Comfort-efficiency-equilibrium

A Proactive, at Room Level Individualized Climate Control System for Smart

Buildings

Antonios Karatzoglou

1,2

, Julian Janßen

1

, Vethiga Srikanthan

1

, Yong Ding

1

and Michael Beigl

1

1

TECO Research Group, Karlsruhe Institute of Technology (KIT), Karlsruhe, Germany

2

Robert Bosch GmbH, Corporate Sector Research and Advance Engineering, Renningen, Germany

Keywords:

Energy Efficiency, Thermal Comfort, Proactivity, Personalization, Smart Building.

Abstract:

Energy efficiency and thermal comfort depict two key topics in indoor climate controlling domain. HVAC

systems are one of the biggest energy consumers in nowadays’ households and yet they have difficulties in

reaching the users’ optimal comfort. We are presenting SVReCLCE, a proactive two-fold climate controlling

approach that takes explicitly both energy consumption, as well as comfort in consideration. A user study in

an office environment shows that our solution can in practice achieve up to 49% energy savings by keeping

the personal comfort level high at the same time. Therefore, SVReCLCE sets a solid basis for future work in

the field of climate control for low-energy buildings.

1 INTRODUCTION

Heating, ventilation and air conditioning systems

(HVAC) represent the largest energy consumers in

buildings. In expectation of hotter summers in the

future, the energy requirement in the climate sector

is expected to increase. Hence, optimizing HVAC

systems is an important step towards decreasing our

ecological footprint. Ideally, an optimal HVAC sys-

tem would be fully aware both of environmental and

contextual conditions as well as of individual charac-

teristics of the occupants and their behavior. Recent

products like Hive

1

and Nest

2

signalize the start of

tangible intelligent climate control in buildings with

focus on energy saving and a better human-machine-

interaction. Still, there is room for improvement.

In this work, we introduce a proactive controlling

concept capable of adapting and reacting on both the

users’ direct feedback of sense of comfort as well as

the actuators energy consumption. In addition, a ma-

chine learning based model is built, trained and used

for modeling and predicting the residents’ attendance.

Finally, a rule base considering common sense users’

behavior is created to support additionally our system.

We tested and evaluated our approach by comparing

1

https://www.hivehome.com/

2

https://nest.com/thermostat/meet-nest-thermostat/

it with two other systems serving as a reference on

a building cooling scenario. For this purpose we de-

signed and conducted a 4-week experiment in an of-

fice environment. The details of our work are pre-

sented as follows. Our SVR enhanced controller is

introduced in section 3. Section 4 describes our ex-

perimental setup. The results of our experiment are

presented in section 5. The last section concludes the

work.

2 RELATED WORK

Collecting a variety of sensor data and utilizing them

for accurate temperature control plays a core role in

many current researches. The art in which intelli-

gent controllers handle these data varies widely. (Ed-

wards et al., 2012) explore seven different machine

learning techniques for predicting the next hour res-

idential energy consumption, such as Feed Forward

Neuronal Network (FFNN) and Support Vector Re-

gression (SVR) a.o. Depending on the data set some

techniques perform better than others. Overall, SVR

represents one of the best methods applied across all

the data sets. (Megri and El Naqa, 2016) use SVM

to predict thermal comfort indices. For this purpose,

the SVM was trained with a group of different factor

258

Karatzoglou, A., Janßen, J., Srikanthan, V., Ding, Y. and Beigl, M.

Comfort-efficiency-equilibrium.

DOI: 10.5220/0006308002580265

In Proceedings of the 6th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2017), pages 258-265

ISBN: 978-989-758-241-7

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

data sets influencing the thermal comfort, such as air

temperature, relative humidity, clothing value etc. An

interesting SVM based approach close to our own but

applied in a complete different domain is the one pro-

posed by (Deng et al., 2014), which is used to improve

the position precision of a servo system. They model

and predict the position error with SVM and then feed

it back to the system, thereby improving the precision.

They show that combining SVM with a PID controller

can raise significantly the prediction accuracy. Occu-

pancy prediction is one way of reducing energy con-

sumption by switching down the heating or cooling,

if no one is in the room like in (Koehler et al., 2013)

and (Scott et al., 2011). However, prediction is not

restricted in occupancy when it comes to energy effi-

ciency and user comfort. (Ellis et al., 2013) use tem-

perature sensors, gas meter sensors, outdoor tempera-

ture sensors and boiler or furnace time in order to pre-

dict the indoor temperature. By predicting the tem-

perature they are able to control the boiler or furnace

more accurately. (Oldewurtel et al., 2012) use the

weather forecast to control the temperature more effi-

ciently. Feldmaier et al. swear by a great number of

fixed and portable sensors in (Feldmeier and Paradiso,

2010). Beyond that they also collect the user’s feed-

back about their thermal comfort by letting them push

one of three buttons (hot, cold and neutral). A control

module collects all information and decides whether

to open or close the window or change the tempera-

ture. Thermal comfort describes the feeling that peo-

ple have about the ambient temperature. There are

different components that influence thermal comfort

like air temperature, air velocity, air humidity, radia-

tion, clothes, activity, outdoor temperature and other

(Dentel and Dietrich, 2013). Fanger created an index

to represent the comfort level - the Predicted Mean

Value (PMV) (Fanger, 1970). It considers energy ex-

change, clothing, air temperature, humidity, velocity

and radiation temperature. The Predicted Percentage

of Dissatisfied (PPD), also developed by Fanger, de-

scribes the satisfaction of a group of people. PMV

and PPD are widely used indices as in (Kalz et al.,

2013) and (Yun and Won, 2012).

3 SVR ENHANCED CLOSED

LOOP COMFORT-ENERGY

CONTROLLER (SVRECLCE)

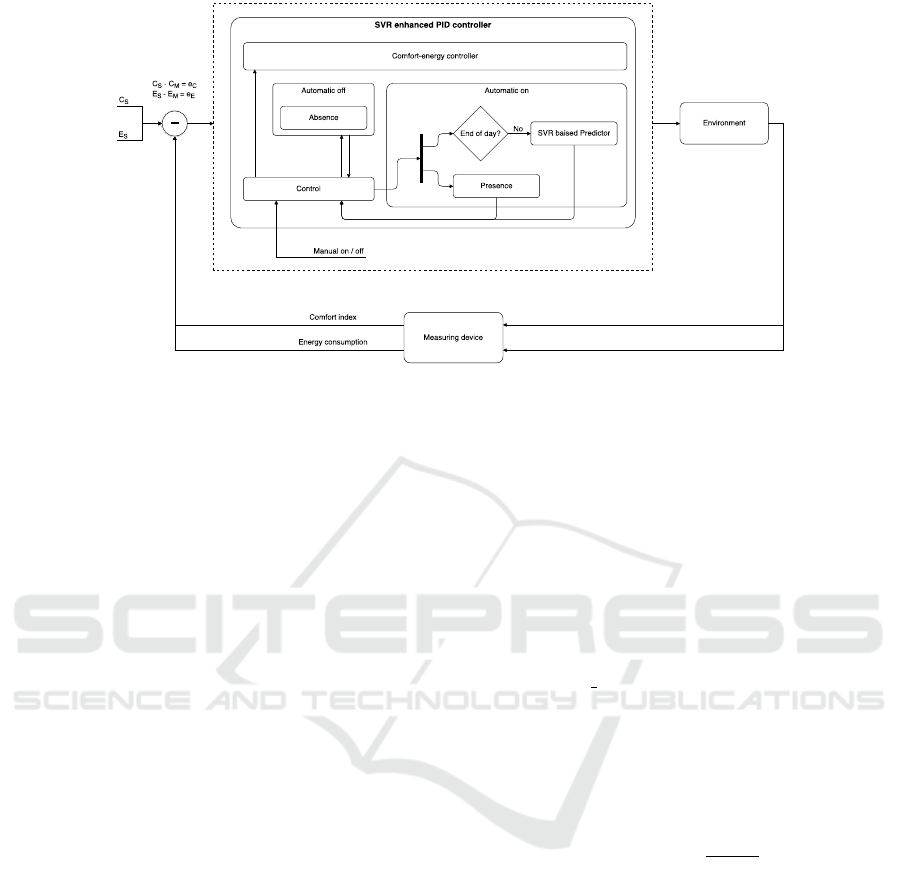

Our proposed closed loop comfort-energy controller

consists of three core components: A PID based com-

ponent, a SVR based prediction component and a rule

based component that pieces i.a. the previous two to-

gether. The system takes both the comfort feedback

of the users, as well as the energy consumption into

account to control the temperature. Moreover, it is

capable of adapting to occupancy patterns describing

how, when and how long people do occupy their of-

fice or living space. The individual components and

their part in the overall system will be discussed in

the next paragraphs. An illustration of SVReCLCE is

shown in figure 1.

3.1 PID-based Component

This section presents in detail the core of our comfort-

energy controller. It is designed to control the room

temperature, depending on both the user comfort and

the energy consumption. To achieve this we built a

twofold comfort-energy controller consisting of two

independent PID controllers (PID

E

and PID

C

) respec-

tively. One for each control variable. While the first

aims at reducing the energy consumption, lies the

scope of the second in optimizing the users’ comfort.

PID

E

(t)=K

p,E

∗e

C,E

(t)+K

i,E

∗

R

t

0

e

C,E

(t)∂t+K

d,E

∂e

C,E

(t)

∂t

(1)

PID

C

(t)=K

p,C

∗e

C,E

(t)+K

i,C

∗

R

t

0

e

C,E

(t)∂t+K

d,C

∂e

C,E

(t)

∂t

(2)

PID

Fused

(t)=w

E

∗PID

E

+w

C

∗PID

C

(3)

w

E

=1−w

C

(4)

In 1 and 2 we can see the output function of the two

PID controllers. They describe the cumulative way,

in which the value of the manipulated variable of the

energy and the comfort PID controller respectively

is being determined. Each function consists of three

K

x

-weighted terms: a proportional, an integral and

a derivative term. The overall behavior of the con-

troller is defined by the summation of the terms and

consequently by the combination of the aforemen-

tioned coefficients. So, the steadiness of the system

can be adjusted by tuning the integral term. Modi-

fying the derivative term fine tunes the speed of the

controller. PID

Fused

represents the overall output of

the comfort-energy core component, which is in our

case the room temperature. This value stems from

the weighted fusion of the two single PID controllers

PID

E

and PID

C

. Configurating the weights w

C

and

w

E

allows a twofold adjustment of the controller’s be-

havior based on both comfort and energy efficiency

accordingly. This enables us to shift from a comfort

based system towards a more energy efficiency aim-

ing one and vice versa.

The comfort of the user is represented by a com-

fort index described in chapter4. It is mapped to a

numerical scale and is subsequently passed on the

Comfort-efficiency-equilibrium

259

Figure 1: SVReCLCE control loop and its elements.

PID

comfort

controller, or more precisely, it is the sys-

tem deviation from the user comfort set point e

C

(t),

which is routed back to the input of the PID controller.

e

C

(t)=C

set

(t)−C

meas

(t) (5)

Analogous to PID

C

the energy focused controller

PID

E

takes the system deviation from the energy set

point e

E

(t) as input.

3.2 SVR-based Prediction Component

The twofold PID-based core component is extended

by a prediction component. The predictor capacitates

the overall controller to behave proactively according

to the expected attendance of the user and thus en-

ables the system to create a comfortable environment

before the users arrives the temperature controlled

area. The underlying presence model is built on the

basis of a support vector machine/regression (SVM)

(Abe, 2005) with a radial basis function (RBF) kernel

described in 10. The goal in SV-based regression is

to find a function f (x), which shows a maximal devi-

ation ε from the obtained objects y

i

for all the given

training data (x

i

, y

i

). The quality of the estimation of

SVR is measured by the loss function shown in for-

mula 6. The actual estimation is given in 9. G(x

n

,x)

represents the kernel function of the SVM. ε defines

the space in which no penalty is added in the loss

function. The penalty error is defined by the parame-

ter C. Finally N is the number of the support vectors

and b gives the bias. The notation used in 6 to 9 corre-

sponds to the dual formulation of SVR. Our presence

model is built upon two features. The time of day and

an indicator that distinguishes between workdays and

non workdays. This basic day differentiating indica-

tor yields a better true positive prediction rate despite

the small amount of the training data. The prediction

component adapts to the current situation by provid-

ing both a short- and a long-term prediction. For this

purpose it considers two separate prediction horizons

of different size. While a short horizon is sufficient

during a normally busy workday in an office, longer

inactivities, e.g. before the begin of the workday and

in holidays, are handled and compensated by a larger

horizon. The selection of the horizons type is deter-

mined by a set of rules comprised in a rule base.

L(α)=

1

2

∑

N

i=1

∑

N

j=1

(α

i

−α

∗

i

)(α

j

−α

∗

j

)G(x

i

,x

j

)

+ε

∑

N

i=1

(α

i

+α

∗

i

)−

∑

N

i=1

y

i

(α

i

−α

∗

i

)

(6)

∑

N

n=1

(α

n

−α

∗

n

)=0 (7)

∀n:0≤α

n

≤C;∀n:0≤α

∗

n

≤C (8)

f (x)=

∑

N

n=1

(α

n

−α

∗

n

)G(x

n

,x)+b (9)

G(x

1

,x

2

)=exp−

kx

1

−x

2

k

2

2σ

2

) (10)

3.3 Rule-based Component

The role of the rule based component lies in extend-

ing the residential behavior model built by SVR and

therefore supporting the prediction and optimizing

the overall control behavior. The rules cover situa-

tions like long absence, short lunch breaks, and even

shorter absences like quick toilet stops during the day

and help to revise inaccurate predictions by defining

two core behavior modes concerning the automatic

start and stop of the system respectively: automatic

on and automatic off. The controller alternates be-

tween these two states during the day.

The automatic on mode relates to the wakening

procedure of the system. During this mode the sys-

tem monitors simultaneously both the current output

SMARTGREENS 2017 - 6th International Conference on Smart Cities and Green ICT Systems

260

of the present detection mechanism, as well as the

outcome of the prediction component and reacts ac-

cordingly. If at least one of them triggers an event,

the system is turned on and its mode is being set to

automatic off, waiting for the right conditions to turn

itself off again. The presence detection mechanism

applies a detection time window to prevent the system

from reacting too sensitive to the output of the motion

detection sensor. An event in an area is only triggered

if the duration of the motion in the particular area

exceeds the detection window length. Some factors

need to be taken into consideration when determining

the length of the detection window. For example too

short visits in the corresponding area should not start

the system. A long enough observation window can

filter this kind of short actions out. On the other hand

if the window is too long, it can lead to discomfort of

the user, due to a slower response time of the system.

In addition to presence detection, a SVR based pre-

diction model is used to estimate the day and time of

the next appearance of a user. Such predictions sup-

ply the system with an extra series of triggering events

enabling it to react in a forward-looking manner.

In the automatic off mode the system monitors

continuously the presence of the users. After a certain

period of time of motionlessness the system is turned

automatically off and the automatic on mode is set.

The length of the positive detected absence observa-

tion window plays again a significant role. On the one

hand, short absence of the user should not be con-

sidered for sending a triggering event. On the other

hand choosing a very long interval would result to a

late turning-off and would therefore affect the over-

all energy efficiency of the system. A correct balance

among these two extremes should be sought.

The user has at any time the possibility to bypass

the automatic process. Sending a manual start signal

would result in starting the system and setting the au-

tomatic off mode. In the case of manually turning the

system off, the system can only be restarted automat-

ically after an additional positive absence detection

that sets it first to the automatic on mode. This pro-

motes further the behavior stability of the controller.

4 USER STUDY AND

EXPERIMENTAL SETUP

We designed and conducted a 4-week user study in

five different rooms of an office building in order to

evaluate our system in practice. Each office contained

one to three people. All in all we had nine partic-

ipants for the study, whereby one of them was our

control person, serving as a comparison. We used the

Figure 2: Sensor and actuator deployment.

first week for testing our infrastructure while collect-

ing training data at the same time. The remaining 3

weeks were then used to test the performance of our

approach among the one of two further reference sys-

tems: one week for each. Figure 3 gives an overview

of our server-based experimental infrastructure.

A mobile air-conditioning device (AC) was in-

stalled in every room, except in the one of our test

person. A Raspberry Pi served both as remote control

unit for the ACs, as well as gateway for collecting and

forwarding all sensor data to our server. In addition to

the AC devices, each office was also equipped with a

temperature and humidity sensor, one to two motion

detectors, depending on the size of the room, and a

smart meter for capturing the energy consumption of

the ACs. A temperature and humidity sensor was also

installed outside of the building in the same floor to

gauge the outdoor temperature. Our server hosted two

different databases. A time series database (TSDB)

was used to store the sensor values. We have chosen

an open solution called influxdata

3

for this purpose.

At the same time, a MySQL Database was used to

store the filled surveys of the users. To safeguard a

flawless operation of our system, we monitored the

data flow with Kapacitor and we used Chronograph

(both from influxdata), a visualization tool, to con-

duct further periodical sample checks. In order to

achieve room level controlling, a separate instance of

the tested climate controller was initiated for each sin-

gle room.

During the study, the participants were asked to

fill out a set of ready-to-use e-surveys on an hourly

basis via a web application. The users were given ad-

ditionally the ability to set a temperature of their de-

sire in their room at any time via the same web inter-

face by adjusting a virtual thermostat. The questions

asked in the surveys aimed mainly at getting feed-

back from the users about their thermal sense of well

being. These were used to derive the corresponding

3

https://www.influxdata.com/

Comfort-efficiency-equilibrium

261

thermal comfort index, which in turn was fed back

to our comfort-energy controller. Our comfort index

is based on the 7-level ASHRAE scale

4

, which de-

scribes 7 states from cold to hot surrounding a neutral

(optimal) value which lies in the middle. Our com-

fort index leverages two different kinds of user feed-

back in parallel. Direct comfort is measured through

the survey and the corresponding queries in which the

user is asked to rank the current felt comfort. Indi-

rect comfort is derived from her interaction with the

virtual thermostat knob. The set value on the thermo-

stat is mapped to the same 7-level scale of ASHRAE

and is finally forwarded to the server after every user

interaction. Some rooms in our testing environment

occupy more than one users. In the case of receiv-

ing different comfort indices from multiple users, we

obtain a mean value by averaging them in order to

achieve the best possible comfort. The floor plan of

one of the offices is shown in figure 2. The remaining

offices show a similar topology.

5 EVALUATION AND

DISCUSSION

In this section, we discuss the performance of our ap-

proach and report the final results of our experimen-

tal study. We implemented and tested three differ-

ent climate controlling approaches during our study:

a basic open-loop (OL) controller, the closed-loop

comfort-energy controller (CLCE) and the SVR en-

hanced closed loop comfort-energy controller (SVRe-

CLCE). Each of them was field-tested for one week.

The open-loop (OL) controller allows the user

to control directly the air conditioner in her room.

Hence, the A/C unit reacts solely to input signals

passed directly through the web thermostat. The basic

principles of the closed-loop comfort-energy (CLCE)

controller are described in section 3.1. It is a two-fold

PID controller, which takes both comfort and energy

consumption into account for regulating the tempera-

ture in a room. We choose a weight of 4/5 in favor

of the comfort. In contrast to the proactive SVRe-

CLCE, starting and stopping of the system is per-

formed here manually by the user. We modeled com-

fort and energy consumption separately with MAT-

LAB Simulink

5

and chose a state space model with

a state vector length of 3. The System Identification

Toolbox was used to identify our models. The PID pa-

rameters were estimated by testing and leveraging the

4

American Society of Heating, Refrigerating and Air-

Conditioning Engineers (https://www.ashrae.org/)

5

https://de.mathworks.com/products/simulink.html

PID Tuner with the goal of obtaining rapid response

and stability at the same time. The following param-

eters have been determined and subsequently applied

on the PID comfort controller: K

p

= 2, K

i

= 0.2, K

d

=

−0.2. Analog, the parameters used by the PID energy

controller are: K

p

= −0.02,K

i

= −0.002,K

d

= 0.0.

These values were utilized for the configuration of

both the CLCE and the SVReCLCE controllers. Neu-

tral comfort and 450W power have been chosen as

reference values for the two controllers respectively.

The energy consumed over a period of 60 minutes

served as input for the energy controller.

After statistically analyzing the users’ behavior

we were able to define the appropriate moving time

window lengths utilized by our prediction algorithm.

So, we selected a 30 minutes time interval as predic-

tion horizon to cover the night, before the workday

begins, while the window during the day is set to 10

minutes due to the increasing change of attendance

state in an office environment. The submission of the

end of day online questionnaire served as an end-of-

workday flag. A detection window of 5 minutes is

used for the actual presence detection and a period of

15 motionless minutes is used to define absence in or-

der to filter short breaks out.

5.1 Energy

Table 1 lists the average energy consumption values

of each room, as well as of all rooms together dur-

ing a period of one week respectively. The average

of the energy consumption over one week and over

both all rooms, as well as rooms B and C (in brack-

ets) for each controller is displayed on the first row,

while the remaining rows below contain the average

one-week consumption in each room. Room D shows

no energy consumption because no A/C unit was de-

ployed there due to being our reference room, where

our control person was. The control person serves as

a reference for the study by providing information re-

garding her sense of comfort from an office without

any climate control. This person is thus only able to

fill out our e-questionnaires but he/she cannot control

the temperature.

As can be seen from table 1, our proactive ap-

proach SVReCLCE yields the best overall results

when it comes to energy efficiency among the rooms

B and C. CLCE and OL take the second and third

place respectively. Looking the total average, our

SVReCLCE performs better than CLCE, but slightly

worse than the OL approach. A closer look at the ta-

ble, shows that room B clearly stands out in a positive

manner. Our controller here helps saving the most en-

ergy. Nearly 14.37% could be saved by SVReCLCE

SMARTGREENS 2017 - 6th International Conference on Smart Cities and Green ICT Systems

262

Figure 3: Overview of the HW and SW experimental infrastructure.

Table 1: Average power consumption over all rooms B and C only and over each room separately.

OL CLCE SVReCLCE

average [W]

(Avg of B and C only)

104.7426

(113.9577)

109.6741

(95.0499)

107.2958

(90.6457)

room A [W] 86.3123 138.9226 140.5962

room B [W] 185.8407 110.4873 94.6095

room C [W] 42.0747 79.6124 86.6819

room D [W] 0 0 0

0

20

40

60

80

100

120

140

160

180

200

Avg Avg of rooms B and C room B

[W]

OL

CLCE

SVReCLCE

Figure 4: Average Power consumption [W] of our tested

controllers among all three rooms (Avg), among rooms B

and C and at room B.

compared to the CLCE and almost half the energy

(49.09%) consumed by the open loop controller OL.

Our controller does not provide us with similar good

results at room A though. On the contrary, SVRe-

CLCE led to a 62.89% increased energy consump-

tion in comparison with the OL. This relies on the

irregular absence of the associated study participant

that used the particular room during the whole third

week which our training data don’t cover. In addi-

tion to the lack of an appropriate data set, two extra

major influence factors have also to be noted here.

Analysis of the questionnaires showed that the par-

ticipant of the same room (A) felt disturbed by the

operating noise of the A/C unit, resulting in extreme

noise-sensitive behavior in which climate control was

used only when absolutely necessary. This reflects,

for the most part, the low power consumption during

the first week, where the users are able to turn the

system on and off manually themselves. A similar

situation is found in room C, illustrated in 2, which

was used explicitly to test the limits of all 3 control-

ling approaches. Both participants used the room on

a quasi-irregular basis and did not occupy the room

every day during the four weeks of our experiment.

The time of day varied as well. Still, certain atten-

dance days and corresponding times of day remained

almost consistent during the study, building weak pat-

terns. Our approach might consume higher amount

of energy compared to OL, but is still more efficient

than in room A due to recognizing and utilizing the

aforementioned patterns. At the same time, our ba-

sic controller CLCE performs in case of room B bet-

ter than OL, but worst compared to SVReCLCE. In

rooms A and C though, it shows a slightly better be-

havior than SVReCLCE. This can be attributed to the

same reasons as with OL mentioned above. It must

be noted that in case of a direct controller like OL, the

energy consumption depends highly on the users’ be-

havior. The more energy-conscious a person handles,

the higher the efficiency of OL would be. All in all, up

to 49,09% energy could be saved with SVReCLCE.

This is also visualized in figure 4. This extrapolates

to almost 400kWh for a period of 6 months, say from

April to September.

Comfort-efficiency-equilibrium

263

Table 2: Average comfort and standard deviation over all rooms, over rooms B and C only and over each room separately.

OL CLCE SVReCLCE

∅ σ ∅ σ ∅ σ

average comfort

(Avg of B and C only)

0.2877

(0.6087)

1.0088

(0.9562)

0.3657

(0.9057)

1.3276

(1.1576)

-

(0.5837)

-

(0.8692)

comfort room A (1p) -0.3542 0.8536 -0.7143 0.9124 - -

comfort room B (2p) 0.4482 0.8544 0.8947 1.0205 0.8947 0.9676

comfort room C (2p) 0.7692 1.1200 0.9166 1.2555 0.2727 0.4453

comfort room D (1p) 1.4857 1.2732 0.0000 0.7071 2.7000 0.4582

5.2 Comfort

On the top of the table 2 we can see the average com-

fort and the corresponding standard deviation values

over the respective 1-week period of use over both all

rooms, as well as rooms B and C (in brackets) for

each controller. The three rows below show the aver-

age comfort and standard deviation measured in office

A, B and C respectively. At last, room D is the room

of our control person. Minus comfort values [-3, 0)

point out the fact that it is too cold for the user and

positive ones (0, +3] state the opposite. The objective

is to get a value close to zero (0). Table 2 indicates

a similar overall performance distribution among the

tested controllers, such the one seen in the energy re-

lated paragraph. Once again SVReCLCE provides

the best results among rooms B and C with an av-

erage comfort value of 0.58. It is followed by OL and

CLCE with a comfort value of 0.61 and 0.91 respec-

tively. As mentioned before, room A was unoccupied

during the third week and was therefore not consid-

ered in the averaging process. By looking closer at

room B and C, one can see that our two test persons

in room C found the temperature by SVReCLCE al-

most 3 (2.820) times more comfortable than by OL

and 3.36 times than CLCE. And this, irrespective of

SVReCLCE using an imperfect occupancy prediction

model (see chapter 5.1). The particular outcome re-

flects in the end our weighting factors chosen for

our 2-fold PID controller, namely 80% comfort and

20% energy efficiency. However in room B, the best

comfort was achieved by the OL controller, where

the users controlled manually the A/C devices them-

selves. SVReCLCE and CLCE take both the second

place with exact the same value. Nevertheless, the

difference between the corresponding comfort values

is fairly small. Comfort value of one (+1) stands for

”slightly warm” on the ASHRAE scale. Hence SVRe-

CLCE results in an environment that is even more

comfortable than slightly warm, which in turn is a

very good outcome for our controller. Looking in the

table at room D we can see that our reference person

felt significantly uncomfortable (in terms of thermal

wellbeing) during week one and three. Furthermore,

thermal comfort is a subjective feeling. Thus, table 2

expresses to a certain degree also the individual satis-

faction of the participants of our study. Our test per-

son in room A for instance felt the temperature in both

first two weeks in average as slightly cold, despite the

warm weather (especially in the first week) and the

fact that he was able to turn off the A/C unit at any

time during this time. The later raises also other is-

sues. Namely, we must not forget that the table 2 gives

only insight about the thermal and not general com-

fort. Users handling by themselves tend to be more

easygoing with their own decisions and less critical

about their own actions. On the other hand, they ex-

pect a perfect outcome from an ”intelligent” system

like ours. This explains additionally the good thermal

comfort values of OL, at the expense of the general

comfort though. SVReCLCE works without the need

of user interaction. This makes it overall more com-

fortable.

6 CONCLUSIONS AND FUTURE

WORK

In this paper, we present SVReCLCE, a two-fold pre-

dictive cooling system that takes explicitly both ther-

mal comfort and energy consumption into considera-

tion in order to provide an optimal balanced outcome

for the inhabitants. At the same time, adaptation and

personalization stand in the foreground. SVReCLCE

is able to shift its focus between energy and comfort

at users’ option. Thereby, our approach meets both

needs of environmental awareness, as well as per-

sonal well being. We tested and evaluated our sys-

tem in comparison to the non-predictive CLCE and

OL, a simple open-loop controller used as baseline,

in practice. We could show that SVReCLCE can sig-

nificantly contribute to saving energy whilst keeping

a high comfort level at the same time. We could also

find a few weak spots in our approach though. Han-

dling irregular attendance is a major issue. While

SVReCLCE performs well by quasi-irregularity (see

chapter 5.1 room C), this is not the case by total un-

SMARTGREENS 2017 - 6th International Conference on Smart Cities and Green ICT Systems

264

expected user behavior such as the visit of a 5-day

conference. This is due to missing knowledge and in-

accuracy of our occupancy model caused in turn by

an incomplete training data set.

In our future work we plan to increase the quality

of the prediction through a larger training data set. In

addition, we plan to extend our approach and enrich

it through semantic information comprising general,

domain and user-specific knowledge such as the per-

sonal calendar of the inhabitants and their personal

preferences. This would complement the missing in-

formation of our machine learner’s model and help

manage irregular behavior. Furthermore, a dynamic,

situation-dependent balance between the two inde-

pendent PID controllers could also improve our sys-

tem both in terms of energy efficiency and user’s’ sat-

isfaction. The needs and the requirements of the user

vary over the day depending on the situation. Having

an extra learning feature for keeping track of this in-

formation and feeding it back to the prediction model

of our controller would improve further the final solu-

tion.

ACKNOWLEDGEMENTS

This work was funded by the German Federal Min-

istry of Education and Research within the Soft-

ware Campus KEESmartHome project (grant number

01IS12051).

REFERENCES

Abe, S. (2005). Support vector machines for pattern classi-

fication, volume 53. Springer.

Deng, C., Xie, S., Wu, J., and Shao, X. (2014). Position

error compensation of semi-closed loop servo system

using support vector regression and fuzzy pid control.

The International Journal of Advanced Manufactur-

ing Technology, 71(5-8):887–898.

Dentel, A. and Dietrich, U. (2013). Thermische

behaglichkeit–komfort in geb

¨

auden.

Edwards, R. E., New, J., and Parker, L. E. (2012). Predict-

ing future hourly residential electrical consumption:

A machine learning case study. Energy and Buildings,

49:591–603.

Ellis, C., Hazas, M., and Scott, J. (2013). Matchstick:

A room-to-room thermal model for predicting indoor

temperature from wireless sensor data. In Proceedings

of the 12th international conference on Information

processing in sensor networks, pages 31–42. ACM.

Fanger, P. (1970). Thermal comfort: Analysis and applica-

tions in environmental engineering. Danish Technical

Press.

Feldmeier, M. and Paradiso, J. A. (2010). Personalized hvac

control system. In Internet of Things (IOT), 2010,

pages 1–8. IEEE.

Kalz, D., H

¨

olzenbein, F., Pfafferott, J., and Vogt, G. (2013).

Nutzerzufriedenheit mit dem thermischen komfort in

b

¨

urogeb

¨

auden mit umweltenergiekonzepten. Bau-

physik, 35(6):377–391.

Koehler, C., Ziebart, B. D., Mankoff, J., and Dey, A. K.

(2013). Therml: occupancy prediction for thermo-

stat control. In Proceedings of the 2013 ACM inter-

national joint conference on Pervasive and ubiquitous

computing, pages 103–112. ACM.

Megri, A. C. and El Naqa, I. (2016). Prediction of the

thermal comfort indices using improved support vec-

tor machine classifiers and nonlinear kernel functions.

Indoor and Built Environment, 25(1):6–16.

Oldewurtel, F., Parisio, A., Jones, C. N., Gyalistras, D., Gw-

erder, M., Stauch, V., Lehmann, B., and Morari, M.

(2012). Use of model predictive control and weather

forecasts for energy efficient building climate control.

Energy and Buildings, 45:15–27.

Scott, J., Bernheim Brush, A., Krumm, J., Meyers, B.,

Hazas, M., Hodges, S., and Villar, N. (2011). Preheat:

controlling home heating using occupancy prediction.

In Proceedings of the 13th international conference on

Ubiquitous computing, pages 281–290. ACM.

Yun, J. and Won, K.-H. (2012). Building environment anal-

ysis based on temperature and humidity for smart en-

ergy systems. Sensors, 12(10):13458–13470.

Comfort-efficiency-equilibrium

265