Design of Intelligent Battery Management System

NingNing Chen

College of mechanical and electrical and Information Engineering

,

Jiangsu Vocational And Technical College of Finance

and Economics

,

Huaian

,

China

Cnn_110@126.com

Keywords: Wireless Charging, Battery Intelligent Management.

Abstract: The battery voltage of light electric vehicles in China mainly focus on the 48V. In order to achieve wireless

charging of light electric vehicles, the lead-acid battery 48V\28Ah as the design object, AT89C51

microcontroller to control the core management, construction of the battery management system of fieldbus

technology and smart battery monitoring chip based on DS2438, it has the advantages of low cost, stable,

reliable, has the advantages of high performance. We have shown good performance in our experimental

studies. In this paper, the hardware design and software design of the battery management system are

introduced in detail.

1 INTRODUCTION

In recent years, China's light electric vehicles

(electric bicycles, electric Qingqi Motorcycle) in the

large-scale industrialization has attracted worldwide

attention. At present, the battery voltage of light

electric vehicles in China are mainly concentrated in

48V.

The battery management system of electric vehicles

is a set of monitoring, control and management as a

whole, the battery management system should be

able to monitor the battery terminal voltage, current,

temperature and charge discharge when the

cumulative value, to ensure that the battery life will

not be reduced due to excessive overcharge and over

discharge, the battery management system should

also give a more accurate estimation of battery

remaining power. In recent years, the battery

powered portable household appliances and the use

of a large number of instruments, the battery for

online monitoring of the surge in demand. Abroad

introduced for monitoring the battery intelligent

dedicated chips, such as the United States DALLAS

series chips, they have a high degree of integration,

low price and strong functional advantages. Relying

on its ability to develop a high performance price

ratio of 48V battery management system.

In this paper, the design of 48V battery intelligent

management system is composed of intelligent

battery monitoring chip DS2438, MCU AT89C51,

liquid crystal display L1602A and a keyboard.

Specific process is as follows: 51 microcontroller a

DS2438 sampling according to the command of key

operation, DS2438 chip after receiving the order to

monitor the real-time state of the battery and

sampling, sampling results stored in the

corresponding internal registers, after sampling, read

by the microcontroller 51 and after processing, the

results will be used as communication message

display.

2 CHIP INTRODUCTION

The system uses the chip mainly has the intelligent

battery monitor core DS2438 and the MCU

AT89C51

2.1 Intelligent Battery Monitoring Core

DS2438

DS2438 is Dallas company launched a micro chip

specially used for battery detection, the chip has a

unique way of single bus work, requires only one

data line, realize the data input / output; chip

integrated temperature sensor, A/D converter,

current integrator circuit, has the function of

measuring the temperature and voltage of battery

current and cumulative power etc.. Measurement of

346

346

Chen N.

Design of Intelligent Battery Management System.

DOI: 10.5220/0006450203460350

In ISME 2016 - Information Science and Management Engineering IV (ISME 2016), pages 346-350

ISBN: 978-989-758-208-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the temperature range of -55°C to 125°C

temperature resolution of 0.03125 degrees. The

built-in ten bit A/D converter for battery terminal

voltage measurement, measurement range 0~10V,

resolution is 10mV; built-in current A/D converter,

current measurement of battery, the two voltage is

supplied via an external resistor on the RSENS

voltage drop or current transformer with a sampling

rate of 36.41 times per second to the current register

in the built-in accumulator; current (ICA)

measurement, storage charge and discharge current

cumulative value of time (cumulative ah), can be

used to estimate the remaining battery power; 40

bytes of EEPROM memory built-in power does not

disappear, important parameters used to record

battery characteristic data; it has the advantages of

small volume, powerful function and low price

measurement is. A method of measuring the chip

with high ratio of performance to price. Its pin as

shown in Figure 1, only six valid pin ports, the

hardware connection is simple.

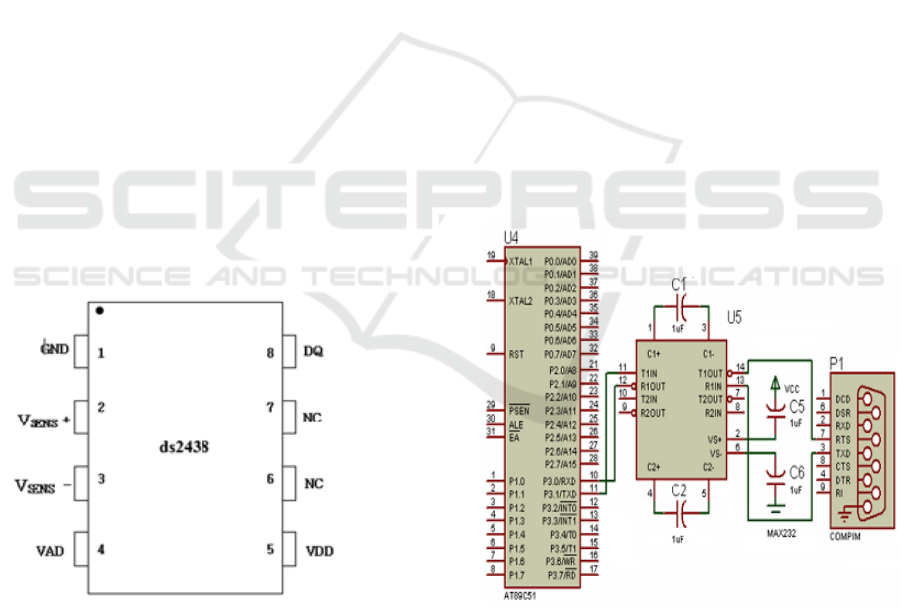

DS2438 pin assignment is shown in Figure 1:

DQ - data input / output

Vad - Universal A/D input

Vsens+ - the input terminal of the battery current

meter

Vsens- - the output terminal of the battery

current meter

Vdd - power supply side (2.4V ~ 10.0V)

GND - ground

NC - no definition (Jiapeng Yan,2011)

Figure 1: The leads package of the ds2438

2.2 MCU AT89C51 Brief Introduction

89C51 is a low power, low voltage, low price, high

performance 8 bit microcontroller, can be flexibly

applied in a variety of control areas. The on-chip

Flash ROM allowed in the system or use the

programmer and can be reprogrammed, cyclic

endurance up to one thousand times more than. The

thirtieth microcontroller AT89C51 pin ALE/PROG

is the address latch enable signal end of the pin

second function as the 89C51 chip Flash ROM to

burn into the curing procedure when the program

pulse input port, this paper uses the pin second

function, so it is set to a low level; the thirty-first pin

EA/ VPP is the external program memory address

allows input curing / programming input voltage,

when the pin is connected with the high level of

CPU, Flash and ROM access on-chip

implementation of internal ROM instructions in the

program counter, when more than 0FFFH, will

automatically turn off chip ROM to execute the

program, and when the pin low level, CPU will only

access off chip ROM in this paper, using the 51

compilers will program in curing the 4KB Flash in

ROM, so the pin is set to high state. AT89C51 serial

port and the serial communication technology, this

paper use 51 MCU programming realization, its

working principle is through the RS-232C interface

communication standard MAX232 SCM and PC

machine, 51 programmer procedures can be directly

burned into the microcontroller program memory 51,

its principle is shown in figure 2.(Fuzhao

Zhong,2014)

Figure 2: Schematic of 89c51’s serial communication

3 HARDWARE DESIGN SCHEME

51 MCU control display is used to display status

information users need to know the battery current,

the keyboard is the information input way for users

Design of Intelligent Battery Management System

347

Design of Intelligent Battery Management System

347

on the battery management system, the user can

control the microcontroller through the operation

button enter the corresponding interrupt subroutine,

the battery information collection. The sampling

system will be stored in the sampling parameters in

the DS2438 or 51 microcontroller with a nonvolatile

E2PROM or static ROM, so the system has the

function of power down protection. 51 single chip

microcomputer as the control and processing core of

the battery information collection subsystem, the

main software of the sampling control process was

completed, which obviously reduced the hardware

complexity of the system.

Figure 3: The structure of battery management system

Single chip using 89C51. Because the 89C51 chip

has ROM 4K, without further expansion of external

memory, the entire system is very simple. Single

chip and DS2438 data acquisition board potential, in

accordance with the communication protocol

provided by DALLAS company, in the way of field

bus data transmission, the following components of

the system.

Voltage measuring circuit : Using the built-in

DS2438 voltage A/D converter to measure the

terminal voltage of the entire set of cells. Because

the voltage measurement range of 0~10V is DS2438,

the terminal voltage of the battery group is 48V, so

the voltage dividing circuit is used to be applied to

the voltage measurement range of DS2438.

Current measuring circuit: Using the built-in

DS2438 current A/D converter to measure the

battery charge and discharge circuit. The sampling

resistance is connected to the battery charging

(discharging) electric circuit, and the charging and

discharging current of the battery can be measured

by measuring the resistance voltage drop of DS2438.

From the current built-in accumulator (ICA) chip,

automatically calculate the battery charge and

discharge current cumulative value of time, when

charging accumulated value is increased, and the

discharge is decreasing. After proper treatment, the

estimation of the remaining power of the battery can

be used.( Zhou Guan,,2015)

Temperature measurement: DS2438 chip close to

the battery, so as to measure the battery shell

temperature, and display and LCD display.

The cumulative ah : In order to estimate the

remaining battery charge and discharge, the total is

very important ah. When accumulated not by SCM

but by detection chip, DS2438 has a built-in current

accumulator (ICA), battery charge and discharge

current measurement of the cumulative value of

time, charge is accumulated, discharge is decreasing.

Cumulative value through the microcontroller, in the

liquid crystal display.

LCD: liquid crystal display selection is the 1602

LCD screen, the display is used to display the

battery voltage, current, power consumption, the

remaining power estimation, battery temperature.

The original design of the LED digital tube to

display the program, but the LED digital tube

display not only occupy more than SCM resources,

but also to maintain the LED digital tube display

requires a lot of energy consumption, to achieve the

display algorithm is relatively complex. LCD liquid

crystal display module and MCU connection

convenient, simple operation, and LED digital tube

display compared to take SCM less resources, and

low energy consumption, very suitable for the

controller design, the final selection of the LCD1602

display system information.

The LCD1602 used in the selection of the standard

16 pin (with a backlight), pin distribution as shown

in Figure4, pin is described below:

Figure 4 : Liquid crystal display circuit

ISME 2016 - Information Science and Management Engineering IV

348

ISME 2016 - International Conference on Information System and Management Engineering

348

4 SOFTWARE DESIGN OF THE

SYSTEM

The battery information collection subsystem

designed to access the DS2438 by the use of 51

single-chip keyboard scanning and monitoring

battery state parameters related to the acquisition,

the specific work process is as follows: first

initialize the 51 microcontroller, LCD display and

smart battery monitoring chip DS2438, and then

enter the keyboard scan subroutine, when scanning

to press a button, determine the key No., enter the

corresponding interrupt subroutine: DS2438 data

acquisition subroutine calls corresponding to, after

sampling, processed and displayed by the 51

microcontroller to read the collected data, and

finally return to the re initialization

Figure 5 : The flow diagram of subprogram sampling

battery Voltage

The battery information collection subsystem to

monitor the battery voltage and temperature of the

sampling process is as follows: firstly, 51 MCU

detects a button 1 is pressed, determine the key

commands by 51 DS2438 microcontroller sends

control commands to collect voltage or temperature

response, and enter the interrupt 1 subroutine, MCU

by conversion of U (T) and U (T Collection)

command, U (T) acquisition, delay U (T)

transformation completed, the completion of U (T)

after conversion, MCU by U (T) AD acquisition

command value, collect the data to the

microcontroller through a single bus, single-chip

LCD display command issued, the acquisition of U

(T), end.

Before the 51 MCU ready to register is read the

contents of DS2438, to determine whether the

DS2438 sampling end, judgment method is through

the level of data line between DS2438 and 51

microcontroller, if the low level shows that the

sampling is ongoing, you cannot read the data, only

goes high can read the correct data. The battery

information collecting subsystem monitoring of

battery power supply mode and current sampling

process is as follows: first by 51 MCU commands

the current analog-to-digital converter DS2438, then

the smart battery monitoring chip DS2438 will

monitor the current sampling every 27.46ms the

battery automatically flows in and out, and the

results will be stored in the current register, then

read by the microcontroller 51, at the same time

through the S register in the current judgment to

judge the state of charge and discharge of the

battery, the software process is shown in figure6.

Figure 6 : The flow diagram of subprogram sampling

battery current

Design of Intelligent Battery Management System

349

Design of Intelligent Battery Management System

349

5 CONCLUSIONS

This paper takes DS2438 as the battery information

sampling chip, using AT8 9 C5 1 microcontroller to

control the core management to build battery

information collecting subsystem, and the lead-acid

battery 48V for the design of hardware and software

realization of battery information collection, which

is characterized by powerful function and low cost,

stable operation, reliable and in practical, our

experimental study shows a good performance. We

are willing to cooperate with the manufacturer, the

technology is applied to the industrialization and

industrialization.

ACKNOWLEDGEMENTS

The authors acknowledge the financial Supported by

a project grant from Huaian technology bureau

(Grand No.HAG2014007).

REFERENCES

Jiapeng Yan,Dazhi Wang,Youchao Jin, 2011.Detection of

High-power Battery Based on DS2438.

Microcontrollers & Embedded Systems.11,40-42

Zhou Guan, Chenxuan Li, Jiang Zhu, Ye Wu. 2015.

Design of large power battery power monitoring

system based on DS2438. Shandong Industrial

Technology,16,118-119

Fuzhao Zhong, 2014. 8051 MCU principle and software

and hardware design, Beihang University

press,Beijing, 2

nd

edition.

ISME 2016 - Information Science and Management Engineering IV

350

ISME 2016 - International Conference on Information System and Management Engineering

350