Automatic Calibration of the Optical System in Passive Component

Inspection

Sungho Suh and Moonjoo Kim

Samsung Electro-Mechanics, 150 Maeyoung-ro, Suwon, Korea

{sh86.suh, moonjoo.kim}@samsung.com

Keywords:

Automatic Calibration of the Optical System, Passive Component Inspection, Gain, White Balance Ratio.

Abstract:

A passive component inspection machine is to obtain a image of a passive component by using a specific

lighting and camera, and to detect defects on the image of the component. It inspects all the aspects of the

component based on the image which is captured by using the lightings and cameras. The number of the

lightings and cameras are proportional to the number of the component aspects. To detect the defects of the

component effectively, the difference between the image quality by each camera should be minimized. Even

if the light conditions are calibrated automatically, the average intensities of the images are different because

of influence of Bayer filter which is used in CCD camera in the passive component inspection machine. More-

over, there is one more problem that the range of the light intensity cannot cover the range of the component

reflectance. Sometimes, it is needed to calibrate a gain value and white balance ratios of the camera manually.

In order to solve the problems, we propose an automatic calibration method of the optical system in passive

component inspection machine. The proposed method minimizes the influence of Bayer filter, does not use

any initial camera calibration, and find the optimal values for the overall gain and white balance ratios of red,

green, blue colors automatically. To reduce the influence of Bayer filter, we perform to find the optimal values

of all colors balance ratio iteratively and formulate a relation between the overall gain and the white balance

ratios to control all the parameters automatically. The proposed method is simple and the experimental results

show that the proposed method provides faster and more precise than the previous method.

1 INTRODUCTION

A passive component is a component that con-

sumes, accumulates, and emits electric power sup-

plied from the outside. It means that the part is in-

capable of an active function. It includes various

types of chips: MLCC (Multi-Layer Ceramic Capac-

itor), BLCC (Boundary Layer Ceramic Capacitor),

VLC (Vertically Laminated Capacitor), EMC (Elec-

tro Magnetic Compatibility), etc. One of the pro-

duction processes for the passive components is a

visual inspection that inspect a chip visually. Prior

to visual inspection, electrical properties inspection

finishes to ship the chip without any visual defects.

A passive component inspection machine (Liu et al.,

2007) (Kim et al., 2013) (chieh Tseng et al., 2006)

(chieh Tseng et al., 2009) is to capture an image of

the passivecomponentby using a specific lighting and

camera, and to judge whether the chip has defects.

The passive component inspection machine is shown

in Figure 1 and the flow of the machine is shown in

Figure 2. It inspects all the aspects of the compo-

nent based on the image captured by the lightings and

cameras. The number of the lightings and cameras are

proportional to the number of the component aspects.

For effective detection, the differencein image quality

by each camera should be minimized. More and more

different image quality between cameras can cause

higher false-positive and false-negative. Therefore, it

is important that the inspection machine should se-

cure uniformity of the image quality and calibrate its

optical system to minimize the difference of the im-

age quality between each camera. The number of the

lighting for inspection is 12 based on two lanes six

sides machine which is shown in Figure 2, and the

number of the lighting channel is 128. And the num-

ber of the used cameras is also twelve and it is nec-

essary to calibrate the overall gain value, red, green,

blue balance ratios. Previously, those are calibrated

by operators manually. Thus, obtained image qual-

ities vary as shown in Figure 3 because the calibra-

tion by each operator is different. Moreover, it takes

around 240 minutes averagely per a machine to set

the optical system manually. In order to improve the

230

Suh S. and Kim M.

Automatic Calibration of the Optical System in Passive Component Inspection.

DOI: 10.5220/0006165402300237

In Proceedings of the 12th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2017), pages 230-237

ISBN: 978-989-758-225-7

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 1: Vision system of passive component inspection.

Figure 2: A flow of inspection machine.

existing manual calibration method, we used an auto-

matic light calibration method of the optical system

to make sure of uniform image quality and reduce the

setting time.

The previous method makes the light channels

grouping and set the directional ratio of lighting.

Based on body area of the chip, user sets a target

value of image intensity and change the light value to

converge into the target value in order of red, green,

and blue. However, the average image intensities are

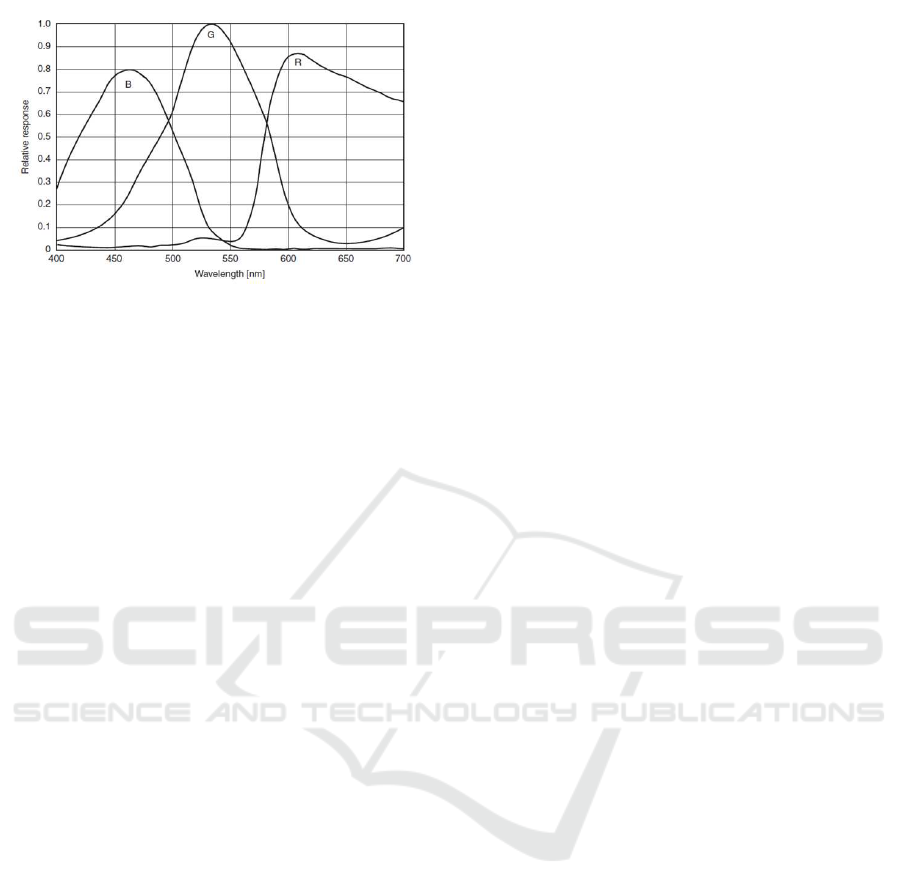

changed because the cameras in the inspection ma-

chine are CCD cameras which use Bayer filter (Hubel

et al., 2004). The spectral response of CCD camera

is shown in Figure 5. In Figure 5, wavelengthes are

duplicated between red and green, and green and blue

colors. Due to the duplicated wavelengths, blue in-

tensity is not only changed, but also green intensity in

the image can be changed when the blue light value

is changed, and green intensity is not only changed,

but also red and blue intensities are affected when the

green light value is changed.

Furthermore, reflectance ratio is different per each

type, model of chip, lot number, capacity. Even

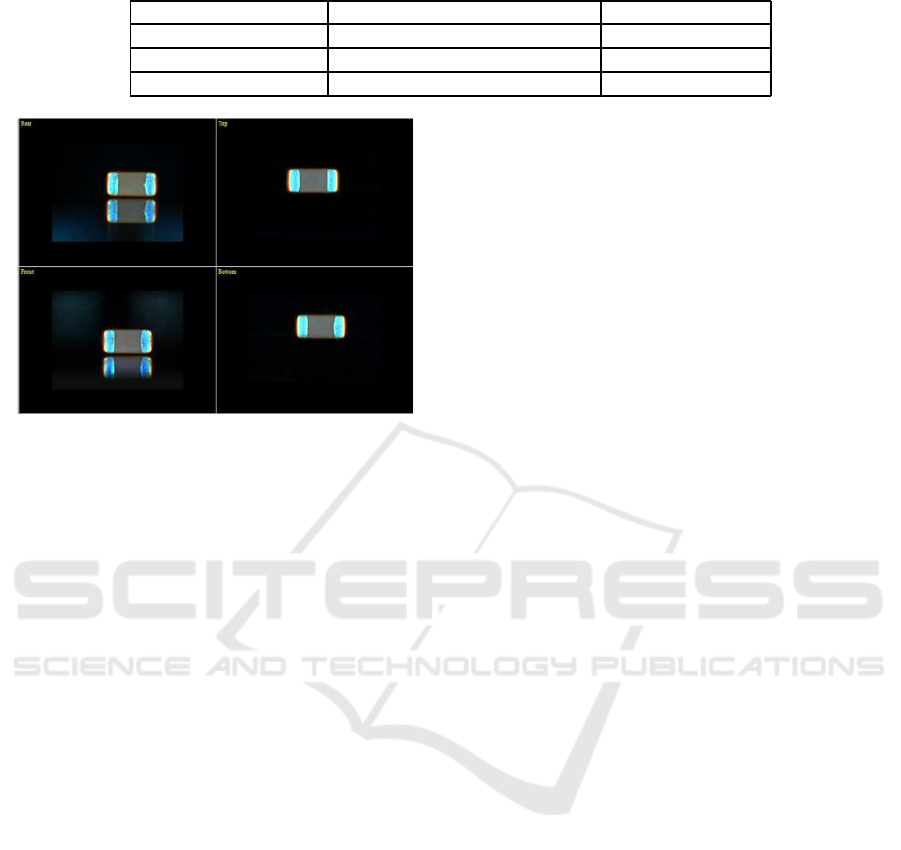

Figure 3: Chip images of four sides.

Figure 4: (a) brightness control by black level offset (b)

Contrast control by gain.

though the lighting value is used as maximum value,

the average intensity can be less than the target value.

Or the average intensity can be higher than the target

value even though the lighting value is set as mini-

mum. In the case, the previous method considers the

automatic lighting calibration as failed and need to

calibrate again manually. It requires more often man-

ual calibration, since there are lots of types of the pas-

sive components and various capacity differences.

There are two ways to improve amount of light

normally. First way is to use brighter lens or change

the light which can reflect more light on the target

object. Second way is to amplify the electrical signal

from output of the camera sensor by increasing gain

and white level of camera sensor. Without changing

hardware configuration, we should use second way.

There are two values to amplify the output power of

image sensor: Black level and white level. Black level

is to change brightness and white level is to change

contrast. In other words, black level is to adjust the

offset in Input-Output graph which is shown in Figure

4 (a). However, it is normally used as initial value

because dynamic range can be reduced and noise level

can be increased when the offset is changed. On the

other hand, gain and white level change the gradient

of the graph in Figure 4 (b). The gain value functions

to change the overall gradient and is represented in

log scale. But the white level is functioned as white

balance ratio in color sensor, changes the ratio of R,

G, B colors, and is represented in integer scale.

As mentioned above, image intensity is deter-

mined by the overall gain value and the white balance

ratios of the camera besides lighting conditions. To

reduce variables, the previous method fixes the gain

value for each camera and measures the combination

of ND filter and back light. Through the measure-

Automatic Calibration of the Optical System in Passive Component Inspection

231

Figure 5: wavelength of color channels.

ment, the white balance ratio values are fixed by man-

ual setting. To fix these values, twelve cameras, based

on the 2 lanes 6 sides machine, are required to cal-

ibrate manually. However, it takes around 180 min-

utes for the initial calibration. In addition, the failure

to convergeon target value frequently occurs since the

determined gain value is not proper to all the compo-

nents. In the case of failure, ratio value of the failed

color should be balanced manually. It also takes lots

of time and the operator feels difficulty to adjust the

values.

In this paper, we propose an automatic calibration

method of the optical system in passive component

inspection machine. The proposed method minimizes

the influence of Bayer filter, does not use any initial

camera calibration, and find the optimal values for the

overall gain and white balance ratios of red, green,

blue colors automatically. To reduce the influence

of Bayer filter, we perform to find the optimal val-

ues of all colors balance ratio iteratively and formu-

late a relation between the overall gain and the white

balance ratios to control all the parameters automati-

cally. Due to the iterate steps, the required time can

slow down, but it does not need the initial calibration

process and any manual calibration. As a result, it can

be calibrated automatically for more various models

and lots.

The rest of this paper is organized as follows. The

details of the automatic calibration method with cam-

era control are proposed in Section2. In Section 3, the

experimental results are presented. The experiments

are performed on the actual inspection machines. The

paper concludes in Section 4 with description of our

future work.

2 AUTOMATIC CALIBRATION

OF OPTICAL SYSTEM WITH

CAMERA CONTROL

2.1 Automatic White Balance Ratio

Calibration

To minimize the influence of Bayer filter and to con-

verge to the target value by using similar lighting

value, all colors of white balance ratios need to be

adjusted. First of all, initial light calibration needs

to be performed. If the initial light calibration suc-

cessfully converges to the target value, the average of

lighting values of all aspects can be calculated. Af-

ter setting the average lighting value to all sides, the

optimal white balance ratio value can be obtained. It

can make image intensities matching with the target

value. It means that image intensities converge to the

target value under same lighting condition. If the im-

ages of all sides have same lighting condition, the in-

fluence of Bayer filter can be reduced. At this time,

the camera calibration needs to be set similar white

balance under similar lighting condition.

To minimize the influence of Bayer filter, we cal-

ibrate the white balance ratio in order of blue, green,

red and recalibrate the blue one. Thereby, all cameras

can converge to the target value with similar lighting

condition. If there is a big difference between initial

white balance ratio value and the optimal value, the

image intensity can be higher or lower than the tar-

get value even though the lighting value reach maxi-

mum value or minimum value. In the case, the white

balance ratio of the failed camera and color should

be adjusted that the initial lighting ca be successfully

calibrated. The process of the white balance ratio cal-

ibration is as follows.

Step 1. Initial Automatic lighting calibration

Step 1.1. Performing iterative lighting calibration

for matching with the target value

Step 1.2. When the initial lighting calibration is

failed, Changing balance ratio of the failed camera

and color for matching with the target value with fixed

lighting value

Step 2. Calibration of blue balance ratio

Step 2.1. Setting the light value of blue channel

for all the cameras as the average value of the initial

lighting values from Step 1

Step 2.2. Performing iterative calibration for blue

white balance ratio with fixed blue light value from

Step 2.1

Step 2.3. Performing the lighting calibration of

green channel

Step 3. Calibration of green balance ratio

VISAPP 2017 - International Conference on Computer Vision Theory and Applications

232

Step 3.1. Setting the light value of green channel

for all the cameras as the average value of the initial

lighting values from Step 2.3

Step 3.2. Performing iterative calibration for

green white balance ratio with fixed green light value

from Step 3.1

Step 3.3. Performing the lighting calibration of

red channel

Step 4. Calibration of red balance ratio

Step 4.1. Setting the light value of red channel

for all the cameras as the average value of the initial

lighting values from Step 3.3

Step 4.2. Performing iterative calibration for red

white balance ratio with fixed red light value from

Step 4.1

Step 4.3. Performing the lighting calibration of

blue channel

Step 5. Re-calibration of blue balance ratio

Step 5.1. Setting the light value of blue channel

for all the cameras as the average value of the initial

lighting values from Step 4.3

Step 5.2. Performing iterative calibration for blue

white balance ratio with fixed red light value from

Step 5.1

Step 5.3. Performing the lighting calibration of all

channels

2.2 Automatic Overall Gain Value

Calibration

If the overall gain value is bigger or smaller than the

optimal value, the captured image intensity cannot

match with the target value even though the white bal-

ance ratios reach maximum or minimum values. And

if the gain value is changed, the image intensity of

all channels also changes. In order to keep the im-

age intensity with changing the overall gain, all chan-

nels of white balance ratios should be changed. And,

running time of the automatic calibration can increase

hugely if we use iterative method for finding the opti-

mal value of the overall gain. Therefore, we propose

an automatic overall gain value calibration by using

relation between gain and balance ratios. The relation

is released in the camera manual.(reference) Through

a verification experiment in Section 3, we verify the

relation. The relation is formulated as follows.

y

Red

= 10

0.0359G/20

B

Red

64

x

Red

y

Green

= 10

0.0359G/20

B

Green

64

x

Green

y

Blue

= 10

0.0359G/20

B

Blue

64

x

Blue

(1)

where (y

Red

,y

Green

,y

Blue

) is the output power of red,

green, blue channels, (x

Red

,x

Green

,x

Blue

) is the input

power of all channels, the unit of all the powers is

dB. G is the setting value of overall gain. Originally,

the gain is represented by dB unit, but represented by

integer scale in this formula. (B

Red

,B

Green

,B

Blue

) is

the white balance ratios of all channels, the minimum

value should be set as 64. Using these formulas, we

need to obtain the relation between the variation of

gain and the variation of each white balance ratio. To

obtain those, we can represent the formulas as fol-

lows.

y

Red

= 10

0.0359(G+∆G/20

B

Red

+ ∆B

Red

64

x

Red

y

Green

= 10

0.0359(G+∆G)/20

B

Green

+ ∆B

Green

64

x

Green

y

Blue

= 10

0.0359(G+∆G)/20

B

Blue

+ ∆B

Blue

64

x

Blue

(2)

where ∆G is the variation of the gain value, and

(∆B

Red

,∆B

Green

,∆B

Blue

) are the variations of the

white balances of all channels. By using (1) and (2),

the relations can be rewritten as

∆G =

20

0.0359

log

10

B

Red

B

Red

+ ∆B

Red

(3)

And using (3), we can calculate the relation be-

tween red and green balance ratios, the relation be-

tween red and blue balance ratios. Thus, we can

rewrite as

∆B

Green

= B

Red

− B

Green

+ ∆B

Red

∆B

Blue

= B

Red

− B

Blue

+ ∆B

Red

(4)

Using (3) and (4), we can obtain the deviation of

the corresponding gain value and the deviations of the

balance ratios of other channels when the red white

balance ratio value is adjusted. Thus, the overall gain

and other channels of balance ratios can be changed

to maintain the image intensity when the white bal-

ance ratio reaches maximum or minimum value. By

changing the gain and other channels of balance ra-

tios, the optimal white balance ratio and gain can be

obtained.

3 EXPERIMENTAL RESULT

In this section, we verify the formulas from Section 2

and evaluate the performanceof the proposed method.

And we compare the results of the proposed method

to the results of the previous work.

Automatic Calibration of the Optical System in Passive Component Inspection

233

3.1 The Experimental Verification of

Correlation between Image Sensor

Gain and the White Balance Ratio

The gain value is defined differently by a manufac-

turer of the image sensor, normally it is separated into

two types.

Gain

dB

= A× Gain

raw

(5)

Gain

dB

= A× log

Gain

raw

B

(6)

In (5), both system gain (Gain

dB

) and raw gain

(Gain

raw

) are defined in dB scale, thus the system

gain is increased in integer scale. In (6), the sys-

tem gain is increased in exponential scale by raw gain.

Also, the system gain is generally set to be increased

in integer scale by balance ratios. In this section,

we verify the output signal value of the input signal

(I

camera−out

/I

sensor−out

) and the relation between the

gain and balance ratios.

In the experiment, Basler Ace 640-GC cam-

era (Basler Vision Technologies, 2015) is used to

verify the relations. For the camera, Gain

dB

and

I

camera−out

/I

sensor

o

ut

are as follows.

Gain

dB

= 0.0359 × Gain

raw

I

camera−out

I

sensor−out

∝ 10

0.0359Gain

raw

20

I

camera−out

I

sensor−out

∝

BalanceRatio

raw

64

(7)

Before verifying the relations, we perform an ex-

periment to check a linearity of camera sensor. The

property of the linearity is related to generate current

from quantum efficiency of sensor and convert it to

voltage. Gain can determine how much amplify the

electrical signal from the process. Thereby, we can

predict the result by changing the amount of light if

the linearity is verified. In the experiment, white LED

dome is used and balance ratios are determined by

putting pure white color target. In the experiment of

the linearity, the current for lighting, the gain value,

and balance ratios are kept constantly and exposure

time of camera sensor is changed from 100µs to 10µs

by decreasing 10µs in order to control the input power

of sensor. And, we check that the intensities of the

ten images are increased linearly. The experimental

result is shown in Figure 6. We can figure out that the

intensities of the images are increased by the exposure

time of camera linearly in Figure 6(a). And the result

of linearity by linear fitting is shown in Table 1. The

value of R-square is 0.9999, and the result of fitting is

reliable. Based on the result, the differences between

Table 1: Result of line fitting for linearity.

Equation y = A+ B× x

Adj.R-Square 0.9999

A(intercept) -2.0158

B(slope) 2.2253

Table 2: Result of curve fitting for increasing the gain value.

Equation y = A+ B× 10

0.0359x/20

Adj.R-Square 1

A(intercept) -0.2613

B(slope) 24.3031

the measured intensity and fitting value is displayed in

Figure 6(b) and non-linearity is calculated by a equa-

tion as follow.

Non− linearity(%) =

| + ∆

max

| + | − ∆

max

|

maximum

× 100

(8)

where +∆

max

is the maximum deviation of positive,

−∆

max

is the maximum deviation of negative, and

maximum is the maximum measured value. The re-

sult of the non-linearity is 0.17%, it means that the

input of camera sensor and the output have a linear

relation. Thus, we can conclude the output intensity

can be increased linearly by the amount of input light.

To verify the relation between the gain and the bal-

ance ratios, we perform three experiments:1) verify-

ing a relation between the gain and output image in-

tensity, 2) a relation between the balance ratios and

output image intensity, 3) a relation between the gain

and balance ratios. To check the influence of the gain

value to the output image intensity, the gain value is

set as operational factor by increasing from 100 to

550, other factors are set as controlled factors. White

LED dome light is also used in the experiment.

I

camera−out

= A+ B× 10

0.0359×Gain

raw

20

(9)

The curve fitting result of (9) to the measured data

is shown in Figure 7 and Table 2. In the result, the

output value is increased nonlinearly, and the curve

fitting result is completely matched with (9).

Next experiment is to verify the relation between

the balance ratios and image intensity. The balance

ratios are composed of three channels;red, green, and

blue. Therefore, when the influence of a specific

channel of the balance ratios is measured, the other

channels of the balance ratios are set as 0 to remove

their influences. The experiment measures the image

intensity by increasing the balance ratio with an in-

crement in 20. The relation to be verified is as follow.

VISAPP 2017 - International Conference on Computer Vision Theory and Applications

234

(a) Result of linearity test (b) Result of Non-linearity analysis

Figure 6: Result of linearity test.

Figure 7: Relation graph for Image intensity and the gain

value.

I

camera−out

= A+ B×

BalanceRatio

raw

64

(10)

If the relation between balance ratio and the inten-

sity has a linearity, 10 can be verified. The measured

outputs and the result of fitting (10) for each channel

are shown in Figure 8 and Table 3. Also, the results

show that all channels of the balance ratios are linear

and (10) is matched to the results. In the results, each

slope of channel is different because it is determined

by spectral response of camera sensor.

Last experiment in this subsection is to verify how

the gain and the balance ratios impact on image inten-

sity. In the experiment, the gain value is fixed as 150,

250, and 350 for three times of measuring the inten-

sity. As same as the previous experiment for the bal-

ance ratios, when the influence of a specific channel

of the balance ratios is measured, the other channels

of the balance ratios are set as 0 to remove their influ-

ences. The verifying relation is as follow.

I

camera−out

= A+ B×10

0.0359×Gain

raw

20

×

BalanceRatio

raw

64

(11)

Using (11), each channel of the balance ratio is

matched to the measured result. The fitting is a type

Figure 8: Relation graph for Image intensity and the balance

ratios.

Table 3: Result of line fitting for increasing each balance

ratios.

Equation y = A+ B× (x/64)

Red Adj.R-Square 0.9999

Red A(intercept) -0.5166

Red B(slope) 25.9076

Green Adj.R-Square 0.9999

Green A(intercept) -0.80093

Green B(slope) 35.1681

Blue Adj.R-Square 0.9999

Blue A(intercept) -0.4936

Blue B(slope) 24.1601

of surface fitting. If the data is placed on the surface,

the relation can be verified. The result is shown in

Figure9 and Table 4. In the result, the fitting results

are perfectly placed on the surface. Therefore, we can

verify the relation between the gain value and the bal-

ance ratios. And we can understand why color is not

balanced when the gain value is adjusted because each

color channel has a different factor.

Automatic Calibration of the Optical System in Passive Component Inspection

235

(a) Red (b) Green (c) Blue

Figure 9: Result of Changing the gain and the balance ratios.

Table 4: Result of surface fitting for increasing gain and

each balance ratios.

Equation y = A+ B × 10

0.0359y

20

x

64

Red Adj.R-Square 0.9999

Red A(intercept) -0.1234

Red B(slope) 4.3491

Green Adj.R-Square 0.9999

Green A(intercept) -0.1708

Green B(slope) 6.3044

Blue Adj.R-Square 1.0000

Blue A(intercept) -0.1324

Blue B(slope) 4.6417

Table 5: Comparison for average required time.

Average required time(sec)

The previous work 55.6

Manual calibration 602.3

The proposed method 60.1

3.2 The Experimental Results of the

Proposed Method

In this subsection, we evaluate the performance of the

proposed method with real products and compare the

results of the proposed method to the results of the

previous work and the manual calibration. The ex-

periments measure the required time, a deviation of

lighting values between all cameras, and a deviation

of average gray scale value for each camera. In our

experiment, seven machines which are used in actual

field are used to measure the time and quality. And

it is applied to 50 different lots. Since the results of

manual calibration for the gain and balance ratios can

be different by each operator, an expert in understand-

ing how to calibrate adjusts the camera setting.

The result of required time is shown in Table 5. In

Table 5, the previous method can be finished within

shortest time, and the manual calibration which cali-

brate the image deviation within 10 gray scale value

Figure 10: The result of the previous work.

Figure 11: The result of the manual calibration.

takes almost ten minutes. When the operator in field

calibrates it, it takes over than twice. The proposed

method takes longer than previous method, but it

takes hugely less than the manual calibration. How-

ever, the required time for the proposed method just

includes the succeeded cases except the failed cases.

Next comparison is the deviation of lighting val-

ues and average gray scale values. If the deviation

of lighting values is huge, the deviation of gray scale

value for all the color channels is increased due to im-

VISAPP 2017 - International Conference on Computer Vision Theory and Applications

236

Table 6: Comparison for deviations of light values and gray-scale.

deviation of light value(R,G,B) gray-scale(R,G,B)

The previous work (80,81,46) (9.6,19.6,13.4)

Manual calibration (74,44,26) (8.7,9.0,10.1)

The proposed method (9,10,6) (3.9,4.1,5.1)

Figure 12: The result of the proposed method.

pact of Bayer filter. In addition, in the case that the de-

viation of lighting value is high butit is converged,the

camera calibration which should make similar gray-

scale values with same light values is not proper. The

deviation of gray-scale values is measured on the cen-

ter area of body in the product. The deviation of light

values and the average gray-scale values are shown

in Table 6. The result of the previous work does not

include the failed cases. Because the previous work

does not calibrate the gain value and the balance ra-

tios, the deviation of light values is huge and the de-

viation of average gray-scale values is over than 10.

Moreover, 35 of the total 50 lots are failed to con-

verge to the target, and it needs to be calibrated man-

ually. The manual inspection gives better image qual-

ity within 10 difference of gray-scale values, but the

deviation of the light values is large. It means that

the difference of colors is improved but the camera

calibration is improper. On the other hand, the pro-

posed method can provide the deviation of the gray-

scale values within 5 and the deviation of the light

values within 10. And, all the lot with the proposed

method are successfully calibrated. The results of the

calibrations are shown in Fig 10, Fig 11, and Fig 12.

4 CONCLUSIONS

In this paper, an automatic calibration method of the

optical system has been proposed for passive compo-

nent inspection. The proposed method calibrated the

gain and white balance ratios of the inspection cam-

eras using the relation between the gain and the bal-

ance ratios. The proposed method set the gain and

the balance ratios to make the obtained images sim-

ilar with same light conditions and make the differ-

ences of the image intensities and the light values

minimized. In the experiment, we compared the pro-

posed method to the previous method and the manual

calibration method. The proposed method gave better

performance than previous work and the manual cali-

bration method. It took less time to calibrate the opti-

cal system and minimized the difference of the image

intensities.

Since the experiment was performed for 50 lots,

we have a plan to experiment more various models

and lots. Furthermore, we need to reduce the re-

quired time for the calibration and apply the calibra-

tion method to other camera models.

REFERENCES

Basler Vision Technologies (2015). User Manual for GigE

Cameras.

chieh Tseng, C., fu Lai, M., and song Lee, P. (2006). Image

Inspection System for Defect Detection of Multilayer

Ceramic Capacitors. International Conference on In-

telligent Information Hiding and Multimedia.

chieh Tseng, C., Wu, J.-H., and Liao, B.-Y. (2009). Defect

Detection of Skewed Images for Multilayer Ceramic

Capacitors. International Conference on Intelligent

Information Hiding and Multimedia Signal Process-

ing.

Hubel, P. M., Liu, J., and Guttosch, R. J. (2004). Spatial fre-

quency response of color image sensors: Bayer color

filters and Foveon X3. SPIE Electronic Imaging.

Kim, D.-H., tae Bae, J., bok Kim, T., and hyeon Kim, G.

(2013). Electrostatic inductive absorption type inspec-

tion table for electronic components.

Liu, D., Braden, D., De, V. R. V., Hawkes, M. V., and

Nebres, J. V. (2007). Inspection machine for surface

mount passive component.

Automatic Calibration of the Optical System in Passive Component Inspection

237