3D Printing and Additive Manufacturing Capability Modelling

Vaughan Michell

University of Reading, Whiteknights, Reading, U.K.

v.a.michell@henley.ac.uk

Keywords: 3D Printing, Capability, Affordance, Capability-Affordance Model, Additive Manufacturing.

Abstract: The use of 3D, or additive manufacturing, is becoming more widespread and is seen as a new industrial

revolution due to the advantages of a material deposition approach compared to material removal. However,

little work has been done to identify and formalise the capabilities of this new technology. This paper formally

analyses the generic 3D printing process of additive manufacturing and compares it with the traditional

subtractive manufacturing process using the capability affordance model to determine its unique capabilities.

The CAM model defines a capability as a mechanism and space-time path. Results show that whilst the

mechanisms differ in terms of force and heat drivers, it is the space time path topology that is key to

manufacturing capability differences. We apply a topological analysis to identify the unique affordance path

of 3D printing which clearly demonstrates its superiority in complex and integrated part manufacture. Finally

we outline the differences in the key capability affordance factors for manufacturing in the two methods. This

paper builds on earlier work concerning the capability affordance model as a knowledge model to analyse and

understand capabilities and the unique advantages and possibilities of 3D printing.

1 INTRODUCTION

Rapid prototyping (RP) is an additive manufacturing

technology based on the addition of materials layer

by layer instead of traditional cutting and removal of

material in subtractive manufacturing (SM) (Berman,

2012). RP was developed to provide a general

fabrication machine enabling construction of

complex 3 dimensional (3D) shapes and to use

designs directly from CAD (Choi and Samavedam,

2002). The term rapid prototyping – RP is often used

to describe the rapid fabrication of parts and

prototypes layer by layer (Berman, 2012). The term

additive manufacturing (AM) is used to generally

denote technology where fabrication of parts and

products occur by adding or depositing material.

Three dimensional printing (3DP) is really a

versatile consumer adaptation of rapid prototyping

technologies evolved from additive manufacturing by

adding a 3rd vertical z dimension to the general

architecture of a typical x-y inkjet or laser printer.

This greatly reduces the cost of the RP/AM machine

by several orders of magnitude, making it affordable

to companies and end users alike. Instead of ink, 3D

printing deposits material, usually hot plastics or their

derivatives. The print head thus becomes a means to

deposit the material as a fluid deposition of 3d

cylinders or ‘slugs’ of material in successive layers

(Berman, 2012). Pham and Guilt (Pham and Guilt,

2012) identified up to eight different technology

approaches to additive manufacturing. For

comparison purposes this paper focuses on a

frequently used 3DP technology where a heater melts

a suitable material and temperature sensors ensure the

correct flow viscosity. To enable a continuous feed of

material a series of rollers is used to drive the plastic

filament at the correct rate to be melted.

1.1 3D Printing Fabrication

3D printers enable CAD models to be converted to a

series of layers that can be printed one layer at a time.

This layer based model is typically in the form of a

stereo lithography or STL file. The STL file records

the surface shape/section of each layer, The internal

structure is reduced to a series of diagonal webs to

reduce both the volume and density of the

construction and the time taken to print it compared

to a solid layer. STL files can be generated from

traditional CAD packages by electronically slicing

the design.

The key to 3DP business success is reducing costs

and complexity of part creation whilst integrating

with consumer software (Pham and Guilt, 2012). For

this reason printing plastics have focused on

73

Michell V.

3D Printing and Additive Manufacturing Capability Modelling.

DOI: 10.5220/0006222400730083

In Proceedings of the Sixth International Symposium on Business Modeling and Software Design (BMSD 2016), pages 73-83

ISBN: 978-989-758-190-8

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

thermoplastics PLA and ABS (Bassett et al., 2015).

However thermoplastics have their own

limitations of strength and robustness as PLA suffers

from degradation. The 3D object is built by

depositing material from the minimum of a point

‘blob’ to an x-y plane of material. Moving the bed on

which the material is deposited along the

perpendicular z axis away from the print head enables

the model to grow vertically. Additional control of the

deposition process is usually achieved by heating the

build bed or enclosing the build volume with a case

to optimise the conditions for solidification without

cracking.

Another fabrication benefit is the ability of a 3D

laser scanner to digitise the spatial position of points

on the surface of a scanned object The CAD

compatibility enables a 3D model to be built from

data capture of the surface of any scanned object. This

enables scanned object models to then be quickly

scaled and printed out on a 3D printer subject to the

size limitations of the deposition mechanism used and

the build bed in a form or ‘scanning to production’ of

a finished part.

3DP has proliferated among manufacturing

companies, designers, end users and hobbyists as it

meets attributes of successful innovation as it is

cheaper than subtractive manufacturing, compatible

with CAD/CAM, less complex, easy to try out and

produces rapid end results. (Pham and Guilt, 2012).

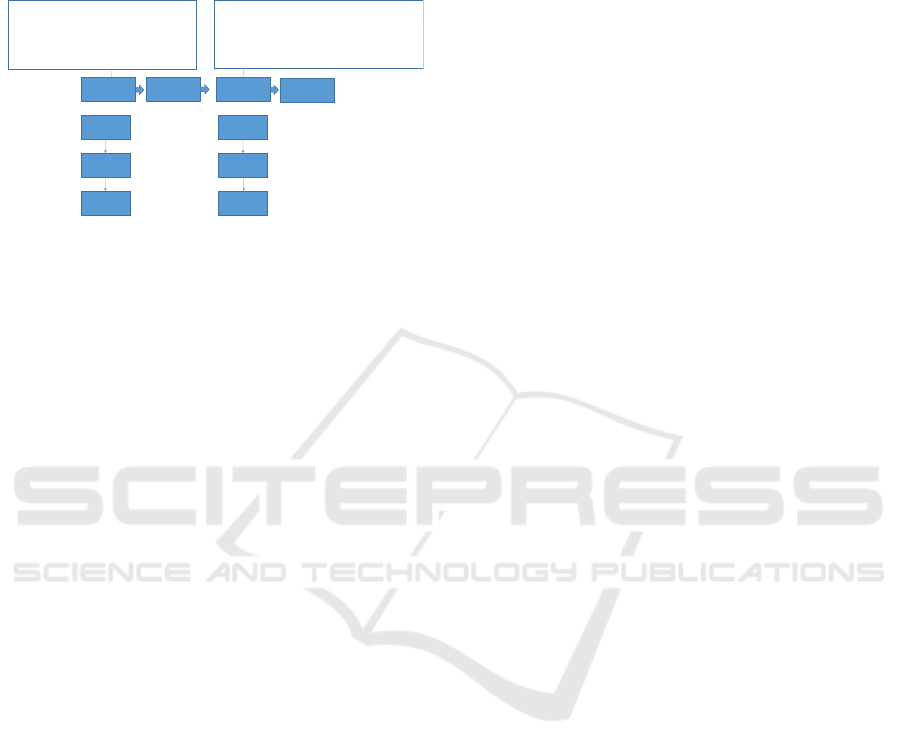

Figure 1: Creation flow using 3D printing.

Any new product idea can be quickly rendered in

CAD and then fabricated after STL conversion on a

3D printer or scanned and then printed. This greatly

reduces the complexity of the design and creation

process as seen in Figure 1.

1.2 Paper Motivation and Layout

3DP is widely reported as a game changer that will

alter the world in terms of product supply,

manufacturing and retail (D'aveni, 2013). Whilst

there are limitations due to low speed of fabrication

and robustness of the materials used these are rapidly

being overcome (Nair, 2014).This is aided by the

rapid and wide use of AM/3DP among industry,

designers and hobbyists and consequent reduction in

unit costs driven by innovation. It prompts two

research questions; a) What are the perceived

business and technical advantages of 3D printing b)

How can we compare and model the capability of 3D

printing with traditional subtractive manufacturing?

To answer these questions our paper sections cover:

• The background to 3D printing and its structure

• Advantages of 3DP from a business and technical

perspectives

• Subtractive manufacturing and limitations

• Capability and affordance modelling

• Mechanism Modelling

• Path Topology Modelling methods

• Discussion of findings/conclusion.

2 3DP PROCESS

CHARACTERISTICS

2.1 Business Advantages of 3DP

The benefits of 3D printing lead to major business

advantages, where a business advantage is defined as

superiority in delivering a strategic business benefit.

3DP/AM offers the benefit of a single general

production tool compared to a myriad of machine

tools required in subtractive manufacturing. 3DP/AM

develops this advantage due to its 3 axis and point

deposition versatility enabling the creation of

complex parts all on one machine. This removes the

need for sequential machining processes and jigging

and tooling (Choi and Samavedam, 2002) necessary

to hold parts firm against the cutting force implicit in

subtractive manufacturing.

3DP/AM also provides the opportunity for

integrated design to manufacture via as the software

format of 3DP has evolved from, and was deliberated

designed to integrate with CAD models (Choi and

Samavedam, 2002).

3DP has a unique benefit of rapid mass

customisation from creator to end user. The designer

and/or the end user is able to rapidly design parts in

well-established CAD formats. High quality and fast

CAD

MODEL

STL

MODEL

PHYSICAL

‘PRODUCT’

SCANNED

MODEL

NewIDEA

EXISTING

Physical

DESIGN

EXISTING

CAD

DESIGN

Scanning

process

CADModelling

process

Layering

process

3Dprinting

process

Accessible

Physical

OBJECT

Inventor Designer

Hobbyist

orend

user

Sixth International Symposium on Business Modeling and Software Design

74

fabrication can also be cheaply outsourced by sending

it to company to print anywhere in the world.

This greatly simplifies and reduces the cost of the

traditional mass customisation models that require

complex processes and equipment, for example used

by companies like Dell (Berman, 2012). This enables

any customer to create a new product, design or adjust

their product off line and send it directly to a

manufacturer in a ‘democratisation of the design

process’ (Hoy, 2013).

With 3DP/ the number of devices required to

enable design to production is reduced to one low cost

unit, reducing the learning curve and start-up costs,

hence encouraging adoption. (Nair, 2014).

2.2 Technical Advantages of 3DP

We define a technical advantage as an advantage in

the process, or mechanism of use, of a technology.

One of the critical advantages of AM over traditional

material removal and moulding methods is the ability

to develop unique shapes. This property is a function

of the topology of the printing device due to its point

deposition of material so that objects can be built in

single 3D points and layers at a time (Rosen, 2007).

The creation of a part from a single point enables

almost any shape to be built (Rosen, 2007) subject to

the need for support at overhangs and specific angles

and fine topographies on certain 3DP process types.

This differs from SM processes that require extensive

force application to remove material via traditional

lathe and milling machinery. AM deposition is

relatively force free apart from the weight of

deposited material that can distort the design when

setting. Depending on the resolution of the print head

and materials used, this enables extremely fine, small

and optimally engineered parts to be produced

without the force problems caused by material

removal. The point disposition ability at any location

within a build volume, coupled with digital design,

also enables parts to be made ‘within a part’ as there

is no necessity for cutter insertion and removal space

as in traditional manufacturing. For example the

creation of ball type bearings inside a complete ball

race can be executed in a single AM operation

(Conner et al., 2014). The point deposition ability of

AM enables sub-assemblies and products to be built

as complete volumes and surfaces, significantly

reducing the need for assembly and reducing costs.

For example a complete nylon ball bearing assembly

can be produced in one operation as one part vs 18

separate parts assembled using traditional

manufacturing due to SM machining limitations

(Conner et al., 2014).

The 3DP point deposition ability further enables

parts to be created as a fine mesh or space frame,

greatly reducing weight, in contrast to machining

from solid. This enables maximisation of strength per

unit volume (Pham and Guilt, 2012).The ability to

deposit in points and layers also supports integrated

materials structure variations within a part and the

creation of cellular materials to support energy,

thermal and acoustic design variations (Rosen, 2007).

This enables ‘designed property gradients’ where the

density of the product can be designed to vary to suit

design needs (Rosen, 2007). 3DP further enables the

creation of generic ‘graded’ ‘cellular materials’ such

as lattices, honeycombs etc to suit design needs for

density and other physical property variations (Rosen,

2007).

A potential revolutionary advantage of the

material deposition technique is that it enables the

embedding of different material types or even whole

components as the part is fabricated. This facilitates

variation in composition of the object material

properties and additional elements such as areas of

electrical conductivity or embedded components to

suit design needs (Doubrovski et al., 2011).

3 SUBTRACTIVE

MANUFACTURING (SM)

3.1 Limitations of SM

This section explores the traditional subtractive

manufacturing process of material removal using a

range of different machine tools based on different

cutter topologies.

The capability of traditional machine tools are

limited by the cutter path which is determined by the

cutter shape and mechanics. For example a lathe has

two degrees of freedom about an axial symmetry,

resulting in a capability for producing axially

symmetric parts. A milling cutter has three degrees of

freedom about x, y, z axes to produce a diverse range

of convex and concave parts. In contrast a drill has

effectively only one degree of vertical freedom to

create a hole of varying depth.

In traditional SM the lack of a universal cutting

machine and limitations of cutter path and finite

cutter size means the order in which a complex part is

manufactured must be considered to avoid unwanted

tool interactions (Matthews, 2007). This order of

processing (OOP) limitation adds complexity by

imposing machining precedence constraints and

conditions on the direction of tool application or

3D Printing and Additive Manufacturing Capability Modelling

75

approachability, limiting what is feasible to fabricate

(Gupta et al., 1997).

One complication is accessibility (AC), where the

arrangement of certain shapes drives the order of

machining, otherwise there would be no cutter access.

Gupta et al., (Gupta et al., 1997) defined feature

accessibility as a condition where the volume of space

required for accessibility Av has not been lost by a

volume already removed from the workpiece.

For example, if the accessible volume of a piece

of material X intersects with the removal volume of

Y, the cutter must approach a through the volume

occupied by Y and hence Y must be machined before

X (Matthews, 2007).

Also if X and Y have different approach

directions, and machining X provides a surface to act

as datum for measurement or tolerance, then X must

be machined first. This is a Datum Dependency (DD)

limitation of SM (Matthews, 2007).

Another concern is approachability (AP): if X is

machined before Y then Y will not be able to

approached or accessed to create the shape (Gupta et

al., 1997). For example eg a hole may need to be

machined first to provide access to cut a slot.

3.2 Cutter Path Limitations (Cpl)

At the fine scale level for SM we must also consider

limitations due to cutter size and geometry.

Whilst convex parts can be relatively easily

machined with SM, concave parts eg edges and

pockets or blind holes to be cut into the part are

limited by the need to ensure cutter access.

Gupta et al (Gupta et al, 1997) defined three types

of limitations for cutter path access:

CPL1: The curvature of the tool must be less than

the curvature of a concave edge – otherwise the

tool cannot follow and cut the edge (dcur);

CPL2: Where two closed edges form a narrow

passage to be cut by the tool the diameter of the

passage must be less than the tool (dpas) to enable

the cutting of the passage by the tool;

CPL3: Concave corners formed by the cutter path

must be larger than the tool (dcor) to enable cutter

access;

CPL4: as the tool size increases the cutting

trajectory (ie the minimum amount of arc that you

can cut with this size cutter decreases ie is a limit

on dtra) beyond which you will cut a bigger arc

than specified;

CPL5: The max diameter of tool also must be less

than the smallest diameter feature (min dmax).

This results in Gupta’s set of cutter path trajectory

limitations for the maximum cutter diameter:

du = min (dcur, dpas, dcor, dtra, dmax) (1)

Some topologies eg producing a part within a part

(PP) using subtractive manufacturing are almost

impossible with SM as it requires a tool to enter the

interior of a billet of material and then the operation

of that tool via a cutter path wholly within the billet.

The geometry of the cutting tool with respect to

the part is also subject to two further cutter geometry

(CG) limitations. The tool cutting edge angle

with respect to the cutter motion ά and the inclination

of the tool cutting edge with respect to the part, ie the

rake angle β must be within ranges to avoid skimming

or gouging the material and adversely affecting

surface quality (Blackenfelt, 2001).

3.3 SM Conceptual Model

Based on the above discussion we can now develop

an outline conceptual model for subtractive

manufacturing. Consider the following: where Ps is a

part to be created by the subtractive manufacturing

process, B = material billet from which the part is

machined, and Fi is the i’th machined feature (eg

hole, passage, curved surface etc) where i = 1,…n .

Then the part is the billet minus the union of all the

features.

Ps = B – ∪Fi

(2)

But each of the i in number features are topological

elements that in SM are created by the intersection of

the swept volume of the j in number cutter operations

Sc required to machine the features with the billet

volume B such that:

Ps = B – (B

sum ( (j= 1-n) Scj)

(3)

But as we have seen the swept volume is limited by

cutter approach geometry, size and access limitations

and the prohibited volumes discussed earlier. Hence

a generic model for traditional machine tool material

removal manufacturing is:

Ps = B – (B

sum ( (j= 1-n) Scj ) - CPV

(4)

Subject to the constraints that the j cutter paths are

processed in the appropriate order and within

processing constraints (AC, DD, AP, CG ) and cutter

path limitations (CPL). Where Sc is the swept volume

of cutter, CPV are the cutter prohibited volumes, such

as a part within a part etc. We will reuse this equation

later, but we now focus on how we can identify and

measure capability.

Sixth International Symposium on Business Modeling and Software Design

76

4 CAPABILITY & AFFORDANCE

4.1 Overview

Capability is a function of an action process, and the

nature of the interaction between two or more objects

or resources (Michell, 2011). Capabilities can be

modelled by understanding the way possible actions

or affordances can or cannot occur. Gibson (Gibson,

1979) defined affordance as the ‘property that the

environment or physical system offered the animal to

enable a possible useful transformation for the benefit

of the animal’. Affordances refer to descriptions of

(verb-noun) object abilities such as a road is

‘walkonable’ or the ‘cup affords drinking’ (Gibson,

1979) indicating that the structure/disposition of a

road or cup– enables it to be walked on or drunk from.

Affordances focus on the possibilities of how the

object could be used by the animal or person.

Affordances require a driving agent, an animal or

natural process for them to occur. Turvey’s

affordance model related animal properties Z and

properties of other entities X in an environment and

showed that affordance depended on the state or

properties of the animal/object and their

‘dispositions’ (Turvey, 1992). Using the concept of

affordance we developed a model of capability – the

capability affordance model (CAM) (Michell, 2012).

The model decomposed the affordance-effectivity

disposition into (i) a causal energy mechanism eg

force, temperature or electrical difference that

enables, the capability to occur. This energy flow is

transferred or dissipated through a (ii) space-time

affordance path that varies with the characteristics of

the animal and objects used in the interaction

(Michell and Roubtsova, 2014).

As affordances require animal or natural changes

to occur to make them realisable we define the

affordance mechanism as the cause and effect

transformation at the interface between two or more

interacting resources and its properties that enable the

transformation (Michell 2013). Mechanism thus

refers to the behaviour and properties of the energy

transfer that drives the transformation. For example a

potential difference enabling an electric motor to

rotate, or human energy is transferred to enable the

capability of a manual device like a syringe to ‘afford’

injection. Affordance mechanisms AM can be

typically modelled as force, heat or other energy

equations. However, for comparison purposes it is not

necessary to include the detailed mathematics, only to

understand their differences. The affordance path AP

is the set of possible space-time movement and

geometric configuration conditions that must exist to

enable the affordance mechanisms to act and execute

the capability (Michell, 2012). In the syringe injection

case the affordance mechanism is the force from the

doctor’s hands holding and pressing the plunger of a

syringe to give a patient an injection. This force is

transmitted along (a linear in this case) affordance

path from the plunger into the drug fluid which is

driven out into the patient (Michell and Roubtsova,

2014). The affordance transmission path for any

capable action forms an affordance chain from the

originating source of energy through the operating

parts of the device.

We can identify the energy mechanism and the

(affordance) path of the energy by observing the

chain of actions to make the man-machine capability

work (Michell and Roubtsova, 2014). At the point of

executing the capability to inject for example the

affordance chain, eg for injection will be a force

transfer from hand to syringe, to drug fluid pressure,

to patient. (See Michell and Roubtsova, 2014 for

details).A specific man- machine combination will

however have specific values and measures of

specific factors such as force, velocity and energy,

path topology and device volume and geometry

limits. These must be within a certain range for the

capability to occur. These capability affordance

factors (CAF) such as the range of angles the syringe

can be held at, or the minimum force to grip a syringe

or maximum force possible before breaking it will

characterise the capability and enables us to model

and compare capabilities (Michell and Roubtsova,

2014). To study and compare the capabilities of

additive vs subtractive manufacturing we therefore

need to identify the a) energy transfer mechanisms of

the two sets of machines and b) their resulting

transmission or affordance path and c) the critical

affordance factors and range of values that make it

possible.

5 MECHANISM MODELLING

5.1 SM Mechanism Affordance Chain

The mechanism represents the difference in energy

that causes an action to occur. In subtractive

manufacturing the affordance mechanism is typically

the application of force greater than the material

strength to cut or remove the material to the desired

shape of the final part. This process is typically

achieved via electrical energy used to rotate electric

motors to drive a rotary cutter and to s move the cutter

or part in a specific intersecting 3D space-time path.

For example a lathe has a motor to rotate the billet

3D Printing and Additive Manufacturing Capability Modelling

77

about an axis, whilst the cutter is stationary and

moved at right angles to the work. In contrast in a

milling machine the cutter is rotated via an electric

motor and the billet is clamped to table that can move

in x, y and z directions with three degrees of freedom.

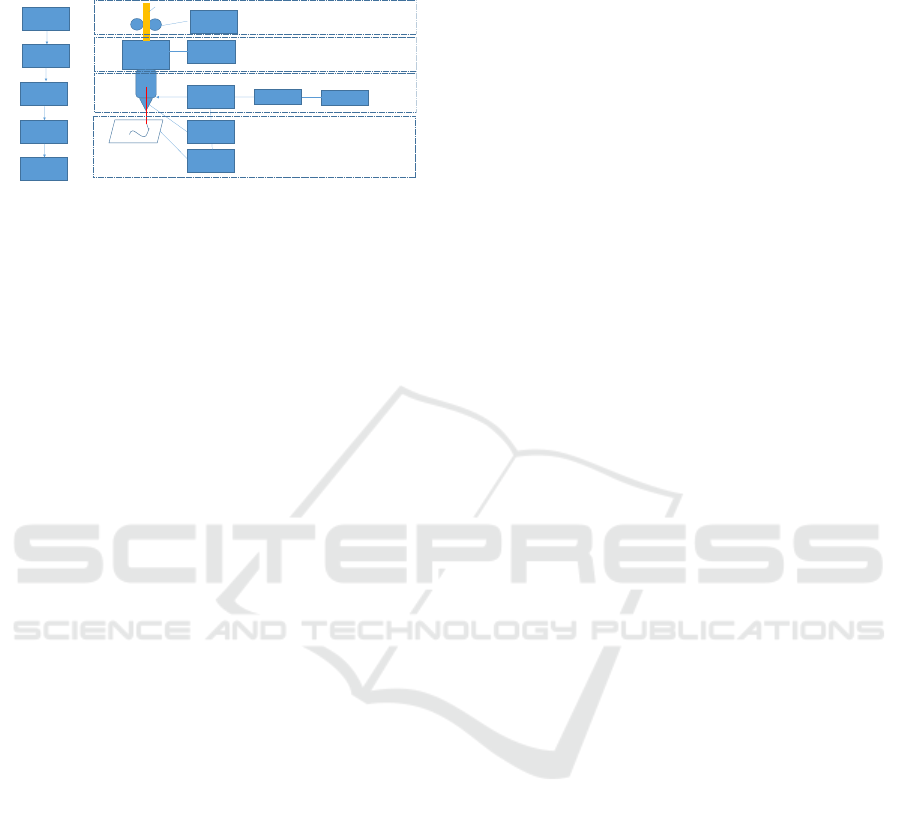

Figure 2: Example SM Mechanisms.

In subtractive manufacturing, unlike 3DP, there is

no universal tool solution. A part, if complex, is

produced with a series of machining actions on

different machining centres, such as a lathe, mill, drill

etc. Hence the affordance path comprises a series of

cutting actions on separate machines, separated by

moving the part between machine set up operations,

where the billet is locked into the correct position and

orientation for cutting. Each cutting operation

comprises a relative simple mechanism or short

affordance chain representing the application of a

cutting force along a space time path in relation to a

constrained billet as dictated by the machine and

cutter geometry as in Figure 2.

5.2 Mechanism Driven CAF for

Subtractive Manufacturing

Due to the forces involved in machining hard

materials fixture constraints to hold the part being

machined against the cutting forces may be required

to be designed, positioned and applied, hence

increasing the complexity and cost of setting up the

additive manufacturing operation (Matthews, 2007).

There are upper and lower bounds in the forces

required to remove unwanted material from a lump of

metal or billet. For example there must be sufficient

average torque Tm to cut the part but less than the

maximum machine torque to damage material. A

related factor is the tool spindle speed w, which again

must be greater than a minimum value to ensure a

smooth surface finish, but less than the critical value

to cause burning or melting of the tool or part. In

addition as tools are liable to be bent with high forces,

the average cutting force Fm must be sufficient to cut

smoothly with minimum tool deflection and less than

the force required to cause part damage or failure such

to limit the average cutter deflection dc will limit the

capability of the tool to produce a quality part. Further

the cutting force Fm must be less than the critical

value necessary to cause significant tool wear

(Blackenfelt, 2001).

The force required to cut a material and the

material properties will dictate potential distortion

especially in features of the manufactured product

that have thin walls (Matthews, 2007). Further there

is a limit to feature production of very fine parts. For

example very thin cylinders or point features are not

able to be machined due to these force limitations.

Similarly the creation of a mesh from a solid billet

would be extremely difficult, time consuming and

very costly.

5.3 Mechanism for Additive

Manufacturing

Additive manufacturing deposition mechanisms can

vary widely from heated molten plastic to laser

sintering (Norton, 2001). For capability comparison

we will focus on the most typical mechanism used in

the cheaper 3D printers – based on heated plastic

deposition. In a typical 3D printer of this form there

are 4 component mechanisms that form an affordance

chain of interacting actions (Figure 3).

Firstly a material feed process is usually via

electrically driven rollers applying a rotary

constraining force to a fibre of the plastic working

material which is dragged into an electrically driven

heating element. This heats the plastic to a pliable

temperature φ and viscosity within a range that

enables the melted plastic to flow through the nozzle

in a continuous stream according to the feed

controller.

The plastic flows through the nozzle at a steady

velocity Vp driven by the force Ff imparted to the

plastic filament by the rotation of the pinch rollers.

For deposition path planning & control, the heater

and nozzle are typically fixed to a framework of

motor driven slides (similar to a 2D inkjet printer) that

enables the precise positioning of a point or a

line/area of the deposited material dictated by the

optimised STL model of the structure driven by the

CAD design model. The material deposited internal

to the shape – the ‘infill’ is not solid but an STL lattice

structure that can be 80% or more less than the full

CAD solid model (Bassett et al., 2015).

Finally full x, y, z coverage of a three degree of

freedom build space is achieved by lowering the x-y

plane or build table in the z direction as successive

layers are added. This table is often heated, or the

build volume enclosed, to minimise warping of the

Lathe–fixedtoolmovedintopathofrotatingbillet

Mechanism:CuttingforceFl perpendiculartorotation

CutterPath:=helicalaboutlatheaxis

Millingmachine–fixedbilletmovedintopathofrotatingtool

Mechanism:CuttingforceFm indirectionofbedtravel(x,y,z)

CutterPath:3dspace‐timevolume–withlimits

accordingtoapproach

andcuttergeometries

Applycutting

Velo cityVl,

ForceFl

Constrainbillet

withsetup

ForcesFcl

Remove

constraints

Movepartto

millingmachine

Constrainbillet

withsetup

ForcesFcm

Applycutting

Vel ocit yVm,

ForceFm

Remove

constraints

Cleanfinishedpart

Millfeatureof

partonmilling

machine

Tur nfeatureof

partonalathe

Sixth International Symposium on Business Modeling and Software Design

78

part which would otherwise occur with rapid cooling

back to room temperature.

Figure 3: 3D Printer Key Components and Mechanism.

5.4 Mechanism Driven CAF for

Additive Manufacturing

A capability affordance factors that limit and define

whether the affordance and capability will occur for

3DP are based on the heat transfer and feed rate

variables for the melted material deposition

mechanism a sample of which is discussed below, but

a wider range can be seen in (Choi and Samavedam,

2002).

Firstly the material melting temperature θ must be

within a range that enables flow, but not burning of

the PLA/ABS material. For example 175 < θpla < 200

degrees, 225 < θabs < 230 degrees (Basset et al,

2015). Secondly the build bed must be heated within

a given temperature range to avoid warping as the part

cools. For example 20 < γpla < 70 degrees, and for

ABS 105 < γ < 105 degrees (Basset et al., 2015). The

material filament feed rate Vf must be within a range

consistent with smooth deposition to avoid gaps or

bunching, or unwanted spreading of the material.

The material viscosity μ at this temperature must

be sufficiently liquid to flow, but not too low to result

in puddling and spreading. The x,y,z velocity of the

nozzle travel Vn-xyz must also be in proportion to the

material viscosity and flow rate and be above a

minimum where material bunching will occur and

less than a maximum that would cause gaps in the

deposition. The deposition layer height hd is

important for part surface finish and fineness and is

dependent on nozzle diameter, but must be above a

minimum value that would unacceptably increase the

time to produce the part (Basset et al., 2015). The

infill structure density р must also be within a range

of values that enables sufficiently rapid printing, but

not too sparse to cause problems with structural

integrity

Various combinations of these factors will affect

the capability and mathematical models have been

built to establish the range of control parameters and

the physics and heat transfer involved (Ganeriwala

and Zohdi, 2014). For example the plastic feed rate

must be related to the x, y, z velocity for a given

material viscosity to avoid gaps or lumps in the

deposited plastic. Feed rate and viscosity will affect

the layer thickness, which in turn will affect surface

accuracy as a series of stacked layers or ‘stair step

effect. (Choi and Samavedam, 2002). The mechanism

driven factors for AM and 3DP can be seen in Figure

5.

6 PATH MODELLING METHODS

To compare 3DP capability with traditional

manufacturing we need to develop a conceptual

model of the affordance path that takes into account

the path geometry and the mechanism of the different

methods. Both manufacturing methods involve the

forming/sculpting of three dimensional solids, one by

removing material from a solid block or billet of

material by force and the other by deposition. Much

research has been conducted into traditional

manufacturing focusing on cutter path geometries

(Feng and Cusiak, 1995) and the study of tool

vibration effects (Blackenfelt, 2001). Other work has

focused on identifying the optimum sequence and

type of machining (Gupta et al, 1997) or machining

process simulation (Blackenfelt, 2001) and the

problem of modelling machining features (Tapie et

al., 2012). However using a mathematical geometric

approach to modelling these methods is unduly

complex and unnecessary for our comparison

purposes.

An alternative method that is appropriate to

accommodate the massive variation in machine tools

and machined or 3dp manufactured objects is to

model the situation from a topological set theory

perspective. Consideration of the problem suggests

that for subtractive manufacturing we need to model

the intersection of a polygonal volume with a cutter

path with different degrees of freedom. The additive

manufacturing (3DP) model can be considered as the

intersection of a bound build volume space with a

three degree of freedom deposition path.

Topological modelling defines spatial

relationships for geometries that are preserved under

rotation and scaling transformations (Egenhofer et al.,

1994). Such modelling can be used to define

topological relationships between two spatial objects

(Borrmann et al., 2006). Based on the fact that

boundaries and interiors have been identified as the

crucial descriptions of polygonal intersections

(Wagner, 1988), Egenhofer developed a point set

model of topological spatial relations between

3DPAffordanceChain

HEATER

MECHANISM

TEMPERATURE

CONTROLLER

ZAXIS

MECHANISM

DepositionPositioning

Materialstatepreparation

DepositionPathPlanning&Control

CADMODEL

x‐yprinterdrive

Tab le&zaxis

Mechanical

pinchrollers

FEED

CONTROLLER

POSITION

CONTROLLER

MaterialFeedMechanism

STLMODEL

X,YAXIS

MECHANISM

Veloc it yV, Force

Ff

Heattotempφ

Deposition

path,x,y

Depositionz

location

Coolfinished

parttoroom

temperature

3DPMechanismBlockDiagram

Solidplasticfilament

3D Printing and Additive Manufacturing Capability Modelling

79

regions or areas (Egenhofer and Franzosa, 1991). The

point set approach considered a set of points x and a

set of points y with neighbouring and overlapping

topologies defined by the set theory. Egenhofer

defined the results of the intersections of the

boundaries and interiors of two shapes in terms of

non-empty ¬ Ø and empty sets Ø , resulting in nine

feasible topological relations.

6.1 Three Dimensional Modelling

The 2D model was formally extended by

specification of the interior, boundary and exterior

point sets of spatial object by Egenhofer et al, who

described the topological relations between two

volumetric cells A and B. He considered A and B as

arbitrary objects composed of sets of points

(Egenhofer, 1994). These comprised three ‘object

parts’; interior designated by ᵒ, boundary designated

by δ and exterior designated by ⁻ and the two point

sets;{Aᵒ, δA, A⁻} and {Bᵒ, δB, B⁻}.

The combinations of intersections between

interior, boundary and exterior point sets result in the

nine intersection model (9-IM).

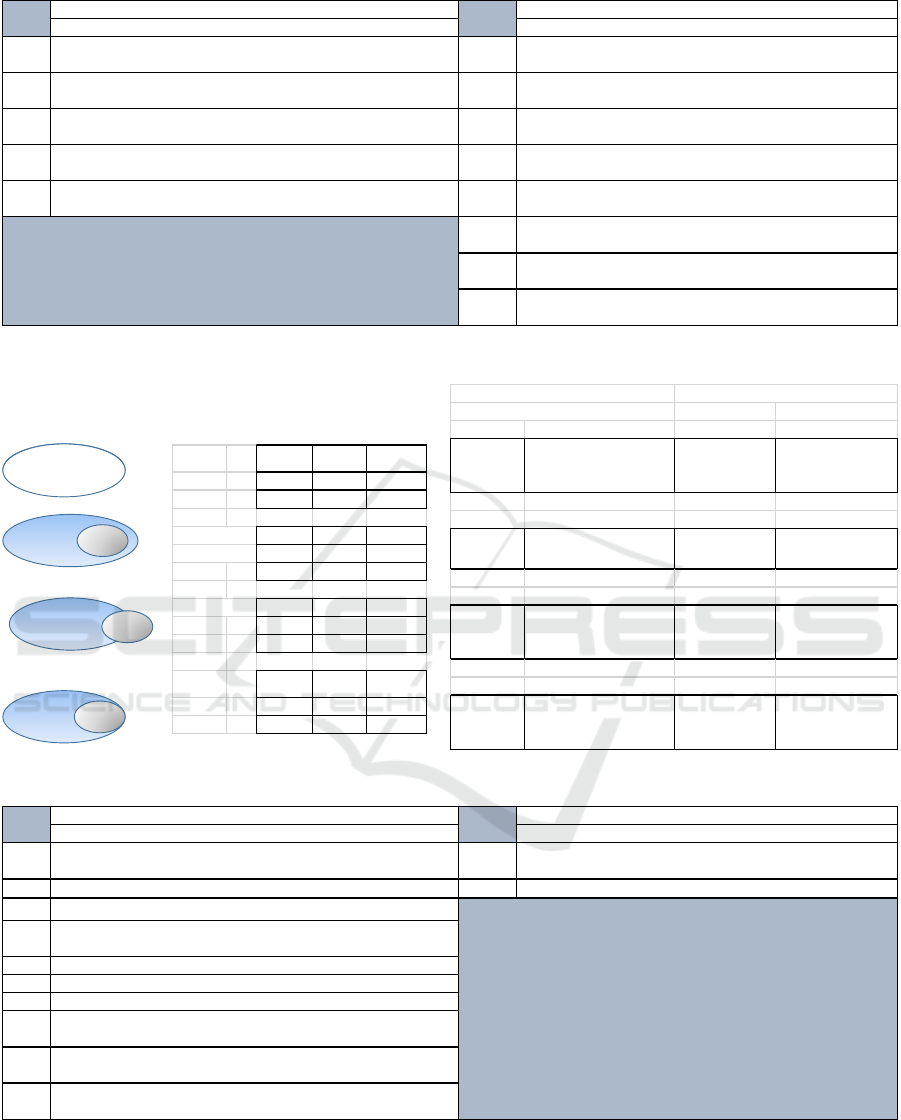

Figure 4: The 9-IM Topological Intersection Model.

Borrmann et al’s work describes a generic

intersection matrix for intersections of point, line,

area and 3d body (Borrmann et al., 2006). This gives

a number of intersection volumes that include; non-

touching (disjoint), equal volumes, a volume

containing and touching a volume and a volume

totally within a volume (Borrmann and Rank, 2009).

Whilst their work focused on modelling intersections

of architectural buildings, as these are simply

intersecting polygons, the same approach can be

adapted to manufacturing of polygonal parts. This is

equivalent of the intersection of the billet and the

cutter path. For our purposes we only consider the

body intersection which we can use to model the 3D

billet, cutter path or deposition path.

Using the same principle, the ‘equal volumes’

topology can be used to describe the 3D printer

situation, where the material deposition volume of a

3D printer is equal to the full 3D build space

available. This represents a ‘total topological

relationship’ (Billen and Kurata, 2008), where any

point, line, area or the full work volume can be

reached with the three degrees of freedom of

deposition of the 3D printer

Earlier in equation 3 we defined Ps as a part

produced by subtractive manufacturing. As

topological relations are indicated by the presence or

absence of intersections in the 9-IM model, we can

rewrite the model for AM and SM and apply the set

theoretic approach to show which relationship holds.

For an additive manufacturing process the

completed part Pa should be exactly the same as the

part produced by subtractive manufacturing Ps. For

Pa the topological path model is a function of the

swept deposition volume Pd and the available build

volume limits V. The finished part depends on the

volume of deposited material defined by the set of

points Pd in relation to the overall volume available

to build in V.

Ps = Pa = V

Pd

(5)

Hence using the same 9-IM matrix M (V, Pd) we can

represents the possible topology for the 3D printer

AM approach. Where A in the original 9M matrix

represents the deposition path volume Pd from the

deposition of melted plastic points in layers. B

represents the available free space V to build in.

6.2 Capability Path Comparison

Using the above topologies the resulting

manufactured part is described by the range of non-

empty sets formed by the intersection of the four

feasible relations in the 9-IM model and defines the

gross path capability of each manufacturing approach

as seen in figure 6. This clearly shows the versatility

of the additive 3DP solution in its ability to deposit

material in any part of the build volume. Additive

manufacturing enables non empty sets for a part

within a part represented by the ‘contains’ relation

where an unused volume is completely contained by

the build volume and by extension a separate part

could also be present if deposition was stopped and

restarted. It also holds for the touch relation where the

internal void produced by AM touches an external

boundary. In contrast for subtractive manufacturing

all these options are empty sets and prohibited, apart

from the intersection topology, which has limitations

based on the capability affordance factors of

accessibility and operation sequence discussed

earlier.

However, despite its greater path flexibility 3DP

has additional path conditions. The material

deposition as a slug of melted plastic will vary with

the curvature of the ‘tool’ or print head and thus build

I=

interiora

interiorbinteriora

boundarybinteriora

exteriorb

bounda rya

interiorb bounda rya

bounda ryb bounda rya

exteriorb

exteriora

interiorbexteriora

bounda rybexteriora

exteriorb

Aᵒ

Bᵒ Aᵒ

δ

B

Aᵒ

B⁻

δA

Bᵒ δA

δB δA

B⁻

A⁻

Bᵒ A⁻

δB

A⁻

B⁻

Sixth International Symposium on Business Modeling and Software Design

80

orientation of the part will also affect final part quality

(Nelaturi and Shapiro, 2015). In addition the cooling

of the melted material in certain geometries may

result in drooping and warping and hence certain

features and overhangs may require additional build

support structure to be added during construction to

prevent this. In contrast the path driven capability

affordance factors for subtractive manufacturing as

discussed earlier are far more numerous, complex and

onerous. See figures 5 and 7 for both sets of factors.

7 SUMMARY & CONCLUSIONS

7.1 Summary

We have analysed the perceived business and

technical advantages of 3D printing and shown how

these are derived by the mechanism and path

limitations of the AM and SM approaches. We have

compared the capability of 3D printing with

traditional subtractive manufacturing using a

capability affordance comparison method and a

topological model. The model demonstrated that the

mechanism of subtractive manufacturing is largely

based on force application and that this leads to the

requirements for extensive jigs and fixtures to hold

the part in place. This compared to the heat transfer

mechanism aided by a small filament force of 3D

printing. The 3DP mechanism in contrast relies on

gravity and the precise location of a point of material

to constrain the finished part. However, the 3DP heat

transfer mechanism produces a greater number of

more difficult to control factors such as flow rate,

viscosity etc as seen in Figure 5.

In contrast the topological model comparison

emphasises how traditional subtractive

manufacturing methods are limited by the path

geometry of the cutters used and the need for cutter

access This is emphasised by the fact that a 3D printer

with three degrees of freedom of point material

deposition has a ‘total topological relationship’,

compared with the ‘partial topological relationship’

of subtractive machining methods. SM is further

limited by the need, especially for complex parts, to

carefully consider the order of subtractive operations,

demonstrated by the larger range of geometric critical

affordance factors than 3DP seen in Figure 7.

However, whilst additive manufacturing has a far

greater capability to produce complex and intricate

parts, the machine parameters involved with the

deposition approach can be more difficult to get right

to ensure a quality part compared with tried and

trusted subtractive force driven mechanisms where

much more is known about the kinematics and

thermodynamics involved ensuring consistent quality

part production.

7.2 Conclusion

A have explored the key business and technology

benefits of 3DP additive manufacturing compared

with traditional subtractive manufacturing. We

applied the capability affordance model (CAM)

defining capability as an energy mechanism operating

through a space time path. We have shown via

topology analysis that the key capability difference

and advantage for 3DP is in its superior space time

affordance path due to the three degrees of freedom

to build from a point to enable construction of

complex single part objects and meshes, parts within

parts and very fine constructions. This is superior to

the limited topology available to additive

manufacturing due to the need for cutter access and

geometry limitations. However the force focused

mechanism of additive manufacturing does enable

more consistent surface quality and durability

compared to the heat flow focused mechanism of 3DP

with its more complex capability affordance factors

that lead to this variation. However, the low cost, ease

of use and design friendly format of 3DP enables

significant benefits to small and medium

manufacturers in producing innovative product

capabilities over traditional methods.

3D Printing and Additive Manufacturing Capability Modelling

81

Figure 5: Affordance Mechanism Comparison.

Figure 6: Comparison of Capability Paths.

Figure 7: Affordance Path Driven Capability Affordance Factors.

Subtra ctiveMa nufacturing(SM)CapabilityAffordanceFactors 3DPAdditiveMa nufacturing(AM)CapabilityAfforda n ceFactors

AFFORDANCEMECHANISMDRIVEN AFFORDANCEMECHANISMDRIVEN

SCM1 sufficienttocutmaterial<AveragemachineTorqueTm<torqueto

damagematerial

ACM1 175 <plamaterialdepositiontemperatureθpla<20 0degrees

SCM2 speedtoproduceroughsurface<toolspindlespeedw

<tool/p art

burningormeltingspeed

ACM2 BuildbedtemperatureForexample20<γPLA<70degrees,105

SCM3 sufficienttocut<averagetoolforceFm<forcerequiredforsurface

damageduetotooldeflection

ACM3 velocityforgapstooccur<materialfilamentfeedra teve locityVf<

velocityfor

unwantedspreading

SCM4 sufficienttocut<Fm<distortionforceforthinwallsections ACM4 mini mumflowvalue<materialviscosityμ<viscosityforpuddling

andspreading

SCM5 sufficienttocut<Fm<forcerequiredtocausesignificanttoolwear ACM5 minimumforspeedrequi rements<depositionlayerheighthd<

surfacefinishfinenessvalue

ACM6

velocityforbunchingofdepositionmaterial<The3Dnozzlevelocity

Vn‐xyz<velocityforgapsindeposition

ACM7 densityforstructuralissues<infillstructuredensityр<densityfor

maximumprinttime

ACM8 materialspecif icheatcapacity<criticalval ue forfailure

(burni ng/partdamage)

a b

a

b

a b

EQUAL

¬Ø Ø Ø

Ø ¬Ø Ø

Ø Ø ¬Ø

CONTAINS

¯ ¯ ¯

acontainsb

Ø Ø ¬Ø

Ø Ø ¬Ø

INTERSECT

¯ ¯ ¯

¯ ¯ ¯

¯ ¯ ¯

TOUCH

¯ ¯ ¯

Ø ¬Ø ¬Ø

Ø Ø ¬Ø

PATHCAPABILITY PATHCAPABILITY

Subtractivemfg Additivemfg

no lackoffeasiblecutterpat h to

accessallpoint sonabillet

(limitedbycutte rsizeand

geometryandkinem atics)

yes abilitytodeposi t

mate ri alanywhereinthe

workspac e

no lackoffeasiblecutterpat h

completelyinsidethebillet

yes abilitytodeposi t

mate ri altocompletely

envelopepart ofthe

yes feasiblecutterpathsto

produce

inters e ction(limited

bycuttersizeandgeometryand

kinematics)

yes abilitytodeposi t

mate ri alinpartofthe

workspac e

no lackoffeasiblecutterpat h

completelyinsidethebillettoa

singlepointonthebounda ry

yes abilitytodeposi t

mate ri altocompletely

envelopetheworks p ace

exceptforan

SubtractiveManufacturing(SM)CapabilityAffordanceFactors 3DPAdditiveManufacturing(AM)CapabilityAffordanceFactors

AFFORDANCEPATHDRIVEN AFFORDANCEPATHDRIVEN

SCP1 OrderofProcessingenablesallmanufacturingfeaturestobeexist(OOP) ACP1 partorien tati on <criticalpathorientationgeometry

SCP2 Accessibilityiswithinaccessconstraints‐(AC) ACP2 geometrytosupportrequirementsforoverhangingparts

SCP3 DatumDe pendency‐(DD)conditionsare

met

SCP4 Approachabil ity–(AP)conditionsaremet

CutterAccessPathlimitations(CPL)

SCP5 CPL1:Thecurvaturedcurofthetool<mincurvatureofconcaveedges

SCP6 CPL2:tool thediameterofthepassagedpas<tooldiame ter

SCP7 CPL3:Concavecornerdiameter(dcor)formedbythecutterpath>tool

diameter

SCP8 CPL4:

cuttingtrajectorydtramustbesufficienttoenablethecutterto

avoidcuttingintothepart

SCP9 CPL5:Themaxdiameteroftooldmax<smallestdiameterfeature(min

dmax)

Sixth International Symposium on Business Modeling and Software Design

82

REFERENCES

Bassett, K., Carriveau, R., & Ting, D. K. (2015). 3D printed

wind turbines part 1: Design considerations and rapid

manufacture potential. Sustainable Energy

Technologies and Assessments, 11, 186-193.

Berman, B. (2012). 3-D printing: The new industrial

revolution. Business horizons, 55(2), 155-162.

Blackenfelt, M. (2001). Managing complexity by product

modularisation

Billen, R., & Kurata, Y. (2008). Refining Topological

Relations between Regions Considering Their Shapes.

In Geographic Information Science (pp. 20-37).

Springer Berlin Heidelberg.

Borrmann, A., Van Treeck, C., & Rank, E. (2006, June).

Towards a 3D spatial query language for building

information models. In Proc. Joint Int. Conf. of

Computing and Decision Making in Civil and Building

Engineering (ICCCBE-XI) (Vol. 2).

Borrmann, A., & Rank, E. (2009). Topological analysis of

3D building models using a spatial query language.

Advanced Engineering Informatics, 23(4), 370-385.

Choi, S. H., & Samavedam, S. (2002). Modelling and

optimisation of rapid prototyping. Computers in

industry, 47(1), 39-53.

Conner, B. P., Manogharan, G. P., Martof, A. N.,

Rodomsky, L. M., Rodomsky, C. M., Jordan, D. C., &

Limperos, J. W. (2014). Making sense of 3-D printing:

Creating a map of additive manufacturing products and

services. Additive Manufacturing, 1, 64-76.

D'aveni, R. A. (2013). 3-D printing will change the world.

Harvard business review, 91(3), 34-35.

Depoorter, B. (2013). Intellectual Property Infringements &

3D Printing: Decentralized Piracy. Hastings LJ, 65,

1483.

Doubrovski, E. L., Verlinden, J. C., & Geraedts, J. M. P.

(2011) From factory to replicator

Egenhofer, M. J., & Franzosa, R. D. (1991). Point-set

topological spatial relations. International Journal of

Geographical Information System, 5(2), 161-174.

Egenhofer‡, M. J., Clementini, E., & Di Felice, P. (1994).

Topological relations between regions with holes†.

International Journal of Geographical Information

Science, 8(2), 129-142.

Egenhofer, M. J. (1994). Deriving the composition of

binary topological relations. Journal of Visual

Languages & Computing, 5(2), 133-149.

Feng, C. X., & Kusiak, A. (1995). Constraint-based design

of parts. Computer-Aided Design, 27(5), 343-352.

Ganeriwala, R., & Zohdi, T. I. (2014). Multiphysics

modeling and simulation of selective laser sintering

manufacturing processes. Procedia CIRP, 14, 299-304.

Gibson, J.: The Ecological Approach to Visual Perception.

Houghton Mifflin Company, Boston (1979) California

Management Review.

Gupta, Satyandra K., William C. Regli, Diganta Das, and

Dana S. Nau. "Automated manufacturability analysis: a

survey." Research in Engineering Design 9, no. 3

(1997): 168-190.

Hoy, M. B. (2013). 3D printing: making things at the

library. Medical reference services quarterly, 32(1), 93-

99.

Matthews, J. A. (2007). A constraint-based approach for

assessing the capabilities of existing designs to handle

product variation (Doctoral dissertation, University

Library).

Michell, V.A.(2011) A Focused Approach to Business

Capability. First International Symposium on Business

Modelling and Software Design – BMSD 2011, Sofia,

Bulgaria, pp. 105–113.

Michell V. (2012) The Capability Affordance Model:

Comparing Medical Capabilities. In: B. Shishkov (Ed.)

Business Modeling and Software Design – BMSD’12

Revised Selected Papers, Springer-Verlag – Lecture

Notes in Business Information Processing, Berlin-

Heidelberg

Michell, V., & Roubtsova, E. (2014). Modelling Capability

and Affordance as Properties of Human/Machine

Resource Systems. In Proceedings of the 4th

International Symposium on Business Modeling and

Software Design, BMSD

Nair 2014 democratising-manufacturing-3d-printing-is-set-

to-change-the-startup-landscape. Available at

http://www.thestar.com.my/business/sme/2014/03/26/

democratising-manufacturing-3d-printing-is-set-to-

change-the-startup-landscape/[ Accessed 04 May 2016]

Nelaturi, S., & Shapiro, V. (2015). Representation and

analysis of additively manufactured parts. Computer-

Aided Design, 67(C), 13-23.

Norton, A. (2001). Utilising Rapid Product Development

and Late Customisation Methodologies within

Manufacturing SMEs. PDF article to link: https://www.

google. com/# q= Rapid+ Product+ De velopment+

and+ Late+ Customisation, 15-16.

Pham, D. T., & Gault, R. S. (1998). A comparison of rapid

prototyping technologies. International Journal of

machine tools and manufacture, 38(10), 1257-1287.

Rosen, D. W. (2007). Computer-aided design for additive

manufacturing of cellular structures. Computer-Aided

Design and Applications, 4(5), 585-594.

Tapie, L., Mawussi, B., & Bernard, A. (2012). Topological

model for machining of parts with complex shapes.

Computers in Industry, 63(5), 528-541.

Turvey, M.T. (1992). Affordances and Prospective Control:

An Outline of the Ontology. Ecological Psychology

4(3), 173–187.

3D Printing and Additive Manufacturing Capability Modelling

83