Langrangian Relaxation of Multi Level Capacitated Lot Sizing

Problem with Consideration of Lead Time

Hanaa Razki and Ahmed Moussa

Laboratory of InformationTechnologies and Communication, ENSA,University Abdelmalek Essaâdi, Tanger, Morroco

Razki.hanaa@gmail.com

Keyword: Tactical Planning, Multi Level Capacitated Lot Sizing Problem, Lagrangian Relaxation.

Abstract: Tactical planning consists to develop production plans by determining the quantities of products

manufactured by period to best meet customer demand at lower costs. This issue has been widely

discussed, according to two criteria: multi level and single level planning. The concept of multi level

reflects well the manufacturing structure. For this, we propose in this work a new mathematical model of lot

sizing finite capacity (Multi Level Capacitated Lot Sizing Problem) based on Lagrangian relaxation

optimization approach. Comparisons of this new model with traditional one demonstrate the efficiency of

this new approach as well in simulated case as real situations. The generated production plans are optimal

with 68% -98% compared to classical models.

1 INTRODUCTION

We are always looking for a relatively effective

solution that can help increase the level of

performance of production systems. This problem of

planning and scheduling production with limited

capacity resources reflects setup times, waiting and

production as well as different costs of production.

The formulations of the Big Bucket model (BB)

as Capacitated Lot Sizing Problem (CLSP) are

considered as a reference model for addressing the

plan generation of problematic production manager

in a single site environment (Comelli et al. 2008),

the Multi Level Capacitated Lot Sizing Problem

(MLCLSP), is recognized as a reference model and

deals with Manufacturing Resources Planning (MRP

and MRPII) issues, can be found in the literature for

some studies this problem (Almeder et al.2011,

Berretta et al.2005, Chen &Chu2003). If single site

issues have been extensively studied in the literature

(Nascimento et al.2010) point to the lack of a

reference model for multi site issues. This model

only determines the production quantities and

periods, regardless of the actual production sequence

of commands within a period of time. This type of

modeling has the advantage that it allows flexible

sequencing orders in a period, a significant cost

calculation. For small-Bucket models (SB) are

known, the Continuous Setup Lot Sizing Problem

(PRSP) and the Proportional Lot Sizing and

Scheduling Problem (PLSP).

The problem Multi Level Capacitated Lot Sizing

Problem (MLCLSP) is one of the most difficult

optimization problems known in the production. It

arises in any company that uses the sequential

approach to planning MRP. The approach was based

on the control of quantities on demand, compliance

with the BOM structure and the level of stock.

Consideration of production capacity and

product classifications pushed the authors to

consider the multiplicity of production resources

(Buschkuhl et al.2008), and we will find models of

mono or multi resource. Multi resource models

enable more accurate modeling of the operating

range of the various products and better estimate the

capacity of the production system. (Bel 1998)

demonstrated that to find feasible solutions for

MLCLSP is NP-complete, and when there are

considered setup time. Therefore, the proposed

Lagrangian heuristics include a feasibility strategy to

find feasible solutions from the penalization of the

constraints of the problem.

Most of the models and algorithms proposed

MLCLSP (Tempelmeier et al.2008) rely on one of

two possibilities: either the lead time is neglected,

and the lead time is taken into account, there is at

least one period for each component, forcing the

transit time (the number of periods) of finished

12

Razki, H. and Moussa, A.

Langrangian Relaxation of Multi Level Capacitated Lot Sizing Problem with Consideration of Lead Time.

In Doctoral Consortium (DCORES 2017), pages 12-19

products to be at least equal to the number of levels

of the BOM.

According to studies, the hypothesis of zero lead

time leads to plans that are not feasible, and the

lower level of scheduling problem is infeasible. On

the other side, if the lead time is positive, it usually

results in significant amounts of work in process,

causing subsequently increase the number of levels

in the nomenclature. This problem has been studied

by different researchers (Buschkühl et al.2010).

A recent study on the different model

formulations and solution methods for MLCSP is in

(Almeder et al.2014), the authors proposed two

models: one is batching and the other is streaming

lot. Computations indicate clearly that the solutions

obtained by MLCLSP are infeasible, and the lead

time excessive work in process from 15% to 60%

increase in the overall cost, they deployed the

algorithms Benders (Almeder et al.2014) variant

with a sanctions significant contribution to improve

the computational effort to find satisfactory

solutions.

The main contributions of our study are as follows:

We show that the solutions obtained with lead time

are feasible. We propose a linear programming

formulation integer. Regarding the approach of the

Lagrangian relaxation is to relax capacity constraints

while penalizing their violation in the objective

function, our experiences show that calculation

variant polarization capacity constraints give the

best solution of the problem. The comparison with

traditional models, we demonstrate the ability of this

new approach with more realistic results (68% -98

%).

In Section 2, we propose the new formulations of

the MLCLSP problem with major constraints. In

Section 3, we present our optimization approach to

problem solving with the new formulation of the

model, and in section 4, we apply the standard

reference instances and we compare the results with

those of classical MLCLSP.

2 PLANNING MODEL GENERIC

2.1 Classic Models

In supply chain management, support for the

medium term decision can be considered in the

construction of a solution (such a plan) it is to build

and generate a solution. The generative of this

approach is shown in Figure 1 (Sambasivan et

al.2002).

Figure 1: Generative approach (Sambasivan et al.2002).

Production management, where the models were

more widely used, the approach described above

concerning the planning model. We use planning

model into an optical performance evaluation to

build an optimal plan.

In this article, we present the classical model of

MLCLSP planning aims to generate a production

plan that minimizes the sum of setup costs and

inventory costs, while respecting the constraints of

stock and capacity.

The objective function of MLCLSP model is as

follows:

Min∑

N

i=1

∑

T

t=1

(C

i

.Y

it

+H

i

.I

it

) (1)

Under the constraints:

I

it+1

=I

it

+X

i(t-li)

-∑

N

j=1

a

ij

*X

jt

- D

it

i,t (2)

∑

N

i=1

P

i

*X

it

≤ C

t

i,t (3)

X

it

≤ G*Y

it

i,t (4)

I

it

≥0 , X

it

≥0 i,t (5)

Y

it

ϵ{0,1} i,t (6)

Model parameters:

i : Product

t: Period

P

i

: Time to produce a unit of product i

C

i

: Cost of setup of product i

D

it

: Demand for the product i at time t (external)

G: Arbitrarily large number (e.g., total demand or

maximum capacity)

H

i

: The cost of stock of product i

C

t

: The available capacity (time) at time t

l

i

: Lead time of item i (non negative integer

corresponding to the number of periods)

a

ij

: Amount of product i to produce a unit of product

j (gozinto-factor).

Decision variables:

I

it

: Stock level of product at the end of period t

X

it

: Quantity of product i in period t

Langrangian Relaxation of Multi Level Capacitated Lot Sizing Problem with Consideration of Lead Time

13

1 if the product and manufactured in the

period

0 no production

The objective function (1) minimizes the total

cost involved in the production plan, namely the

costs of production and storage, as well as fixed

setup costs, inventory costs. Constraint (2) expresses

the conservation of flux across the horizon with the

stress of lead time. Constraint (3) expresses the fact

that the plan that we would calculate to be finite

capacity. Indeed, for the realization of a plan, we

have an amount of resources that will be consumed

by the production of one or more references. Total

consumption should be less than the available

capacity. Constraint (4) to model the following

condition: if the setup of production, while the

quantity produced must not exceed an upper bound

of the output G. This represents the minimum

between the maximum amount of the reference can

be produced and the total demand on the horizon [t,

.., T]. Constraint (5) means that X

it

and I

it

variables

are continuous no negative for any reference i, for

each period t. The last constraint (6) expresses the

fact that Y

it

is a binary variable for any reference i in

each period t.

Many researchers are studying this model,

assume that the lead time is negligible, to the effect

that the predecessors and successors could be

produced in the same period ( l = 0 for all i ). The

MLCLSP is a model BB and the periods are

supposed to cover the long time intervals with a

number of production batches, so it would result in

significant amounts of work in production. If we

assume that the lead time is positive for at least one

period ( l = 1 for all i ) , we deliver the requested

quantity respecting the delivery time , There is

always in practice, there is always the possibility of

use of overtime to make production in our model the

objective function (1) does not account for

additional fabrication.

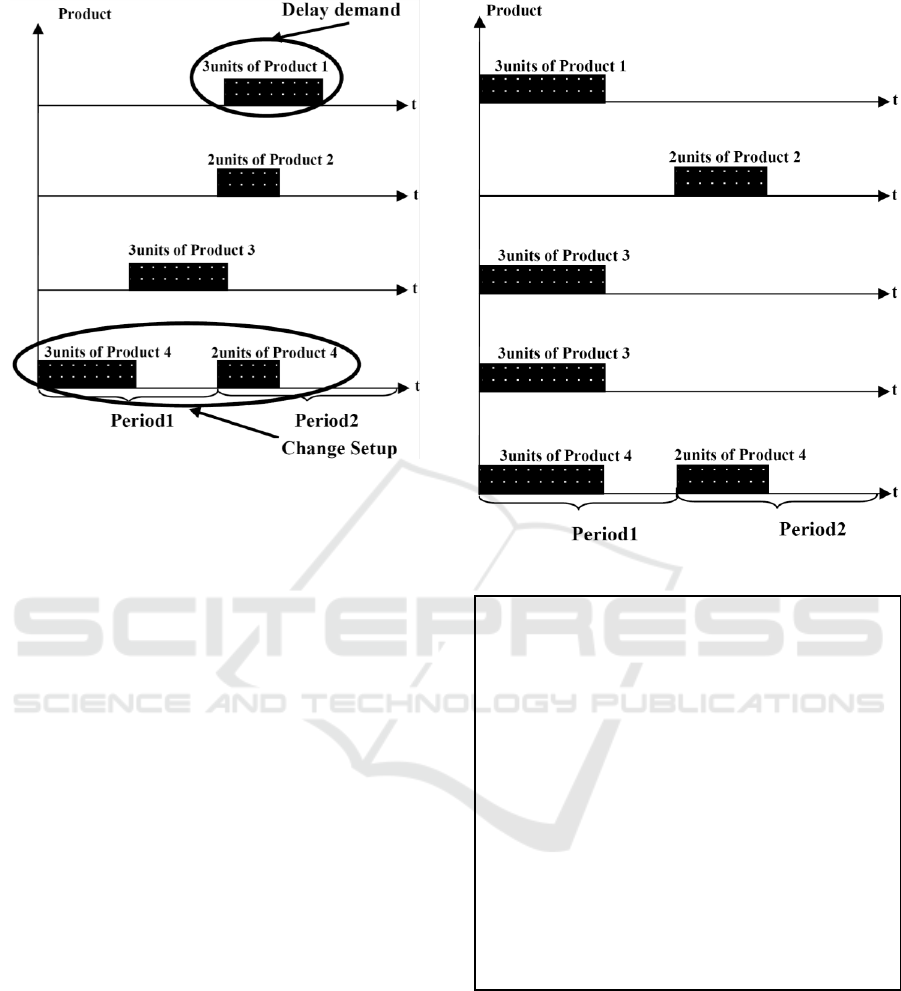

To verify the model, the example of Table 1

represents a lot sizing problem in 2 periods, 4

products and unconstrained capacity, Figure 2 shows

the structure of the nomenclature (Almeder et al.

2014).

Table 1: Data example.

Product

D

i1

D

i2

H

i

C

i

P

i

1

3

0

3

5

0.1

2

0

2

2

5

0.1

3

0

0

2

5

0.1

4

0

0

1

5

0.1

Figure 2: Example of nomenclature.

Figure 3: Limitation of the Multi Level Capacitated Lot

Sizing Problem.

The configuration presented in Figure 3 provides

the solution of the classical model, if we assume that

the lead time is negligible, and no setup change to

produce the product 4 , but with this solution we do

not respond to the objective function to optimize the

cost of the stock.

With this plan in Figure 4, we produce only the

amount requested for each period, for example in the

period 1 we produce an amount of 3 units of

product 4, we change the setup to produce product 3

and subsequently the product 1, which results in a

delay in customer demand level for product 1

because production will end in period 2. So with this

solution we are not optimizing the cost of setup and

customer demand.

Y

it

1

4

3

2

t

t

t

t

Period1

Period2

5units of Product 4

2units of Product 2

3units of Product 3

3units of Product 1

Setting stock

Product

Period2

DCORES 2017 - DOCTORAL CONSORTIUM

14

Figure 4: Limitation of the Multi Level Capacitated Lot

Sizing Problem.

2.2 Proposed Model

If we consider the two plans proposed above, we

notice that the constraint that violates our

optimization objective function is the constraint of

stock (2), so we propose a new formulation which

provides an optimal solution for our model, applying

the product of the net principle need i at time t, we

produce the necessary need in period t, and our

formulation we consider a lead time period to meet

customer delivery time.

The proposed new constraint:

I

it+1

= D

it

-I

it

-X

i(t-li)

i,t (7)

This plan in Figure 5, allows us to produce our

net needs at time t, if we take our example, our net

need for the period 1 of the finished product 1 is 3

units, so for the produce we must have 3 units of

subsets 3 and 4, with this solution we gain at the cost

of stock, the same principle to produce the finished

product 2.

We implemented the proposed model in CPLEX

12.2 (User’s Guide Standard Version Including

CPLEX Directives.2010), to see if our new

formulation is optimized for our objective function.

After the simulation, results are optimized with a

target of 40.

Figure 5: Verification of our new formulation.

Figure 6: Simulation results with CPLEX Solver.

3 OPTIMIZITION METHOD

3.1 Lagrangian Relaxation

The Lagrange relaxation technique has been the

subject of several studies (Fisher, M 2004) and was

raised in the problems of integration of production.

// solution (optimal) with objective 40

plan[1][1]=

<fabrication:1,production:3,stock:0>

plan[1][2]=

<fabrication:1,production:0,stock:0>

plan[2][1]=

<fabrication:1,production:0,stock:0>

plan[2][2]=

<fabrication:1,production:0,stock:0>

plan[3][1]=

<fabrication:1,production:0,stock:0>

plan[3][2]=

<fabrication:1,production:0,stock:0>

plan[4][1]=

<fabrication:1,production:0,stock:0>

plan[4][2]=

<fabrication:1,production:0,stock:0>

Langrangian Relaxation of Multi Level Capacitated Lot Sizing Problem with Consideration of Lead Time

15

This method can be used to approximate solutions,

seek a lower bound (ZLB) of the problem or to

obtain more optimal solutions. (Wu et al.2013)

developed a strategy for finding upper bounds

(ZUB) on the relaxation using Lagrangian for a lot

sizing problem with multiple products. A

metaheuristic was proposed in (Toledo et al.2014) to

resolve an extension of CLSP with to carry over.

(Nascimento et al.2010) proposed a strategy that

incorporates a genetic algorithm with a linear

program to find approximate solutions to a lot sizing

level problem and scheduling.

The approach of the Lagrangian relaxation is to

relax a subset of constraints while penalizing their

violation in the objective function by associating a

Lagrangian multiplier λit.

As shown in section 2, our new formulation of

MLCLSP model allows us to achieve an optimal

plan, but draws the MLCLSP is a BB model and

periods are supposed to cover long intervals with

several production batches, so it would lead to a

significant production capacity, and our equation (3)

expresses that our plan must be calculated with finite

capacity. That is why the approach of the

Lagrangian relaxation will be based on the

penalization of capacity constraints. (Berretta et

al.2005) presented a heuristic based on the

Lagrangian relaxation of the capacity constraints of

the mathematical formulation. To find a lower

bound (ZLB) for the problem.

Our news formulation of the objective function

is:

Min∑

N

i=1

∑

T

t=1

(C

i

.Y

it

+H

i

.I

it

) +

∑

N

i=1

∑

T

t=1

λ

it

(C

t

-∑

N

i=1

P

i

*X

it

) (8)

Under the constraints:

I

it+1

= D

it

-I

it

-X

i(t-li)

i,t

(9)

X

it

≤ G*Y

it

i,t (10)

I

it

≥0 , X

it

≥0 i,t (11)

Y

it

ϵ{0,1} i,t (12)

(Sambasivan et al.2005) points out three main

approaches in his study: the sub-gradient method

and the multiplier λ

it

adjustment method. This last

and according to (Fisher, M 2004) proved to be too

costly compared to the sub-gradient method.

Although the adjustment method has a high

potential, exceeding the sub-gradient method in

some case studies, but the sub-gradient is the most

used to determine the Lagrange multipliers tool.

So to solve this dual problem, the method chosen

is the sub-gradient. The sub-gradient algorithm

introduced in (8). It updates iteratively multipliers:

λ

it

= max {0; λ

it

+TG

i

) i,t (13)

T is the step of the iteration method, and G

i

is the

difference between the time required to produce all

units of product i in period t and the capacity limit in

period t, calculated in Equation (14):

G

i

= C

t

-∑

N

i=1

P

i

*X

it

i,t (14)

It is necessary to initialize the values T and λ

it

for

each iteration. The step T is important to optimize

our solution.

The choice of the step size T, is of importance

for the convergence of the sub-gradient method for

the optimal solution. Thus, the T update is given by

the equation below:

T =π (ZUB-ZLB)/G

i

²

(15)

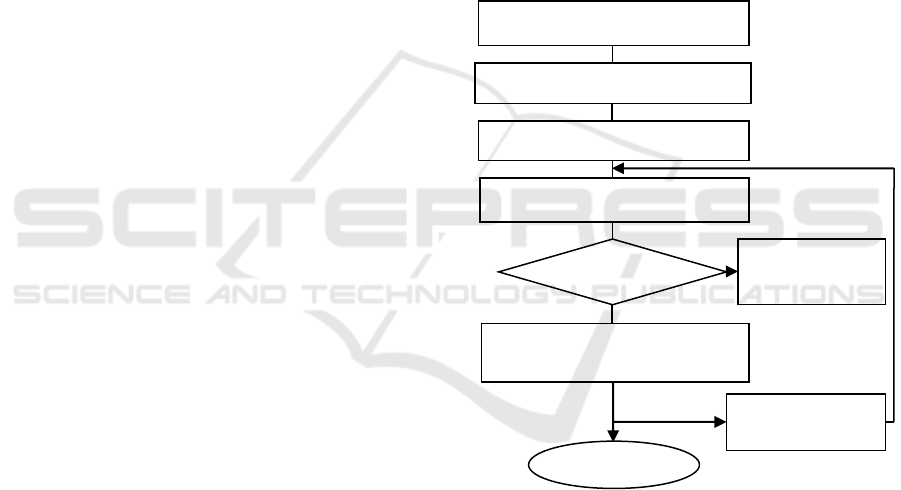

Figure 4 shows the algorithm of the principle of our

approach.

Figure 7: Flowchart of the principle of our approach.

To ensure the convergence of the method, the

solutions at each iteration step means that the T

tends to 0. According to the equation (15) T depends

the upper bound (ZUB) and the lower bound (ZLB),

if no lower bound is found to iterate , so the solution

is infeasible. (Almeder,C.2010) most BB models

provide the best lower bound.

Following algorithm shows a pseudo code of our

approach to feasibility of the solution:

Data: Approximate dual solution

Result: Either a heuristic solution for

the primal problem or infeasible

solution

Fin

Initialize π & λ

it

Calculate Subgradient

Calculate step T

Lagrangian problem solver

ZLB found

Update λ

it

λ

it

=max(0 ; λ

it

+TG

i

)

Infeasible

solution

Yes

Increment

iteration

No

DCORES 2017 - DOCTORAL CONSORTIUM

16

Repeat

Initialize arrays and variables used in

the loop that follows

Initialize π ]0; 2]

Initialize λit values

Executes Lower Bound and Upper Bound

model

Calc sub-gradient G

i

= Ct-∑P

i

*X

it

Calc T = π(ZUB−ZLB)/G

i

²

Solve the model to get the Upper

Bound

Update λ

it

to pass it as input data to

Lower Bound model in next iteration

End loop

4 SIMULATION

The optimal solution of the lot sizing problem

presented in Table 3 is obtained using Lagrangian

relaxation. The results are obtained by the linear

programming solver integer CPLEX 12.2 (User’s

Guide Standard Version Including CPLEX

Directives.2010).

All tests were implemented in C ++ and run on a

PC with 4G HP Core i5 processor.

4.1 Test Instances

We have carried out tests on a series of instances of

(C.Almeder et al.2014). The characteristics of bodies

are described in Table 2.

Table 2: Instances of C.Almeder et al. (2014).

Class

Instances

Periods

Products

A

1500

4

10

B

600

4

10

C

599

16

40

D

573

16

40

4.2 Analysis of Proposed Method

The model MLCLSP feasibility problem is to

consider a minimum period of lead time. As

mentioned previously this period may cause

amounts of work in production, then a substantial

increase in the stock.

(C.Almeder et al.2014) demonstrated the

infeasibility of the MLCLSP problem by running the

model with conventional test instances without

synchronization with a period of lead time. With a

run time limit of 10 minutes for CPLEX.

This document puts the Lagrangian strategies for

the upper and lower bounds of good quality for cases

tested and shows that our proposed approach will

guarantee us an optimal solution for the proposed

production plans with consideration of one period of

lead time.

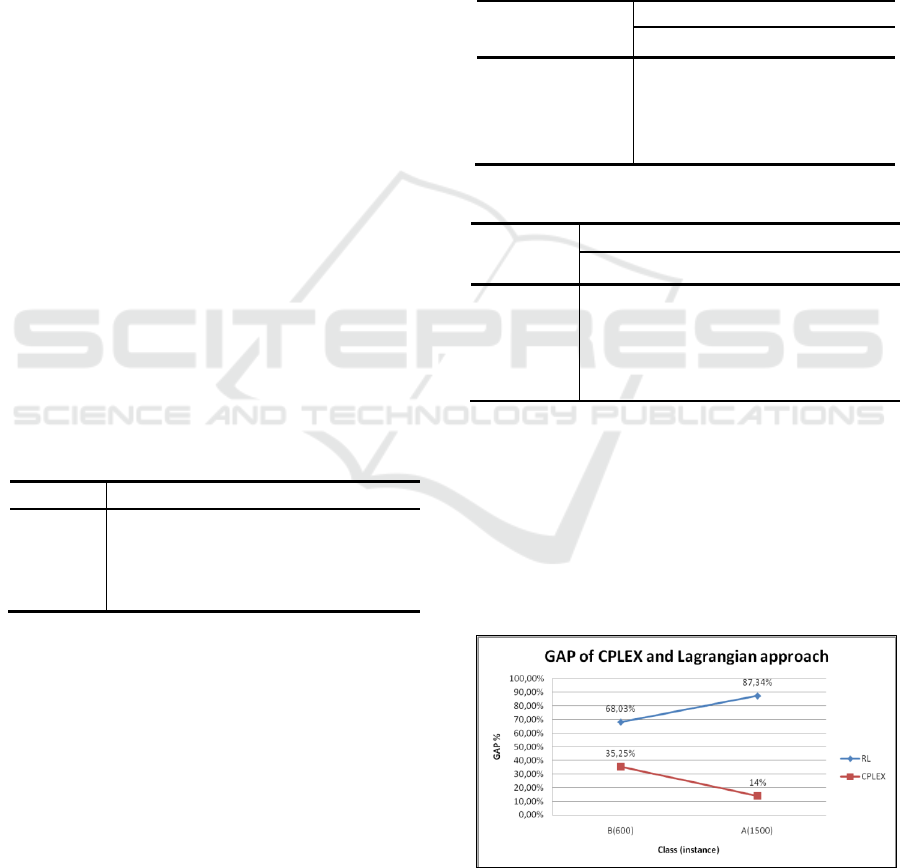

Table 3 presents results obtained by CPLEX

Solver and table 4 presents the resulting solutions

for our approach, the columns show the lower bound

greater than the percentage of optimality GAP =

(ZUB- ZLB) / ZUB for each test class to improve

our cost model by considering a period of lead time.

Table 3: Simulation with CPLEX Solver.

Class

(Instance)

CPLEX

GAP

Time

A(1500)

14%

30s

B(600)

35,25%

9s

C(599)

infeasible

_

D(573)

infeasible

_

Table 4: Simulation with Lagrangian approach.

Class

(Instance)

RL

ZUB

ZLB

GAP

Time

A(1500)

205,5

26

87,34%

5s

B(600)

206,5

66

68,03%

6s

C(599)

16363

808

95%

25s

D(573)

16362

168

98,97%

26s

Table 4 presents the best values of the proposed

method of MLCLSP. So with the relaxation of

Lagrangian approach, we find optimal solutions with

87.34% for Class A, 68.03% for Class B, 95% for

Class C and 98.97% for Class D.

Table 3 shows that the solutions implemented in

CPLEX, are optimal with 14% for Class A and

35.25% for Class B, but for Class C and Class D

solutions are infeasible.

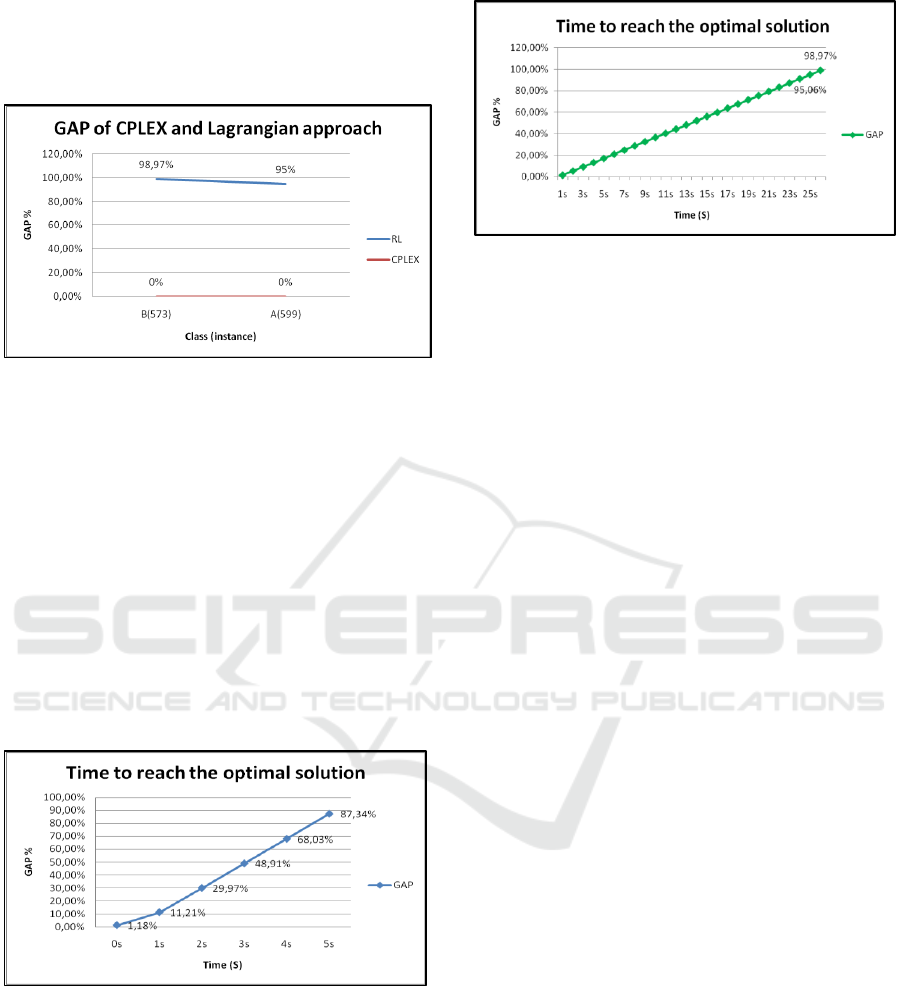

Figure 8: Results obtained for SB.

This graph shows that with the Lagrangian approach

we obtain the best optimal solutions for the model

Langrangian Relaxation of Multi Level Capacitated Lot Sizing Problem with Consideration of Lead Time

17

SB, even if we increase the instance. On the other

hand, we observe that the results obtained with the

CPLEX solver are lower and decrease with the

increase of the instance.

Figure 9: Results obtained for BB.

On this graph, we show that for the model BB

our plan remains optimal with the Lagrangian

approach, but for CPLEX Solver the solution is

infeasible.

So we show with our new formulation, BB or SB

model is optimized, resulting in a clear cost estimate

from stock and production and in parallel we are

responding to the constraint of important quantities

of production work, which request the use of

overtime to make up for production.

Comparing the results with those obtained by the

classical MLCLSP, we realize a 4.5% increase to

that produced by the Benders algorithms proposed

by (C.Almeder et al.2014).

Figure 10: The trend for SB.

The Proposed formulation we guarantee an

optimal solution after less 5s for SB and less than

25s for BB. The penalization of capacity constraint

provides lower bound to optimize our objective

function even if we consider the lead time. Figures

10 and 11, we show the improvement of the

objective value of the best solution for the cases

studied. Trends show that the improvement is

achieved in the initial iterations.

Figure 11: The trend for BB.

5 CONCLUSION

This paper presented a new formulation and solution

for the multi level capacitated lot sizing problem

(MLCLSP) with considering one period of lead time

that requires an important quantity of production

work requesting thus the use of overtime to make up

for production.

Besides, the proposed optimization method of

our problem was Lagrangian relaxation based on the

penalization capacity constraints. The performance

on several classes with different instances generated

was compared with the CPLEX Solver, and the

results show the efficiency of 68% to 98.97%. It

should be noted that the proposed model is more

suitable with the production constraints of planning.

We also remember that this approach is now under

implementation for real situations.

REFERENCES

Comelli, M., M. Gourgand et D. Lemoine, 2008. A review

of tactical planning models, Journal of Systems

Science and Systems Engineering, Vol.17(2), pp 204-

229.

Almeder,C.,&Almada-Lobo,B.(2011). Synchronization of

scarce resources for a parallel machine lot sizing

problem. International Journal of Production Research,

49(24),7315–7335.

Berretta, R., Franca, P., Armentano, V., 2005.

Metaheuristic approaches for the multilevel resource-

constraint lot-sizing problem with setup and lead

times. Asia - Pacific Journal of Operational Research

22 (2), 261–286.

Chen, H. et Chu, C. (2003). A lagrangian relaxation

approach for supply chain planning with order/ setup

costs and capacity constraints, Journal of System

Science and Systems Engineering.

Nascimento, M. C. V., M. C. G. Resende, and F. M. B.

Toledo (2010). GRASP with path-relinking for the

DCORES 2017 - DOCTORAL CONSORTIUM

18

multi-plant capacitated lot sizing problem. European

Journal of Operational Research 200, 747–754.

Buschkuhl, L., F. Sahling, S. Helber, and H. Tempelmeier

(2008). Dynamic capacitated lot sizing a classification

and review of the literature on \big bucket" problems.

[Bel 1998] Bel G., Aide à la conception et à la conduite de

systèmes à événements discrets : Application aux

systèmes de production, Habilitation à diriger des

recherches, Université Paul Sabatier, Toulouse, Mai

1998.

Tempelmeier, H., Buschkühl, L., 2008. Dynamic multi-

machine lotsizing and sequencing with simultaneous

scheduling of a common setup resource. International

Journal of Production Economics 113, 401–412.

Buschkühl, L., Sahling, F., Helber, S., Tempelmeier, H.,

2010. Dynamic capacitated lot-sizing problems: a

classification and review of solution approaches. OR

Spectrum 32, 231–261.

C. Almeder, R.Traxler al. 2014, Lead time considerations

for the multi-level capacitated lot-sizing problem,

European Journal of Operational Research 000 (2014)

1–12.

Sambasivan, M. and C. P. Schimidt (2002). A heuristic

procedure for solving multi-plant, multi-item, multi-

period capacited lot-sizing problems. Asia Pacific

Journal of Operational Research 19, 87–105.

IBM ILOG AMPL, Version 12.2. User’s Guide Standard

(Command-line) Version Including CPLEX

Directives. May 2010.

Fisher, M. L. (2004). The lagrangian relaxation method for

solving integer programming problems. Management

science 50 (12 supplement), 1861–1871.

Wu, T., C. Zhang, Z. Liang, and S. C. Leung (2013). A

lagrangian relaxation-based method and models

evaluation for multi-level lot sizing problems with

backorders. Computers & Operations Research 40,

1852–1863.

Toledo, C. F. M., L. de Oliveira, R. de Freitas Pereira, P.

M. Fran¸ca, and R. Morabito (2014). A genetic

algorithm/mathematical programming approach to

solve a two-level soft drink production problem.

Computers &Operations Research 48, 40–52.

Nascimento, M. C. V., M. C. G. Resende, and F. M. B.

Toledo (2010). GRASP with path-relinking for the

multi-plant capacitated lot sizing problem. European

Journal of Operational Research 200, 747–754.

Berretta, R., Franca, P., Armentano, V., 2005.

Metaheuristic approaches for the multilevel resource-

constraint lot-sizing problem with setup and lead

times. Asia - Pacific Journal of Operational Research

22 (2), 261–286.

Sambasivan, M. and S. Yahya (2005). A lagrangean-based

heuristic for multi-plant, multi-item, multi-period

capacitated lot-sizing problems with inter-plant

transfers. Computers and Operations Research 32,

537–555.

Almeder,C.(2010). A hybrid optimization approach

formulation level capacitated lot sizing problems.

European Journal of Operational Research, 200,599–

606

Langrangian Relaxation of Multi Level Capacitated Lot Sizing Problem with Consideration of Lead Time

19