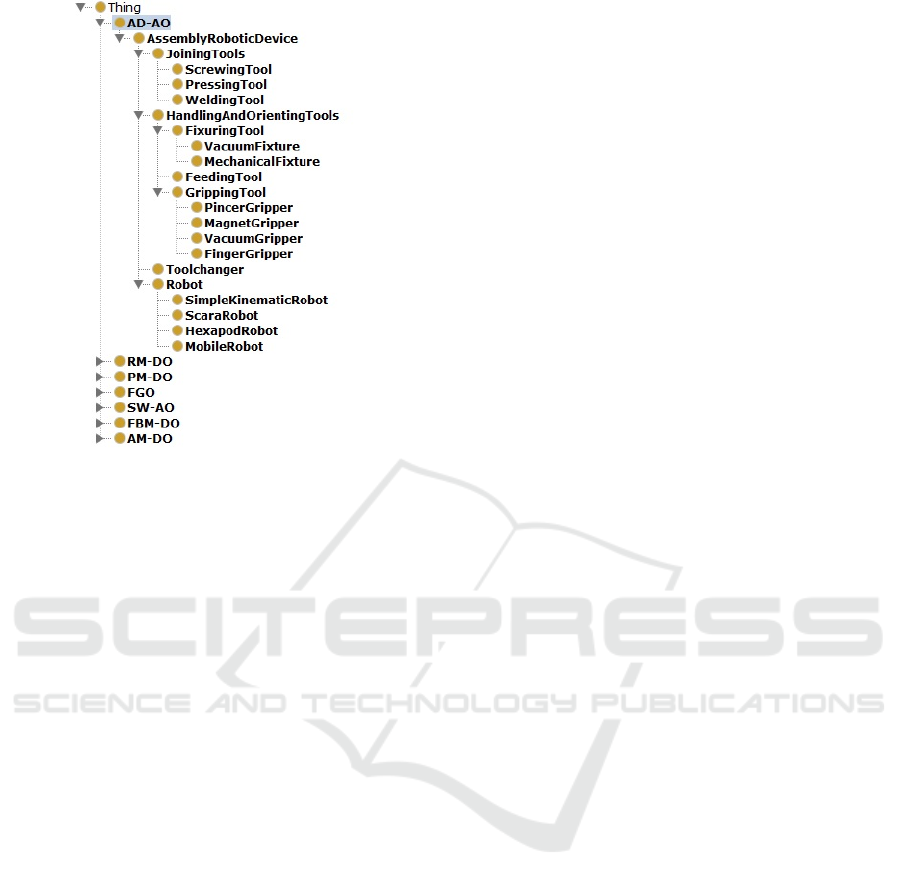

The SD-AO (Figure 13) represents robotic

assembly device and consists of several units, which

are represented by subclasses:

HandlingAndOrientingTools, JoiningTools,

ToolChanger and Robot. The first two subclasses

include all different tools that will be used in

handling, orienting and joining parts during

assembly. The FixturingTool, GrippingTool and

FeedingTool are subclasses for the

HandlingAndOrienting class. Different types of

gripping tools as PincerGripper

, MagnetGripper,

VacuumGripper and FingerGripper under

GrippingTool subclass. Attributes and properties

could be defined for each gripper type such as

gripping range, gripping power and force.

JoiningTools includes WeldingTool, PressingTool,

and ScrewingTool. The Robot class includes

different robots that are commonly used in robotic

assembly devices such as ScaraRobot, MobileRobot,

and HexapodRobot.

Figure 12: Class hierarchy and concepts of the SW-AO.

The integration between product design domain

and APP will be performed through a mapping

procedure between SW-AO and SD-AO. The

processes and resources represented by different

tools in SD-AO will be selected according to the

product design semantics represented in SW-AO.

For example, a width dimension in Dimensions class

in SW-AO may determine the type of gripping

(whether it is finger gripping or magnet gripping) in

SD-AO. Another example is that a type of a hole in

ShapeFeature class in SW-AO might determine the

joining tool in SD-AO.

The ontology part in this paper will be expanded

in further work by defining axioms for the FDO and

properties for the DSOs and ASOs. Also a detailed

mapping procedure based on defined properties of

SW-AO and AD-AO has to be performed in the

future work.

KEOD 2016 - 8th International Conference on Knowledge Engineering and Ontology Development

110

Figure 13: Class hierarchy and concepts of the SD-AO.

4 CONCLUSIONS

In this paper, a proposed approach for extracting and

integrating product design semantics to APP is

proposed. The proposed approach based on

extracting the related assembly design knowledge by

using SW-API, and on structure-layered ontology

for sharing and integrating product design semantics

with APP. Future work includes upgrading the

structure-layered ontology by developing the

ontological mapping procedure between assembly

design domain and APP.

REFERENCES

Delamer, I. M., & Lastra, J. L. 2006. Ontology modeling

of assembly processes and systems using Semantic

Web Services. International conference on industrial

informatics (pp. 611-617). IEEE.

Demoly, F., Matsokis, A., & Kiritsis, D. 2012. A

Mereotopological product relationship description

approach for assembly oriented design. Robotics and

Computer-Integrated Manufacturing, 28, 681–693.

Fikes, R., and Farquhar, A., 1999. Distributed

Repositories of Highly Expressive Reusable

Ontologies, IEEE Intelligent System, vol. 14, no. 2,

pp.73-79.

Gruber, T. R., 1993. Toward Principles of the Design of

Ontologies Used for Knowledge Sharing, International

Workshop on Formal Ontology in Conceptual

Analysis and Knowledge Representation.

Kim, K. 2003. Assembly operation tools for. Assembly

operation tools for e product design and realization.

PhD dissertation thesis. University of Pittsburgh.

Lanz, M., Garcia, F., Kallela, T., & T, R. 2008. Product-

process ontology for managing assembly specific

knowledge between product design and assembly

system simulation. In S. K. Svetan Ratchev, Micro-

Assembly.

Technologies and Applications (Vol. 260, pp. 99-108).

Boston: Springer.

Liu, Z. Y., Tan, J. R., Zhang, S. Y. and Jian, Z. F, 2000.

Design semantics of assembly modeling in virtual

environment: expression, transfer and transformation,

Chinese Journal of Computers, Vol. 23 No. 11, pp.

1208-14.

Lohse, N., Hirani, H., & Ratchev, S. 2006. Equipment

Ontology for modular reconfigurable assembly

systems. International journal of flexible

manufacturing system, 17, 301-314.

Miao, H. K., Sridharan, N., & Shah, J. J., 2002. CAD-

CAM integration using machining features.

International Journal of Computer Integrated

Manufacturing.

Mostefai, S., Bouras, A., & Batouche, M. 2006. Effective

collaboration in product development via a common

sharable ontology. International Journal of

Computational Intelligence, 206-212.

Patil, L., Dutta, D., and Sriram, R., 2005. Ontology-Based

Exchange of Product Data Semantics, IEEE

Transactions on Automation Science and Engineering,

vol. 2, no. 3, pp. 213-225.

Sanchez-Alonso, S., & Garcia-Barriocanal, E. 2006.

Making use of upper ontologies to foster

interoperability between SKOS concept schemes.

Online Information Review, 30(3), 253-277.

Shah, J. and Rogers, M. 1993. Assembly modeling as an

extension of feature-based design. Research in

Engineering Design, 5(3-4), pp.218-237.

Van Holland, W. 1997, Assembly features in modelling

and planning, PhD thesis, Delft University of

Technology.

Wierda, L., 1991. Linking Design, Process Planning and

Cost Information by Feature-based Modelling. Journal

of Engineering Design, 2(1), pp.3-19.

Wingard, L. 1991, Introducing Form Features in Product

Models, A step Towards CAD CAM with Engineering

Terminology, Licenciate Thesis, KTH: Royal Institute

of Technology.

Zhan, P., Jayaram, U., Jayaram, S., 2008. A Semantic

Approach for CAD/CAE Integration, Proceedings of

2008 NSF Engineering Research and Innovation

Conference.

Zhu, L. J., Jayaram, U., Jayaram, S., and Kim, O., 2009.

Ontology-Driven Integration of CAD/CAE

Applications: Strategies and Comparisons, ASME

IDETC/CIE Conference.

Ontological Approach to Share Product Design Semantics for an Assembly

111