Mature 25Gb/s Silicon Photonic Platform towards Multi-Layer

Circuits for High Integration Level Aplications

C. Kopp

1

, B. Szelag

1

, D. Fowler

1

, C. Dupre

1

, K. Hassan

1

and C. Baudot

2

1

Univ. Grenoble Aplpes, CEA, LETI, MINATEC Campus, F38054 Grenoble, France

2

STMicroelectronics SAS, 850 rue Jean Monnet, 38926 Crolles Cedex, France

Keywords: Silicon Photonics, Process Integration, Optical Communications, Network on Chip.

Abstract: Silicon photonics is definitely a key technology in next-generation communication systems from Long-Haul

networks to short reach data interconnects. To address 25 Gb/s and above applications, we present our R&D

platform that uses a CMOS foundry line. The fabrication process is following a modular integration scheme

which leads to a flexible platform, allowing various device combinations. Moreover this platform is associated

to a device library in a PDK which includes specific photonic features and which is compatible with

commercial EDA tools. Based on the maturity of this platform to build high-speed optical transceivers, we

present our strategy to anticipate the next integration disruptive level by implementing multi-layer photonic

circuits. Such a technology represents a new paradigm for the design of very high integration circuits that we

consider first for optical interposer, and finally for optical network on chip with the convergence of photonics

and electronics.

1 INTRODUCTION

Optical communications are definitively playing a

major role in high speed interconnects in servers,

datacenters, and supercomputers. In these systems,

copper cables have been replaced by active optical

cables in order to deal with data rate typically above

100Gbps per module. Mainly based today on optical

sub-assembly modules using VCSEL emitters,

optical links remain an expensive solution. As a

result, the next generation of optical components

must meet the challenge of high speed, low cost, low

energy consumption, and high–volume

manufacturing. Silicon photonics is now widely

accepted as a key technology (Kopp, 2011) to cope

with this challenge, leading also to a convergence

between photonics and electronics in terms of

fabrication foundry, design tool environment, and

circuit co-integration.

In this paper, we present the fabrication process of

our silicon photonic platform to address optical

communication application at 25 Gb/s and above,

from Long-Haul networks to short reach data

interconnects. This R&D platform on 200mm SOI

wafers exhibits several advantages. Indeed, this

platform is evolutionary allowing the addition of new

modules or functionalities to extend the targeted

applications. For instance, we can mention the

heterogeneous integration of IIIV material to make

lasers, electro absorption modulators, and optical

amplifiers, the integration of edge coupler for large

bandwidth applications, and the micro-bumping back

end of line for 3D staking of electronics on photonics.

The mature devices on this platform are implemented

in a Physical Design Kit. Moreover, this platform is

compatible with DAPHNE, the R&D platform on

300mm SOI wafers developed at ST-

Microelectronics (Baudot, 2016). Finally, we present

a strategy to address very high integration level for

optical network on chip architectures. This strategy is

based on implementing multi-layer photonic circuits

on the same die. The benefit of such an approach is

detailed at a component level for a ring resonator.

2 FABRICATION PROCESS

Wafers are fabricated in a fully CMOS compatible 8

inches fab at CEA-LETI. Starting materials are

Silicon-On-Insulator (SOI) substrates featuring a

310nm thick silicon film on top of an 800nm thick

76

Kopp C., Szelag B., Fowler D., Dupre C., Hassan K. and Baudot C.

Mature 25Gb/s Silicon Photonic Platform towards Multi-Layer Circuits for High Integration Level Aplications.

DOI: 10.5220/0006147700760081

In Proceedings of the 5th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2017), pages 76-81

ISBN: 978-989-758-223-3

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Buried Oxide (BOX); handling wafers use high

resistivity silicon. A modular approach is used to

build the process flow that supports various sets of

devices. The simplest process flow allows to fabricate

passive devices only meanwhile, the full process

includes the fabrication of active devices such as

photodiodes and modulators as well as tuning

capability using a thermal heater option. Figure 1

shows the overall technology integration scheme.

Figure 1: CEA-LETI photonic process integration scheme.

A modular approach is used, meaning that the process can

be adjusted with respect to the required devices.

The main devices needed to fabricate a

conventional photonic chip are shown in the

schematic cross-section of Figure 2. Tilted Scanning

Electron Microscopy (SEM) pictures show some of

the device fabricated. The front end modules will be

described in the next sections. The proposed Back

End Of the Line (BEOL) consists in 2 Al-Cu

interconnection levels with W plugs and vias. A thick

metal layer is used in order to improve RF

performances thanks to low access resistances. An

optional metal heater can be added within the oxide

layer between the silicon and the first metal layer. A

thin TiTiN layer is used to that end. Dedicated vias

are then used to connect the heater level to the first

metal contact layer. An additional Under Bump

Metallization (UBM) process is available. The last

feature is used for packaging, in particular for

electronic Integrated circuit (IC) assembly on top of

Photonic IC (Boeuf, 2015).

3 EDA SUPPORT

One key advantage of silicon photonics is that is uses

the production capacities of CMOS foundries (e.g.

big volume and low cost manufacturability). Another

important aspect for the platform spreading is the use

of a design flow based on the existing CMOS one. For

Figure 2: Schematic cross section of a photonic chip.

Multiple level silicon patterning is used to define passive

and active devices. The planarized BEOL is based on

conventional 0.18µm CMOS interconnection levels. Top

pictures are tilted SEM images of (a) 1D grating coupler,

(b) shallow rib wave guides, (c) a Mach-Zendher

Interferometer (MZI) modulator arm and (d) a Ge

photodiode at the end of a waveguide.

a designer, a Physical Design Kit (PDK) is the

gateway to the technology; it is then also strategic for

silicon photonic foundries to propose PDK

compatible with widely diffused EDA tools. Figure

23 presents the design flow developed in the frame of

PLAT4M project to support CEA-LETI silicon

photonic platform. It is close to what is done for

CMOS process, except the Optical Rule Check

module which has been specifically developed in

order to validate the signal path integrity, checking if

connection path exists between an input coupler and

an output coupler. This feature can be seen as the

ERC (Electrical Rule Check) proposed within the

CMOS support EDA tools.

Figure 3: Supported silicon photonics design flow.

This part of the PDK includes the Schematic,

Simulation and Layout boxes of the previous

diagram. For all the supported devices, a model and a

layout view are proposed. The optical bus used to

simulate the devices has been extensively presented

(Martin, 2014). It consists in a 9 lines structures. This

bus can deal with light polarized along two axes and

Mature 25Gb/s Silicon Photonic Platform towards Multi-Layer Circuits for High Integration Level Aplications

77

account for light reflection which is not the case if

only power and phase are used to represent the optical

signal as it is often done. Native device models are

developed in the Verilog-A behavioral language

which has the main advantage of being supported by

most of the SPICE commercial simulators.

Layout view proposed in the PDK are either fixed

cells (for grating coupler for instance) or parametric

cells. In that case some specific features related to the

photonic specificities have been added. For instance,

since photonic designs are not following the CMOS

Manhattan configurations, it is useful to have some

information like to overall optical length or the

minimum radius for bended structures. It is done

using callback in the user environment when

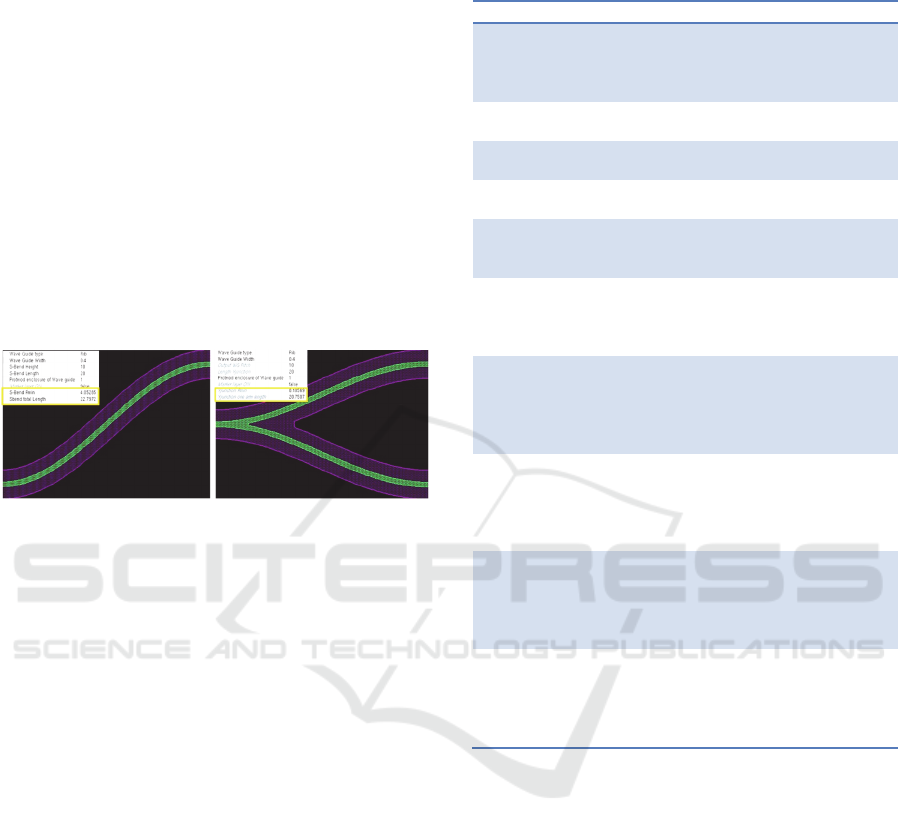

instantiating a cells as illustrated in Figure 24 in the

case of an S-Bend wave guide.

Figure 4: Layout views for S-Bend (left) and Y-junction

(right). Insets are the user parameters in which are

highlighted the additional information on radius and optical

path length calculated from instantiation parameters.

Table 1

is an extract from our PDK device library

with indicative performance for applications at

1310nm. All the devices fully supported by the

platform’s PDK. Specifications are given for

designer’s information; they are, most of the time,

associated with the worst case corner of the device

models. Complete behaviours of the devices are

described in their Verilog-A models.

Design Rule Checking (DRC) is used to ensure

that the geometric layout of designer contribution is

compliant with rules which are described in the

Design Rule Manual (DRM) to have a reliable

fabrication and acceptable functional yield. However,

trouble emerges when performing DRC on the

photonic layout which is full of non-Manhattan

geometries (spikes, tapers, etc.) and curvilinear

shapes. This is expands the complexity of the DRC

tasks. New and dedicated rules must then be

developed. To do this, two main developments were

made: introduction of new capabilities for layout

verification tools (Cibrario, 2014) and creation of a

design rules library (DRL) specific to silicon

photonics.

Table 1: Extract from the PDK device library for 1310 nm

operation.

To adapt the complex geometrical design of

photonic integrated circuits (PIC), we use new

capabilities for DRC, i.e. equation-based DRC, which

are mostly used in advanced CMOS technology. This

extends the capability of traditional DRC and allow

users to analyze complex, multidimensional

interactions (Figure 5) and addressed in this manner a

new way to write rules check (Cao, 2014). To tackle

grid snapping effect (Figure 6) which create lots of

false errors, a tolerance value is introduced for some

rules.

Using a new approach to write design rules with a

high-level description language offers noticeable

modularity and reusability through a generic Design

Rule Library (DRL) concept. This methodology

fastens and simplifies DRC rules file writing by

allowing substantial reduction of the number of lines

Device Specification Value

Straight rib

waveguide

Loss <2.5 dB/cm

(W=400nm)

0.25 dB/cm

(W=1.8µm)

Straight strip

waveguide

Loss <4dB/cm

Bend (R=5µm)

stripwaveguide

Loss 0.015dB/90°

Fiber grating

coupler

Insertionloss

1dBbandwidth

<3dB

30nm

Germanium

photodiode

OEbandwidth@‐1V

Responsivity

Darkcurrent@20°C

>30GHz

0.75A/W

<10nA

MZImodulator EObandwidth@‐2V

Length

Insertionloss

Vpi@‐2V

>20GHz

4mm

<8dB

5V

Ringmodulator EObandwidth@‐2V

DCInsertionloss

VppRF@‐2V

DCER

RFER

15GHz

<0.5dB

0.8V

18dB

3.5dB

Ringfilter Qualityfactor

FreeSpectralRange

Thermaltuning

loss

ExtinctionRate

12000

6.6nm

0.4nm/mW

<0.5dB

18dB

MUX 100GLR4

WDM

Channel separation

Bandwidth @‐1 dB

IL over bandwidth

Crosstalk over

bandwidth

4.53nm

2nm

4dB

>18dB

MUXCWDM Channel separation

Bandwidth @‐1 dB

IL over bandwidth

Crosstalk over

bandwidth

20nm

13nm

4dB

>15dB

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

78

Figure 5: Errors not filtered by traditional DRC (without

equation-based DRC).

Figure 6: Width modification introduced by the snapping

effect.

while keeping the possibility of using the latest DRC

capabilities. This concept improves the robustness of

the physical verification, thus reducing the risk of

errors.

4 TECHNOLOGY PLATFORM

EVOLUTION

As our platform aims to address various applications

and needs, some new functionalities are continuously

added. Typically, we develop the heterogeneous

integration of IIIV material (Duprez, 2016) for lasers

(Figure 7), electro absorption modulators, and optical

amplifiers, the integration of edge couplers for large

bandwidth applications, and micro-bumping back end

of line for 3D staking of electronics on photonics.

These developments mainly address the optical

communication transceiver roadmap. On one hand,

we consider the data rate increasing towards terabit

speeds which require high speed modulators and

photodetectors, wavelength multiplexing, and

advanced modulation formats. On the other hand, we

Figure 7: Heterogeneous integration on silicon of IIIV laser

source.

consider the requirement to move photonics from

front panel modules to mid-board modules in order to

place it closer to high performance electronics.

The next integration step of photonics with

electronics appears to be the development of optical

network on chip (NoC) for high-performance

computing (Thonnart, 2014). Indeed, comparing with

electrical interconnects, photonics unique features

such as: low latency leading to no fundamental

difference between on-chip and off-chip links, high

speed end-to-end network paths, high bandwidth

density NoC, low power consumption, and high

integration level. Moreover, photonics enable the

evolution towards new architectures and resource

management such as: architecture with unified

switched photonic network, single writer – multiple

reader optical buses, high-speed low-latency optical

memory for reduced cache levels and optimized

memory coherence, partitioning strategies for

wavelength-routed optical NoC, or wavelength

reservation protocol for reconfigurable optical NoC.

In order to anticipate this evolution of the

requirement from gigabits per module to terabits per

square centimeter, we prepare our photonic platform

to be compatible with the integration of multi-layer

silicon photonic circuits. Indeed, this integration

should be mandatory to deal with highly integrated

circuits such as routers or optical network on chip

described previously. In this approach, for instance,

at least two silicon photonic circuits will operate

together. The silicon waveguide layers are close

enough (i.e. 100nm) to deal with efficient optical

coupling. Regarding the packaging, these circuits will

share the same BEOL (Figure 8).

Mature 25Gb/s Silicon Photonic Platform towards Multi-Layer Circuits for High Integration Level Aplications

79

Figure 8: Schematic cross section of a photonic chip with 2

photonic circuit layers.

This integration scheme offers a new degree of

freedom to designers both to improve the

performance of the existing components, and to

develop new functions. The development of this

multi-layer photonic platform is programmed in two

steps: first with passive components, second with

active components.

As a first example, we present the design of a ring

resonator with the ring waveguide being processed on

the upper circuit. In this design the upper circuit is

patterned on a 304nm thick amorphous silicon layer

with 100nm of intervening SiO2 (

Figure 9

).

Figure 9: Ring to waveguide coupling structure for FDTD

simulation.

The coupling coefficients between a straight strip-

type waveguide and a curved waveguide with a

constant 5µm radius have been simulated using 3D-

FDTD.

Figure 10

shows that for a given SiO2

thickness and waveguide offset, the coupling

coefficient is relatively stable for typical variations of

waveguide geometry. For example, with identical

waveguides of 304/350nm height/width a SiO2

thickness of 100nm and a waveguide offset of 300nm

gives a coupling coefficient of -15.1dB (3.1%),

±10nm variations in the height and width of the

input/output waveguides lead to at worst -15.1±1dB

(2.5-4%) variations in the coupling coefficient.

Figure 10: FDTD simulation results of the coupling

coefficient between a straight waveguide and a superposed

curved waveguide.

This coupling structure shows benefit both for

passive and active functions. Indeed, as a passive

function it will be used as a wavelength selective

coupler between the upper circuit and the lower

circuit. It is a relevant degree of freedom for

switching circuits which require thousands of

crossings (Testa, 2016). As an active function, it

enables the modulation of the entire ring

circumference which will significantly improve the

performance for small ring radii (i.e. less than 5µm).

5 CONCLUSION

Silicon photonics exhibits now a high level of

maturity to develop next-generation high speed

transceivers for optical fibre networks. This maturity

is based on the research effort from academia and

industry by using conventional silicon integrated

circuit infrastructure with Electronic Design

Automation tools, CMOS foundries, and wafer-level

testing. The CEA-Leti 200mm R&D platform has

fueled the demonstration of multiple applications

(Bernabé, 2016). Now, the evolution of this platform

is mainly based on heterogeneous integration of IIIV

material to make laser source, and multi-layer

photonics to address the high density level of optical

network on chip.

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

80

ACKNOWLEDGEMENT

The R&D platform on 200mm SOI at CEA-Leti has

been developed thanks to funding from the French

national program ‘proramme d’investissements

d’avenir, IRT Nanoelec’ ANR-10-AIRT-05, and

from the European Union’s Seventh Framework

Program (FP7/2017-2013) under Grant agreement

n°318178-PLAT4M.

REFERENCES

Kopp, C., 2011. Silicon Photonic Circuits: On-CMOS

Integration, Fiber Optical Coupling, and Packaging.

IEEE Journal of Selected Topics in Quantum

Electronics, vol. 17, no. 3, pp. 498–509, May 2011.

Baudot, C., 2016. DAPHNE silicon photonics

technological platform for research and development

on WDM applications. 2016, vol. 9891, p. 98911D–

98911D–18.

Boeuf, F., 2015. Recent Progress in Silicon Photonics R&D

and Manufacturing on 300mm Wafer Platform. Optical

Fiber Communication Conference, OSA Technical

Digest (online) (Optical Society of America, 2015),

paper W3A.1.

Martin, P., 2014. Modeling of Silicon Photonics Devices

with Verilog-A. Proc. MIEL 2014, pp 209-212.

Cibrario, G., A High-Level Design Rule Library

Addressing CMOS and Heterogeneous Technologies.

IEEE ICICDT 2014.

Cao, R., 2014. Silicon Photonics Design Rule Checking:

Application of a Programmable Modeling Engine for

Non-Manhattan Geometry Verification. VLSI-SoC

2014.

Duprez, H., 2016. Hybrid IIIV on Silicon Laterally Coupled

Distributed Feedback Laser Operating in the –Band.

IEEE Photonics Technology Letters, vol. 28, no. 18, pp.

1920–1923, Sep. 2016.

Thonnart, Y., 2014. Technology assessment of silicon

interposers for manycore SoCs: Active, passive, or

optical?. Eighth IEEE/ACM International Symposium

on Networks-on-Chip (NoCS), 2014, pp. 168–169.

Testa, F., 2016. Design and Implementation of an

Integrated Reconfigurable Silicon Photonics Switch

Matrix in IRIS Project. IEEE Journal of Selected Topics

in Quantum Electronics, vol. 22, no. 6, pp. 1–14, Nov.

2016.

Bernabé, S., 2016. Packaging of Photonic Integrated Circuit

Based High-Speed Coherent Transmitter Module. 2016

IEEE 66th Electronic Components and Technology

Conference (ECTC), 2016, pp. 1081–1086.

Mature 25Gb/s Silicon Photonic Platform towards Multi-Layer Circuits for High Integration Level Aplications

81