High Brightness Multi-Mode Fiber Lasers

A Novel Sources for in-Band Cladding Pumping of Singlemode Fiber Lasers

Leonid V. Kotov

1*

, Oleg I. Medvedkov

1

, Mikhail M. Bubnov

1

, Denis S. Lipatov

2

,

Aleksei N. Guryanov

2

and Mikhail E. Likhachev

1

1

Fiber Optics Research Center of the Russian Academy of Science, 38 Vavilov Street, Moscow 119333, Russia

*

Now with College of Optical Sciences, University of Arizona, 1630 East University Blvd., Tucson, Arizona 85721, U.S.A.

2

Institute of Chemistry of High Purity Substances RAS, 49 Tropinina street, Nizhny Novgorod 603950, Russia

Keywords: Multi-Mode Laser, Er-doped Fiber, in-Band Pumping, High-Power Laser, High-Brightness Pump.

Abstract: A novel design of multi-mode Er-doped fiber lasers operated in the spectral region of 1530-1600 nm have

been proposed and realized. The lasers efficiency exceed 35-42% (depending on the wavelength), while

maximum output power is limited on the level of 60 W only by pump power available in the experiment. The

developed multi-mode laser can be used as an efficient high-power and high-brightness pump source for Er-

doped (pump at 1530-1535 nm) and Tm-doped (pump at 1560-1600 nm) singlemode fiber lasers. Utilization

of the same concept to the Yb-doped lasers could strongly accelerate output power growth of single-mode

lasers in the 1 µm region as well.

1 INTRODUCTION

Resonant pumping is a promising approach in a

development of kW-level single-mode fiber lasers. A

small quantum defect allows one to obtain a high

pump-to-signal conversion efficiency and, thus, to

reduce a thermal load on an active fiber. There is a

strong need in efficient and high-power sources at

1010-1040 nm for in-band pumping of Yb-doped

lasers; at 1530-1535 nm – for pumping of Er-doped

and at 1560-1600 nm – for Tm-doped fiber lasers

(Zhang J., 2011; Jebali M.A., 2014).

However development of such sources is a

challenging task by itself. For 1530-1535 nm spectral

region (pump of Er-doped fiber lasers) a multi-mode

semiconductor diode can be used. However, to the

moment price, available power and electrical-to-

optical efficiency of multimode diodes at 1532 nm

significantly inferior to that of well-developed pump

diodes at 980 nm. Another problem of such diodes is

a thermal drift of central wavelength. The thing is in

rather small (several nm) width of erbium absorption

peak near 1532 nm. So, wavelength change with

power can lead to decrease of pump absorption and

efficiency rollover. Moreover, high power

semiconductor diodes for longer wavelengths (1560-

1600 nm) are not available at all.

Another option to build 1530-1600 nm pump laser

is combining of several single-mode Er-Yb fiber

lasers which in turn are pumped by 9XX diodes

(Jebali M.A., 2014). However, output power of lasers

based on commercially available single-mode Er-Yb

fibers is limited by Yb emission near 1 µm at ~10 W

level (Sobon G., 2014). So, although such pump

source provides great wavelength stability and

efficiency, it requires huge number of Er-Yb lasers

(36 in ref. (Jebali M.A., 2014)) that significantly

increase cost of the laser.

Development of pump sources operated in the

spectral region near 1010-1040 nm is also not an easy

task. Absence of efficient pump diodes in this region

requires utilization of Yb-fiber lasers operated at this

wavelength. However a specially developed large

core-to-cladding ratio fibers are required to achieve a

high inversion (to get a non-zero gain) and reasonable

efficiency (Aleshkina S.S., Likhachev M.E., 2016).

The goal of our work is the development of

compact and cheap pump source for in-band pumping

of single-mode fiber lasers. The current

communication is focused on the development of

multi-mode Er-doped lasers for 1.5 µm region.

However, we suggest that the same principles could

be used for building of multi-mode pump source near

1 µm spectral range for in-band pumping of Yb-

doped lasers.

Kotov L., Medvedkov O., Bubnov M., Lipatov D., Guryanov A. and Likhachev M.

High Brightness Multi-Mode Fiber Lasers - A Novel Sources for in-Band Cladding Pumping of Singlemode Fiber Lasers.

DOI: 10.5220/0006166800990105

In Proceedings of the 5th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2017), pages 99-105

ISBN: 978-989-758-223-3

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

99

2 DESIGN OF THE PUMP LASER

2.1 Er-doped Multimode Fiber

As mentioned above, the output power of a laser at

15XX nm based on commercially available single-

mode Er-Yb co-doped fiber is limited by parasitic

lasing near 1 µm. A solution to this problem could be

the utilization of Yb-free Er-doped double clad fiber

as the active media for high power pump lasers near

1532-1535 nm (for Er-doped fiber lasers) or 1560-

1600 nm (for Tm-doped fiber lasers). It was shown

recently that such fibers are able to demonstrate

optical-to-optical efficiencies up to 40% when

pumped at 980 nm (Kotov L.V., 2013. Opt. Lett.).

However, special design of these fibers is required.

This design includes a large core diameter to provide

high pump absorption, an optimized core

composition (including low concentration of Er

3+

ions) to suppress clustering. A fiber with a core

diameter of 35 µm was proposed and realized in

(Kotov L.V., 2013. Opt. Lett.). This core size was

limited by the requirements of single mode operation

and reasonably low bending loss. The maximum

slope efficiency demonstrated with this fiber was

40 % and was achieved at an operation wavelength of

1585 nm. This source is suitable for pumping Tm-

doped fiber lasers, but the long fiber length (~40 m)

and a relatively high bend sensitivity (fiber should be

wounded on a spool with 30 cm diameter) makes it

rather cumbersome. Moreover the influence of

clustering became much stronger for shorter

wavelengths and results in a reduction of the

efficiency down to 15 % near 1532 nm

(ICONO/LAT). Thus, such lasers are not applicable

for efficient pumping of the Er-doped single-mode

fiber lasers.

On the other hand, there is no need for a high

beam quality of the cladding pump for singlemode

fiber lasers. The parameters of the fiber core are

limited only by the requirement to match them to the

pump ports of standard pump combiners:

core/cladding diameters of 105/125 µm and

numerical apertures (NA) of 0.15. Therefore, the

active fiber core could be multimode and has

diameter up to 105 µm. We performed a numerical

analysis similar to (Kotov L.V., 2013. Opt. Lett.) to

define the optimum erbium concentration. The signal

grey loss was taken to be about 5 dB/km, pump loss

– to be about 20 dB/km. The pump-to-signal slope

conversion efficiency (PCE) of the amplifier based on

co-propagating pump and signal power based on

60/125 µm and 90/125 double-clad Er-doped fibers

operating at 1535 nm and 1585 nm were computed

(Fig 1a). An efficiency of about 45% for signal at

1532 nm and 47% for signal at 1585 nm could be

achieved. Wavelength dependence of maximum

pump-to-signal conversion efficiency (PCE) is rather

weak near the optimal concentration (see Fig.1b) and

its maximum lies near 1565 nm wavelength.

Figure 1: a - Computed pump-to-signal slope conversion

efficiency (PCE) of the amplifier at 1532 nm and at 1585

nm for different Er

3+

ions concentration and core/clad ratio;

b – PCE dependence on wavelength for Er concentration

about 710

24

m

-3

and core/clad ratio as 105/125 µm.

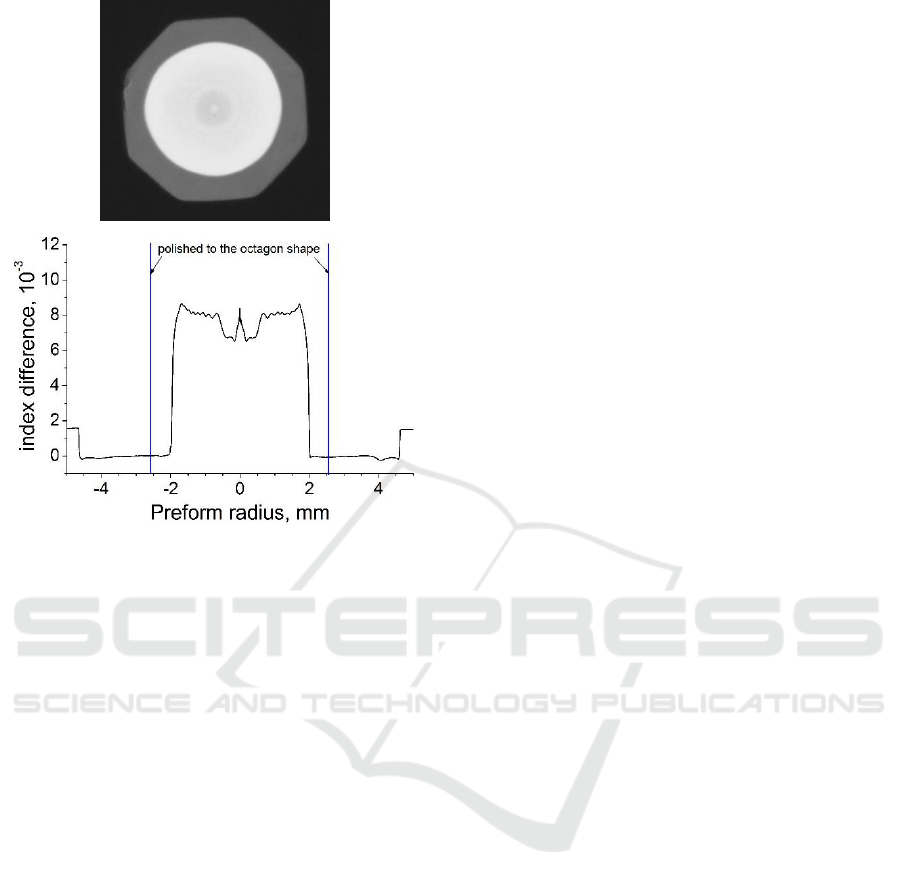

Based on the simulation results, a fiber preform

with aluminosilicate core and ~4∙10

24

m

-3

Er

3+

ions

concentration was produced using the Modified

Chemical Vapor Deposition (MCVD) technique. The

preform was polished to an octagonal shape and

double clad fiber was drawn down from it. The

resulting fiber has core/cladding diameters

of95/125 µm and was coated with polymer providing

a pump NA of 0.46. Microscope image of the fiber

facet is presented in Fig.2a. The refractive index

profile (RIP) of the fabricated MCVD preform is

presented in Fig. 2b. The core grey loss at 1200 nm

was measured to be about 35 dB/km.

a

b

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

100

Figure 2: a - Microscope image of the fiber facet; b -

Refractive index profile of the fabricated Er-doped preform.

2.2 Multi-mode Er-doped Fiber

Amplifier at 1565 nm

At first the developed multi-mode Er-doped fiber was

tested in a simple amplifier scheme, shown in Fig.3a.

The standard 2+1-to-1 pump and signal combiner was

used to deliver signal and pump into the Er-doped

fiber. Signal fiber was standard single-mode 8/125

µm double clad fiber. The pump ports were based on

standard 105/125 µm fiber. The pump module has

maximum pump power of 50 W and it wavelength

was stabilized at 976±0.5 nm by an internal volume

Bragg grating. The pump combiner output was

spliced to the developed multi-mode Er-doped fiber.

The multi-mode fiber output was spliced to a standard

multi-mode 105/125 µm fiber. A pump stripper

similar to the described in (Aleshkina S., Kochergina

T.A., 2016) was built at the splice point.

Our calculations has shown that the developed

amplifier has the maximum efficiency when operates

near 1565 nm. An Er-Yb laser with maximum output

power of 0.5 W (limited by available isolator) was

used as a seed source. The length of multi-mode Er-

doped fiber was about 16.7 m that is close to the

optimal one (according to our calculations).

Dependence of output power at 1565 nm on pump

power at 976nm is shown in Fig.3b. The dependence

of output power on input signal (see Fig.3c) shows

that the multi-mode fiber operated in saturation

regime. Both dependences are fairly close to those,

calculated using model and data (i.e. clustering level)

from (Kotov L.V., 2013. Opt. Lett.) and actual

parameters of the developed multi-mode fiber

(core/clad diameters, Er-concentration and grey loss).

The slope pump-to signal conversion efficiency was

found to be as high as 42.4%, which is the highest

ever reported value for high-power Er-doped fiber

lasers pumped at 980 nm. It is still below the

predicted maximum PCE (see Fig.1), which is caused

by increase of grey loss from 5 to 35 dB/km. We

suggest that improvement in preform production

process would result in further increase for the PCE

in the developed multi-mode fiber amplifier.

2.3 Multi-mode Pump Laser at 1535

nm

In addition to a high efficiency, there are other

important demands for the pump source:

compactness, high long-term stability, small size and

low cost. The amplifier scheme presented in previous

paragraph is quite efficient, but it requires operation

of additional seed laser. Presence of the seed laser that

is powerful enough to saturate the amplifier increases

the cost and footprint of the system and makes it more

cumbersome. Moreover, even in saturated regime the

back-reflected signal can strongly affect the amplifier

– a significant signal power might propagate in the

backward direction in this case. Thus, it is preferable

to keep power of the seed laser to be on the level of

4-10% of the output power to ensure a safe operation

regime. When output power would grows to the level

of 100 and even 200 W (see discussion section) the

required seed laser power would exceed limit that is

possible to achieve with Er-Yb lasers. By this reason

in this section we propose a new laser design, free

from aforementioned drawbacks.

The simplest and, therefore, the cheapest scheme

for a fiber laser consists of a gain fiber spliced

between two fiber Bragg gratings (FBGs). However,

it is known that different modes have different

reflection spectra from FBG written in multimode

fiber. As a result, the spectrum of such a multimode

laser has several peaks (Kurkov A.S., 2007), leading

to effective spectral broadening. In addition, this

effect could result in unstable operation because of

mode competition. To ensure a narrow spectrum of a

multimode laser, a master oscillator power amplifier

(MOPA) scheme could be used.

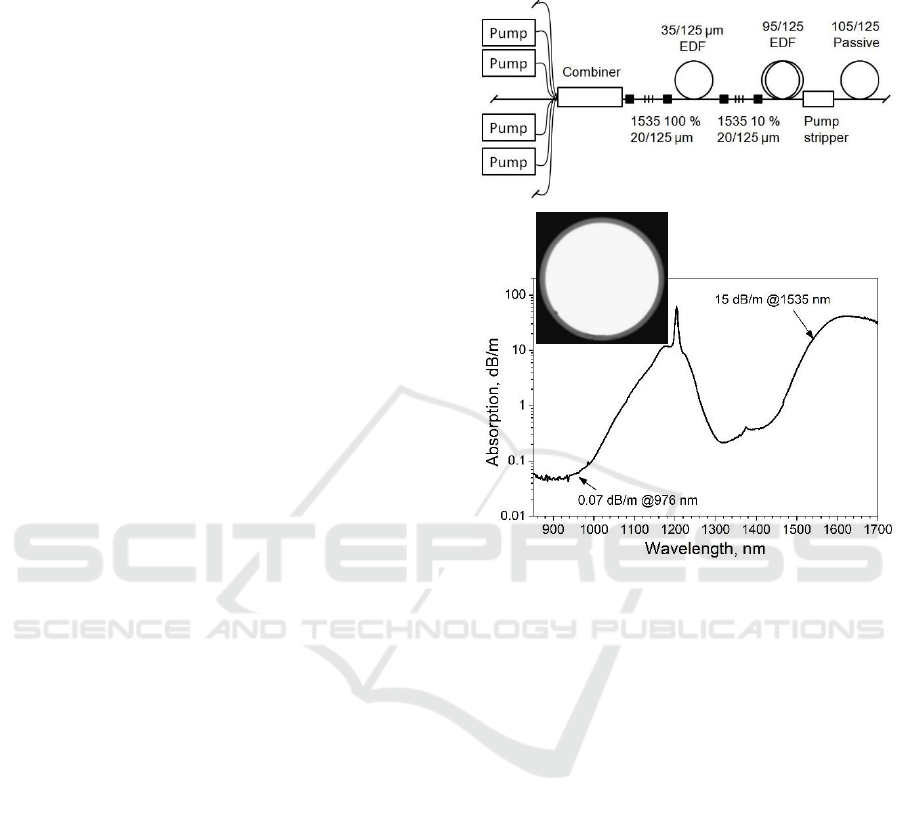

In this work, we propose the new, simple

multimode laser scheme shown in Fig. 4 a. A pump at

a

b

High Brightness Multi-Mode Fiber Lasers - A Novel Sources for in-Band Cladding Pumping of Singlemode Fiber Lasers

101

980 nm was launched into the cavity formed by 1.5 m

of the single-mode double clad EDF developed in

(Kotov L.V., 2013. Opt. Lett.) and a pair of FBGs.

Four multimode pump diodes with an operation

wavelength stabilized at 976 nm and overall

maximum power of 173 W were coupled through a

commercially available 7x1 pump combiner into the

laser resonator. The FBGs were written in 20/125

passive fiber (NA~0.08/0.45) and had reflections of

~100 % and 10 % at 1535 nm with bandwidths <0.8

nm. The small-signal absorption from the cladding

near 980 nm of the single-mode EDF is ~0.6 dB/m

(Kotov L.V., 2013. Opt. Lett.), so only ~5 % of the

overall pump power was absorbed in the single-mode

laser cavity. It generated light at 1535 nm with a slope

efficiency of ~45 % with respect to the absorbed

power. This signal was used as the seed radiation for

the 12 m piece of multimode EDF described above

that was spliced to the 10 % FBG of the single-mode

cavity. Commercially available 105/125 µm

multimode fiber was spliced at the output of the laser,

and a cladding pump stripper similar to that described

in (Aleshkina S., Kochergina T.A., 2016) was built at

the splice point. Therefore, the seed laser and

amplifier were both pumped by the same pump

diodes at 976 nm, and the spectral width of the laser

was locked by the FBGs written in the single mode

fiber, resulting in a relatively narrow output spectrum.

A specially developed multimode Tm-doped fiber

was produced using the MCVD technique in order to

protect the pump diodes from possible backward

radiation near 1.5 µm. The fiber had a Tm-doped

germanosilicate core and pure silica cladding with

diameters of 105/125 µm and NA~0.22 (see insert to

Fig4b). Thus, this fiber was matched to standard

multimode pump fibers. The fiber loss was measured

to be ~15 dB/m at 1535 nm and <70 dB/km at 976 nm

(see Fog.4b). Two meter pieces of the Tm-doped fiber

were spliced to each pump diode (not shown in Fig. 4

a). Due to the low feedback, large core diameter and

long length of the Tm-doped fibers, the threshold for

2 µm lasing was orders of magnitude higher than the

power of the potential back-propagating signal.

Therefore, this signal would only be absorbed by the

Tm ions and converted into spontaneous

luminescence and heat. Thus, the developed Tm-

doped fiber is an efficient pump protector for high

power systems operating near 1.55 µm and pumped

at 980 nm.

Fig. 5 a shows the output power of the developed

multimode laser; 60 W of output power, which was

limited by the available pump power, was achieved.

The slope efficiency of the laser was estimated to be

35 %. The output spectrum measured over all spectral

Figure 3: a - Scheme of the multi-mode Er-doped fiber

amplifier; b – Dependence of the output power at 1565 nm

on pump power, insert – output spectrum; c - Dependence

of output power on input signal power at 1565 nm (pump

power was fixed at 20 W). Blue lines – calculations,

symbols – measurements.

range with 0.5 nm resolution is presented in the Fig.

5 b. A small part (~8 % relative to the output power

of the laser) of unabsorbed pump at 976 nm was

propagated in the multimode laser core together with

the signal near 1535 nm. No active cooling was

applied to the EDF during operation. Short-term

temporal stability was investigated using a

photodetector. A stable cw operation without self-

pulsing was found (see Fig.5 c). Typical for all CW

lasers noise on the time trace was caused by

interference of different modes within 0.5 nm spectral

bandwidth.

b

c

a

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

102

3 DISCUSSION

This work is devoted to a new concept of a multimode

pump laser which could be used for in-band pumping

of single-mode fiber lasers. Highly efficient operation

is demonstrated for 1565 nm signal wavelength

(suitable for pumping of Tm-doped fiber lasers) and

for 1535 nm signal wavelength (suitable for pumping

of Er-doped fiber lasers). An output power of 60 W at

1535 nm was achieved with a slope efficiency of 35

% with respect to the launched pump power at 976

nm. Taking into account the electrical-to-optical

efficiency of the diodes at 980 nm (50 %), the overall

"wall-plug" efficiency of the developed laser is ~17.5

%, which is fairly close to that of multimode diodes

operating in this spectral region (25 %). Meanwhile,

there are two serious advantages of the developed

source over semiconductor pump diodes:

First, it has perfect output wavelength

stabilization. The laser scheme includes FBGs written

into single-mode fiber as a wavelength-stabilizing

element. For this reason, the multimode fiber laser

operates with a narrow bandwidth (~0.5 nm) at the

chosen central wavelength independent of the output

power. At the same time, thermal drift and a broad

output spectrum are well-known problems of high

power semiconductor diodes.

Second, the demonstrated power of 60 W is

already higher than the values that could be found

from commercially available multimode diodes at

1535 nm with 105/125 µm output fibers (typically ~

30 W). The demonstrated output power is guided by

the core with diameter of 105 µm and NA of 0.15. To

the best of our knowledge obtained brightness of

7.6610

4

W/mm

2

sr is the highest ever reported

brightness for this spectral region.

Also it should be stressed that power of the

proposed multi-mode fiber laser could be easy scaled.

Indeed, only four of seven pump ports of the laser

were utilized in the experiment. This means that using

three additional pump diodes at 976 nm with the same

power level it is possible to increase output power to

more than 100 W power level. Moreover a 100 W

multimode pump diode sources at 976 nm with

105/125 µm fiber pigtail are commercially available.

Thus, the utilization of 7 of them and a 7 to 1 pump

combiner allows one to achieve more than 200 W at

1535 nm from 105/125 fiber with NA=0.15 at the

output of the multimode laser. Finally even this

output power level from multi-mode fiber laser is not

limited. As it was seen in Fig.1a the decrease of PCE

is not very significant for Er-doped multi-mode fiber

with core-to-clad ratio about 0.5 (60/125 µm). This

means that multi-mode Er-doped fiber with core and

clad equal to 100 and 200 µm could be realized and

its PCE can be equal to 35% (same as in

Figure 4: a - Scheme of the multi-mode Er-doped fiber

laser; b – Absorption in the Tm-doped 105/125 µm fiber,

used as pump protector; insert: Tm-doped fiber cross

section.

current laser) if the fiber grey loss are optimized.

Currently pump combiners with 19 pump ports

(105/125 µm, NA=0.15) and output into fiber with

outer diameter of 200 µm and NA=0.45 are

commercially available. This means that there are no

fundamental limitation to scale output power of

multi-mode lasers at 1530-1590 nm (output inside

105/125 µm fiber with NA=0.15) to the level of 600

W of output power.

Utilization of such powerful pump sources instead

of semiconductor pump diodes (Zhang J., 2011) or

Er-Yb fiber lasers (Jebali M.A., 2014) could be very

promising. In particular using of 7+1-to1 pump

combiner and 7 such pump sources with a highly

efficient in-band pumped Er-doped fiber laser (up to

75% PCE was demonstrated in (Jebali M.A., 2014))

could allow one to scale output power of the single-

mode laser to the unprecedented level of more than 3

kW.

Same pump and laser design could be utilized for

Tm-doped fiber lasers. Moreover a higher

demonstrated PCE for the multi-mode Er-doped

a

b

High Brightness Multi-Mode Fiber Lasers - A Novel Sources for in-Band Cladding Pumping of Singlemode Fiber Lasers

103

Figure 5: a – Dependence of the output power at 1535 nm

and unabsorbed pump on pump power at 976 nm, b –

Typical spectrum at the laser output, c – time trace from

photodetector.

fiber laser operated at 1565 nm (42.4%) simplify

power scaling to even higher level. Simple utilization

of seven 100 W semiconductor lasers at 976 nm

would allow one to achieve near 300 W output pump

level. Optimization of parameters of Er-doped fiber

with core and cladding diameters of 100 µm and 200

µm should allow one to increase output power to 800

W. A high in-band PCE efficiency of Tm-doped

lasers (70% in (Shen D.Y., Sahu J.K., and Clarkson

W.A., 2006)) can allow power scaling to almost 4 kW

level.

Finally the power scaling of Yb-doped fiber lasers

looks most promising with such laser design. In this

case utilization of 100/400µm multi-mode Yb-doped

fiber could allow one to realize few-kW multi-mode

pump sources near 1.01-1.04 µm. In its turn

utilization of such source to pump fiber laser, based

on a perfectly single-mode (10..15)/(200..400) µm

fiber can allow one scale output power of single-

mode Yb-doped lasers to over 10 kW.

4 CONCLUSIONS

In conclusion, a simple, cheap and efficient scheme

of the pump multimode laser has been proposed and

realized. PCE of 35-42 % and output power up to

60 W was demonstrated with realized lasers schemes.

Simple power scalability of such pump source is

discussed. A new approach for the development of

high-power, in-band pumped, single-mode fiber

lasers is presented. Thanks to the easy power

scalability of the developed system, few kWs-level

single-mode Er-doped and Tm-doped fiber lasers

near 1.55 µm could be realized in the near future.

Possibility to apply the same laser concepts for the

Yb-doped fiber lasers and scale output power of

single-mode lasers to beyond 10 kW are also

indicated.

ACKNOWLEDGEMENTS

This work was supported by grant 16-12-10553 from

the Russian Science Foundation. The authors are

grateful to E.M. Dianov, scientific supervisor of the

Fiber Optics Research Center for his continuous

interest in and support of this work.

REFERENCES

Zhang J., Fromzel V., and Dubinskii M., 2011. Resonantly

cladding-pumped Yb-free Er-doped LMA fiber laser

with record high power and efficiency, Opt. Express,

19, 5574-5578.

Jebali M.A., Maran J.-N., and LaRochelle S., 2014. 264 W

output power at 1585 nm in Er–Yb codoped fiber laser

using in-band pumping, Opt. Lett. 39, 3974-3977.

Sobon G., Sliwinska D., Abramski K.M. and Kaczmarek P.,

2014. 10 W single-mode Er/Yb co-doped all-fiber

amplifier with suppressed Yb-ASE, Laser Phys. Lett.

11, 025103.

Aleshkina S.S., Likhachev M.E., Lipatov D.S., Medvedkov

O.I., Bobkov K.K., Bubnov M.M., Guryanov A.N.,

2016. 5.5 W monolitic single-mode fiber laser and

a

b

c

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

104

amplifier operating near 976 nm, Proc. SPIE 9728,

Fiber Lasers XIII: Technology, Systems, and

Applications, 97281C (March 11);

doi:10.1117/12.2209610.

Kotov L.V., Likhachev M.E., Bubnov M.M., Medvedkov

O.I., Yashkov M.V., Guryanov A.N., Lhermite J.,

Fevrier S., and Cormier E., 2013. 75 W 40% efficiency

single-mode all-fiber erbium-doped laser cladding

pumped at 976 nm, Opt. Lett. 38, 2230-2232.

Kotov L., Likhachev M., Bubnov M., Medvedkov O.,

Yashkov M., Guryanov A., Fevrier S., Lhermite J.,

Cormier E., 2013. Optimization of double-clad Er-

doped fibers for high power highly efficient lasers and

amplifiers, ICONO/LAT 2013, paper LWF4.

Aleshkina S., Kochergina T.A., Bobkov K.K., Kotov L.V.,

Bubnov M.M., Park J., and Likhachev M.E., 2016.

High-Power 125-μm-Optical-Fiber Cladding Light

Stripper, in Conference on Lasers and Electro-Optics,

OSA Technical Digest (online) (Optical Society of

America, 2016), paper JTu5A.106.

Kurkov A.S., Paramonov V.M., Yashkov M.V., Goncharov

S.E. and Zalevskii I.D., 2007. Multimode cladding-

pumped erbium-doped fibre laser, Quantum Electron.

37(4), 343.

Shen D.Y., Sahu J.K., and Clarkson W.A., 2006. High-

power widely tunable Tm:fibre lasers pumped by an

Er,Yb co-doped fibre laser at 1.6µm, Opt. Express 14,

6084-6090.

High Brightness Multi-Mode Fiber Lasers - A Novel Sources for in-Band Cladding Pumping of Singlemode Fiber Lasers

105