Compensation Filters for Visualization of White Leds through the

Ceramic Glass in Induction Cooktops

Enrique Carretero, Rafael Alonso and Cristina Pelayo

Department of Applied Physics, University of Zaragoza, C/Pedro Cerbuna, 12, 50009 Zaragoza, Spain

Keywords: Interference Filters, Thin Films, Color Compensation, Illumination.

Abstract: White LEDs visualization in induction cooktops is hindered by the non-uniformity in wavelength of the

transmission of the ceramic glass used as the cooking surface, as it modifies the chromaticity of the LEDs.

In this work, a compensation filter is developed by thin-film interference filter deposition techniques, which

has a transmission spectrum that allows for the preservation of the light source intrinsic chromaticity. This

permits a perfect visualization of white LEDs across ceramic glasses.

1 INTRODUCTION

Nowadays, induction heating cooktops are one of

the most common home appliances. One main

feature of these cooktops is the fact that they use a

ceramic glass as cooking surface, by means of which

they successfully isolate the electronics of the device

from the user. Such ceramic glass must have some

very specific characteristics, as a very low

coefficient of thermal expansion, so that it can

withstand high thermal gradients without cracking

(Siebers et al., 2013).

Currently there are two types of ceramic glasses,

which mainly differ in their optical properties,

particularly in their visible transmittance. On the one

hand, bulk absorption ceramic glass is the typical

black-coloured glass (with low reflection and high

absorption) integrated in most low-medium range

cooktops (SCHOTT, 2010). On the other hand,

transparent ceramic glass can be used on cooktops,

but it requires the deposition of a coating that

confers a proper aesthetic appearance to the cooking

surface (SCHOTT, 2012). This second option is

more expensive and is at present aimed at top-of-

the-range products.

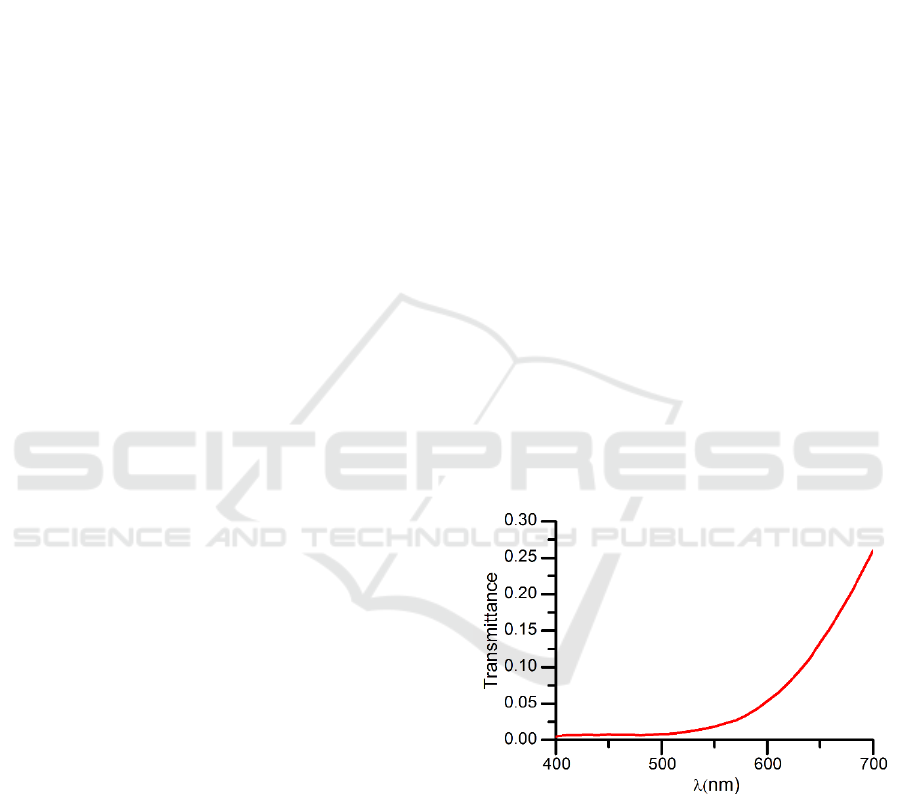

A serious disadvantage of the black-coloured

bulk absorption ceramic glass is the non-uniformity

of its transmittance over the visible spectrum range

(Fig.1). Its transmittance increases with wavelength,

and that is the main reason why signalling and

illumination in induction cooktops has been

traditionally based on red LEDs, as the value of

transmittance at the wavelength of the colour red

(630nm) is higher than for other visible colours

(blue, green…). At present, the strong attenuation

the ceramic glass produces over blue can be

compensated by the enhancement in the

performance of blue LEDs and the use of high

power LEDs.

Figure 1: Visible transmittance of “Brigther

HighTransECO (Schott)” ceramic glass.

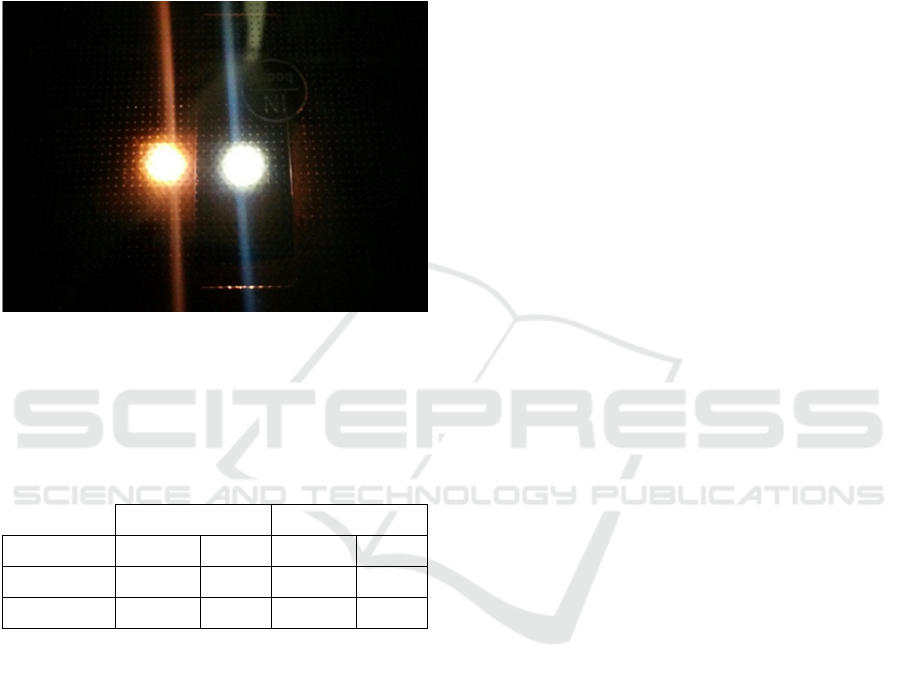

Another significant effect of the use of ceramic

glass on cooktops is the fact that when a light source

with a relatively wide spectrum as a white LED is

used (Fig.2), the non-uniform transmittance of the

glass notably changes the chromaticity of the LED.

This effect implies that a white LED seen through a

bulk absorption ceramic glass is visualised as a pink-

orange colour (Fig.3).

Carretero E., Alonso R. and Pelayo C.

Compensation Filters for Visualization of White Leds through the Ceramic Glass in Induction Cooktops.

DOI: 10.5220/0006167602650268

In Proceedings of the 5th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2017), pages 265-268

ISBN: 978-989-758-223-3

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

265

This work tackles the problem of the

chromaticity change for wide spectrum light sources.

A compensation interference filter has been

designed so that the filter+ceramic glass system has

a closely neutral transmittance in the visible range of

the spectrum. The compensation filter is based on a

multilayer structure of SiAlO

x

and TiO

x

thin films

deposited by magnetron sputtering.

Figure 2: Visible spectrum of a white LED.

Figure 3: Visualization of a white LED through a ceramic

glass.

Interference filter development by means of

dielectric thin films is a well-known technique (J. A.

Dobrowolski, 1995; Macleod, 2010; Thelen, 1989).

In this way, using one dielectric material with a high

refraction index, as TiO

2

with n=2.34 @550nm

(Palik, 1985), and another dielectric material with a

low index of refraction, as SiAlO

x

with n=1.47

@550nm, a transmittance curve can be achieved that

compensates for the non-uniformity of the ceramic

glass transmittance.

TiO

2

is a commonly used dielectric material with

a high index of refraction, so one can easily find

several references in this regard (Willey, 2002). As a

low index material, SiO

2

is more typically used (Gao

et al., 2013; Thelen, 1989), but we have rather

deposited SiAlO

x

films which comprise a low

percentage of Al, because it enhances deposition

conditions (faster sputtering rate, fewer electric arcs

occur during deposition…) and has a very similar

refraction index to that of SiO

2

.

This proposed solution also presents some

advantages for its use with transparent ceramic

glass, because this type of glass requires a multilayer

deposited over its entire surface, while the

compensation filter is only needed in the user

interface area of the cooktop, where the illumination

and signalling elements are placed. Furthermore, the

thermal requirements for the multilayer are less and

can be easily achieved because the filter does not

cover the cooking area.

2 MATERIALS AND METHODS

Optical interference filters were deposited in a semi-

industrial high vacuum magnetron sputtering system

by the DC pulsed technique (Martin, 2009; Mattox,

2010) using rectangular targets with dimensions

600x100mm and 12mm thick. Substrates were

microscope slide pieces of 76x25mm and 1mm

thick. Substrates were cleaned with a detergent

solution (ACEDET 5509) and finally rinsed with

distilled water.

Thin films were grown with a base pressure of

2.0·10

-6

mbar and working pressure in the range of

10

-3

mbar. Ar and O

2

(both 99.99%) flows were

introduced into the process chamber and controlled

via mass flow controllers. The substrate was

maintained at room temperature during deposition.

Thin films of SiAlO

x

were deposited by reactive

sputtering from a SiAl target (90% Si and 10% Al,

99.99% pure). Applied power was 2500W,

equivalent to a power density of 4.17W/cm

2

. The Ar

flow was fixed at 160sccm (Standard Cubic

Centimeters per Minute) and the O

2

flow at 40sccm

(In our deposition system a flow of 200sccm is

approximately equivalent to a pressure of 1.5·10

-3

mbar). Thin films of TiO

2

were deposited by

reactive sputtering from a Ti target (99.99% pure).

Applied power was 5000W, equivalent to a power

density of 8.33W/cm

2

. This power is high because

the sputtering rate of TiO

2

is very low, in this way

we get a reasonable deposition rate. The Ar flow

was fixed at 140sccm and the O

2

flow at 60sccm.

Spectrophotometric measurements were

performed with a home-made spectrophotomer

(designed and built by some of the authors) in the

visible region of the electromagnetic spectrum,

between 400nm and 700nm with 10nm intervals, at

an angle of incidence of 8º. Only specular

transmittance was measured, without an integrating

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

266

sphere, because the “low” roughness of the substrate

minimizes the scattered component to negligible

values and because the specular measurements are

more precise.

The macroscopic roughness of the internal side

of the ceramic glass makes it difficult to measure its

specular transmittance. An epoxy resin (epo-tek 301

type) with a low optical absorption and an index of

refraction similar to that of the ceramic glass was

applied to correct that roughness, and to stick the

compensation filter to the ceramic glass.

3 RESULTS

The transmittance spectrum of the compensation

filter should be one that meets the following

expression in the visible region of the spectrum:

filter glass

TT cte

(1)

If the filter+ceramic glass system has a constant

transmittance, it won’t unbalance the wide spectrum

of the illumination source, so there won’t be certain

wavelengths gaining weight and the compensation

effect won’t be achieved.

Therefore, one can calculate the transmittance

curve of the compensation filter from the measured

transmittance curve of the ceramic glass. Once we

knew the target transmittance, we proceeded to the

design of the multilayer using a simulation software

that is based on formalisms used for the calculation

of optical properties for interference coatings

(Macleod, 2010; Thelen, 1989).

A 9-layer structure was estimated as satisfactory

enough to achieve the necessary contrast between

high and low transmittance areas for an adequate

compensation filter (Table 1).

Figure 4 shows the transmittance curves for an

ideal filter+ceramic glass system (calculation, blue

line) and for the real system (measured, green line).

The transmittance absolute value of the ideal system

has been located at 0.65% because the ceramic glass

transmittance in the wavelength range of the blue

colour is around 0.70%, and this value represents an

upper limit. The transmittance curve of the

experimentally made system is close to the ideal

value, although in the limits of the visible range of

the spectrum we find more discrepancies, but in this

range the human eye sensitivity is low, so this zone

has less relative weight when determining the

chromaticity of the light source that is used. In this

way, a discrepancy lower than 15% is accomplished

between the ideal and real measured values of

transmittance, whereas the ceramic glass without the

filter has a transmittance which is 10 times lower at

460nm (blue peak of a white LED spectrum) tan at

620nm (where the phosphorescent emission of the

LED is still high and human eye sensitivity is still

considerable).

Table 1: Thin film structure and layer thicknesses of the

compensation filter.

Material Thickness (nm)

Substrate 1 mm

TiO

2

85

SiAlO

x

143

TiO

2

72

SiAlO

x

116

TiO

2

70

SiAlO

x

104

TiO

2

69

SiAlO

x

93

TiO

2

78

Figure 4: Transmittance curves for: compensation filter

(black line), ceramic glass (red line), real filter+ceramic

glass system (green line) and ideal filter+ceramic glass

system (blue line).

By using a greater number of layers, we can

better adjust the experimental system to the ideal

one, as a greater number of adjustment parameters

for the multilayer appear (i.e., the thicknesses of

each layer). Nevertheless, it has been proven that the

developed filter achieves good results and manages

to correct the chromaticity change for white LEDs.

Figure 5 finally shows the visualization of two white

LEDs through a ceramic glass, illustrating the effect

of the compensation filter, which accomplishes the

goal of a good colour reproduction.

Compensation Filters for Visualization of White Leds through the Ceramic Glass in Induction Cooktops

267

The chromaticity coordinates of a light source

having the spectrum of the D65 illuminant seen

through a ceramic glass are far from the white colour

coordinates, as well as those of a typical white LED

seen through a ceramic glass. However, when the

compensation filter+ceramic glass system is used,

the chromaticity coordinates in both cases are within

the zone of the white colour (Table 2).

Figure 5: Visualization of a white LED through a ceramic

glass: without compensation filter (left) and with

compensation filter (right).

Table 2: Chromaticity coordinates for the ceramic glass

and for the compensation filter+ceramic glass system,

expressed by using the D65 illuminant and a white LED

(Osram model LW W5SM).

Ceramic glass Cer. glass+filter

Illuminant D65 LED D65 LED

x 0.54 0.52 0.31 0.32

y 0.37 0.38 0.33 0.32

4 CONCLUSIONS

This work verifies that thin-film interference optical

filters can be used to compensate the non-uniformity

in transmittance of the ceramic glass that is used in

induction cooktops. There are several alternative

manufacturing methods for such filters, but optical

interference filters allow a greater adjustment of its

transmittance curve. In this case, a nine-layer

structure alternating TiO

2

(high index of refraction)

and SiAlO

x

(low index of refraction) layers is

necessary. Adding this filter into the illumination

and signalling area of induction cooktops, we can

correct the chromaticity change that the ceramic

glass introduces for wide spectrum light sources,

such as white LEDs. This effect has been verified

not only visually but also by calculation of the

chromaticity coordinates for light sources with

spectra of the D65 illuminant and of a white LED.

ACKNOWLEDGEMENTS

We thank Carmen Cosculluela for her valuable help.

This work was partly supported by the Spanish

MINECO under grant RTC-2014-1847-6, in part by

the Diputación General de Aragón / Fondo Social

Europeo through the funding for the Photonics

Technologies Group (GTF), in part by the

Diputación General de Aragón under FPI

programme B143/12 and in part by the BSH Home

Appliances Group.

REFERENCES

Gao, L., Lemarchand, F., Lequime, M., 2013. Refractive

index determination of SiO2 layer in the UV/Vis/NIR

range: spectrophotometric reverse engineering on

single and bi-layer designs. J. Eur. Opt. Soc.-Rapid

Publ. 8, 13010. doi:10.2971/jeos.2013.13010.

J. A. Dobrowolski, 1995. Optical properties of films and

coatings, in: Handbook of Optics. McGraw-Hill.

Macleod, H.A., 2010. Thin-Film Optical Filters, Fourth

Edition. CRC Press.

Martin, P.M., 2009. Handbook of Deposition Technologies

for Films and Coatings: Science, Applications and

Technology. William Andrew.

Mattox, D.M., 2010. Handbook of Physical Vapor

Deposition (PVD) Processing. William Andrew.

Palik, E.D., 1985. Handbook of optical constants of solids.

Academic Press, Orlando.

SCHOTT, 2012. CERAN CLEARTRANS Cooktops

Panels, Technical Delivery Specification TL 1 09 23

01 - 02.

SCHOTT, 2010. CERAN HIGHTRANS eco Cooktops

Panels, Technical Delivery Specification TL 1 07 04

01 - 03.

Siebers, F., Weiss, E., Gabel, F., 2013. Glass ceramic as a

cooktop for induction heating having improved

colored display capability and heat shielding, method

for producing such a cooktop, and use of such a

cooktop. US2013201678.

Thelen, A., 1989. Design of Optical Interference Coatings.

McGraw-Hill.

Willey, R.R., 2002. Practical Design and Production of

Optical Thin Films. CRC Press.

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

268