Event Classification from Sensor Data using Spectral Analysis in Robotic

Finishing Processes

Bobby K. Pappachan

1

, Tegoeh Tjahjowidodo

2

and Tomi Wijaya

1

1

Rolls-Royce @ NTU Corporate Lab c/o, Nanyang Technological University, 65 Nanyang Avenue, Singapore, Singapore

2

Nanyang Technological University, Singapore, Singapore

Keywords:

Machining, Finishing, Passes, Welchs Estimate.

Abstract:

Process monitoring using indirect methods leverages on the usage of sensors. Using sensors to acquire vital

process related information also presents itself with the problem of big data management and analysis. Due to

uncertainty in the frequency of events occurring, a higher sampling rate is often used in real-time monitoring

applications to increase the chances of capturing and understanding all possible events related to the process.

Advanced signal processing methods helps to further decipher meaningful information from the acquired

data. In this research work, power spectrum density (PSD) of sensor data acquired at sampling rates between

40 kHz-51.2 kHz was calculated and the co-relation between PSD and completed number of cycles/passes is

presented. Here, the progress in number of cycles/passes is the event this research work intends to classify

and the algorithm used to compute PSD is Welchs estimate method. A comparison between Welchs estimate

method and statistical methods is also discussed. A clear co-relation was observed using Welchs estimate to

classify the number of cyceles/passes.

1 INTRODUCTION

In machining processes, ensuring the quality of a fin-

ished product is crucial and with advances in man-

ufacturing technology, a need exists to integrate in-

process monitoring technology into the production

environment, so as to avoid manufacturing induced

anomalies (G. Byrne and Teti, 1999; D. Dornfeld

and Vijayaraghavan, 2009). Advanced process mon-

itoring technology coupled with an intelligent deci-

sion making support system can reduce the time taken

to otherwise perform rework on finished components

with defects. This will save costs and also reduce

the dependency on skilled operators. A report re-

leased by the Federal Aviation Authority (FAA) in

partnership with the Aerospace Industries Association

(AIA) Rotor Manufacturing (RoMan) Project Team in

the year 2006, stresses the importance of incorporat-

ing advance process monitoring and control technol-

ogy in manufacturing processes especially for critical

aerospace components (Team, 2006). Process mon-

itoring is generally classified into direct and indirect

methods. In direct method, the quantity of the output

variable is measured or monitored directly whereas

in indirect method, the output variable is deduced

through monitoring the quantity of process variables

such as vibration, speed (P. Stavropoulos and Chrys-

solouris, 2013). While direct method is known for

its accuracy, indirect method is widely accepted since

they are more realistic to be implemented in an indus-

trial environment as the cost incurred is comparatively

less than direct method. Indirect process monitor-

ing is performed by capturing these process variables

with the means of sensor systems for e.g., accelerom-

eter, dyanamometer, temperature sensor etc. Standard

data acquistion (DAQ) systems are then used to ac-

quire, sample and log the data. The data is further

analysed to identify any significant and/or persisting

trend/patterns. Subsequently, the analysed data can

be used to deduce the required output variable. This

analysis can also be performed real-time making indi-

rect method more efficient than direct methods. A im-

portant step involved in the data analysis is to identify

the signal signature. This paper focuses on identify-

ing a relevant signature that gives direct information

of the progress of machining process. In the sections

following, an overview of sensor based monitoring

and signal processing methods in machining applica-

tions is presented. Sections 3 and 4 covers the exper-

iment setup under which this research work was per-

formed, the results received and inferences deduced

from the results.

80

Pappachan B., Tjahjowidodo T. and WIjaya T.

Event Classification from Sensor Data using Spectral Analysis in Robotic Finishing Processes.

DOI: 10.5220/0006204900800086

In Proceedings of the 6th International Conference on Sensor Networks (SENSORNETS 2017), pages 80-86

ISBN: 421065/17

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 PROCESS MONITORING IN

MACHINING

Machining is the term used for manufacturing pro-

cesses that involves varying range of material re-

moval rate (MRR). Machining performed with hard

tool/cutter has higher material removal rate compared

with finishing processes wherein compliant abrasive

tools/brushes/belts are used. In a machining process

monitoring system as shown in figure 1, the cutting

region comprises of several process variables, such as

vibrations, cutting forces, acoustic emission, temper-

ature, surface finish. The various factors that influ-

ence these process variables include the state of the

cutter/tool, coolant flow, chip packing and other ma-

terial removal process conditions.

Figure 1: Building blocks of machining process monitor-

ing(Indirect).

By using appropriate physical sensors, the vari-

able that needs to be measured can be continually

monitored and variations can be logged (R. Teti and

Dornfeld, 2010). The data acquired is processed with

the aim to identify patterns, trends or abnormal pro-

cess conditions. Further analysis is performed on the

acquired data with the help of machine learning algo-

rithms such as neural networks and fuzzy logic. Upon

detection of any process related information or pro-

cess faults, the information is communicated either

to the operator or fed directly to robot controller to

take relevant corrective/adaptive actions (R. Teti and

Dornfeld, 2010; C. Bisu and Cahuc, 2013). A ma-

jority of past research works on process monitoring is

performed on processes involving hard tool, for e.g.

milling, turning. In most cases the focus of the work is

inclined towards tool condition monitoring (G. Byrne

and Teti, 1999). Focus of this research work is to

identify information that has some co-relation with

the completed number of passes in a robot assisted

finishing process. This was achieved by analyzing the

corresponding magnitude levels of frequency domain

signal from different passes and belonging to a fixed

frequency band. Further details on the experiment are

mentioned in section 3.

2.1 Sensing System and Signal

Processing

Some potential measurable process phenomena in a

robotic machining environment are shown in figure

2. Power and current flow of the spindle delivers

the required cutting force. Hence monitoring the

power intake and current flow in motors that drive the

spindle can be used to understand the MRR (G. W.

Fritz Klocke, 2008; Pritschow and Kramer, 2005).

However, in robot assisted finishing processes, mon-

itoring and implementing spindle drive control is im-

practical due to complex architecture compared with

traditional milling or turning machines or numerical

control (NC) machines. As shown in figure 2, mon-

itoring the measurable phenomena which are closer

to the machining area is a better alternative to under-

stand and analyse the nature of the process. This in-

clude acoustic emission (AE), force/torque exerted by

the tool on the workpiece, vibration and spindle mo-

tion displacement.

Figure 2: Measurable phenomena in machining environ-

ment.

Signal signatures often consist of embedded infor-

mation which can be co-related to process variable

itself. Signal processing plays a pivotal role in per-

forming this task by extracting the relevant signatures

and also to identify trends/patterns. Wide range of

signal processing techniques exists and choosing an

ideal technique relies heavily on the type of applica-

tion. Acoustic emission (AE) sensor is known for its

susceptibility towards high frequency signals (above

20 kHz) and clearly seems to be a favorite choice in

most machining process monitoring applications. Us-

ing AE sensor also reduces the requirement to per-

form further signature extraction as AE signal has

Event Classification from Sensor Data using Spectral Analysis in Robotic Finishing Processes

81

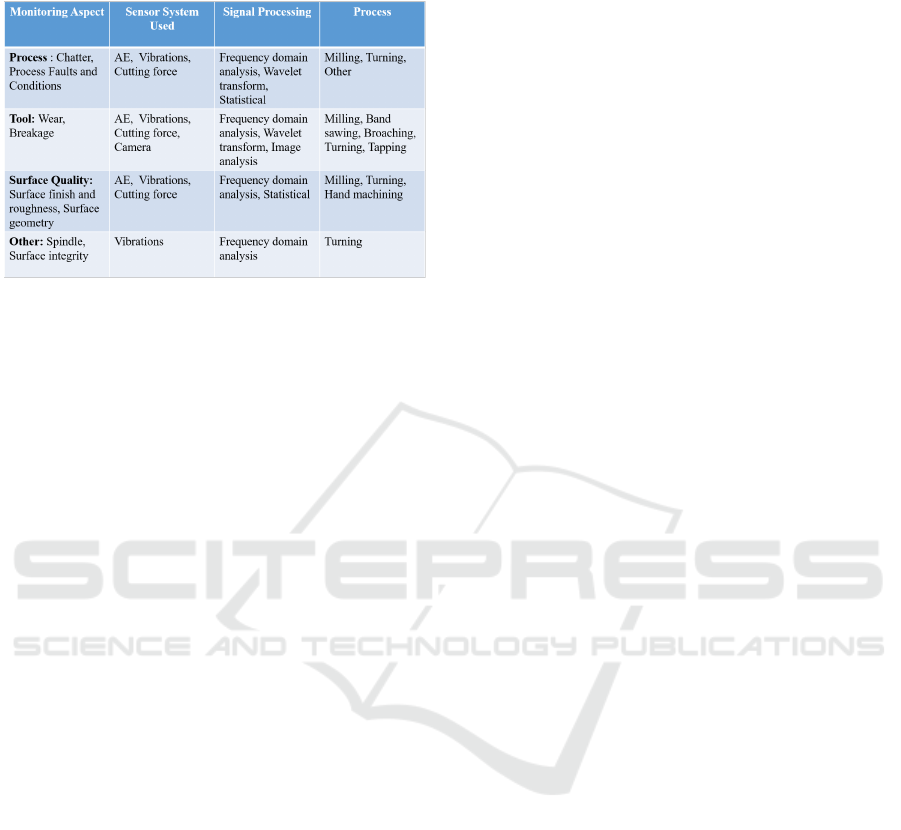

Table 1: Process monitoring classified based on monitoring

variable. (R. Teti and Dornfeld, 2010).

relatively higher signal to noise (S/N) ratio and im-

proved frequency response for high frequencies (Lee

and Dornfeld, 1998). However, in applications that

involve low material removal rate (MRR), magnitude

of elastic waves produced by tool-workpiece interac-

tion is much lower compared to processes like turn-

ing, milling, drilling etc. In such cases, other sensing

systems must be relied upon to give meaningful in-

formation regarding the process (e.g. Vibration sen-

sor). Table 1 gives a summary of past literature on

types of sensing system and signal processing used,

classified based on monitoring aspect. An exhaustive

review on process monitoring including the types of

sensors used and signal processing methods is given

in (R. Teti and Dornfeld, 2010). In our experiments

we have employed a tri-axial accelerometer to capture

vibration data.

2.2 Frequency Domain Analysis

Signal processing techniques can be broadly classi-

fied as time domain and frequency domain. Sev-

eral researches have used both techniques in appli-

cations involving tool wear/breakage detection and

indirect surface integrity detection. For instance, in

(T. I. El-Wardany and Elbestawi, 1996), kurtosis(time

domain) and frequency domain analysis is used suc-

cessfully to understand tool properties in a drilling

process. In time domain analysis, statistical meth-

ods are used to distinguish persisting patterns/trends.

This includes skewness, kurtosis, co-relation coeffi-

cient etc.In frequency domain analysis, captured sig-

nal is analyzed in the frequency domain and changes

to individual frequency components are often indica-

tive of the changes in process variables.

Frequency domain analysis also helps to visualize the

effect of noise filtering and various other window-

ing and filtering techniques. As the sampling fre-

quencies in this experiment falls in the range of 40-

51.2 kHz, performing time domain analysis proved to

be challenging due to the size of data captured and

hence frequency domain analysis was effective to un-

derstand process characteristics. Signal power also

contains pertinent information regarding the source of

signal generation. Conventionally, fast fourier trans-

form (FFT) can be used to determine power spec-

trum. In stochastic processes, performing FFT will

not be useful to reduce the noise embedded in the sig-

nal, hence some averaging needs to be performed to

increase the S/N ratio. Welch’s power spectrum esti-

mate essentially calculates power spectrum using FFT

coupled with averaging. This helps to minimise the

signal power caused by random variations. FFT do

not account in for discontinuities between successive

periods as the data captured is assumed to be of a sin-

gle period of a periodically repeating waveform and

this phenomenon is referred to as spectal leakage. Ap-

plying Welch’s estimate method also helps to reduce

spectral leakage and reduces the effect caused by un-

desired frequencies.

Welch’s method to compute PSD is performed by di-

viding the time series data into segments that are suc-

cessive and averaging the periodograms of each seg-

ments or frames. Consider x

m

(n) to be the input signal

where m = 0,1,..,K − 1,K = total number of frames

and n = 0,1,..,M − 1, periodogram of m th frame is

given by,

Px

m

,M(k) = 1/M |

N−1

∑

n=0

x

m

(n)e

−2πnk/N

|

2

(1)

then Welch’s power spectrum estimate is computed

as,

S

W

x

(w

k

) = 1/K

K−1

∑

m=0

Px

m

,M(k) (2)

Upon analyzing the power readings of certain fre-

quency components, it was noted that the changes

observed was corresponding to the completed num-

ber of passes. Analysing frequency component of

the vibration signal is imperative to finshing processes

as the fundamental frequency and its harmonics con-

tain coherent information which can be atributed to

spindle behavior and also the finshing of the compo-

nent. Shop floor operators require systems that are

less sophisticated and adopting a frequency domain

analysis method gives that flexbility as opposed to

other machine learning algorithms or statistical meth-

ods. Welch’s estimate method is preferred as an eas-

ier method to implement in such cases as it gives a

more visual means of interpretation. However, ma-

chine learning algorithms provide more stability in

applications involving predictive maintenance.

SENSORNETS 2017 - 6th International Conference on Sensor Networks

82

3 EXPERIMENT SETUP

The experiment setup (Fig. 3) comprises of an ABB

IRB 6660 machining robot and PDS colombo spin-

dle. The representative work coupon used for ma-

chining is a boss hole of combustor casing and the

objective is to remove the burrs until a chamfer is de-

veloped. As mentioned in section 2, vibration signa-

tures were measured using a tri-axial accelerometer,

Kistler 8763B (IEPE). The RPM of spindle was kept

constant at 10000 RPM and feed rate at 30mm/s. The

data acquisition devices used was NI cDAQ-9184 and

NI 9234 IEPE.

Figure 3: Trial and experiment setup.

3.1 Data Analysis and Results

Data was captured at a sampling rate of 40kHz and for

computational ease, pre-processed to 1000 samples

per each iteration of Welch’s estimate calculation. A

total of 12 sets of experiment was conducted with 8

being used for offline analysis and co-relation and an-

other 4 for validation. After each cycle of machin-

ing, the chamfer length was manually measured using

laser measuring device. In offline data analysis, co-

relation between the measured values and variations

in estimated power spectrum is analysed. The co-

relation between the power spectrum and number of

cycles was subsequently validated in real-time. Fig-

ure 4 shows the process flow of how experiments were

conducted.

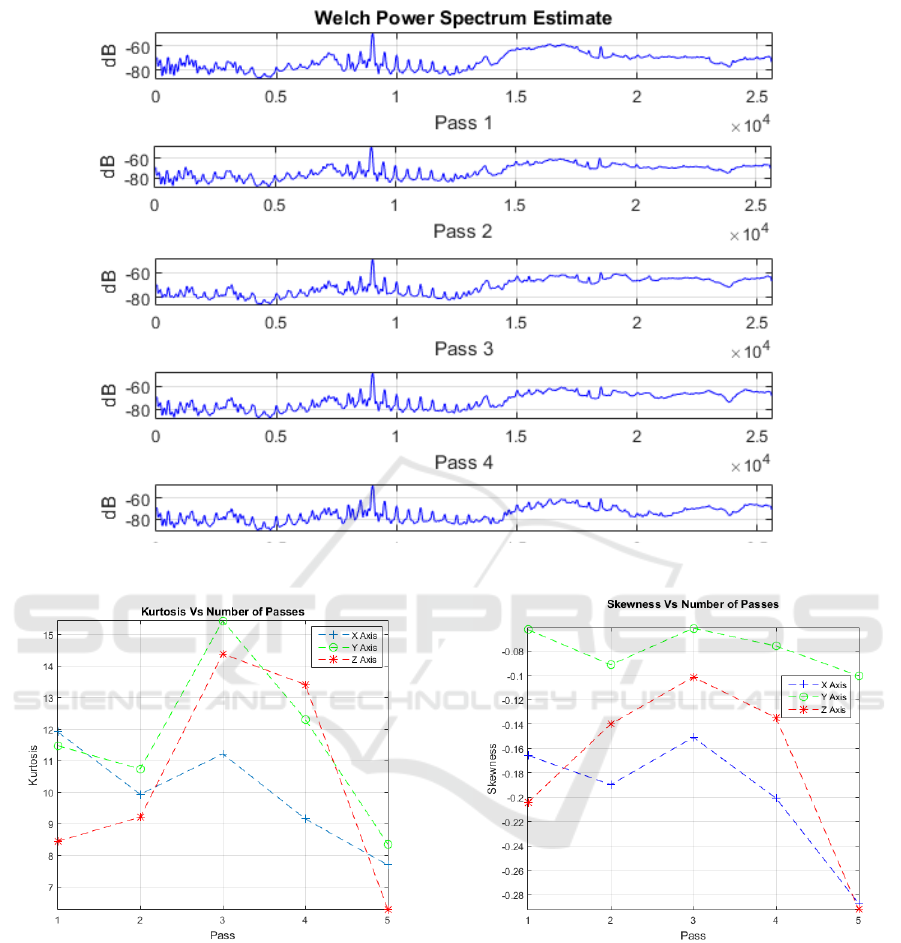

Different data analysis techniques were used

on acquired data sets. For instance, kurtosis and

skewness values for respective passes were calculated

but it failed to show any consistent trend or pattern

with increasing number of passes. Table 2 shows cal-

culated kurtosis and skewness values for each pass. It

can be noted from the numbers that a pattern or trend

Figure 4: Process flow diagram.

Table 2: Kurtosis and Skewness Values.

is not obvious. This can also be also understood from

the figures 6 and 7.

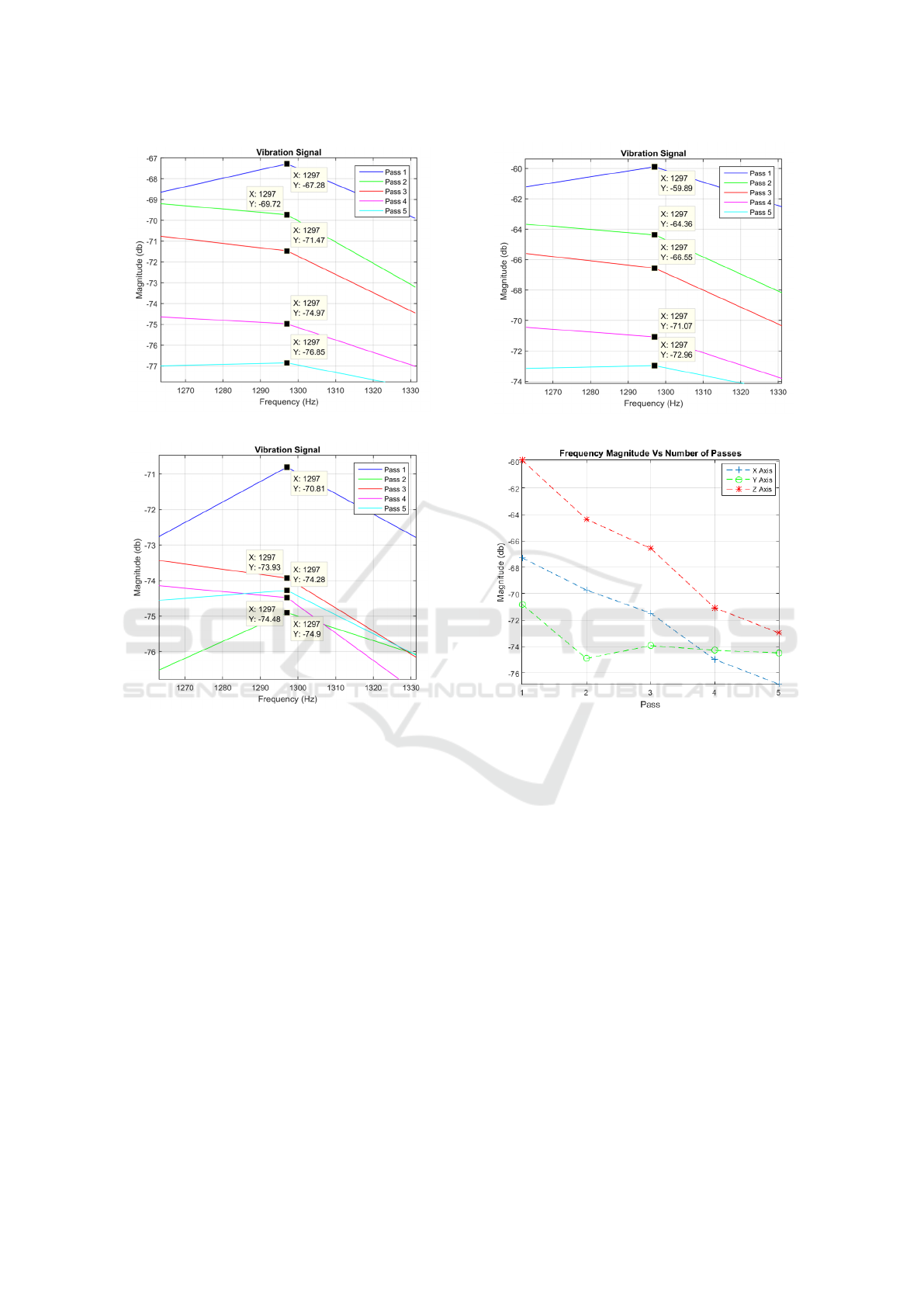

Results obtained after performing Welch’s power

spectrum estimate is shown in figure 5. Figures 8, 9

and 10 shows the Welch’s power spectrum estimate at

1.297Khz. As shown in figures 8, 9 and 10, the power

values of vibration signal decreases with respect to

the increasing number of passes. The trend here when

compared with kurtosis and skewness values is more

obvious to the naked eye. The decrease in signal mag-

nitude is indicative of the strength of the signal. It is

also understood that the decrease in strength of sig-

nal is caused due to the smoothening of edges of boss

hole with increasing number of passes(Table 3 shows

the increase in chamfer radius with different pass).

From the vibration signatures, it can be concluded

that a co-relation exists with the different number of

passes and the PSD at 1.297 kHz. This signal is be-

lieved to be the 8th harmonic of the fundamental fre-

quency generated due to the spindle RPM. The spin-

dle RPM is controlled by a variable frequency drive

(VFD) controller and the frequency is fixed at 165 Hz.

This is however with the exception of Y axis measure-

Table 3: Increase in Chamfer Radius.

Event Classification from Sensor Data using Spectral Analysis in Robotic Finishing Processes

83

Figure 5: Welch’s Power Spectrum Estimate for each Pass/Cycles.

Figure 6: Kurtosis Vs Number of Passes.

ment and is caused due to the orientation and place-

ment of the sensor. Figure 11 shows the correlation

between magnitudes of the captured signal with in-

creasing number of passes. From the figure it can be

seen that, magnitude of vibration signal in Y axis is

relatively low as compared to X and Z axis measure-

ment which further confirms the assumption on sensor

location aspect.

Figure 7: Skewness Vs Number of Passes.

4 CONCLUSION

The focus of this experiment was to explore the re-

lationship between captured vibration signal and the

progress of the actual finishing process. The exper-

iment result establishes a linear co-relation between

vibration signals with completed number of passes.

One major limitation which the authors noted during

this research work is that, the results obtained were

dependent on the training experiments and hence ap-

SENSORNETS 2017 - 6th International Conference on Sensor Networks

84

Figure 8: Vibration signature in X direction.

Figure 9: Vibration signature in Y direction.

plying the classification technique to other finishing

processes may not yield the same expected outcome.

This will be the focus of future research directions

of this work; to validate and set up a similar clas-

sification technique across other finishing processes

like polishing. Spectral analysis proved to be a vi-

able solution for performing this task and is seen as

a promising technique to be implemented in real-

time applications involving high sampling frequen-

cies. The advantage seen here is that, analyzing a

particular frequency component relieves the need of

bulk data processing as opposed to statistical meth-

ods wherein packets of data needs to be computed to

understand the co-relation between different statisti-

cal attributes with the number of passes completed.

Besides, the welch spectrum estimate showed signifi-

cant co-relation with the completed number of passes

as opposed to time-domain features like kurtosis and

skewness.

This research work was conducted primarily to

understand possible co-relation between sensor signal

Figure 10: Vibration signature in Z direction.

Figure 11: Signal Magnitude Vs Number of Passes.

features and the progress of the finishing process. The

co-relation observed will be integrated to the robotic

finishing software environment used for tool path pro-

gramming and will serve as a visual aid to shop floor

operators enabling them to monitor the progress of the

finishing process. In the next phase of the project, the

signature identified as a classifier will subsequently

be used as an input parameter for machine learning

algorithms. Additionally, a control strategy could be

deployed with a feedback loop in the robot control

system to dynamically adjust the process variables to

compensate for any unexpected behavior.

ACKNOWLEDGEMENTS

The authors would like to thank Mr. Arthur Wee and

Mr. Muhammad Izzat Roslan from Rolls-Royce Plc

Singapore for the support received in preparation of

this paper and the associated research work.

Event Classification from Sensor Data using Spectral Analysis in Robotic Finishing Processes

85

REFERENCES

C. Bisu, L. Olteanu, R. L. P. D. and Cahuc, O. (2013). Ex-

perimental approach on torsor dynamic analysis for

milling process monitoring and diagnosis. In Proce-

dia CIRP, vol. 12, pp. 73-78.

D. Dornfeld, P. Wright, M. H. and Vijayaraghavan, A.

(2009). Enabling manufacturing research through in-

teroperability. In ed.

G. Byrne, D. Dornfeld, I. I. G. K. W. K. and Teti, R. (1999).

Tool condition monitoring (tcm) the status of research

and industrial application, cirp annals - manufacturing

technology. In vol. 44, pp. 541-567, // 1995.

G. W. Fritz Klocke, D. V. (2008). Design approach for adap-

tive axial force control in gun drilling. In Mechanical

Systems and Control vol. 11,. .

Lee, Y. and Dornfeld, D. A. (1998). Application of open

architecture control system in precision machining. In

31st CIRP International Seminar on Manufacturing

Systems, CIRP, Berkeley, CA, pp. 436441. .

P. Stavropoulos, D. Chantzis, C. D. A. P. and Chryssolouris,

G. (2013). Monitoring and control of manufacturing

processes: A review. In Procedia CIRP, vol. 8, pp.

421-425.

Pritschow, G. and Kramer, C. (2005). Open system archi-

tecture for drives. In CIRP Annals - Manufacturing

Technology, vol. 54, pp. 375-378. .

R. Teti, K. Jemielniak, G. O. and Dornfeld, D. (2010). Ad-

vanced monitoring of machining operations. In CIRP

Annals - Manufacturing Technology, vol. 59, pp. 717-

739.

T. I. El-Wardany, D. G. and Elbestawi, M. A. (1996). Tool

condition monitoring in drilling using vibration sig-

nature analysis. In International Journal of Machine

Tools and Manufacture, vol. 36, pp. 687-711. .

Team, R. P. (2006). Guidelines to minimize manufacturing

induced anomalies in critical rotating parts. In ed.

SENSORNETS 2017 - 6th International Conference on Sensor Networks

86